Академический Документы

Профессиональный Документы

Культура Документы

JIS B 1301-1996 - Chavetero PDF

Загружено:

Pablo PasqualiniИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

JIS B 1301-1996 - Chavetero PDF

Загружено:

Pablo PasqualiniАвторское право:

Доступные форматы

Metric_1801-1886 3/1/06 10:32 Page 1854

’Technical Data»

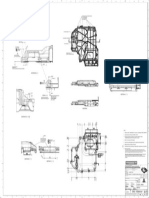

Excerpt from JIS B 1301(1996)

Machine Keys and Key Grooves

1. Parallel Key and Key Groove 2. Taper Key, Gib Head Key and Key Groove

- S1

1.6 Section of Key Section of Key Groove - S1 Gib Head Key Section of Key

Taper Key 6.3

b

b

(Code T)

b

1

1.6 S 1 =Tolerance b M r2

c

- S1 R

25

25

2 6.3 6.3

h

R

h

A

b

6.3 b2 C c

- S2 6.3 6.3 30 Bf

25

25

1 c 6.3 - S2 R

S 2=Tolerance h M 6.3 3.2 Inclina

tion 1 Ú 1

h

3.2

2 b1 100 1000

h1

6.3 6.3 1

S 1 =Tolerance bM

h

h

A

h2

t2

r1 2 1.6

1.6

Section of Key Groove

h 2=h,f=h,e—b - S1

h

S 2 =Tolerance hM h 2=h,f—h,e=b r2

2

t1

d

t2

b2 6.3

6.3

6.3

t 12

d b1

6.3

r1

Unit:mm

Dimension of Key Groove Reference Unit:mm

Nominal (Sliding Type) Regular Class Precision

Size of Standard Applicable Dimension of Key Dimension of Key Groove Reference

Standard Standard Tolerance Nominal

b1 b2 b1 b2 (1)

Key Dimension b1 and b2 r1 and r2 Dimension Dimension of Size of b h b1 and b2 Standard Standard Tolerance Applicable

of Tolerance Tolerance Tolerance Tolerance Tolerance of t1 of t2 t1Ct2

Shaft Dia. Key (1) (2)

bM h

b1Cb2 (H9) (D10) (N9) (Js9) (P9) d Standard Tolerance Standard h1 c R Standard Tolerance r1 and r2 Dimension Dimension of

Shaft Dia.

