Академический Документы

Профессиональный Документы

Культура Документы

Shrink Disc Type HSD: Mounting and Removal Instructions For

Загружено:

Guang ChenzОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Shrink Disc Type HSD: Mounting and Removal Instructions For

Загружено:

Guang ChenzАвторское право:

Доступные форматы

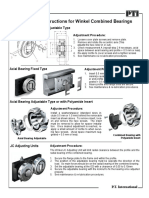

Mounting and Removal Instructions for

Shrink Disc Type HSD

Before Mounting Conical surfaces After Mounting

and bolts are

lubricated

grease free

Mounting Dismounting

®

The STÜWE shrink discs type HSD are supplied ready This is similar to mounting.

to be mounted. Therefore they should not be dismantled

1. Loosen all tightening bolts, initially not more than a

prior to employing the unit for the first time.

quarter turn per bolt, one after one.

1. Degrease shaft and hub bore.

The outer surface of the hub may be greased. Under no circumstances should the locking

bolts be completely removed as this could be

2. Slide shrink disc onto hub. dangerous and result in injury.

Do not tighten the tightening bolts before the

2. Should the outer ring, when loosening the bolts, not

shaft is mounted.

slide automatically from the inner ring, this can be

assisted by removing those locking bolts adjacent

3. Fit the shaft or slide the hub onto the shaft.

to the tapped bores provided for jacking purposes

4. Tighten four bolts distributed evenly over the and screwing them into these. The jacking procedure

circumference by reduced torque (approx. 50 to 70% must be continued until a complete release of the

of maximum tightening torque). outer ring is achieved.

5. Afterwards tighten all tightening bolts uniformly, one 3. Dismount shaft or draw off hub. Remove rust which

by one, over several revolutions until the outer ring may have formed on the shaft in front of the hub.

and inner ring are flush.

4. Remove shrink disc from hub.

This indicates that the full transmissible torque is

achieved. Cleaning and lubrication

6. Check each tightening bolt twice for the required Dismounted shrink discs do not have to be dismantled

tightening torque. and re-lubricated before remounting.

The shrink disc has to be cleaned and re-lubricated only

Examples: if employed in dirty environment.

Lubricant Source Use a solid containing lubricant with a high content

of MoS2 and a coefficient of friction of μ = 0,04 to

Molykote D 321 R (bonded coating) Dow Corning

lubricate the conical surfaces. Usually a combination of

Aema-Sol MO 84-K (bonded coating) A.C. Matthes bonded coating and paste is chosen.

Molykote G Rapid + (paste) Dow Corning

Aema-Sol M 19 P (paste) A.C. Matthes

The bolts have to be renewed if possible.

The bolts are lubricated with commercially availabe bolt

lubricants (μ = 0,1)

Stüwe GmbH & Co. KG - Zum Ludwigstal 35 - 45527 Hattingen - Germany

Tel. +49 2324 394-0 - Fax +49 2324 394-30 - www.stuewe.de - info@stuewe.de

Вам также может понравиться

- HDBIДокумент5 страницHDBIkevlar315Оценок пока нет

- Proper handling of bearingsДокумент16 страницProper handling of bearingszakizaki100% (1)

- BR3 007 ManualДокумент5 страницBR3 007 ManualRodrigo Jechéla BarriosОценок пока нет

- SPL U Joint Service Guide PDFДокумент2 страницыSPL U Joint Service Guide PDFLeonardo PeñalozaОценок пока нет

- Geared Coupling Manual PDFДокумент5 страницGeared Coupling Manual PDFSatОценок пока нет

- Chiksan Swivel Joints Repacking Instructions Longsweep Standard Service PDFДокумент2 страницыChiksan Swivel Joints Repacking Instructions Longsweep Standard Service PDFCikalong Yard100% (1)

- Keyless Bushing Instruction Manual July 2019Документ2 страницыKeyless Bushing Instruction Manual July 2019huseyinОценок пока нет

- Shrink Disc Type HYD 22: Mounting and Removal Instructions ForДокумент1 страницаShrink Disc Type HYD 22: Mounting and Removal Instructions ForAkash RockОценок пока нет

- Techlok PocketguideДокумент1 страницаTechlok PocketguideJacobus CalvelageОценок пока нет

- TimkenTT en Vol1 Iss3Документ2 страницыTimkenTT en Vol1 Iss3grupa2904Оценок пока нет

