Академический Документы

Профессиональный Документы

Культура Документы

Ball Valves - R43/R44 Trunnion Mounted

Загружено:

ThomasFrenchОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Ball Valves - R43/R44 Trunnion Mounted

Загружено:

ThomasFrenchАвторское право:

Доступные форматы

Ball Valves - R43/R44 Trunnion Mounted

Sizes 50 - 400mm

Richards two and three piece full or reduced bore

trunnion design ball valves.

Available in ANSI class 150 to 1500.

• Series R43 full bore

• Series R44 reduced bore

Features

• Designed to API 6D & BS 5351.

• Fire-tested to BS 6755 Pt 2 &

API 607 4th Edition Witnessed by

Lloyd’s Register

• Integral trunnion design.

• Body bolting design complies

with ANSI B16.34 & ASME VIII.

• Large diameter integral trunnion

bearings.

• Spring energized constrained seat

design.

• Cavity relieving seat assembly.

• Double block & bleed capability

• Equipped with cavity pressure

bleed fitting.

• Secondary "fire-safe" seal.

• External replaceable weather seal.

• Optional emergency seat and

stem sealant facilities.

• Spring energized stem

assembly to compensate for

wear and temperature changes.

• Anti-static compliance witnessed

by Lloyd’s Register.

• Additional cavity vent facility for

valves 150mm and above.

• Manufactured under quality

system ISO 9001 Cert. No.

929678 and API 6D Q1

Cert. No. 6D-0243.

• Available in ANSI B16.5 flanged,

weld end and clamplock end

connections.

• Body and seat hydrostatic and

seat air test. Documentation to

EN10204 / ISO 10474 type 3.1.B.

Material certification for pressure

containing components. General Applications

Ideally suited for pipeline installations,

gas production, pressure regulating

and metering stations, FVO/LVO and

platform duties, petroleum,

petrochemical and allied industries.

© Copyright by Tyco International Ltd R43/R44/02/00

A.C.N. 000922690

Richards reserves the right to change product designs and specifications without notice.

Ball Valves - R43/R44 Trunnion Mounted

Sizes 50 - 400mm

Advantages of Trunnion Mounted Ball

With conventional floating ball designs, the upstream pressure forces the closed

ball to move onto the downstream seat. The resulting torque is a factor of load and

friction between the ball and seat surfaces. The break to open torque is increased

significantly with an increasing differential pressure and/or an increase in the size

of the valve seating area. As the size or the differential pressure increase it

becomes increasingly difficult to operate the valve due to the torque generated by

pressure.

Trunnion design ball valves alleviate this problem by ensuring that the ball is fixed

within the valve body, and the seats are energised to the ball. The differential

pressure loading is now distributed to the trunnion plates and bearings, resulting in

smaller seating surface designs and greatly reduced break to open and operating

torque.

Integral Trunnion Design

Richards trunnion valves incorporate integral trunnion bearings, which are

machined to the top and bottom of the ball. With the integral trunnion design, the

ball is fixed by means of the trunnion plate assemblies, which are constrained

within the valve body. The spring and pressure energized seat assemblies are

guided to the ball surface in order to achieve sealing integrity.

When pressure is applied to the upstream side of the ball, the resultant forces are

distributed to the two large diameter trunnion bearings, which are housed in the

trunnion plates. When the valve is in the closed position there is no side loading

being applied to the stem that can result in premature stem and stem seal wear.

The integral trunnion affords a compact, cost effective design. This design also

minimizes the number of potential external leak paths in high pressure valves,by

reducing the requirement for outboard trunnion cover plates.

Double Block and Bleed Design

Trunnion valves are typically used for pipeline, compressor stations and gas

processing plant service; also on oil and petroleum product lines. Obviously seat

integrity is required for these block valve services.

In either the fully closed or open position, with the aide of energised seat design,

the body cavity pressure may be relieved as a means of checking seat integrity. As

the Richards stem drive does not penetrate the bore of the ball, the valve does not

have to be returned to the closed position, which may cause operational problems

for the process. For manifolds that carry several media’s, this can provide a positive

means of product isolation and prevent mixing of product, should seat damage

occur.

© Copyright by Tyco International Ltd R43/R44/02/00

Richards reserves the right to change product designs and specifications without notice.

Ball Valves - R43/R44 Trunnion Mounted

Sizes 50 - 400mm

Stem Sealing and Injection System

Due to the use of integral trunnion bearings, the stem side loading is minimised,

therefore reducing premature wear to the stem seal assembly. The stem seal

arrangement incorporates a multi-step blowout proof stem, complimented with large

contact area PTFE primary seals with o-ring seals. Field replaceable exterior seals

can be serviced with the valve cavity vented and with the actuator or gearbox

removed.

Spring loaded anti-static devices ensure electrical continuity between the ball and

the body.

Should stem seal damage occur in the service, a temporary seal can be effected by

injecting a viscous sealant via the emergency injection assembly. This optional

system is provided for on 150mm valves and larger.

Seat Injection System

As trunnion valves are used in gas transmission and other critical services,

Richards offer as an option, an emergency seat renewal system. Should seat

damage occur, this enables a viscous sealant backup system to temporarily

maintain a seal until maintenance can be scheduled.

