Академический Документы

Профессиональный Документы

Культура Документы

002 - HCM-Q202C344-Vung Tau, DMT Factory-Spec - 20200629 - R0

Загружено:

Nguyễn Huy HoàngИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

002 - HCM-Q202C344-Vung Tau, DMT Factory-Spec - 20200629 - R0

Загружено:

Nguyễn Huy HoàngАвторское право:

Доступные форматы

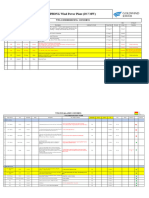

Project Name:

Vung Tau, DMT Factory

MEDIUM VOLTAGE SWITCHGEAR

SOLUTION POWER S24

TECHNICAL SPECIFICATION

FOR

PROPOSAL

TECHNICAL SPECIFICATION FOR PROPOSAL

Doc. No. : THTDE-E-eF-003.R02

1 Rev.date: May-25-2020

Erp No: Q202C344 Date: 6/29/2020

Project: Vung Tau, DMT Factory Rev No.: 00

Item/model: MV SWGR/ Solution power S24

Contents

1. SCOPE

2. REFERENCE DRAWING LIST

3. SITE AND SERVICE CONDITIONS

4. STANDARDS

5. ELECTRICAL CHARACTERISTICS

6. BASIC CONSTRUCTION

7. POWER CIRCUIT BREAKER

8. CABLE EARTHING

9. INSTRUMENT AND CONTROL POWER TRANSFORMER

10. FINISH

11. TESTING AND INSPECTION

12. PROVISION FOR HANDLING AND FIELD ERECTION

13. SHIPPING

14. PREPARATION FOR SHIPMENT

* ATTACHMENT DATA

TECHNICAL SPECIFICATION FOR PROPOSAL

Doc. No. : THTDE-E-eF-003.R02

2 Rev.date: May-25-2020

Erp No: Q202C344 Date: 6/29/2020

Project: Vung Tau, DMT Factory Rev No.: 00

Item/model: MV SWGR/ Solution power S24

1. SCOPE

1.1 This specification describes the assemblies of Medium Voltage Metal enclosed Air

Insulated Switchgear for project: Vung Tau, DMT Factory

1.2 This specification covers only the general requirements of the switchgear. The

specific requirements of each assembly (voltage class, breaker ratings, relaying,

metering, control scheme, etc.) will be shown on the attachment data and drawings.

2. REFERENCE DRAWING LIST

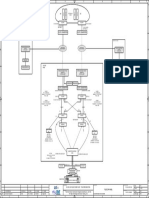

2.1 Q202C344 - S24 : Outline drawing for Solution Power S24

3. SITE AND SERVICE CONDITIONS

3.1 Altitude : ≤1000 m, above sea level

3.2 Temperature : 5~40 0

C

3.3 Climatic condition : Tropical climate

3.4 Specific corrosive elements at side : Moisture

4. STANDARDS

The switchgear is to be designed and manufactured in accordance with the

requirement of the latest edition of the appropriate I.E.C recommendation, unless

otherwise specified.

5. ELECTRICAL CHARACTERISTICS

• Normal systems voltage : 22kV

• Rated voltage : 24kV

• Rated frequency : 50Hz

• Basic impulse withstand voltage, dry ( peak ) : 125kV

• One minute power frequency withstand voltage dry(rms) : 50kV

• Busbar normal current (Main bus) : 630A

• Rated short time withstand current : 25kA

• Time duration : 1s

• Test voltage of auxiliary circuits : 1.5kV

TECHNICAL SPECIFICATION FOR PROPOSAL

Doc. No. : THTDE-E-eF-003.R02

3 Rev.date: May-25-2020

Erp No: Q202C344 Date: 6/29/2020

Project: Vung Tau, DMT Factory Rev No.: 00

Item/model: MV SWGR/ Solution power S24

6. BASIC CONSTRUCTION

6.1 The cubicles shall be fabricated of sheet steel. The thickness of sheet steel shall

not less than 2.0 mm in thickness.

6.2 Each switchgear assembly will consist of metal enclosed, free standing, vermin-

proof, vertical, containing power buses, each bus, circuit breaker, necessary auxiliary

control devices, specified instrument transformers, and other accessories to make a

complete working unit as required by the specification and data sheets.

6.3 Each switchgear cubicle will be divided four (4) compartments as circuit breaker

compartment, busbar compartment, and cable connection compartment including

current transformer and low voltage compartment by metal partition plate. Pressure

relief flaps will be provided to release the abnormal high pressure inside the cubicle

while there is an arc fault. Busbar compartments will be extended through all

switchgear with the partition plate and wall bushing between cubicles.

6.4 Automatic metallic safety shutter shall be provided which cover the busbar and

circuit spouts when the breaker is in the test (isolated position) in the cubicle and

when the breaker is withdrawn. Padlocking facility shall be provided in the closed

6.5 Each cubicle shall be provided with front hinged doors with built in handless and

locks.

6.6 Each switchgear assembly will be suitable for the future addition of units on either

end.

6.7 Each switchgear will be designed, manufactured according to all specified

conditions.

Degrees of protection are IP4X for enclosure and IP2X for partitions and shutters.

