Академический Документы

Профессиональный Документы

Культура Документы

PSG Epoxy Glass Phenolics

Загружено:

madhunnadigИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

PSG Epoxy Glass Phenolics

Загружено:

madhunnadigАвторское право:

Доступные форматы

EPOXY GLASS PHENOLICS

Glass cloth impregnated with synthetic thermosetting resins. When heat and pressure are applied to the layers, a chemical reaction

(polymerization) transforms the separate layers into a single laminated material with a "set" shape that cannot be softened again -- therefore,

these materials are called "Thermosets". A variety of resin types and cloth materials can be used to manufacture thermoset laminates with a

range of mechanical, thermal, and electrical properties.

GENERAL PROPERTIES

Physical strength, resiliency, ease and versatility of fabrication, and excellent electrical properties make Phenolic Laminates useful as support

components in a wide range of mechanical and electrical applications. Phenolic Laminates are strong, stiff, and have high impact and

compressive strengths. And, they do not soften upon re-heating, so they are easy to saw, drill, tap, and machine with ordinary tools. "FR" grades

are flame retardant. Glass-based grades have the highest dimensional stability and mechanical strength, as well as low moisture absorption.

However, they are not as easily machined as paper or cotton fabric laminates.

GLASS-BASED PHENOLIC GRADES -- G-10 and G-11 (Glass Cloth / Epoxy Resin)

These glass-epoxy laminates are specified for their extremely high strength and high dimensional stability over temperature. G-10 and G-11 are

used for high humidity applications, electrical and electronic test equipment and electric rotor insulation. G-10 is slightly stronger while G-11 is a

better insulator and can take higher temperatures. FR-4 is a fire-retardant G-10 glass-epoxy laminate that is used primarily in the printed circuit

board industry.

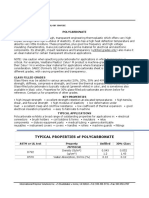

TYPICAL PROPERTIES of GLASS LAMINATES (SHEET FORM)

( mechanical properties of rod and tube forms may differ )

ASTM or

UL test Property G-3 G-5/G-9 G-7 G-10 G-11

PHYSICAL

Density (lb/in³) 0.065 0.067 0.065 0.065 0.065

D792

(g/cm³) 1.8 1.85 1.8 1.8 1.8

D570 Water Absorption, 24 hrs (%) 2.65 0.6 0.1 0.1 0.2

MECHANICAL

Tensile Strength (psi)

D638 -lengthwise 42,000 61,600 20,000 45,000 43,000

-crosswise 34,000 51,100 - 38,000 37,000

Flexural Strength (psi)

D790 -lengthwise 40,500 61,600 30,000 75,000 80,000

-crosswise 34,000 51,100 - 65,000 70,000

Flexural Modulus (Kpsi)

D790 -lengthwise 1,800 2,000 1,600 2,700 3,000

-crosswisep ( 1,400 1,700 - 2,400 2,700

lb/in)

D256 -lengthwise 12.0 12.5 13.0 14.0 12.0

-crosswise 11.0 8.5 - 12.0 9.0

D695 Compressive Strength (psi) 55,000 65,000 50,000 65,000 63,000

D785 Hardness, Rockwell M M110 M115 M105 M110 M112

THERMAL

Expansion 0.83 0.83 0.72 0.55 0.72

(x 10-5 in./in./°F) 1.00 1.00 0.90 0.66 0.83

D696

-lengthwise

p-crosswise

g p(

- °C) 340 / 170 285 / 140 430 / 220 284 / 140 329 / 165

Thermal Conductivity

C177 (BTU-in/ft²-hr-°F) 2.0 2.0 2.0 2.0 2.0

(x 10-4 cal/cm-sec-°C) 7.0 7.0 7.0 7.0 7.0

UL94 Flammability Rating H-B V-0 H-B H-B H-B

g ( ) ELECTRICAL

D149 short time, 1/8" thick 460 300 350 800 900

D150 Dielectric Constant at 1 MHz 7.3 6.3 4.5 5.0 4.5

D150 Dissipation Factor at 1 MHz 0.023 0.019 0.018 0.019 0.020

D495 Arc Resistance (sec) 180 180 240 100 120

NOTE: The information contained herein are typical values intended for reference and comparison purposes only. They should NOT be used as a basis for design specifications or quality control.