- Impak 2Документ11 страницImpak 2Vasudev AgrawalОценок пока нет

- Reverse Modulated Wet Disc Brake System: SectionДокумент7 страницReverse Modulated Wet Disc Brake System: SectionAlexander MugabeОценок пока нет

- Angular Co Installation GuideДокумент2 страницыAngular Co Installation GuideGabrielОценок пока нет

- Installation and Maintenance Instructions Reverse Acting Rupture Disc AssembliesДокумент5 страницInstallation and Maintenance Instructions Reverse Acting Rupture Disc AssembliesGuilherme AugustoОценок пока нет

- RTL Sleevoil Instruction Manual 499970Документ11 страницRTL Sleevoil Instruction Manual 499970गुंजन सिन्हाОценок пока нет

- Ringfeder Locking Assemblies: RFN 7012/Rfn 7012-InДокумент3 страницыRingfeder Locking Assemblies: RFN 7012/Rfn 7012-Inoscarlopez12345Оценок пока нет

- 2531Документ5 страниц2531sangkil05Оценок пока нет

- Vasim 2Документ17 страницVasim 2Vasim shaikhОценок пока нет

- MSA5TCD97L3692Документ3 страницыMSA5TCD97L3692Mudflap CalizayaОценок пока нет

- Dismounting of Rolling Bearings Hydraulic Dismounting FAG PDFДокумент5 страницDismounting of Rolling Bearings Hydraulic Dismounting FAG PDFNoche de EstrellasОценок пока нет

- Armado 2Документ3 страницыArmado 2Edgar Meza ChávezОценок пока нет

- Hydrodynamics Journal BearingДокумент14 страницHydrodynamics Journal BearingAhmad Shayuty75% (4)

- Hilliard Flame Clutch InstallationДокумент4 страницыHilliard Flame Clutch InstallationDavid CarsonОценок пока нет

- Mounting Tapered Bore Spherical Roller Bearings On Adapter SleevesДокумент7 страницMounting Tapered Bore Spherical Roller Bearings On Adapter SleevesHamza NoumanОценок пока нет

- SAP PARTS: Installation Guidelines For Installation Guidelines For Duo-Cone SealsДокумент5 страницSAP PARTS: Installation Guidelines For Installation Guidelines For Duo-Cone SealsRavi MirzaОценок пока нет

- Cummins Ism QSM PDFДокумент11 страницCummins Ism QSM PDFEng-AhmedRashadОценок пока нет

- Cummins Ism, QSMДокумент11 страницCummins Ism, QSMibnu67% (6)

- QD Bushings CatalogДокумент5 страницQD Bushings CatalogYuri OrellanoОценок пока нет

- Mounting WhitepaperДокумент7 страницMounting WhitepaperSamik MukherjeeОценок пока нет

- MN3085 - 0222 (W)Документ12 страницMN3085 - 0222 (W)mariamalloney1730Оценок пока нет

- TITLE Engine Assembly Guide: 12V140E-3 Series Cylinder Liner InstallationДокумент39 страницTITLE Engine Assembly Guide: 12V140E-3 Series Cylinder Liner InstallationЕгорОценок пока нет

- Winkel Bearing Adjustment Re Lube Instructions 0719Документ2 страницыWinkel Bearing Adjustment Re Lube Instructions 0719huseyinОценок пока нет

- Connecting Rod ReplacementДокумент11 страницConnecting Rod Replacementfjafarvand100% (1)

- Blue Diamond Assembly Procedure 1593Документ2 страницыBlue Diamond Assembly Procedure 1593Stephen GerhauserОценок пока нет

- 23152 CCK_W33 - Mounting -_ Withdrawal sleeve -_ Mechanical mountingДокумент14 страниц23152 CCK_W33 - Mounting -_ Withdrawal sleeve -_ Mechanical mountingpmf engineering limitedОценок пока нет

- May Cap Da Voi Nhiet DienДокумент14 страницMay Cap Da Voi Nhiet Dienlinhcdt3Оценок пока нет

- Catalogo de Servicos I Td226b Eng Rev1 2011Документ26 страницCatalogo de Servicos I Td226b Eng Rev1 2011AndreyIvanov100% (1)

- GS150&200 Engine Service GuideДокумент51 страницаGS150&200 Engine Service GuideMiguel LemosОценок пока нет