6.8 Each switchgear will be furnished with maintenance power socket outlets for

portable maintenance and test equipment. The outlets will supply 220VAC single

phase, 13A with 3-pin, flat and 2-pin, round socket.

6.9 Grounding

1) Grounding bus

A copper grounding bus of 6x25mm thickness and width shall be provided

for each group of lined switchgears.

TECHNICAL SPECIFICATION FOR PROPOSAL

Doc. No. : THTDE-E-eF-003.R02

4 Rev.date: May-25-2020

Erp No: Q202C344 Date: 6/29/2020

Project: Vung Tau, DMT Factory Rev No.: 00

Item/model: MV SWGR/ Solution power S24

2) Grounding of enclosure

Each enclosure will be connected to each earth bus bar. Excepting live parts,

metal parts such as partition plates will be bolted or welded for electrical

connection to the enclosure. Earthing shall be provided between frame and

door by earth cable.

6.10 Power buses

1) Power bus will be insulated copper. All busbars shall be silver plated and

securely tightened.

2) Busbars will be rated for the full load current of the switchgear.

3) Horizontal and vertical buses will be isolated such that when the rear cover

of a vertical section is opened. The only exposed bare parts are load terminal of

breaker.

4) The bus will be mechanically braced to withstand the maximum

asymmetrical current of interrupting capacity of system fault level in each

assembly.

5) The load terminal of equipment located in the bottom of cubicle in a vertical

section will be arranged, fixed, extended, ext. to permit easy connections for

outgoing cable.

6) The continuous ampere rating of the main power bus will be shown on the

data sheets.

7) Earthing switch will be provided for every bus bar and will be equipped with

with key lock (Not applicable)

6.11 Indication and control device

1) Control switches, selector switches, indicator lights, protective relays, etc.

will be mounted on the front of the cubicle door and arranged in logical,

symmetrical manner.

2) Neon type voltage indicators shall be provided on each phase of each circuit,

of each circuit, of each breaker show the presence of voltage (Not applicable)

3) Switches will be built up of individual stages separated from each other by

insulation barrier.

4) All control and selector switches will be equipped with handle.

TECHNICAL SPECIFICATION FOR PROPOSAL

Doc. No. : THTDE-E-eF-003.R02

5 Rev.date: May-25-2020

Erp No: Q202C344 Date: 6/29/2020

Project: Vung Tau, DMT Factory Rev No.: 00

Item/model: MV SWGR/ Solution power S24

6.12 Suitable LED lamp of single phase 10W , 220VAC 50Hz , controlled by door

switch will be provided inside of the low voltage compartment for the convenience of

access and carrying out maintenance work.

6.13 Space heaters, single - phase 220VAC 50Hz with ON-OFF switch and

humidity controller setting range from 5°C to 35°C will be provided inside of the cable

compartment and C.B compartment.

6.14 Nameplates will be made of Acryl material and fixed with stainless steel

screws or bolts. Wording, in nameplates, instruction signs, instrument scale, etc. will

be in English and metric.

6.15 Internal wiring will be nearly run and adequately supported either saddle or

spiral ties or carried across a hinged portion of a chassis or door will be flexible, and

sufficient slack will be provided to avoid tension. All panel wiring will be copper

conductor, ( KIV ) Vinyl insulation. Minimum size will be 1.5sqmm for control

circuits and 2.5sqmm for PT’s secondary circuit and 4.0sqmm CT’s secondary circuits.

6.16 Terminal blocks will be supplied with clear marking for wiring.

6.17 Wiring procedure

The color code of wire coating will be as follows:

PT Secondary circuit R S T N

Red Yellow Blue Black

CT Secondary circuit R S T N

Red Yellow Blue Black

AC control circuit : Red

DC control circuit : Grey

Ground circuit : : Green & Yellow

* PT : Potential transformer or Voltage transformer

* CT: Current transformer

6.18 Color code of a conductor’s polarity

* AC 3 phase circuit

First phase (R) : Red

Second phase (S) : Yellow

Third phase (T) : Blue

TECHNICAL SPECIFICATION FOR PROPOSAL

Doc. No. : THTDE-E-eF-003.R02

6 Rev.date: May-25-2020

Erp No: Q202C344 Date: 6/29/2020

Project: Vung Tau, DMT Factory Rev No.: 00

Item/model: MV SWGR/ Solution power S24

6.19 Phase arrangement

* AC 3 phase circuit

From left to right : First phase, second phase, third phase

From top to bottom : First phase, second phase, third phase

From front to back : First phase, second phase, third phase

6.20 Structure of switchgear

1) The enclosure will be an independent self-standing type for indoor use.

2) The enclosure frame will be made of steel plates not less than 2,0mm

thickness and will provide sufficient solidity.

3) Front door will be made of steel plates not less than 3.0mm thickness and

will be provided with a door lock.

4) Rear cover will be made of a steel plate not less than 2.0mm thickness.

5) The cable chamber will have sufficient width for easy cable termination

treatment and for safety maintenance and inspection.

7. POWER CIRCUIT BREAKER

7.1 The power circuit breaker will be electrically operated, vacuum 3 poles,

withdrawable type, provided with self aligning, line side and load side disconnecting

devices.