bM h Tolerance of t of t C

Dimension (h9) Dimension Dimension (D10) 1 2 t1 t2

d

2M 2 2 +0.025 +0.060 -0.004 -0.006 1. 2 1. 0 6~ 8

Ú0.0125 2M 2 2 0 2 0 - 6~ 30 2 +0.060 1.2 0.5 +0.05 6~ 8

3M 3 3 0 +0.020 -0.029 -0.031 0.08~0.16 1. 8 1. 4 8~10 0.16 0.08

3M 3 3 -0.025 3 -0.025 - 6~ 36 3 +0.020 1.8 0.9 0 8~ 10

+0.1 ~0.25 ~0.16

4M 4 4 2. 5 1. 8 10 ~12

+0.030 +0.078 0 -0.012 0 4M 4 4 4 7 8~ 45 4 2.5 1.2 10 ~1 2

5M 5 5 Ú0.0150 3. 0 2. 3 12 ~17 0 0 h9 +0.078

0 +0.030 -0.030 -0.042 5M 5 5 5 8 10 ~ 56 5 3.0 1.7 +0.1 12 ~1 7

6M 6 6 3. 5 2. 8 17 ~22 -0.030 -0.030 +0.030

0.16~0.25 6M 6 6 6 10 0.25 14 ~ 70 6 0.16 3.5 2.2 0 17 ~2 2

(7M 7) 7 4. 0 3. 0 20 ~25 0 ~0.40 ~0.25

+0.036 +0.098 0 -0.015 (7M 7) 7 7.2 -0.036 10 16 ~ 80 7 4.0 3.0 20 ~2 5

8M 7 8 Ú0.0180 4. 0 3. 3 22 ~30 0 +0.098

0 +0.040 -0.036 -0.051 8M 7 8 7 11 18 ~ 90 8 4.0 2.4 22 ~3 0

10M 8 10 5. 0 3. 3 30 ~38 -0.036 +0.040

10M 8 10 8 0 12 22~110 10 5.0 2.4 +0.2 30 ~3 8

12M 8 12 5. 0 3. 3 38 ~44 -0.090

h11

0

12M 8 12 8 12 28~140 12 5.0 2.4 38 ~4 4

14M 9 14 5. 5 3. 8 44 ~50

+0.043 +0.120 0 -0.018 0.25~0.40 14M 9 14 9 14 0.40 36~160 14 0.25 5.5 2.9 44 ~5 0

(15M10) 15 Ú0.0215 5. 0 5. 0 50 ~55 0 ~0.60 +0.120 ~0.40 +0.1

0 +0.050 -0.043 -0.061 (15M10) 15 10.2

0

-0.070 h10 15 40~180 15 5.0 5.0 50 ~5 5

16 6. 0 4. 3 50 ~58 -0.043 +0.050 0

16M10 +0.2 16M10 16 10

0

16 45~180 16 6.0 3.4 50 ~5 8

-0.090

18M11 18 7. 0 4. 4 0 58 ~65

18M11 18 11 18 50~200 18 7.0 3.4 +0.2 58 ~6 5

20M12 20 7. 5 4. 9 65 ~75 0 h11

0

20M12 20 12 20 56~220 20 7.5 3.9 65 ~7 5

22M14 22 9. 0 5. 4 75 ~85 -0.110

+0.052 +0.149 0 -0.022 22M14 22 14 22 63~250 22 9.0 4.4 75 ~8 5

(24M16) 24 Ú0.0260 8. 0 8. 0 80 ~90 0 +0.149 +0.1

0 +0.065 -0.052 -0.074 0.40~0.60 (24M16) 24 16.2

0

-0.070 h10 24 0.60 70~280 24 0.40 8.0 8.0 80 ~9 0

25M14 25 9. 0 5. 4 85 ~95 -0.052 +0.065 0

25M14 25 14 22 ~0.80 70~280 25 ~0.60 9.0 4.4 85 ~9 5

28M16 28 10. 0 6. 4 95~110 0 +0.2

28M16 28 16 h11 25 80~320 28 10.0 5.4 95~110

32M18 32 11. 0 7. 4 110~130 -0.110 0

32M18 32 18 28 90~360 32 11.0 6.4 110~130

(35M22) 35 11. 0 11. 0 125~140 0 +0.15

(35M22) 35 22.3 -0.084 h10 100~400 35 11.0 11.0 0 125~140

36M20 36 12. 0 8. 4 130~150 32

0 +0.3

36M20 36 20 -0.130 h11 - 36 12.0 7.1 0 130~150

(38M24) 38 +0.062 +0.180 0 -0.026 12. 0 12. 0 140~160 0 +0.15

Ú0.0310 (38M24) 38 0 24.3 -0.084 h10 36 - 38 +0.180 12.0 12.0 0 140~160

40M22 40 0 +0.080 -0.062 -0.088 0.70~1.00 13. 0 9. 4 150~170 1.00 0.70

40M22 40 -0.062 22

0

-0.130 h11 36 - 40 +0.080 13.0 8.1 +0.3

150~170

(42M26) 42 13. 0 13. 0 160~180 ~1.20 ~1.00 0

0 +0.15

(42M26) 42 26.3 -0.084 h10 40 - 42 13.0 13.0 0 160~180

45M25 45 15. 0 10. 4 170~200

+0.3 45M25 45 25 0 40 - 45 15.0 9.1 170~200

50M28 50 17. 0 11. 4 200~230 -0.130

0 50M28 50 28 45 - 50 17.0 10.1 200~230

56M32 56 20. 0 12. 4 230~260

56M32 56 32 50 - 56 20.0 11.1 230~260

63M32 63 +0.074 +0.220 0 -0.032 1.20~1.60 20. 0 12. 4 260~290 1.60 1.20

Ú0.0370 63M32 63 0 32 50 - 63 +0.220 20.0 11.1 +0.3 260~290

70M36 70 0 +0.100 -0.074 -0.106 22. 0 14. 4 290~330 h11 ~2.00 ~1.60

70M36 70 -0.074 36 0 56 - 70 +0.100 22.0 13.1 0 290~330

80M40 80 25. 0 15. 4 330~380 -0.160

80M40 80 40 63 - 80 25.0 14.1 330~380

90M45 90 +0.087 +0.260 0 -0.037 2.00~2.50 28. 0 17. 4 380~440 2.50 2.00

Ú0.0435 90M45 90 0 45 70 - 90 +0.260 28.0 16.1 380~440