Contact us for manufacturers' complete material property datasheets.

All values at 73°F (23°C) unless otherwise noted.

Вам также может понравиться

- 6th Central Pay Commission Salary CalculatorДокумент15 страниц6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Nephrology FormulasДокумент3 страницыNephrology FormulasM Patel0% (1)

- Manual: Installation, Operation & MaintenanceДокумент86 страницManual: Installation, Operation & MaintenanceNhân NgọcОценок пока нет

- Computation of Area of A Closed TraversedДокумент3 страницыComputation of Area of A Closed TraversedDaryl Ballesteros100% (1)

- BNC Lesson 1-4Документ34 страницыBNC Lesson 1-4Alyssa LoisОценок пока нет

- LADBS - Swimming PoolsДокумент43 страницыLADBS - Swimming PoolsMichael James100% (1)

- Care of Older Adults Notes PT 1Документ5 страницCare of Older Adults Notes PT 1Edson John Demayo100% (1)

- Biology 5th Brooker Test BankДокумент34 страницыBiology 5th Brooker Test BankRamiqq67% (3)

- SEMINAR On Laminated CompositesДокумент15 страницSEMINAR On Laminated CompositesPraveengouda PatilОценок пока нет

- Doosan SD200 SpecДокумент22 страницыDoosan SD200 SpecAndrea T FilottoОценок пока нет

- Shears Cysts of The Oral and Maxillofacial Regions, 5th Edition (Paul Speight)Документ382 страницыShears Cysts of The Oral and Maxillofacial Regions, 5th Edition (Paul Speight)Miriam Tovar OgazonОценок пока нет

- Property of Polyfelt TS Nonwoven GeotextilesДокумент1 страницаProperty of Polyfelt TS Nonwoven GeotextilesAgis Satryo Falck100% (1)

- Polyester MicrofiberДокумент37 страницPolyester Microfiberpsyish80% (5)

- How To Use PathlossДокумент32 страницыHow To Use Pathlosspathlossanwar100% (9)

- Cumene ManufactringДокумент74 страницыCumene ManufactringTan JieSheng100% (1)

- Technical Data Sheet G-10: General DescriptionДокумент1 страницаTechnical Data Sheet G-10: General Descriptionbahtiar affandyОценок пока нет

- Teflon PTFE - PSG - Mechanical PropertyДокумент1 страницаTeflon PTFE - PSG - Mechanical PropertyGovarthanan GovaОценок пока нет

- Technical data sheet for linen phenolic laminatesДокумент1 страницаTechnical data sheet for linen phenolic laminatesKissa DolautaОценок пока нет

- Zeus Inc. Properties Of Extruded FluoropolymersДокумент1 страницаZeus Inc. Properties Of Extruded FluoropolymersAmir KhanОценок пока нет

- Technical Data Sheet Peek: Typical Properties of Virgin (Unfilled) PeekДокумент2 страницыTechnical Data Sheet Peek: Typical Properties of Virgin (Unfilled) PeekSyed MoinОценок пока нет

- Technical Data Sheet Polyimide: Benefits ApplicationsДокумент3 страницыTechnical Data Sheet Polyimide: Benefits Applicationssanthosha rkОценок пока нет

- PolycarbonateДокумент2 страницыPolycarbonatepuvitta sudeshilaОценок пока нет

- PolycarbonateДокумент2 страницыPolycarbonateAdnan KhanОценок пока нет

- PolycarbonateДокумент2 страницыPolycarbonateROHIT SHARMAОценок пока нет

- LdpeДокумент1 страницаLdpeArdy WiyogoОценок пока нет

- Nylon Materials ChartДокумент1 страницаNylon Materials ChartPrabhat SharmaОценок пока нет