7.2 The withdrawable mechanism will hold the breakers rigidly in the racked-in and

“test” position / “racked-out” position. When breaker is opened, it is possible to move

the breaker to any of the position.

7.3 Interlock will be provided to prevent the connecting between Circuit breaker and

Bus terminal or disconnecting Circuit breaker and Bus terminal unless Circuit breaker

opened (or trip). In addition, interlock will be also provided between circuit breaker

and door of circuit breaker compartment to prevent dangers due to unlocking the

compartment door while the circuit breaker is located at service position.

7.4 The switchgears shall be provided with a comprehensive system of electrical and

mechanical interlocks to prevent any dangerous or undesirable operations.

7.5 The breaker continuous ampere and nominal short circuit rating will be shown on

the data sheets.

TECHNICAL SPECIFICATION FOR PROPOSAL

Doc. No. : THTDE-E-eF-003.R02

7 Rev.date: May-25-2020

Erp No: Q202C344 Date: 6/29/2020

Project: Vung Tau, DMT Factory Rev No.: 00

Item/model: MV SWGR/ Solution power S24

7.6 A metallic shutter which effectively close the bus terminal disconnect openings

when the breakers are test (isolation) and with-drawn position, will be provided.

7.7 Each breaker will be equipped with the motor operation type. Each will be

possible to open and close the breakers manually.

7.8 Circuit breakers of the same ratings and control voltage can be interchangeable.

7.9 Each breaker has in excess of control circuit auxiliary contact requirement a

minimum of 10NO/10NC auxiliary contacts.

7.10 Each breaker have a position indicator with appropriate description colors, such

as “CLOSED” on red background and “OPEN” on a green background.

7.11 The secondary disconnecting device shall be of automatic and manual plug-in

type.

8. CABLE EARTHING (Not applicable)

8.1 The earthing switches of three phases, quick acting, fault making, mechanically

operated type will be provided at the cable side of each circuit breaker cubicle.

8.2 The earthing switches shall be hand operated and spring mechanism.

8.3 The earthing switch operations can be performed without opening the front door.

8.4 The earthing switches shall be mechanically interlocked with their respective

circuit breaker. When circuit breaker is service position, earthing switch cannot be

closed. If the earthing switch is closed, circuit breaker cannot be put-into the service

8.5 Each earthing switches shall be provided with the auxiliary contact (6N.O + 6N.C)

8.6 Earthing switches can be operated by operation handle at the front door and be

drawn-out the circuit breaker to the draw-out/test position for the outgoing cable.

The operation of earthing switch for incoming cable shall be interlocked with

upstream Circuit Breaker or Disconnector switches.

8.7 Earthing switches will be equipped with key lock. Mechanical and Electrical

interlock between earthing switches and adjacent circuit breaker is provided. Electrical

interlocking between earthing switches and remote isolators can be provided.

TECHNICAL SPECIFICATION FOR PROPOSAL

Doc. No. : THTDE-E-eF-003.R02

8 Rev.date: May-25-2020

Erp No: Q202C344 Date: 6/29/2020

Project: Vung Tau, DMT Factory Rev No.: 00

Item/model: MV SWGR/ Solution power S24

9. INSTRUMENT TRANSFORMER

9.1 Current transformers.

1) Each current transformer will be 1A secondary and a primary rating will be

shown on the data sheets and drawings.

2) Accuracy will be in accordance with IEC standard for the metering and relay

applications shown on the data sheets.

9.2 Potential transformers

1) Potential transformers will be mounted in separated compartment.

2) Each transformer will be protected with current limiting primary fuse and will

be designed to withstand the basic impulse level of the switchgear.

3) Each transformer will be N/A secondary and its classifications meet the

the requirements of the applications as shown on the data sheets and drawings.

4) Rated primary voltage and burden of the potential transformers will be

shown on the data sheets and drawings.

10. FINISH

The switchboard enclosures will be cleaned, primed and painted in accordance with

the manufacturer’s standard.

10.1 Scope

This painting procedure will be used on electrical panel for project.

10.2 Cleaning procedure

1) Degreasing and cleaning with soap

2) Rinsing

3) Phosphatting

4) Dry

10.3 Painting procedure

1) Apply one coat of epoxy - polyester powder MUNSELL 5Y7/1

and D.F.T of this coat shall be not less than 40µ

2) Dry & Cure for 20 minutes at 175 - 185°C

3) Do not allow any running, sagging, peeling, wrinkling of loss of adhesion.

TECHNICAL SPECIFICATION FOR PROPOSAL

Doc. No. : THTDE-E-eF-003.R02

9 Rev.date: May-25-2020

Erp No: Q202C344 Date: 6/29/2020

Project: Vung Tau, DMT Factory Rev No.: 00

Item/model: MV SWGR/ Solution power S24

11. TESTING AND INSPECTION

Minimum tests will be performed in accordance with the followings.

The performance of testing will be followed IEC standard.

11.1 Visual inspection

1) Equipment No.

2) Construction

3) Rating

4) Name plate

5) Painting

6) Accessories

7) Quantities

8) Any other items at the description of specification

11.2 Dimensional inspection.

Outline dimension of main parts will be measured.