100M50 100 0 +0.120 -0.087 -0.124 31. 0 19. 5 440~500 ~3.00 ~2.50

100M50 100 -0.087 50 80 - 100 +0.120 31.0 18.1 440~500

Note( )

:The applicable shaft diameter is calculated from the torque corresponding to the strength of the key and is

1

Note(1):From the values forRgiven below, which are in the appropriate range in the table, one should be selected:

presented as referential data for general-purpose use. When the key is of an appropriate size relative to

Note(1):The tolerance forRshould be h12 under JIS B0401(dimension tolerance and fitting)

the torque to be transmitted, a shaft thicker than the applicable shaft diameter may be used. In that case,

6,8,10,12,14,16,18,20,22,25,28,32,36,40,45,50,56,63,70,80,90,100,110,125,140,160,180,200,220,250,280,320,360,400.

t1 and t2 should be adjusted so that a side of the key will come into uniform contact with the shaft and the

Note(2):The appropriate shaft diameter should be matched with the torque corresponding to the strength of the key.

hub. A shaft narrower than the applicable shaft diameter should not be used.

Remark:The nominal size given in( )should not be used unless they are absolutely necessary.

Remark:The nominal size given in( )does not conform to the relevant international standard and must not be

Referenc The groove for the boss should be slanted to 1/100, in principle.

used.

1855 1856

Вам также может понравиться

- Audit Report Summary and ConclusionДокумент13 страницAudit Report Summary and ConclusionSunday OluwoleОценок пока нет

- Chios Reiki Attunement ManualДокумент12 страницChios Reiki Attunement Manualkeithmac100% (1)

- Dimensions, Sizes and Specification of BS 4505 and en 1092 FlangesДокумент5 страницDimensions, Sizes and Specification of BS 4505 and en 1092 FlangesHanumanthu GollaОценок пока нет

- Metric Bolt StrengthДокумент18 страницMetric Bolt StrengthSachin ShindeОценок пока нет

- Renault Truck - KДокумент16 страницRenault Truck - KPaul FisherОценок пока нет

- Method Statement For Installation of Access ScafoldingДокумент9 страницMethod Statement For Installation of Access Scafoldingbureau servicesОценок пока нет

- EN 10025: 2004 Is The New European Standard For Structural Steel.Документ6 страницEN 10025: 2004 Is The New European Standard For Structural Steel.Alin DavidОценок пока нет

- Tightening Torques PDFДокумент1 страницаTightening Torques PDFlaweenceОценок пока нет

- Sigra Sirkuit DiagramДокумент147 страницSigra Sirkuit DiagramKhilmi Ainur RifqiОценок пока нет

- Hot-Rolled and Cold-Finished Age-Hardening Stainless Steel Bars and ShapesДокумент8 страницHot-Rolled and Cold-Finished Age-Hardening Stainless Steel Bars and ShapesradziОценок пока нет

- Lib HydraulicДокумент72 страницыLib HydraulicD'Armi StefanoОценок пока нет

- Fasteners Vol1 TocДокумент3 страницыFasteners Vol1 TocLucas Willian100% (2)

- FastenersДокумент56 страницFastenersAnonymous Dp4DdscGSОценок пока нет

- Jis B1171 1996Документ15 страницJis B1171 1996TUAN NGUYEN VANОценок пока нет

- Pressure Tight Thread Joints ISO 7Документ3 страницыPressure Tight Thread Joints ISO 7Adrian BurlacuОценок пока нет

- Din 434Документ1 страницаDin 434RaduZapciroiuОценок пока нет

- BSEN1092 16 DimensionsДокумент2 страницыBSEN1092 16 DimensionsalfonscarlОценок пока нет