With the Richards design, sizes up to 100mm have the sealant injected directly to

the centre of the body. With larger size valves the sealant is directly injected into

each seat assembly. The sealant is channeled into the seat assembly using a high

pressure pump. The sealant is distributed to the ball sealing face via a series of

ports drilled around the seat circumference. The sealant injection fitting features a

check valve and safety vent cap, with a positive metal seat.

Constrained Seat Assembly

All Richards trunnion mounted valves feature the spring energised constrained seat

design, which ensures seat integrity under high differential pressures. It also allows

for seat inter-changeability, lower torque and provision for emergency sealant

injection. The seat design has been qualified with high velocity blow-down testing

and extended pressure / temperature testing. The standard seat material for valves

to Class 900 is carbon filled PTFE which allows service conditions to 260°C, with

PEEK being used for Class 1500 and where conditions exceed the limits of

CFPTFE. Alternative seating is also available.

Fire Tested Design

In the event of the valve being engulfed in fire, the valve is designed to ensure

minimal leakage is maintained both via the seat and the valve body. As the resilient

seat burns away, the seat assembly is energised to the ball. A metal to metal

contact is effected by the secondary firesafe seat. Body integrity is also maintained,

with 316/graphite spiral wound gaskets as auxiliary connector seals.

All Richards trunnion valves are fire tested to the latest fire test standards ,

including the stringent API 607 4th Edition.

Alternate Sealing Material

Richards designs incorporate a wide range of seals and o-rings to withstand

explosive decompression service conditions. Please consult Richards with specific

service requirements.

© Copyright by Tyco International Ltd R43/R44/02/00

Richards reserves the right to change product designs and specifications without notice.

Ball Valves - R43/R44 Trunnion Mounted

Sizes 50 - 400mm

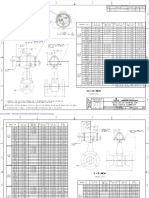

200

012

026

100

531

009

001

011

010

543 Note: Two piece cast body design illustrated .

200

012

026

100

531

009

001

011

010

543 Note: Three piece forced body design

illustrated.

Stem Detail Seat Detail

200

207

206 148

205

235 223 106

251

532 102

203 103 101

202

201 104

245

139 151

© Copyright by Tyco International Ltd R43/R44/02/00

Richards reserves the right to change product designs and specifications without notice.

Ball Valves - R43/R44 Trunnion Mounted

Sizes 50 - 400mm

Parts List

No. Description Carbon Steel Low Temp Impact Stainless Steel

Tested Carbon Steel

001 Body ASTM A105N/216-WCC ASTM A350-LF2/A352-LCC ASTM A351-CF8M/A182-F316

009 Body connector ASTM A105N/216-WCC ASTM A350-LF2/A352-LCC ASTM A351-CF8M/A182-F316

010 Body connector stud ASTM A193 GrB7 ASTM A320 GrL7 ASTM A320-B8M Cl 2

011 Body connector nut ASTM A194 Gr2H ASTM A194 Gr 4 ASTM A194 GR B8

012 Body connector seal Viton A* Fluorosilicone* Viton A*

026 Firesafe connector gasket 316 SS/Graphite 316 SS/Graphite 316 SS/Graphite

100 Ball AISI 316 S/S AISI 316 S/S AISI 316 S/S

101 Seat ring (150# to 900#) Carbon reinforced PTFE Carbon reinforced PTFE Carbon reinforced PTFE

Seat ring (1500#) Carbon reinforced PEEK Carbon reinforced PEEK Carbon reinforced PEEK

102 Seat follower AISI 316 S/S AISI 316 S/S AISI 316 S/S

103 Seat support ring AISI 316 S/S AISI 316 S/S AISI 316 S/S

104 Seat spring Inconel X750 Inconel X750 Inconel X750

106 Seat O-ring Viton A* Fluorosilicone* Viton A*

139 Ball thrust washer (> 150mm) 316 SS/ ENP/PTFE 316 SS/ENP/PTFE 316 SS/ENP/PTFE

148 Seat O-ring Viton A* Fluorosilicone* Viton A*

151 Bearing ring CS/ PTFE/ENP CS/PTFE/ENP CS/PTFE/ENP

200 Stem Duplex UNS S31803 Duplex UNS S31803 Duplex UNS S31803

201 Primary stem seal Pure PTFE Pure PTFE Pure PTFE

202 Firesafe stem seal Comp. Carbon Fibre Comp. Carbon Fibre Comp. Carbon Fibre

203 Stem seal Viton A* Fluorosilicone* Viton A*

205 Stop plate AISI 316 S/S AISI 316 S/S AISI 316 S/S

206 Stem spring Inconel X750 Inconel X750 Inconel X750

207 Stem nut Carbon Steel ENP Carbon Steel ENP AISI 316 S/S

223 Stem seal follower AISI 316 S/S AISI 316 S/S AISI 316 S/S

235 Auxiliary stem O-ring Buna-N Buna-N Buna-N

245 Bearing plate AISI 316 S/S AISI 316 S/S AISI 316 S/S

251 Weather seal Comp. Carbon Fibre Comp. Carbon Fibre Comp. Carbon Fibre

531 Sealant fitting (optional) 4140 (NACE) AISI 316 S/S AISI 316 S/S

532 Anti-static device AISI 316 SS/Inconel AISI 316 SS/Inconel AISI 316 SS/Inconel

543 Bleed/vent fitting 4140 (NACE) AISI 316 S/S AISI 316 S/S

Note: Pressure Containing Materials conform with NACE MR0175.