11.3 Mechanism test

The operation of mechanical part such as switching mechanism and interlocking

mechanism will be checked.

11.4 Sequence test.

All parts, controlling circuit and alarming circuit will be checked in accordance

with the sequence drawings.

11.5 Power frequency voltage dry test.

11.6 Voltage test on auxiliary circuit.

11.7 Verification of each continuity.

11.8 Part test

The following electrical equipment assembled in the switchgear will be checked

through the manufacturer’s factory test reports.

1) Circuit breaker

2) Potential transformers

3) Current transformers

4) Protective relays

TECHNICAL SPECIFICATION FOR PROPOSAL

Doc. No. : THTDE-E-eF-003.R02

10 Rev.date: May-25-2020

Erp No: Q202C344 Date: 6/29/2020

Project: Vung Tau, DMT Factory Rev No.: 00

Item/model: MV SWGR/ Solution power S24

11.9 Insulation resistance between electric parts and earth will be measured in

accordance with the following table.

Tested Parts Insulation Allowable insulation

Resistance test Resistance

Main circuit rated 1000V 50 MΩ

voltage 600V or

over

Control circuits 500V 2 MΩ

11.10 Dielectric tests

The dielectric tests between electric part and earth will be carried out at the

following power frequency test voltage for one minute and they will be free

from electrical and mechanical defects.

Tested Parts Nominal voltage Test voltage

Main circuit 22kV 50kV

Control circuits 0.6kV 1.5kV

11.11 Manufacturer’s test reports will be submitted.

12. PROVISION FOR HANDLING AND FIELD ERECTION

12.1 Each “shipping section” of stationary structures will be furnished with removable

eye bolts suitable for fork or hooks or slings.

12.2 Each “shipping section” will be furnished with removable steel channel base

plates which will permit using pipe rollers of dollies without damaging the frame steel

of the equipment.

12.3 The suitable handling equipments will be provided for convenient removal,

insertion and movements at each switchgear location for all circuit breakers and

withdrawal equipment weighing more than 20 kg gross.

TECHNICAL SPECIFICATION FOR PROPOSAL

Doc. No. : THTDE-E-eF-003.R02

11 Rev.date: May-25-2020

Erp No: Q202C344 Date: 6/29/2020

Project: Vung Tau, DMT Factory Rev No.: 00

Item/model: MV SWGR/ Solution power S24

13. SHIPPING

If shipped separately, each power circuit breaker will be individually crated and

tagged with its proper unit number and the equipment number of the assembly to

which it belongs.

14. PREPARATION FOR SHIPMENT

Preparation for shipment will be in accordance with manufacturer’s standards.