- Documenting Childrens Learning Examples PDFДокумент19 страницDocumenting Childrens Learning Examples PDFArief lukman100% (1)

- Astm A31 (1995)Документ4 страницыAstm A31 (1995)gsb2100% (1)

- Pins and KeysДокумент12 страницPins and KeysSam GillilandОценок пока нет

- Drill Size Recommended For TapДокумент4 страницыDrill Size Recommended For Tapnithin83aОценок пока нет

- Hollow Steel Catalog PDFДокумент44 страницыHollow Steel Catalog PDFaiyubi2Оценок пока нет

- Comparison of USCS and AASHTOДокумент2 страницыComparison of USCS and AASHTOkitefly100% (2)

- Garnituri DIN 2697Документ12 страницGarnituri DIN 2697Dumitru SorinaОценок пока нет

- Blind Flange 1,2, Hinge, Handlen & Plug PDFДокумент1 страницаBlind Flange 1,2, Hinge, Handlen & Plug PDFArief MaulanaОценок пока нет

- STD 25.iso 27830 2017Документ9 страницSTD 25.iso 27830 2017Seda ErsoyОценок пока нет

- Continuously Hot-Rolled Low Carbon Steel Sheet and Strip For Cold FormingДокумент12 страницContinuously Hot-Rolled Low Carbon Steel Sheet and Strip For Cold FormingudayОценок пока нет

- A788 PDFДокумент12 страницA788 PDFrohit kumarОценок пока нет

- Threads - NPTF Taper Thread GagingДокумент5 страницThreads - NPTF Taper Thread GagingTrushantОценок пока нет

- Din 2577Документ2 страницыDin 2577zaharievОценок пока нет

- Obturation of Root Canal LectureДокумент8 страницObturation of Root Canal LectureOsama AsadiОценок пока нет

- KFC Case StudyДокумент3 страницыKFC Case StudyAnkita shaw100% (2)

- V-Belt: Design ManualДокумент102 страницыV-Belt: Design ManualCARLOS OLIVEROSОценок пока нет

- Metric Heavy Hex Nut DimensionsДокумент3 страницыMetric Heavy Hex Nut DimensionsSenthillkumar BalasubramaniamОценок пока нет

- SKF Lock Nuts PDFДокумент22 страницыSKF Lock Nuts PDFgrupa2904Оценок пока нет

- Thread Standard BSPДокумент7 страницThread Standard BSPĐạt TrầnОценок пока нет

- Iso 888 1976Документ4 страницыIso 888 1976202218et490Оценок пока нет

- 25CrMo4Документ1 страница25CrMo4Hans GoetheОценок пока нет

- FYH ZlockДокумент2 страницыFYH ZlockRodrigo Jechéla BarriosОценок пока нет

- Iso Metric 32Документ2 страницыIso Metric 32rahul caddОценок пока нет

- Astm F-568M - 98Документ8 страницAstm F-568M - 98awesome_600Оценок пока нет

- Uni 663 Grade Fe55 1 Tubes PDFДокумент1 страницаUni 663 Grade Fe55 1 Tubes PDFMitul MehtaОценок пока нет

- Fittings Din11852 Din11850Документ14 страницFittings Din11852 Din11850dingobk1Оценок пока нет

- Circlip Dimensions PDFДокумент71 страницаCirclip Dimensions PDFBoobalan ShriОценок пока нет

- Bossard Taptite Self Tapping Screw CatalogueДокумент10 страницBossard Taptite Self Tapping Screw CataloguepmlmkpОценок пока нет

- European Standard Norme Europeenne Europaische Norm: Ultrasonic Testing of $teel BarsДокумент13 страницEuropean Standard Norme Europeenne Europaische Norm: Ultrasonic Testing of $teel BarspraveenОценок пока нет

- 06 Eurocodes Steel Workshop WALDДокумент136 страниц06 Eurocodes Steel Workshop WALDFrancisco RojasОценок пока нет

- Mil STD 810h HumidityДокумент22 страницыMil STD 810h Humiditymariela baigorriaОценок пока нет

- Nes 833-34 PDFДокумент2 страницыNes 833-34 PDFBHARGAVОценок пока нет

- Tapping Drill IS 10952Документ6 страницTapping Drill IS 10952George ThomasОценок пока нет