- UHMW Mechanical Properties: Comparison of Dynamic Coefficient of Friction On Polished SteelДокумент4 страницыUHMW Mechanical Properties: Comparison of Dynamic Coefficient of Friction On Polished SteeldangdinhthyОценок пока нет

- Polye PДокумент2 страницыPolye PFranco Gabriel MercadoОценок пока нет

- Technical Data Sheet Nylon: (Polyamide)Документ3 страницыTechnical Data Sheet Nylon: (Polyamide)Dharmendra DubeyОценок пока нет

- PTFE Technical Data Sheet Highlights Chemical Resistance and Wide Temperature RangeДокумент1 страницаPTFE Technical Data Sheet Highlights Chemical Resistance and Wide Temperature RangeMarisa Yuni Nur AzizaОценок пока нет

- Technical Data Sheet Teflon (Ptfe) : (Polytetrafluoroethylene Resin)Документ1 страницаTechnical Data Sheet Teflon (Ptfe) : (Polytetrafluoroethylene Resin)Dharmendra DubeyОценок пока нет

- Technical Data Sheet Abs: (Acrylonitrile-Butadiene-Styrene)Документ1 страницаTechnical Data Sheet Abs: (Acrylonitrile-Butadiene-Styrene)Paulo RicardoОценок пока нет

- Acetal: Acetal Grades ACETAL COPOLYMER (Unfilled)Документ1 страницаAcetal: Acetal Grades ACETAL COPOLYMER (Unfilled)Anonymous UcmNTu6rОценок пока нет

- Acrylic Not Recc For ChlorinatedДокумент2 страницыAcrylic Not Recc For ChlorinatedoktavОценок пока нет

- Technical Characteristics 2020 ENДокумент1 страницаTechnical Characteristics 2020 ENezzularabОценок пока нет

- PVC and CPVC properties referenceДокумент2 страницыPVC and CPVC properties referenceAdnan KhanОценок пока нет

- Durolon HFR 1910Документ2 страницыDurolon HFR 1910elrolo3000Оценок пока нет

- Resin-Coated Low-Density, High-Performance Ceramic Proppant: Features BenefitsДокумент2 страницыResin-Coated Low-Density, High-Performance Ceramic Proppant: Features Benefitsarturo_partida_1Оценок пока нет

- Technical Information: (BR) (WR-2) (Special F)Документ1 страницаTechnical Information: (BR) (WR-2) (Special F)johnОценок пока нет

- Data Sheet - Polyfelt® TS HD (100 600-td-02-19)Документ1 страницаData Sheet - Polyfelt® TS HD (100 600-td-02-19)andriarisetiawanОценок пока нет

- SUPA GD100™ Slickline: UNS S32760Документ1 страницаSUPA GD100™ Slickline: UNS S32760hoss mosafaОценок пока нет

- Technical Data Sheet Uhmw Polyethelyne (Uhmw Pe) : (Ultra High Molecular Weight Polyethylene)Документ1 страницаTechnical Data Sheet Uhmw Polyethelyne (Uhmw Pe) : (Ultra High Molecular Weight Polyethylene)HARSHA PОценок пока нет

- Technical Data Sheet Polycarbonate: Benefits ApplicationsДокумент2 страницыTechnical Data Sheet Polycarbonate: Benefits ApplicationsjackОценок пока нет

- PolystyreneДокумент1 страницаPolystyrenejoshkajasmineОценок пока нет

- Technical Data Sheet High Density Polyethylene: Typical Properties of PolyethyleneДокумент1 страницаTechnical Data Sheet High Density Polyethylene: Typical Properties of PolyethyleneQuality teamОценок пока нет

- PP Technical Data Sheet Provides Key Properties and BenefitsДокумент2 страницыPP Technical Data Sheet Provides Key Properties and BenefitsSabuj SaikiaОценок пока нет

- Hylar SolefДокумент6 страницHylar SolefKylaОценок пока нет

- Technical Data Sheet PVC: (Polyvinyl Chloride)Документ1 страницаTechnical Data Sheet PVC: (Polyvinyl Chloride)Adnan KhanОценок пока нет

- Spec Sheet - SD200NДокумент16 страницSpec Sheet - SD200NGchica MejiaОценок пока нет