* ATTACHMENT DATA

A. STANDARDS

1. The equipment will be rated in accordance with:

Metal enclosed Air insulated switchgear : IEC 62271-200

Circuit breaker : IEC 62271-100

Earthing switches : IEC 62271-102

Load break switches : IEC 62271-105

Current transformer : IEC 61869-2

Voltage transformer : IEC 61869-3

Protective relay : IEC 60255

B. RATING AND CHARACTERISTICS

• Rated voltage : 24kV

• Nominal service voltage : 22kV

• Rated frequency : 50Hz

• Rated insulation level

Impulse withstand voltage : 125kV

One minute withstand voltage : 50kV

• Rated short-time withstand current : 25kA

• Rated peak withstand current : 62.5kA

• Busbar rating : 630A

• Degree of protection

Enclosure : IP4X

Partition and shutters : IP2X

TECHNICAL SPECIFICATION FOR PROPOSAL

Doc. No. : THTDE-E-eF-003.R02

12 Rev.date: May-25-2020

Erp No: Q202C344 Date: 6/29/2020

Project: Vung Tau, DMT Factory Rev No.: 00

Item/model: MV SWGR/ Solution power S24

• Auxiliary voltage : 220VAC

• Control voltage : 110VDC

C. MAIN EQUIPMENT

1. VACUUM CIRCUIT BREAKER

1) Type : VL-20H

2) Rated voltage : 24kV

3) Rated frequency : 50Hz

4) Rated current : 630A

5) Short time withstand current : 25kA

6) Rated operating sequence : O-0.3s-CO-15s-CO

7) Power frequency withstand voltage : 50kV

8) Basic impulse level / 1.2/ 50/ µs : 125kV

9) Operating mode : 3 pole

10) Operating coil voltage : 110VDC

11) Number of auxiliary contact : 10NO/10NC

12) Maker : LS Electric/Korea

2. LOAD BREAK SWITCH

1)Type : N/A

2) Rated voltage : N/A

3) Rated current : N/A

4) Short time withstand current : N/A

5) Operating method : N/A

6) Insulation : N/A

7) Maker : N/A

3. EARTHING SWITCH

1) Type : N/A

2) Rated voltage : N/A

3) Rated frequency : N/A

4) Short time withstand current : N/A

5) Maker : N/A

4. CURRENT TRANSFORMER

1) Type : Epoxy resin

2) Rated voltage : 24kV

3) Rated frequency : 50Hz

4) Secondary current output : 1A

5) Metering core class : 0.5CL

6) Protection class 1 : 5P20

TECHNICAL SPECIFICATION FOR PROPOSAL

Doc. No. : THTDE-E-eF-003.R02

13 Rev.date: May-25-2020

Erp No: Q202C344 Date: 6/29/2020

Project: Vung Tau, DMT Factory Rev No.: 00

Item/model: MV SWGR/ Solution power S24

7) Protection class 2 : N/A

8) Burden : 20VA

9) Short time withstand current : 25kA

10) Maker : ESITAS or Equivalent

5. VOLTAGE TRANSFORMER

1) Type : N/A

2) Rated voltage : N/A

3) Rated frequency : N/A

4) Secondary output : N/A

5) Metering core class : N/A

6) Protection core class : N/A

7) Burden : N/A

8) Maker : N/A

6. ZERO SEQUENCE CURRENT TRANSFORMER

1) Type : N/A

2) Ratio : N/A

3) Rated Burden : N/A

4) Accuracy class : N/A

5) Maker : N/A

7. POWER FUSE

1) Type : N/A

2) Rated voltage : N/A

3) Rated frequency : N/A

4) Rated current : N/A

5) Maker : N/A

8. LIGHTNING ARRESTER.

1) Type : N/A

2) Rated voltage : N/A

3) Rated frequency : N/A

4) Nominal Discharge Current : N/A

5) Line discharge class : N/A

6) Maker : N/A

9. DIGITAL PROTECTION & MONITORING EQUIPMENT

1) Type : Numerical

2) Protection function

As customer requirement

3) Measurement function : A,V,W,Var...

4) Communication prototol : IEC 61850

TECHNICAL SPECIFICATION FOR PROPOSAL

Doc. No. : THTDE-E-eF-003.R02

14 Rev.date: May-25-2020

Erp No: Q202C344 Date: 6/29/2020

Project: Vung Tau, DMT Factory Rev No.: 00

Item/model: MV SWGR/ Solution power S24

5) Maker : LSE or Equivalent

10. INSTRUMENTS

AMPERE METER

1) Type : N/A

2) Accuracy class : N/A

3) Maker : N/A

VOLT METER

1) Type : N/A

2) Accuracy class : N/A

3) Maker : N/A

MULTI-FUNCTION METER

1) Type : N/A

2) Accuracy class : N/A

3) Maker : N/A

WATTHOUR&VARHOUR METER

1) Type : N/A

2) Accuracy class : N/A

3) Maker : N/A

TRANSDUCER: A, V, P, VAR

1) Type : N/A

2) Output : N/A

2) Accuracy class : N/A

3) Maker : N/A

D. COMMAND SWITCH & AUX. DEVICE

1. SEMAPHORE

1) Type : N/A

2) Position : N/A

3) Maker : N/A

2. CONTROL SWITCH

1) Type : YS

2) Position : Open-Close

3) Pull turn spring return

4) Maker : YongSung/Korea

TECHNICAL SPECIFICATION FOR PROPOSAL

Doc. No. : THTDE-E-eF-003.R02

15 Rev.date: May-25-2020

Erp No: Q202C344 Date: 6/29/2020

Project: Vung Tau, DMT Factory Rev No.: 00

Item/model: MV SWGR/ Solution power S24

3. SELECTOR SWITCH

1) Type : YS

2) Position : Local/Remote

3) Maker : YongSung/Korea

4. VOLT-METER SELECTOR SWITCH

1) Type : N/A

2) Position : N/A

3) Maker : N/A

5. AM-METER SELECTOR SWITCH

1) Type : N/A

2) Position : N/A

3) Maker : N/A

6. PUSH BUTTON SWITCH

1) Type : YSAP

2) Size : 25 Ø round

3) Color : Red, Green,

Yellow, Black

4) Maker : YongSung/Korea

7. AUXILIARY RELAY

1) Type : MR

2) Number of contact : 4 or 8

3) Rated voltage : 110VDC

4) Maker : LS Electric/Korea

E. OTHERS

1. SPACE HEATER

- 1 Phase, AC 220VAC , 80W

2. LIGHTING FIXTURE

- LED type

- 1 Phase, AC 220VAC , 80W

3. TEST TERMINAL

- 3P 3W, 3P 4W

- Plug-in type

TECHNICAL SPECIFICATION FOR PROPOSAL

Doc. No. : THTDE-E-eF-003.R02

16 Rev.date: May-25-2020

Вам также может понравиться

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsОт Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsРейтинг: 4 из 5 звезд4/5 (1)

- Instruction Manual FOR New Mather Metals, Inc.: Ajax TOCCO Magnethermic CorporationДокумент289 страницInstruction Manual FOR New Mather Metals, Inc.: Ajax TOCCO Magnethermic Corporationnerko100% (1)

- 50 TMSS 01 R0Документ0 страниц50 TMSS 01 R0renjithas2005Оценок пока нет

- Specification of 11kv SF6 Insulated Ring Main UnitsДокумент8 страницSpecification of 11kv SF6 Insulated Ring Main UnitsGAGANОценок пока нет

- B353 OL3 001 2 Text RevAДокумент296 страницB353 OL3 001 2 Text RevAvrajakisoriDasiОценок пока нет