- Metric DIN 127 SpecДокумент5 страницMetric DIN 127 SpecmahfuzОценок пока нет

- Thread-Cutting Tools and ProceduresДокумент31 страницаThread-Cutting Tools and ProcedureszaidoОценок пока нет

- Ejot - Delta PTДокумент2 страницыEjot - Delta PTLucas VeronaОценок пока нет

- Astm A193 PDFДокумент12 страницAstm A193 PDFjoserodriguezherazoОценок пока нет

- Din 1670Документ10 страницDin 1670GODREJ LAB THANEОценок пока нет

- Wilsons LTD Copper and Copper Alloys Def Stan 02 833 NES833 CW307G 119Документ2 страницыWilsons LTD Copper and Copper Alloys Def Stan 02 833 NES833 CW307G 119lijojose1Оценок пока нет

- 17 PinsДокумент16 страниц17 PinsRolffoTello100% (1)

- Techincal Data For PCD Dia & Torque ChartДокумент1 страницаTechincal Data For PCD Dia & Torque ChartTuff quality100% (1)

- Gulf Fasteners & Metal Industries ProfileДокумент4 страницыGulf Fasteners & Metal Industries ProfiledprosenjitОценок пока нет

- ARNOLD - Thread Forming ScrewДокумент4 страницыARNOLD - Thread Forming ScrewgirishawantiОценок пока нет

- DIN 00267 (Referencia)Документ77 страницDIN 00267 (Referencia)WVP100% (1)

- Seleccion Chaveteros Norma JIS PDFДокумент1 страницаSeleccion Chaveteros Norma JIS PDFalanv8Оценок пока нет

- Blind Flange 1,2, Hinge, Handlen & PlugДокумент1 страницаBlind Flange 1,2, Hinge, Handlen & PlugArief MaulanaОценок пока нет

- (Cont. Next Page) 6 Hilux: Engine Control (2TR-FE)Документ4 страницы(Cont. Next Page) 6 Hilux: Engine Control (2TR-FE)autocomtrucksОценок пока нет

- Second Floor Partial Lighting Plan (Pe2) : KAP4 - Security Planning and Development Agency KAP4 ProjectДокумент1 страницаSecond Floor Partial Lighting Plan (Pe2) : KAP4 - Security Planning and Development Agency KAP4 ProjectJose JohnОценок пока нет

- WFBR22F00382-0 - 860 - 6-6 - P5ZL - 35 - Pa - 38 - 10 - AДокумент1 страницаWFBR22F00382-0 - 860 - 6-6 - P5ZL - 35 - Pa - 38 - 10 - AAlan Miguel PuffОценок пока нет

- DWG - SLDDRW SR05 PDFДокумент1 страницаDWG - SLDDRW SR05 PDFluisA1923Оценок пока нет

- El 01Документ1 страницаEl 01Faheem ShahzadОценок пока нет

- Intermediate Forming Questions - WhereДокумент1 страницаIntermediate Forming Questions - WherePablo PasqualiniОценок пока нет

- Intermediate Forming Questions - WhatДокумент1 страницаIntermediate Forming Questions - WhatPablo PasqualiniОценок пока нет

- Intermediate Forming Questions - HowДокумент1 страницаIntermediate Forming Questions - HowPablo PasqualiniОценок пока нет

- Standard Metal Expansion JointsДокумент40 страницStandard Metal Expansion JointsPablo PasqualiniОценок пока нет

- Tabla QuimicaДокумент12 страницTabla QuimicaPablo PasqualiniОценок пока нет

- Visores de Nivel de Columna PDFДокумент1 страницаVisores de Nivel de Columna PDFPablo PasqualiniОценок пока нет

- Klingersil C-4500Документ6 страницKlingersil C-4500Pablo PasqualiniОценок пока нет

- El Concepto Multi CapaДокумент2 страницыEl Concepto Multi CapaPablo PasqualiniОценок пока нет

- Doucette Industries, IncДокумент12 страницDoucette Industries, IncPablo PasqualiniОценок пока нет

- Juntas EnchaquetadasДокумент1 страницаJuntas EnchaquetadasPablo PasqualiniОценок пока нет