- Technical Data Sheet Ultem (Pei) : (Polyetherimide)Документ3 страницыTechnical Data Sheet Ultem (Pei) : (Polyetherimide)Dynamic SaravananОценок пока нет

- Static Dissipative Polyetherimide (Pei) / Static Dissipative UltemДокумент1 страницаStatic Dissipative Polyetherimide (Pei) / Static Dissipative UltemVC KannanОценок пока нет

- Physical and Piezoelectric Properties of APC Materials ChartДокумент2 страницыPhysical and Piezoelectric Properties of APC Materials ChartTrương Anh DuyОценок пока нет

- Technical Data Sheet CPVC: (Chlorinated Polyvinyl Chloride)Документ1 страницаTechnical Data Sheet CPVC: (Chlorinated Polyvinyl Chloride)Nam NguyenОценок пока нет

- Technical Information: (A) (SF) (ST) (F)Документ1 страницаTechnical Information: (A) (SF) (ST) (F)johnОценок пока нет

- Data Sheet PPSUДокумент2 страницыData Sheet PPSUluuiissОценок пока нет

- Calcium Silicate Board Insulation: 4641 Mcree Avenue 314-773-7500 St. Louis, Mo 63110 Fax 314-773-8371Документ1 страницаCalcium Silicate Board Insulation: 4641 Mcree Avenue 314-773-7500 St. Louis, Mo 63110 Fax 314-773-8371abdulmenem arafaОценок пока нет

- 1 Wa-Catalog7Документ1 страница1 Wa-Catalog7johnОценок пока нет

- VERTEC 1009: VERTEC 1009™ Is A Polymer Filled PTFE (Polytetrafluorethylene) Material. It Exhibits Good SealabilityДокумент1 страницаVERTEC 1009: VERTEC 1009™ Is A Polymer Filled PTFE (Polytetrafluorethylene) Material. It Exhibits Good Sealabilityseeralan_1986Оценок пока нет

- Ceramic Fiber Blanket CatalogДокумент7 страницCeramic Fiber Blanket Catalogevelyn reksaОценок пока нет

- SUPA75 Slickline Rev 29 May 18Документ1 страницаSUPA75 Slickline Rev 29 May 18hoss mosafaОценок пока нет

- Hydraulic Attachment Tools: Demolition, Waste Management and Earth-MovingДокумент48 страницHydraulic Attachment Tools: Demolition, Waste Management and Earth-MovingmiquelОценок пока нет

- Slabmate BrochureДокумент2 страницыSlabmate BrochureEnter “Energy & Water Saving” ShopОценок пока нет

- 63d93608e6e8109c61ab104e_Datasheet XCS E-Line US 123Документ2 страницы63d93608e6e8109c61ab104e_Datasheet XCS E-Line US 123Vuong NguyenОценок пока нет

- White High Efficiency HD IP67: AdonisДокумент6 страницWhite High Efficiency HD IP67: AdonisShoeb UndreОценок пока нет

- SSAB Data Sheet 2136 Docol 420LA 2016-11-25 317 371857150 enДокумент4 страницыSSAB Data Sheet 2136 Docol 420LA 2016-11-25 317 371857150 enchristos032Оценок пока нет

- Data Sheet 2136 Docol 420LA 2016-11-25 317 371857150 en PDFДокумент4 страницыData Sheet 2136 Docol 420LA 2016-11-25 317 371857150 en PDFchristos032Оценок пока нет

- ITW Product Catalog30 PDFДокумент1 страницаITW Product Catalog30 PDFjohnОценок пока нет

- Tecanat™ Tecanat™ Gf20 (Polycarbonate and Glass Filled Polycarbonate)Документ1 страницаTecanat™ Tecanat™ Gf20 (Polycarbonate and Glass Filled Polycarbonate)David Matthew Kurniawan BEngОценок пока нет

- BF Runner Mix 20 MT VesuviusДокумент3 страницыBF Runner Mix 20 MT VesuviusSaumit PalОценок пока нет