- Static Kramer Drive - T.moodleyДокумент14 страницStatic Kramer Drive - T.moodleyThuven Moodley100% (1)

- Power System Operation and Control - B. R. GuptaДокумент84 страницыPower System Operation and Control - B. R. GuptamaulikchauhanОценок пока нет

- Technical Data Book of NGRДокумент54 страницыTechnical Data Book of NGRAlind Dubey0% (1)

- 25458-000-V12-MBPD-02559 Sub 002Документ228 страниц25458-000-V12-MBPD-02559 Sub 002rajbharath.pОценок пока нет

- 3.3KV VCB SpecДокумент9 страниц3.3KV VCB SpecVishnuraj RОценок пока нет

- Technical Specification For Gas Insulated Metalclad 36kV Switchgear For Indoor ApplicationДокумент30 страницTechnical Specification For Gas Insulated Metalclad 36kV Switchgear For Indoor ApplicationS.M.Touhidur RahmanОценок пока нет

- Engineering Specification For MV SwitchgearДокумент21 страницаEngineering Specification For MV SwitchgearSundaresan SabanayagamОценок пока нет

- SECTION 26 24 13 Switchboards Part 1 - GeneralДокумент6 страницSECTION 26 24 13 Switchboards Part 1 - GeneralJeremy ProffittОценок пока нет

- ZJ40DBST Drilling Rig Standardized Power Supply and Distribution System at Well Site Operation MaДокумент15 страницZJ40DBST Drilling Rig Standardized Power Supply and Distribution System at Well Site Operation MaJohn SimancaОценок пока нет

- ZW32 24Документ2 страницыZW32 24Alex FreireОценок пока нет

- HT Termination Kit Techical SpecificationДокумент10 страницHT Termination Kit Techical SpecificationYörükОценок пока нет

- Tech Spec SS - IIДокумент253 страницыTech Spec SS - IIkrcdewanewОценок пока нет

- RMU Technical SpecificationДокумент15 страницRMU Technical SpecificationGAGANОценок пока нет

- Cable SizingДокумент24 страницыCable SizingPrashant Kumar Punia100% (2)

- Ts of 33 KV in Door Switch Board-IДокумент29 страницTs of 33 KV in Door Switch Board-ISunil SinghОценок пока нет

- MV Soft Starter Switchgear SpecificationДокумент10 страницMV Soft Starter Switchgear SpecificationjcvillablОценок пока нет

- 5SY6 Brochure 2011Документ20 страниц5SY6 Brochure 2011Roberto FinaОценок пока нет

- 02 CSS SpecsДокумент23 страницы02 CSS Specsshimla kaurОценок пока нет

- Technical Specification VCB PanelДокумент14 страницTechnical Specification VCB PanelDarshit VyasОценок пока нет

- Sun2000 (3ktl 10ktl) m1 Quick GuideДокумент29 страницSun2000 (3ktl 10ktl) m1 Quick GuideVedran AzabagicОценок пока нет

- Remarks On Diff BW TI - SPC - PSI - PROTCT - 6071 & 6072 DraftДокумент6 страницRemarks On Diff BW TI - SPC - PSI - PROTCT - 6071 & 6072 DraftRAJADEVANОценок пока нет

- June 30, 2010Документ41 страницаJune 30, 2010TTPL ProjectsОценок пока нет

- Specification 11kV VCB Panel - IndoorДокумент29 страницSpecification 11kV VCB Panel - Indoormayur100% (1)

- 3Документ33 страницы3toogooodОценок пока нет

- Electrical Tender NoticeДокумент163 страницыElectrical Tender NoticeRaja Bharath DonthiОценок пока нет

- Spec MDBДокумент16 страницSpec MDBDolyОценок пока нет

- Annexure - A Part-I (Technical Bid)Документ19 страницAnnexure - A Part-I (Technical Bid)Prachi DongreОценок пока нет

- Tech Spec For DC String CablesДокумент6 страницTech Spec For DC String CablesPaari BОценок пока нет

- TS - 11 KV SwitchgearДокумент21 страницаTS - 11 KV Switchgearraj_stuff006Оценок пока нет

- Effect of Free Wheeling Diode in Single Phase Fully-Controlled Bridge ConverterДокумент1 страницаEffect of Free Wheeling Diode in Single Phase Fully-Controlled Bridge Converternavin3007Оценок пока нет

- Specification No. PROJ-ELEC/C&I-TS-MSSS-0007 Rev No: 01 DATE: 28/12/2006 SheetДокумент45 страницSpecification No. PROJ-ELEC/C&I-TS-MSSS-0007 Rev No: 01 DATE: 28/12/2006 SheetPinak ProjectsОценок пока нет

- Advance SpecificationДокумент19 страницAdvance Specificationsankuma100% (1)

- June 30, 2010Документ41 страницаJune 30, 2010mohamedОценок пока нет

- Govt EPL Techinical-SpecificationДокумент98 страницGovt EPL Techinical-SpecificationkotiОценок пока нет

- Material SpecificationsДокумент27 страницMaterial Specificationssat palОценок пока нет

- 5sj4 Ul489 Overview September09Документ29 страниц5sj4 Ul489 Overview September09Suriya AudthamulОценок пока нет