ENP = Electroless Nickel Plated.

* Explosive decompression resistant O-ring seals available on request.

© Copyright by Tyco International Ltd R43/R44/02/00

Richards reserves the right to change product designs and specifications without notice.

Ball Valves - R43/R44 Trunnion Mounted

Sizes 50 - 400mm

ØF

C1

C

ØB ØA

E

Note: Two piece body

design illustrated.

D

ØF

C1

C

ØB ØA

E

Note: Three piece body

design illustrated.

D

© Copyright by Tyco International Ltd R43/R44/02/00

Richards reserves the right to change product designs and specifications without notice.

Ball Valves - R43/R44 Trunnion Mounted

Sizes 50 - 400mm

Dimensions (mm) - Series R431 - Class 150

Valve Raised Weld Ring Valve G'Box

Size Bore Face End Groove Mass G'Box Mass

mm A B C C1 D D D E F K kg Model kg

150 152 260 226 267 394 457 406 197 457 285 154 B 10

200 203 290 254 295 457 521 470 228.5 457 285 263 B 10

250 254 355 337 390 533 559 546 266.5 457 310 458 D 22

300 305 384 365 429 610 635 622 305 610 310 685 E 23

350 337 395 402 407 686 762 699 343 610 380 870 G 40

400 386 427 444 550 762 838 775 381 610 380 1190 G 40

Dimensions (mm) - Series R433 - Class 300

Valve Raised Weld Ring Valve G'Box

Size Bore Face End Groove Mass G'Box Mass

mm A B C C1 D D D E F K kg Model kg

150 152 260 226 267 403 457 419 201.5 457 285 178 B 10

200 203 290 254 295 502 521 518 251 457 285 330 B 10

250 254 254 337 390 568 559 584 284 457 310 535 D 22

300 305 384 365 429 648 635 664 324 610 310 794 E 23

350 337 395 402 407 762 762 778 381 610 380 1037 G 40

400 386 442 444 550 838 838 854 419 610 380 1414 G 40

Dimensions (mm) - Series R436 - Class 600

Valve Raised Weld Ring Valve G'Box

Size Bore Face End Groove Mass G'Box Mass

mm A B C C1 D D D E F K kg Model kg

50 58 148 80 151* 292 292 295 146 275* N/A 26 N/A N/A

80 76 156 112 193* 356 356 359 178 810* N/A 52 N/A N/A

100 102 176 132 271* 432 432 435 216 850* N/A 100 N/A N/A

150 152 220 222 263 559 559 562 279.5 457 285 200 B 10

200 203 262 298 351 660 660 664 330 457 310 351 D 22

250 254 337 343 407 787 787 791 393.5 610 310 782 F 36

300 305 389 375 480 838 838 841 419 610 380 1064 G 40

350 337 422 423 587 889 889 892 444.5 610 455 1411 H 94

400 386 461 460 624 991 991 994 495.5 610 455 1936 H 94

Dimensions (mm) - Series R439 - Class 900

Valve Raised Weld Ring Valve G'Box

Size Bore Face End Groove Mass G'Box Mass

mm A B C C1 D D D E F K kg Model kg

50 58 148 80 151* 368 368 371 184 275* N/A 44 N/A N/A

80 76 156 112 193* 381 381 384 190.5 810* N/A 64 N/A N/A

100 102 176 191 232 457 457 460 228.5 457 285 119 B 10

150 152 225 267 320 610 610 613 305 457 310 268 D 22

200 203 263 288 352 737 737 740 368.5 610 310 428 E 23

250 254 358 338 443 838 838 841 419 610 380 874 G 40

300 305 406 394 558 965 965 968 482.5 610 455 1393 H 94

350 337 422 423 587 1029 1029 1038 514.5 610 455 1711 H 94

400 386 461 450 614 1130 1130 1140 565 610 455 2161 H 94

Dimemsions (mm) - Series R435 - Class 1500

Valve Raised Weld Ring Valve G'Box

Size Bore Face End Groove Mass G'Box Mass

mm A B C C1 D D D E F K kg Model kg

50 58 145 106.5 200* 368 368 371 150 387* N/A 63 N/A N/A

80 76 200 174 215 470 470 473 235 457 285 130 B 10

100 100 247 240 293 546 546 549 273 457 310 263 D 22

150 145 300 285 349 705 705 711 352.5 610 310 521 F 36

200 193 371 357 521 832 832 841 416 610 455 1061 H 94

250 254 444 429 593 991 991 1000 495.5 610 455 1920 H 94

© Copyright by Tyco International Ltd R43/R44/02/00

Richards reserves the right to change product designs and specifications without notice.