- Technical guide cardan shaftsДокумент6 страницTechnical guide cardan shaftsEdwin FontechaОценок пока нет

- Lubrification Hub de RoueДокумент4 страницыLubrification Hub de Rouerene chapdelaineОценок пока нет

- GEN Info: Disassembly and AssemblyДокумент1 страницаGEN Info: Disassembly and AssemblyPHUONG NGUYENОценок пока нет

- Mounting of Machine Elements On Transmission Shaft (Pulley & Bearing)Документ30 страницMounting of Machine Elements On Transmission Shaft (Pulley & Bearing)Rushabh MeherОценок пока нет

- Wheel Bearing Repacking or ReplacementДокумент8 страницWheel Bearing Repacking or Replacementthe_monkeys_teacupОценок пока нет

- 16163676Документ30 страниц16163676ADWAIT SHINDEОценок пока нет

- Installation and Removal of Q.D. and Taper Lock Bushings: Exercise E223-S05-EXR-RV1.wpdДокумент7 страницInstallation and Removal of Q.D. and Taper Lock Bushings: Exercise E223-S05-EXR-RV1.wpdirawan malikОценок пока нет

- B-02 Mechnical Seal For SBPO LubeДокумент8 страницB-02 Mechnical Seal For SBPO LubeMarvin DuarteОценок пока нет

- SKF Wheel Bearing Installation Guide With Free End PlayДокумент20 страницSKF Wheel Bearing Installation Guide With Free End Play2bjornОценок пока нет

- At 4 ClutchДокумент3 страницыAt 4 ClutchKevin Heather TVОценок пока нет

- Tapered Roller Bearings InformationДокумент8 страницTapered Roller Bearings Informationmans2014Оценок пока нет

- Diagram of Vitamix Blade Blade Assembly: InstructionsДокумент5 страницDiagram of Vitamix Blade Blade Assembly: InstructionsRenato PurcinoОценок пока нет

- Blower k430 Snh60 Overhaul ProcedureДокумент39 страницBlower k430 Snh60 Overhaul ProcedurejamiekuangОценок пока нет

- 2010-2015 DHX RC4 - RC2 Rebuild - Bike Help Center - FOXДокумент34 страницы2010-2015 DHX RC4 - RC2 Rebuild - Bike Help Center - FOXYadi RomaОценок пока нет

- Wheel Assembly Inspection and Maintenance InspectionДокумент5 страницWheel Assembly Inspection and Maintenance InspectionrajОценок пока нет

- Preparation and Installation of The ULTRX HP (DD) Rupture Disc / ULTRX Double Disc Holder AssemblyДокумент6 страницPreparation and Installation of The ULTRX HP (DD) Rupture Disc / ULTRX Double Disc Holder AssemblyPaul LauОценок пока нет

- EteclowerДокумент4 страницыEteclowercapemarinesurveyОценок пока нет

- VDL Service ManualДокумент13 страницVDL Service ManualSergio Martín BrionesОценок пока нет

- Key Points about Assembling or Disassembling WP6 Diesel Engines 培训资料 Training Material 国际配套服务部 徐衍国Документ27 страницKey Points about Assembling or Disassembling WP6 Diesel Engines 培训资料 Training Material 国际配套服务部 徐衍国Manutenção Base AnápolisОценок пока нет

- Angular Contact Bearing InstallationДокумент3 страницыAngular Contact Bearing Installationdk4monjureОценок пока нет

- Service Manual Yamaha Scorpio Chapter 6 ChasisДокумент50 страницService Manual Yamaha Scorpio Chapter 6 Chasisjolang46Оценок пока нет

- RINGFEDER Damping TechnologyДокумент22 страницыRINGFEDER Damping TechnologyGuang ChenzОценок пока нет

- Ringfeder Fricton Spring Manual (2019)Документ3 страницыRingfeder Fricton Spring Manual (2019)Guang ChenzОценок пока нет

- Market Report - Regional: Count HKD Billion USD BillionДокумент3 страницыMarket Report - Regional: Count HKD Billion USD BillionGuang ChenzОценок пока нет

- Product Attribute Ref. Value: Part NumberДокумент2 страницыProduct Attribute Ref. Value: Part NumberGuang ChenzОценок пока нет