- Well-Site Power Supply and Distribution System User ManualДокумент17 страницWell-Site Power Supply and Distribution System User ManualAhmedОценок пока нет

- LDB SpecДокумент40 страницLDB SpecNavneet SinghОценок пока нет

- J0231 LV TR - FINAL变压器2Документ21 страницаJ0231 LV TR - FINAL变压器2SerhiiОценок пока нет

- ZS1 - Technical Specification 2019 Rev0Документ24 страницыZS1 - Technical Specification 2019 Rev0Charles RobiansyahОценок пока нет

- Single Phase Pad Mounted Transformer Specifications For Constumers and Electrical ContractorsДокумент37 страницSingle Phase Pad Mounted Transformer Specifications For Constumers and Electrical ContractorsJuan Juan100% (1)

- SECTION 16675 Isolated Power SystemsДокумент7 страницSECTION 16675 Isolated Power Systemsno nameОценок пока нет

- Client:-Visa Power Limited: Released For ConstructionДокумент36 страницClient:-Visa Power Limited: Released For Constructionraj sekharОценок пока нет

- Technical Data Bio-Ethanol - M&EДокумент57 страницTechnical Data Bio-Ethanol - M&EJack NgОценок пока нет

- CL-NG-6460-002-023 Checklist For CT Rev00Документ2 страницыCL-NG-6460-002-023 Checklist For CT Rev00WajahatОценок пока нет

- Technical Description: Gas-Insulated, Metal-Enclosed Medium-Voltage SwitchgearДокумент19 страницTechnical Description: Gas-Insulated, Metal-Enclosed Medium-Voltage SwitchgearNedyHortetlОценок пока нет

- Electrical Revamp Cahier de Charge ENДокумент20 страницElectrical Revamp Cahier de Charge ENben sanОценок пока нет

- Industrial Power System Design by Benigno S JimenezДокумент11 страницIndustrial Power System Design by Benigno S JimenezmjpadzОценок пока нет

- BESCOM Technical-Specification-HT-UG-CablesДокумент15 страницBESCOM Technical-Specification-HT-UG-Cablesಪರಮಮಿತ್ರಸಂಪತ್ಕುಮಾರ್ಶೆಟ್ಟಿОценок пока нет

- 27 - 400 - 220 - 132kV - DB - Tandem Isolator R3 Jan 12 PDFДокумент30 страниц27 - 400 - 220 - 132kV - DB - Tandem Isolator R3 Jan 12 PDFAshok KumarОценок пока нет

- Terminaiton Kit SpecificaitonДокумент5 страницTerminaiton Kit SpecificaitonVaibhav ShahОценок пока нет

- 8DN8 General DescriptionДокумент9 страниц8DN8 General DescriptionsamreeniqbalОценок пока нет

- Beko 14.2 Chassis Full TV SMДокумент34 страницыBeko 14.2 Chassis Full TV SMJosep Maria Bargallo MoyaОценок пока нет

- Specification: Electricity Distribution System and LightingДокумент63 страницыSpecification: Electricity Distribution System and LightingVăn Thủ [VCC] TrầnОценок пока нет

- Iso-Phase Bus Duct Typical MaintenanceДокумент18 страницIso-Phase Bus Duct Typical MaintenancesulemankhalidОценок пока нет

- List of Electrical Standard Specifications: Power Control Centres, Motor Control Centres Document STD002.U07 1/33 Rev. AДокумент33 страницыList of Electrical Standard Specifications: Power Control Centres, Motor Control Centres Document STD002.U07 1/33 Rev. Avaithy1990Оценок пока нет

- Protection of Substation Critical Equipment Against Intentional Electromagnetic ThreatsОт EverandProtection of Substation Critical Equipment Against Intentional Electromagnetic ThreatsОценок пока нет

- S&L - Honeywell BESSДокумент19 страницS&L - Honeywell BESSNguyễn Huy HoàngОценок пока нет

- WTG Commissioning Concern - 2023.08.29Документ2 страницыWTG Commissioning Concern - 2023.08.29Nguyễn Huy HoàngОценок пока нет

- Droop Frequency - Renewable MicrogridДокумент11 страницDroop Frequency - Renewable MicrogridNguyễn Huy HoàngОценок пока нет

- Datalist Scada - NMDG HongPhong1Документ13 страницDatalist Scada - NMDG HongPhong1Nguyễn Huy HoàngОценок пока нет

- Temperature and Humidity Transmitter User Manual: 1. Product DescriptionДокумент8 страницTemperature and Humidity Transmitter User Manual: 1. Product DescriptionNguyễn Huy HoàngОценок пока нет

- No. Item Short Order Code Siemens Q'ty Unit Remarks: P1G431398 BCU w/25 For OHLДокумент4 страницыNo. Item Short Order Code Siemens Q'ty Unit Remarks: P1G431398 BCU w/25 For OHLNguyễn Huy HoàngОценок пока нет

- Substation Protocol Gateway: SYNC 2000 SeriesДокумент2 страницыSubstation Protocol Gateway: SYNC 2000 SeriesNguyễn Huy HoàngОценок пока нет