- Interlaced Braided Ptfe Packing: Operating ConditionsДокумент2 страницыInterlaced Braided Ptfe Packing: Operating ConditionsPablo PasqualiniОценок пока нет

- UK Environment Agency RM-QG6 - Calibrating Particulate-Monitoring Continuous Emission Monitoring Systems (CEMs), Especially For Low Concentrations of Particulate MatterДокумент7 страницUK Environment Agency RM-QG6 - Calibrating Particulate-Monitoring Continuous Emission Monitoring Systems (CEMs), Especially For Low Concentrations of Particulate MatterTomy SetiyadiОценок пока нет

- MMZG 533Документ8 страницMMZG 533Prakash Kumar SenОценок пока нет

- 1st Grading Exam in MILДокумент3 страницы1st Grading Exam in MILArchie Alipongoy KolokoyОценок пока нет

- Grade 8 Term 3 Project 2021Документ2 страницыGrade 8 Term 3 Project 2021Londiwe PrincessОценок пока нет

- INVESTIGATION REPORT eFNCR 076 - BOP Test Plug Stuck in CHHДокумент4 страницыINVESTIGATION REPORT eFNCR 076 - BOP Test Plug Stuck in CHHOmer Abd Al NasserОценок пока нет

- Itl 518 Project Based Learning Template 1Документ24 страницыItl 518 Project Based Learning Template 1api-431944437100% (1)

- Stereotypes in General-Advantages and Disadvantages: Being Typically EnglishДокумент2 страницыStereotypes in General-Advantages and Disadvantages: Being Typically EnglishDiana IrimieaОценок пока нет

- Froebelian Eglantyne Jebb, Save The ChildrenДокумент3 страницыFroebelian Eglantyne Jebb, Save The ChildrenLifeinthemix_FroebelОценок пока нет

- Statement of Teaching Interests-ExampleДокумент3 страницыStatement of Teaching Interests-ExampleNedelcuGeorgeОценок пока нет

- Sl500 User Manual NewДокумент40 страницSl500 User Manual NewAmrutha SudhakaranОценок пока нет

- Tissue Paper Hot Air Balloon: Andrea Badua Period 2 Physics Ms. BuenconsejoДокумент14 страницTissue Paper Hot Air Balloon: Andrea Badua Period 2 Physics Ms. BuenconsejoAndrea BaduaОценок пока нет

- GIS Project ProposalДокумент2 страницыGIS Project ProposalKevin OdonnellОценок пока нет

- Ctenocephalides Felis Felis vs. Ctenocephalides Canis (Siphonaptera: Pulicidae) : Some Issues in Correctly Identify These SpeciesДокумент11 страницCtenocephalides Felis Felis vs. Ctenocephalides Canis (Siphonaptera: Pulicidae) : Some Issues in Correctly Identify These SpeciesstfnhmwnОценок пока нет

- d17 Vega Using SqltraceДокумент66 страницd17 Vega Using SqltraceViorel PanaiteОценок пока нет

- Fundamentals of Momentum, Heat and Mass TransferДокумент87 страницFundamentals of Momentum, Heat and Mass TransferSlim KanounОценок пока нет

- Oracle Fusion Middleware Developer GuideДокумент1 422 страницыOracle Fusion Middleware Developer GuideahsunОценок пока нет

- Practice Problems 2012Документ5 страницPractice Problems 2012Anonymous Fj3YPHОценок пока нет

- Natural Motion in Physics (Aristotle, Newton, Einstein)Документ11 страницNatural Motion in Physics (Aristotle, Newton, Einstein)George Mpantes mathematics teacherОценок пока нет

- 3826 ID Job Satisfaction and Performance of Nurse Based On Workload in Bhayangkara HospiДокумент9 страниц3826 ID Job Satisfaction and Performance of Nurse Based On Workload in Bhayangkara HospiDiam Sudah MuhtarОценок пока нет

- Studies Regarding The Influence of Music On The Wheat Plants GrowthДокумент4 страницыStudies Regarding The Influence of Music On The Wheat Plants GrowthLakshmi AjithОценок пока нет

- Full TextДокумент6 страницFull TextVasco ClaroОценок пока нет