- Brosur Intermediate Rubber Strips STL NL UncuredДокумент2 страницыBrosur Intermediate Rubber Strips STL NL UncuredGuang ChenzОценок пока нет

- Flashguard Xenon Beacons GuideДокумент1 страницаFlashguard Xenon Beacons GuideGuang ChenzОценок пока нет

- GE Model Number EN218101 - Up To Date Replacement Proposal # 18MA12305Документ4 страницыGE Model Number EN218101 - Up To Date Replacement Proposal # 18MA12305Guang ChenzОценок пока нет

- Product Attribute Ref. Value: Part NumberДокумент2 страницыProduct Attribute Ref. Value: Part NumberGuang ChenzОценок пока нет

- On-Site Inspection of Magnetic Separators-1Документ6 страницOn-Site Inspection of Magnetic Separators-1jamilvoraОценок пока нет

- Product Attribute Ref. Value: Part NumberДокумент2 страницыProduct Attribute Ref. Value: Part NumberGuang ChenzОценок пока нет

- ROTAStop PU1TRA (Manual)Документ2 страницыROTAStop PU1TRA (Manual)Guang ChenzОценок пока нет

- K&J Magnetics, Inc. Material Safety Data Sheet: Section 1 - Product Name Section 2 - Hazardous IngredientsДокумент2 страницыK&J Magnetics, Inc. Material Safety Data Sheet: Section 1 - Product Name Section 2 - Hazardous IngredientsGuang ChenzОценок пока нет

- Rocktrans Presentation PDFДокумент24 страницыRocktrans Presentation PDFGuang ChenzОценок пока нет

- Klaxon QBS Led Flashing BeaconДокумент1 страницаKlaxon QBS Led Flashing BeaconGuang ChenzОценок пока нет

- ECP Safe T Pull SSB-DIP (2019)Документ2 страницыECP Safe T Pull SSB-DIP (2019)Guang ChenzОценок пока нет

- ECP Safe-T-Pull Remote (2019)Документ2 страницыECP Safe-T-Pull Remote (2019)Guang ChenzОценок пока нет

- ECP Safe-T-Pull SD Dissipative (2019)Документ2 страницыECP Safe-T-Pull SD Dissipative (2019)Guang ChenzОценок пока нет

- Rocktrans Belt (GN - Slide) PDFДокумент11 страницRocktrans Belt (GN - Slide) PDFGuang ChenzОценок пока нет

- ECP Safe-T-Pull SSB Stainless (2019)Документ2 страницыECP Safe-T-Pull SSB Stainless (2019)Guang ChenzОценок пока нет

- ECP Safe-T-Pull PBT (2019)Документ2 страницыECP Safe-T-Pull PBT (2019)Guang ChenzОценок пока нет

- Safety Devices DesignДокумент2 страницыSafety Devices DesignWaris La Joi WakatobiОценок пока нет

- Ameraal Flexam-High-ImpactДокумент2 страницыAmeraal Flexam-High-ImpactGuang ChenzОценок пока нет

- Conti PRE-formed Splice KitДокумент3 страницыConti PRE-formed Splice KitGuang ChenzОценок пока нет

- Assembly Magnetic SeparatorДокумент1 страницаAssembly Magnetic SeparatorGuang ChenzОценок пока нет

- Datasheet SBFL514471 en USДокумент2 страницыDatasheet SBFL514471 en USGuang ChenzОценок пока нет

- 1119GB en Tip Top Heating Solution STL-RF4 Free of 0056Документ7 страниц1119GB en Tip Top Heating Solution STL-RF4 Free of 0056Guang ChenzОценок пока нет

- #12 Conveyor Belt Repair OptionsДокумент7 страниц#12 Conveyor Belt Repair OptionsawfahОценок пока нет

- CST Form-1Документ1 страницаCST Form-1Guang Chenz100% (1)

- Black Gold Energy Power (BEP - 20151228)Документ2 страницыBlack Gold Energy Power (BEP - 20151228)Guang ChenzОценок пока нет

- Safety of High-Rise BuildingsДокумент14 страницSafety of High-Rise BuildingsHananeel Sandhi100% (2)

- Instruction/Special Maintenance Instruction (IN/SMI)Документ2 страницыInstruction/Special Maintenance Instruction (IN/SMI)ANURAJM44Оценок пока нет