- Type MRTP Supervision For AC Pilot CircuitsДокумент8 страницType MRTP Supervision For AC Pilot CircuitsNguyễn Huy HoàngОценок пока нет

- Discrepancy Switch - Sơ Đ ChânДокумент5 страницDiscrepancy Switch - Sơ Đ ChânNguyễn Huy HoàngОценок пока нет

- Sicam Sicam SCC Human-Machine Interface (HMI)Документ550 страницSicam Sicam SCC Human-Machine Interface (HMI)Nguyễn Huy HoàngОценок пока нет

- THT-PM-F0003-List of Relay Protections For Cambodia, BHT1. Rev01Документ1 страницаTHT-PM-F0003-List of Relay Protections For Cambodia, BHT1. Rev01Nguyễn Huy HoàngОценок пока нет

- Telecommunication Scheme of Cam Lam Solar Power PlantДокумент1 страницаTelecommunication Scheme of Cam Lam Solar Power PlantNguyễn Huy HoàngОценок пока нет

- Solved Chap 4 1st Year Physics MCQsДокумент4 страницыSolved Chap 4 1st Year Physics MCQsAmna ShakeelОценок пока нет

- Liebert Hipulse D Data SheetДокумент6 страницLiebert Hipulse D Data SheetDharmesh ChanawalaОценок пока нет

- Saylors-Wind Farm Collector System GroundingДокумент16 страницSaylors-Wind Farm Collector System GroundingkcirrenwodОценок пока нет

- Single Phase TransformerДокумент6 страницSingle Phase TransformersivaiahjettiОценок пока нет

- Eaton Laposte CasestudyДокумент25 страницEaton Laposte CasestudyFamiglia RedОценок пока нет

- The Renewable Transition in Spain and GermanyДокумент14 страницThe Renewable Transition in Spain and GermanyBrian VaughnОценок пока нет

- English Layout F and B MinДокумент12 страницEnglish Layout F and B MinAnonymous jBwSm8WОценок пока нет

- Cable Volatge Drop For Different Size of Cables (1.1.19)Документ24 страницыCable Volatge Drop For Different Size of Cables (1.1.19)jiguparmar1516Оценок пока нет

- 105 Data PDFДокумент2 страницы105 Data PDFAnas BasarahОценок пока нет

- 1208 CAP XX Charging A Supercapacitor From A Solar Cell PDFДокумент12 страниц1208 CAP XX Charging A Supercapacitor From A Solar Cell PDFmehralsmenschОценок пока нет

- SuperCritical TechnologyДокумент67 страницSuperCritical TechnologyAnil SinghОценок пока нет

- BEE051 & Distributed Generation and Micro GridДокумент2 страницыBEE051 & Distributed Generation and Micro GridRenga RajanОценок пока нет

- Lesson 4 - MTF1 - Energy, Energy Transfer and General Energy Analysis - 2021Документ11 страницLesson 4 - MTF1 - Energy, Energy Transfer and General Energy Analysis - 2021Thabo MokgosiОценок пока нет

- Mos Ups 1Документ4 страницыMos Ups 1MohamedAhmedFawzyОценок пока нет

- Clearances and CreepageДокумент4 страницыClearances and CreepageAjit KalelОценок пока нет

- AC GeneratorДокумент26 страницAC GeneratorKamesh Gupta100% (1)

- 7UT CT-Requirements enДокумент22 страницы7UT CT-Requirements enEddyОценок пока нет

- B. Tech. IV, Electrical, 7 Sem. Switchgear & Protection Mid-Semester Exam Marks: 30 October-2020 Time: 2 HrsДокумент2 страницыB. Tech. IV, Electrical, 7 Sem. Switchgear & Protection Mid-Semester Exam Marks: 30 October-2020 Time: 2 HrsTushar SanwareyОценок пока нет

- 1mrk513011-Ben en Auxiliary Current Transformer For Radss 1-Phase and 3-Phase Slce 12 Slce 16 Slxe 4Документ4 страницы1mrk513011-Ben en Auxiliary Current Transformer For Radss 1-Phase and 3-Phase Slce 12 Slce 16 Slxe 4GustavoForsterОценок пока нет

- Power Transformer Capacitance and Dissipation Factor TestДокумент2 страницыPower Transformer Capacitance and Dissipation Factor Testpayolin77Оценок пока нет

- Zone of Protection SystemДокумент4 страницыZone of Protection Systemtefe yabatuОценок пока нет

- What Is A FuseДокумент11 страницWhat Is A FuseAshutoshОценок пока нет

- 30AWH015HD9 Classe Energetica+EtiquetaДокумент4 страницы30AWH015HD9 Classe Energetica+EtiquetalhdulofvfxqlwzocmcОценок пока нет

- Fuji Lm2a Errors 1Документ1 страницаFuji Lm2a Errors 1Pim KoedijkОценок пока нет

- (NB24-BX40-01D) Specsheet 01152010Документ2 страницы(NB24-BX40-01D) Specsheet 01152010nextekpowerОценок пока нет

- PLCДокумент12 страницPLCfirecityvОценок пока нет

- QUICK-LPLUS - enДокумент1 страницаQUICK-LPLUS - enmanual imbОценок пока нет