Ball Valves - R43/R44 Trunnion Mounted

Sizes 50 - 400mm

Dimensions (mm) - Series R441 - Class 150

Valve Raised Weld Ring Valve G'Box

Size Bore Face End Groove Mass G'Box Mass

mm A B C C1 D D D E F K kg Model kg

200 152 290 254 295 457 521 470 197 457 285 167 B 10

250 203 335 337 390 533 559 546 228.5 457 285 295 B 10

300 254 384 365 429 610 635 622 266.5 457 310 510 D 22

350 305 395 402 566 686 762 699 305 610 310 719 E 23

400 337 427 444 608 762 838 775 343 610 380 926 G 40

Dimensions (mm) - Series R443 - Class 300

Valve Raised Weld Ring Valve G'Box

Size Bore Face End Groove Mass G'Bbox Mass

mm A B C C1 D D D E F K kg Model kg

200 152 260 226 267 502 521 518 201.5 457 285 204 B 10

250 203 290 254 295 568 559 584 251 457 285 360 B 10

300 254 355 337 390 648 635 664 284 457 310 596 D 22

350 305 384 365 429 762 762 778 324 610 310 853 E 23

400 337 395 402 407 838 838 854 381 610 380 1112 G 40

Dimensions (mm) - Series R446 - Class 600

Valve Raised Weld Ring Valve G'Box

Size Bore Face End Groove Mass G'Box Mass

mm A B C C1 D D D E F K kg Model kg

80 58 148 80 151* 356 356 359 146 275* N/A 41 N/A N/A

100 76 156 112 193* 432 432 435 178 810* N/A 81 N/A N/A

150 102 176 132 271* 559 559 562 216 850* N/A 142 N/A N/A

200 152 220 222 263 660 660 664 279.5 457 285 252 B 10

250 203 262 298 351 787 787 791 330 457 310 567 D 22

300 254 337 343 407 838 838 841 393.5 610 310 845 F 36

350 305 389 375 480 889 889 892 419 610 380 1140 G 40

400 337 422 423 587 991 991 994 444.5 610 455 1604 H 94

Dimemsions (mm) -Series R449 -Class 900

Valve Raised Weld Ring Valve G'Box

Size Bore Face End Groove Mass G'Box Mass

mm A B C C1 D D D E F K kg Model kg

80 58 148 80 151* 381 381 384 184 275* N/A 50 N/A N/A

100 76 156 112 193* 457 457 460 190.5 810* N/A 87 B 10

150 102 176 191 232 610 610 613 228.5 457 285 176 D 22

200 152 225 267 320 737 737 740 305 457 310 345 E 23

250 203 263 288 352 838 838 841 368.5 610 310 635 G 40

300 254 358 338 443 965 965 968 419 610 380 1011 H 94

350 305 406 394 558 1029 1029 1038 482.5 610 455 1500 H 94

400 337 422 423 587 1130 1130 1140 514.5 610 455 1859 H 94

Dimensions (mm) - Series R445 - Class 1500

Valve Raised Weld Ring Valve G'Box

Size Bore Face End Groove Mass G'Box Mass

mm A B C C1 D D D E F K kg Model kg

80 58 148 106.5 200* 470 470 473 235 387* N/A 80 N/A N/A

100 76 200 174 215 546 546 549 273 457 285 160 B 10

150 100 247 240 293 705 705 711 352.5 457 310 332 D 22

200 145 300 285 349 832 832 841 416 610 310 637 F 36

250 193 371 357 521 991 991 1000 495.5 610 455 1286 H 94

300 254 444 429 593 1130 1130 1146 565 610 455 2200 H 94

Notes:

B = Centre line of valve to bottom of drain fitting.

C1 = Dimension from centre line of valve to centre line of handwheel.

C1* = Dimension from centre line of valve to centre line of wrench.

D = Face to Face dimensions in accordance with API 6D (Standard Pattern).

F = Dimension for diameter of handwheel.

F* = Dimension for length of wrench

Valve masses nominated are for bare shaft valves.

Dimensions are nominal ±1mm.

© Copyright by Tyco International Ltd R43/R44/02/00

Richards reserves the right to change product designs and specifications without notice.

Ball Valves - R43/R44 Trunnion Mounted

Sizes 50 - 400mm

Pressure/Temperature Graph Pressure/Temperature Ratings

Class 150 (Figure R431/R441)

Temperature °F

Carbon Reinforced PTFE Seated

-40 60 160 260 360 460 560 Carbon Steel : 2000 kPa/20 bar max.

: 260°C max.

5000 Stainless Steel : 1900 kPa/19 bar max.

Class 300 700 : 260°C max.

600 Class 300 (Figure R433/R443)

4000 4

Carbon Reinforced PTFE Seated

500 Carbon Steel : 5170 kPa/51.7 bar max.

Pressure kPa

Pressure psi

3000 : 260°C max.

400 Stainless Steel : 4960 kPa/49.6 bar max.

2

: 260°C max.

2000 300

Class 150 Class 600 (Figure R436/R446)

200 Carbon Reinforced PTFE Seated

1000 Carbon Steel : 10335 kPa/103.3 bar max.

100 : 260°C max.

Stainless Steel : 9920 kPa/99.2 bar max.

0 0 : 260°C max.

-40 0 40 80 120 160 200 240 280

Temperature °C Class 900 (Figure R439/R449)

Carbon Reinforced PTFE Seated

Carbon Steel : 15500 kPa/155 bar max.

: 260°C

Temperature °F Stainless Steel : 14885 kPa/148.9 bar max.

-40 60 160 260 360 460 560 : 260°C

27500

Class 1500 (Figure R435/R445)

Carbon Reinforced PEEK Seated

25000 Carbon Steel : 25530 kPa/255.3 bar max.

Class 1500

3500 : 260°C

Stainless Steel : 24800 kPa/248 bar max.

22500 : 260°C

3000 Note:

20000 These pressure/temperature ratings are for

total valve assembly with the respective

4 seat material fitted. The seat material is

17500 capable of much higher pressures,

2500

however are limited by the maximum rating

Pressure kPa

of the valve body material.