- Lenex 3.0 Technical DocumentationДокумент31 страницаLenex 3.0 Technical DocumentationGalina DОценок пока нет

- 13 Daftar PustakaДокумент2 страницы13 Daftar PustakaDjauhari NoorОценок пока нет

- Structures Module 3 Notes FullДокумент273 страницыStructures Module 3 Notes Fulljohnmunjuga50Оценок пока нет

- Proprietar Utilizator Nr. Crt. Numar Inmatriculare Functie Utilizator Categorie AutovehiculДокумент3 страницыProprietar Utilizator Nr. Crt. Numar Inmatriculare Functie Utilizator Categorie Autovehicultranspol2023Оценок пока нет

- Feb 22-Additional CasesДокумент27 страницFeb 22-Additional CasesYodh Jamin OngОценок пока нет

- IT support tips for non-tech colleaguesДокумент7 страницIT support tips for non-tech colleaguesLeo KrekОценок пока нет

- FC Bayern Munich Marketing PlanДокумент12 страницFC Bayern Munich Marketing PlanMateo Herrera VanegasОценок пока нет

- Capran+980 CM en PDFДокумент1 страницаCapran+980 CM en PDFtino taufiqul hafizhОценок пока нет

- Verifyning GC MethodДокумент3 страницыVerifyning GC MethodHristova HristovaОценок пока нет

- "Corbel" - Concrete Corbel Analysis: Program DescriptionДокумент4 страницы"Corbel" - Concrete Corbel Analysis: Program DescriptioniuliandurdureanuОценок пока нет

- DX133 DX Zero Hair HRL Regular 200 ML SDS 16.04.2018 2023Документ6 страницDX133 DX Zero Hair HRL Regular 200 ML SDS 16.04.2018 2023Welissa ChicanequissoОценок пока нет

- M Series CylindersДокумент61 страницаM Series CylindersAndres SantanaОценок пока нет

- Micro Controller AbstractДокумент6 страницMicro Controller AbstractryacetОценок пока нет

- SHIPPING TERMSДокумент1 страницаSHIPPING TERMSGung Mayura100% (1)

- WSM 0000410 01Документ64 страницыWSM 0000410 01Viktor Sebastian Morales CabreraОценок пока нет

- Exercise Manual For Course 973: Programming C# Extended Features: Hands-OnДокумент122 страницыExercise Manual For Course 973: Programming C# Extended Features: Hands-OnAdrian GorganОценок пока нет

- Telangana Budget 2014-2015 Full TextДокумент28 страницTelangana Budget 2014-2015 Full TextRavi Krishna MettaОценок пока нет

- Amended ComplaintДокумент38 страницAmended ComplaintDeadspinОценок пока нет

- Contemporary World Prelim Exam Test DraftДокумент5 страницContemporary World Prelim Exam Test DraftGian Quiñones93% (45)

- StrutsДокумент7 страницStrutsBatrisyialya RusliОценок пока нет

- Guardplc Certified Function Blocks - Basic Suite: Catalog Number 1753-CfbbasicДокумент110 страницGuardplc Certified Function Blocks - Basic Suite: Catalog Number 1753-CfbbasicTarun BharadwajОценок пока нет

- Model Paper 1Документ4 страницыModel Paper 1Benjamin RohitОценок пока нет

- Nmea Components: NMEA 2000® Signal Supply Cable NMEA 2000® Gauges, Gauge Kits, HarnessesДокумент2 страницыNmea Components: NMEA 2000® Signal Supply Cable NMEA 2000® Gauges, Gauge Kits, HarnessesNuty IonutОценок пока нет

- Data Collection Methods and Tools For ResearchДокумент29 страницData Collection Methods and Tools For ResearchHamed TaherdoostОценок пока нет

- Coa - Ofx-8040a (H078K5G018)Документ2 страницыCoa - Ofx-8040a (H078K5G018)Jaleel AhmedОценок пока нет

- AP Statistics - 2014-2015 Semester 1 Test 3Документ4 страницыAP Statistics - 2014-2015 Semester 1 Test 3Camden BickelОценок пока нет

- Whats The Average 100 M Time For An Olympics - Google SearchДокумент1 страницаWhats The Average 100 M Time For An Olympics - Google SearchMalaya KnightonОценок пока нет

- HandoverДокумент2 страницыHandoverKumaresh Shanmuga Sundaram100% (1)