- TecamidДокумент2 страницыTecamidTejas HuddarОценок пока нет

- Data Sheet - Mirafi® HPa (200 613-td-05-15)Документ1 страницаData Sheet - Mirafi® HPa (200 613-td-05-15)khairul umamОценок пока нет

- TMPRO CASABE 1318 Ecopetrol Packer SuperiorДокумент10 страницTMPRO CASABE 1318 Ecopetrol Packer SuperiorDiego CastilloОценок пока нет

- Optimal Design of A Hybrid Electric Car With Solar Cells: I.Arsie, M.Marotta, C.Pianese, G.Rizzo, M.SorrentinoДокумент12 страницOptimal Design of A Hybrid Electric Car With Solar Cells: I.Arsie, M.Marotta, C.Pianese, G.Rizzo, M.SorrentinomadhunnadigОценок пока нет

- Carbon FibreДокумент1 страницаCarbon FibremadhunnadigОценок пока нет

- Applied Thermodynamics Practice QuestionsДокумент4 страницыApplied Thermodynamics Practice QuestionsAshish KumarОценок пока нет

- The Design of Tomato Paste Plant - Problem StatementДокумент3 страницыThe Design of Tomato Paste Plant - Problem StatementvictorОценок пока нет

- SSCM Roads and Bridges - Annex III Technical Specifications 105 C1 PDFДокумент254 страницыSSCM Roads and Bridges - Annex III Technical Specifications 105 C1 PDFSite Engineer.2p2100% (1)

- Moral vs Non-Moral Standards ExplainedДокумент2 страницыMoral vs Non-Moral Standards ExplainedLee PascuaОценок пока нет

- MM 361: Advanced Manufacturing: InstructionsДокумент3 страницыMM 361: Advanced Manufacturing: InstructionsSimLo Lulumani Ko'osiko Taloanimae'aОценок пока нет

- ACS560 Drives (0.75 To 160 KW, 1.0 To 215 HP) : Hardware ManualДокумент164 страницыACS560 Drives (0.75 To 160 KW, 1.0 To 215 HP) : Hardware ManualNutan PowerОценок пока нет

- Safety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/ UndertakingДокумент10 страницSafety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/ UndertakingBradyОценок пока нет

- Report of Mechanics of Machines 1Документ12 страницReport of Mechanics of Machines 1muhammaduzairОценок пока нет

- AR213 PostWar AjKanokwan HandoutДокумент28 страницAR213 PostWar AjKanokwan Handoutpranutchaya.bamОценок пока нет

- Vikas KumarДокумент4 страницыVikas Kumarsanju sharmaОценок пока нет

- Leadership Theory Application and Skill Development 5th Edition Lussier Test Bank 1Документ36 страницLeadership Theory Application and Skill Development 5th Edition Lussier Test Bank 1douglasbrownyipsmrgkob100% (29)

- Fiche New FM Airbus enДокумент2 страницыFiche New FM Airbus enCrystal LiuОценок пока нет

- D3.6.SmartAKIS - Recommendations Danemarca Cu SiteДокумент47 страницD3.6.SmartAKIS - Recommendations Danemarca Cu SitebubuhomeОценок пока нет

- Acid Dissociation ConstantДокумент4 страницыAcid Dissociation ConstantJair RangelОценок пока нет

- Godrej Group Is An Indian Conglomerate Headquartered in MumbaiДокумент4 страницыGodrej Group Is An Indian Conglomerate Headquartered in MumbairahulbastyОценок пока нет

- Statepfofileofvidarbha PDFДокумент53 страницыStatepfofileofvidarbha PDFAditiОценок пока нет

- Theories and philosophies that shaped early childhood educationДокумент3 страницыTheories and philosophies that shaped early childhood educationJamille Aira PascuaОценок пока нет

- UntreatedДокумент29 страницUntreatedhahahaОценок пока нет

- Abinash Master SeminarДокумент51 страницаAbinash Master SeminarAGRICULTURE BOYОценок пока нет

- Ashrae Handbook 2000 CHДокумент32 страницыAshrae Handbook 2000 CHKazuto NakazatoОценок пока нет