Pressure psi

15000

Class 900

2000

Class 900#

12500

Class 600# 2

1500

10000

Class 600

7500

1000 Note:

1. Pressure class ratings displayed are for

carbon steel A105 (Reference: ASME

5000

B16.5-1996 Table 2-1.1 Group 1.1

500

materials). For other materials ratings

refer to Richards.

2500

2. Seat Pressure/temperature limitations

displayed are in combination with Viton-

A o-ring seals. For other seat/sealing

0 0

materials refer to Richards.

-40 0 40 80 120 160 200 240 280

Temperature °C

Seat Code: 2 - Carbon Reinforced PTFE

4 - Carbon Reinforced PEEK

© Copyright by Tyco International Ltd R43/R44/02/00

Richards reserves the right to change product designs and specifications without notice.

Ball Valves - R43/R44 Trunnion Mounted

Sizes 50 - 400mm

Typical specifying sequence

Example 150 R436 C A A 2 S A 3 / 08

Valve Figure Body End End Seat Trim Body Certification Valve Standard

Size No. Material Conn Conn Type Material Seal Code Variant Options

(Note 1) (Note 2) (Note 3)

Note:

R43 designates full bore, R44 designates reduced bore.

The pressure class is also defined as follows:

1 = Class 150, 3 = Class 300, 6 = Class 600, 9 = Class 900 and 5 = Class 1500.

i.e. R436 = full bore, class 600.

Size Range: 50 - 400mm

Figure No: R431 - Firesafe and antistatic, full bore, trunnion ball design, ANSI Class 150 ball valve.

R433 - Firesafe and antistatic, full bore, trunnion ball design, ANSI Class 300 ball valve.

Figure Trim Body End End Seat Trim Body Seal

No. Code Material Conn Conn

R431 CAA2SA Carbon Steel ANSI Flg ANSI Flg Carbon R’PTFE 316 S/S Viton

R433 SAA2SA 316 S/S ANSI Flg ANSI Flg Carbon R’PTFE 316 S/S Viton

Size Range: 50 - 400mm

Figure No: R436 - Firesafe and antistatic , full bore, trunnion ball design, ANSI Class 600 ball valve.

R439 - Firesafe and antistatic , full bore, trunnion ball design, ANSI Class 900 ball valve.

Figure Trim Body End End Seat Trim Body Seal

No. Code Material Conn Conn

R436 CAA2SA Carbon Steel ANSI Flg ANSI Flg Carbon R’PTFE 316 S/S Viton

R446 SAA2SA 316 S/S ANSI Flg ANSI Flg Carbon R’PTFE 316 S/S Viton

R439 LAA2SS Low Temp C/S ANSI Flg ANSI Flg Carbon R’PTFE 316 S/S Fluorosilicone

R449 CAA4SW Carbon Steel ANSI Flg ANSI Flg Peek 316 S/S Walker FR58/90

Size Range: 50 - 250mm

Figure No.: R435 - Firesafe and antistatic , full bore, trunnion ball design, ANSI Class 1500 ball valve.

Figure Trim Body End End Seat Trim Body Seal

No. Code Material Conn Conn

R435 SAA4SW 316 S/S ANSI Flg ANSI Flg Peek 316 S/S Walker FR58/90

R435 CAA4SW Carbon Steel ANSI Flg ANSI Flg Peek 316 S/S Walker FR58/90

Notes:

1. Certification Code: Standard certification code 3 includes pressure test certification and material certification of the pressure containing

components conforming to EN 10204 / ISO 10474. For additional certification requirements, refer to the “Richard's

Ordering Sequence”.

2. Valve Variant: Standard Valve is not offered with variants. Should a valve variant be required, refer to the “Richard's Ordering Sequence”

for variant listing and order code details.

3. Standard Options: Base valve is supplied bare shaft - Code 08. For other valve options, refer to “Richard's Ordering Sequence “ for

listing and the code details. For fitment of Wrench, Gearbox or Actuator, order requirement is to be specified as "Complete With"

followed by the detail of the requirement - e.g.: Complete with Wrench Kit.

© Copyright by Tyco International Ltd R43/R44/02/00

Richards reserves the right to change product designs and specifications without notice.

Вам также может понравиться

- Kent. 1913. The Mechanical Engineers' Pocket-Book. A Reference-Book of Rules, Tables, Data, and Formulæ, For The Use of Engineers, Mechanics, and StudentsДокумент1 505 страницKent. 1913. The Mechanical Engineers' Pocket-Book. A Reference-Book of Rules, Tables, Data, and Formulæ, For The Use of Engineers, Mechanics, and StudentsDougKneОценок пока нет

- API 602 Forged Steel Gate, Globe & Check Valves (Vel-Sfv-Web) PDFДокумент22 страницыAPI 602 Forged Steel Gate, Globe & Check Valves (Vel-Sfv-Web) PDFThomasFrenchОценок пока нет

- Design Check List Section VIII, Division 1: Drawing + Bill of Material (BOM)Документ2 страницыDesign Check List Section VIII, Division 1: Drawing + Bill of Material (BOM)shazanОценок пока нет

- Alga AlgasДокумент40 страницAlga AlgasGGUNAОценок пока нет

- Pip Resp003v 1997Документ47 страницPip Resp003v 1997zufriateguiОценок пока нет

- QC Welding Inspector InterviewДокумент286 страницQC Welding Inspector InterviewNDT CTC100% (7)

- Techlok Product Range A4 V003 2014Документ4 страницыTechlok Product Range A4 V003 2014alfreddieick1Оценок пока нет

- 3 - 2011 570 Answers (27 75 102)Документ22 страницы3 - 2011 570 Answers (27 75 102)Sunny Thundil100% (2)

- Bidirectional Sealing Ball Valves in Power ApplicationsДокумент3 страницыBidirectional Sealing Ball Valves in Power Applicationsxisefengchuang100% (1)

- ASME B16.34-2017 Valves-Flanged, Threaded, and Welding EndДокумент2 страницыASME B16.34-2017 Valves-Flanged, Threaded, and Welding Endscribd.va0% (1)

- VANLT-0001-En Series 30,000 Rotary Process ValveДокумент12 страницVANLT-0001-En Series 30,000 Rotary Process ValveOneil ZárateОценок пока нет

- VIRGO - Floating-Ball ValvesДокумент16 страницVIRGO - Floating-Ball ValvesKamalОценок пока нет

- Ball Valve - CameronДокумент36 страницBall Valve - CameronMeet JaniОценок пока нет

- RB 4700 BrochureДокумент6 страницRB 4700 Brochuretuan pham minhОценок пока нет

- Iso 9393 2 2005Документ9 страницIso 9393 2 2005mohanrulesОценок пока нет

- Astm 194-2017 PDFДокумент13 страницAstm 194-2017 PDFThiago CurvoОценок пока нет

- Koio - Forged Steel Valve PDFДокумент42 страницыKoio - Forged Steel Valve PDFThomasFrenchОценок пока нет

- EVS en ISO 16137 2006 en PreviewДокумент11 страницEVS en ISO 16137 2006 en PreviewMohamed MOUKHTARIAОценок пока нет

- LT Pipeline Ball ValvesДокумент19 страницLT Pipeline Ball ValvessiswoutОценок пока нет

- PFS WedgeДокумент26 страницPFS WedgeMontheardОценок пока нет

- Asme B16.24 - 2001Документ24 страницыAsme B16.24 - 2001luigiОценок пока нет

- Spare Parts Catalogue: Bajaj Auto LimitedДокумент74 страницыSpare Parts Catalogue: Bajaj Auto LimitedWilly Mansilla AОценок пока нет

- Aa10208 FINAL - 1Документ139 страницAa10208 FINAL - 1Surendra MalasaneОценок пока нет

- Mesc Spe 77-100 Oct 2012 Ball Valve To Bs 5351Документ17 страницMesc Spe 77-100 Oct 2012 Ball Valve To Bs 5351Dwayne YiiОценок пока нет

- Series 900 BrochureДокумент40 страницSeries 900 BrochureLungisaniОценок пока нет

- Triple-Offset Butterflyvalves PDFДокумент8 страницTriple-Offset Butterflyvalves PDFDiwakar NigamОценок пока нет

- BS Iso 10631-2013Документ24 страницыBS Iso 10631-2013GT-LUCAS BARCI0% (1)

- En10083 1Документ28 страницEn10083 1skidanjeОценок пока нет

- F1685 PDFДокумент10 страницF1685 PDFDaniel LodiОценок пока нет

- Bs 5351 1986 PDFДокумент31 страницаBs 5351 1986 PDFSSFPLОценок пока нет

- Piston ValveДокумент28 страницPiston ValveDamien BouticourtОценок пока нет

- SAEJ110 V 002Документ13 страницSAEJ110 V 002Marcos Verissimo Juca de PaulaОценок пока нет

- MSS SP 55-2006 - Quality Standard For Steel Castings For Valves, Flanges, Fittings, and Other Piping CДокумент22 страницыMSS SP 55-2006 - Quality Standard For Steel Castings For Valves, Flanges, Fittings, and Other Piping CAllan SousaОценок пока нет

- Api 602 Forged Steel Valve PDFДокумент4 страницыApi 602 Forged Steel Valve PDFThomasFrenchОценок пока нет

- ISO 15348 2002 Metal Bellows Expansion Joints PDFДокумент8 страницISO 15348 2002 Metal Bellows Expansion Joints PDFFernando GómezОценок пока нет

- Properties of Ss410Документ5 страницProperties of Ss410gregkilatonОценок пока нет

- Ampliflow T-Boost Ssfly000029-Ena4Документ2 страницыAmpliflow T-Boost Ssfly000029-Ena4carburoОценок пока нет

- U1CДокумент4 страницыU1CAdriana HernandezОценок пока нет

- Sferova API6 Ball Valve CatalogueДокумент27 страницSferova API6 Ball Valve CatalogueWong JowoОценок пока нет

- Ico3s Iom ManualДокумент2 страницыIco3s Iom ManualAditya B. RyantoОценок пока нет

- 3 - Rite Manual de Instalacion y MantenimientoДокумент18 страниц3 - Rite Manual de Instalacion y MantenimientoRoman Arango Herrera0% (1)

- Regulator VNN-505 - DN50Документ25 страницRegulator VNN-505 - DN50aminОценок пока нет

- Overallstructure PDFДокумент11 страницOverallstructure PDFChhoan NhunОценок пока нет

- Gate, Globe and Check Valves (Amendments/Supplements To Iso 15761)Документ13 страницGate, Globe and Check Valves (Amendments/Supplements To Iso 15761)윤규섭100% (1)

- Karhula - Model Z-Y100Z-2 - Manual.Документ8 страницKarhula - Model Z-Y100Z-2 - Manual.German ZuletaОценок пока нет

- Face-To-Face Valve Dimensions - EN-558-1: DN Basic SeriessДокумент3 страницыFace-To-Face Valve Dimensions - EN-558-1: DN Basic Seriessdona_001Оценок пока нет

- Iso 10294 2 1999 PDFДокумент8 страницIso 10294 2 1999 PDFhoang nguyenОценок пока нет

- Files PDFДокумент1 страницаFiles PDFSouravОценок пока нет

- Fire Test Cert - Top Entry Ball - VelosiДокумент1 страницаFire Test Cert - Top Entry Ball - VelosijajakaОценок пока нет

- Astm A193 PDFДокумент12 страницAstm A193 PDFjoserodriguezherazoОценок пока нет

- Astm A 494Документ7 страницAstm A 494Rodrigo BarrosОценок пока нет

- Asme I-2013 Section 62Документ28 страницAsme I-2013 Section 62ahmed messallamОценок пока нет

- Pneumatic, Piston Type: Needle Valve ActuatorsДокумент20 страницPneumatic, Piston Type: Needle Valve Actuatorsarif fadhillahОценок пока нет

- 302 Design Criteria Asme b31.3Документ2 страницы302 Design Criteria Asme b31.3Ton BlokОценок пока нет

- Comparison List Copper Bronze 2011 1Документ7 страницComparison List Copper Bronze 2011 1NaldoVicenteОценок пока нет

- MSS SP 6 PDFДокумент8 страницMSS SP 6 PDFfeelingsudoОценок пока нет

- PASCAL Check Valves CatalogueДокумент19 страницPASCAL Check Valves Cataloguecrys100% (1)

- Sanitary Fittings (MS 02 124 E) R2Документ4 страницыSanitary Fittings (MS 02 124 E) R2herysyam1980Оценок пока нет

- TUBE, UNS S31600/S31609, SMLS, AnnealedДокумент2 страницыTUBE, UNS S31600/S31609, SMLS, AnnealedTuấn Dương QuốcОценок пока нет

- Anti Blow Out StemДокумент48 страницAnti Blow Out StemimthiyazmuhammedОценок пока нет

- Din 3357-4-1981Документ5 страницDin 3357-4-1981олегОценок пока нет

- AISI 410: Stainless Steel, Martensitic, AISI 410S, Wrought, AnnealedДокумент4 страницыAISI 410: Stainless Steel, Martensitic, AISI 410S, Wrought, AnnealedLinus LooОценок пока нет

- ASGEpg187 PDFДокумент3 страницыASGEpg187 PDFbkprodhОценок пока нет

- SAE J10 Dated 11-2007 Air BrakesДокумент3 страницыSAE J10 Dated 11-2007 Air BrakesLaura GarciaОценок пока нет

- Line Class - NDT RateДокумент24 страницыLine Class - NDT RateThân KhaОценок пока нет

- Valve End Connections, Screwed, Flanged, Socket-Weld, Butt-Weld, Capillary, Spigot PDFДокумент2 страницыValve End Connections, Screwed, Flanged, Socket-Weld, Butt-Weld, Capillary, Spigot PDFjitendrakumarsahuОценок пока нет

- DTW 1239Документ16 страницDTW 1239GANESH GОценок пока нет

- Butterfly Valve ConcentricДокумент6 страницButterfly Valve ConcentricpramodtryОценок пока нет

- Cameron Fully Welded Ball Valves PDFДокумент36 страницCameron Fully Welded Ball Valves PDFCARLOSОценок пока нет

- Cameron Fully Welded Ball Valves BrochureДокумент36 страницCameron Fully Welded Ball Valves BrochurenwabukingzОценок пока нет

- Des Cote Actuated Globe ValvesДокумент4 страницыDes Cote Actuated Globe ValvesOrueta ClaudioОценок пока нет

- Lugged Butterfly Valve 2-12 PDFДокумент1 страницаLugged Butterfly Valve 2-12 PDFThomasFrenchОценок пока нет

- Nicholson Mechanical Steam Traps PDFДокумент24 страницыNicholson Mechanical Steam Traps PDFThomasFrenchОценок пока нет

- G-4202 GoratorPump Brochure PDFДокумент12 страницG-4202 GoratorPump Brochure PDFThomasFrenchОценок пока нет

- Lugged Butterfly Valve 14-24 PDFДокумент1 страницаLugged Butterfly Valve 14-24 PDFThomasFrenchОценок пока нет

- Ball Valves PDFДокумент34 страницыBall Valves PDFThomasFrenchОценок пока нет

- Forged Steel Check Valves - Bs 5352, Ansi B16.34 CLASS-600,800,1500 & 2500Документ2 страницыForged Steel Check Valves - Bs 5352, Ansi B16.34 CLASS-600,800,1500 & 2500ThomasFrenchОценок пока нет

- Dimensions, Sizes and Specification of ANSI ASME Reducing Flanges PDFДокумент3 страницыDimensions, Sizes and Specification of ANSI ASME Reducing Flanges PDFThomasFrenchОценок пока нет

- DS - TW9515 - GB - 726 - Poço de Proteção RoscadoДокумент3 страницыDS - TW9515 - GB - 726 - Poço de Proteção RoscadoThomasFrenchОценок пока нет

- DS - TW9512 - GB - 724 - Poço de Proteção FLG Materiais EspeciaisДокумент4 страницыDS - TW9512 - GB - 724 - Poço de Proteção FLG Materiais EspeciaisThomasFrenchОценок пока нет

- 0002 PDFДокумент6 страниц0002 PDFThomasFrenchОценок пока нет

- DS - TE6504 - GB - 7494 - Threaded Thermocouple, Miniature DesignДокумент6 страницDS - TE6504 - GB - 7494 - Threaded Thermocouple, Miniature DesignThomasFrenchОценок пока нет

- Termination Heads: 1000/ 4000 F Series 7000/ 8000 SeriesДокумент1 страницаTermination Heads: 1000/ 4000 F Series 7000/ 8000 SeriesThomasFrenchОценок пока нет

- DS - TE6508 - GB - 8754 - Thermocouple Without ThermowellДокумент8 страницDS - TE6508 - GB - 8754 - Thermocouple Without ThermowellThomasFrenchОценок пока нет

- DS - TE6512 - GB - 8332 - Thermocouple in Flame Proof Design For An Additional ThermowellДокумент6 страницDS - TE6512 - GB - 8332 - Thermocouple in Flame Proof Design For An Additional ThermowellThomasFrenchОценок пока нет

- DS - TE6502 - GB - 7296 - Thermocouples For Additional ThermowellДокумент7 страницDS - TE6502 - GB - 7296 - Thermocouples For Additional ThermowellThomasFrenchОценок пока нет

- Mechanical Design of in Acc. With: H / E Tema & AsmeДокумент30 страницMechanical Design of in Acc. With: H / E Tema & AsmeNeel MacwanОценок пока нет

- 855 Tech Pages 855 1103ENДокумент26 страниц855 Tech Pages 855 1103ENMohamed HardmanОценок пока нет

- Tsurumi AeratorДокумент12 страницTsurumi Aeratorariyanagung29Оценок пока нет

- Hydrant Dry Type UL FMДокумент8 страницHydrant Dry Type UL FMAmeen Hamed AlwseyОценок пока нет

- Wey Knife Gate Valve Model A3 W0 W1 W2 W3 PDFДокумент4 страницыWey Knife Gate Valve Model A3 W0 W1 W2 W3 PDFcvfОценок пока нет

- Flange DimensionsДокумент30 страницFlange DimensionshibhavuОценок пока нет

- APCO AVV-140/150 AND 1100 Air/Vacuum Valves: Instruction June 2014Документ14 страницAPCO AVV-140/150 AND 1100 Air/Vacuum Valves: Instruction June 2014MASOUDОценок пока нет

- Vent Silencer - PulscoДокумент13 страницVent Silencer - PulscodigecaОценок пока нет

- Atuador Flowserve RG Series PDFДокумент12 страницAtuador Flowserve RG Series PDFEderson SantosОценок пока нет

- ZULUF PROJECT (0-8887) : 10-08643-0005 Saudi Aramco 0-8887-2-P-3130-MC2-A GAS-JGC-MOS-MECH-006 FA NMR Ref NOДокумент52 страницыZULUF PROJECT (0-8887) : 10-08643-0005 Saudi Aramco 0-8887-2-P-3130-MC2-A GAS-JGC-MOS-MECH-006 FA NMR Ref NORiaz Ali Khan BangashОценок пока нет

- Saudi Aramco Inspection Checklist: Final Insp of Tank Installation (Tanks) SAIC-D-2021 1-Dec-06 MechДокумент4 страницыSaudi Aramco Inspection Checklist: Final Insp of Tank Installation (Tanks) SAIC-D-2021 1-Dec-06 Mechரமேஷ் பாலக்காடுОценок пока нет

- Iso 5752 2021Документ13 страницIso 5752 2021Santiago RodaОценок пока нет

- Centrifugal Pumps Horizontal FpsДокумент2 страницыCentrifugal Pumps Horizontal FpsMiloradRadnovicОценок пока нет

- AC-036413-001 Orifice Flange AssemblyДокумент1 страницаAC-036413-001 Orifice Flange Assemblynarutothunderjet216Оценок пока нет

- GCBV2e V1Документ11 страницGCBV2e V1Kemal GokovicОценок пока нет

- AFF Clamp Connectors-GLok SML v2 4dbf3f7512a5eДокумент37 страницAFF Clamp Connectors-GLok SML v2 4dbf3f7512a5eFakeОценок пока нет

- 05.Хидромеханичка Опрема 3delДокумент45 страниц05.Хидромеханичка Опрема 3delStefan AngelovОценок пока нет

- Geareducer Model 32.2: UsermanualДокумент8 страницGeareducer Model 32.2: UsermanualR BhattacharyaОценок пока нет

- Bombas ZTN Aceite TermicoДокумент47 страницBombas ZTN Aceite Termicoandreshuertascalderon02Оценок пока нет

- Manometro Winters PFPДокумент6 страницManometro Winters PFPDaniela Gomez JimenezОценок пока нет

- SRG LPG Float Gauge Type 487: Container Connection Mounting Head MaterialsДокумент1 страницаSRG LPG Float Gauge Type 487: Container Connection Mounting Head Materialsalvaro_arcvОценок пока нет

- PP 2006 03Документ4 страницыPP 2006 03Born ToSinОценок пока нет