Академический Документы

Профессиональный Документы

Культура Документы

Hydraulic Quick Couplings General Purpose Couplings: Special Order Information

Загружено:

shahrol effendy rodziОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Hydraulic Quick Couplings General Purpose Couplings: Special Order Information

Загружено:

shahrol effendy rodziАвторское право:

Доступные форматы

General Purpose Couplings

Hydraulic Quick Couplings 60 Series

Special Order Information

60 Series couplings are available in zinc plated steel, brass,

303 stainless steel, and 316 stainless steel. Brass couplings

have double O-Ring seals and stainless locking balls.

Standard seal materials are Buna-N (Nitrile); optional seal

materials are available.

For 316 stainless steel products, standard seal material is

Viton™, and other seal materials are available upon request.

See Fluid Compatibility Chart at end of this catalog.

All sizes of 60 Series can be furnished with locking sleeves.

Place suffix letters “-SL” (Sleeve-Lok) after regular catalog

numbers. Example H3-62-SL. Parker 60 Series heavy duty

nipples are recommended where high cycle rates and

pressure surges are encountered. Machined from high tensile

steel and induction hardened, they are zinc plated with a

Applications yellow chromate finish. To specify a heavy duty nipple, add

Parker general purpose couplings, are used across the the prefix “HD” to the steel part number; thus: HDH2-63.

spectrum of hydraulic applications. These Double Shut-Off

couplings can be found anywhere that fluid transfer lines

need to be connected and disconnected for operation or

maintenance of equipment, and a loss of fluid is undesirable. Note

Primarily used with hydraulic fluid, general purpose Double

Shut-Off couplings are also used with chemicals, water, Protective dust plugs and caps play a crucial role in the life of

steam, and some gases. a quick coupling and no purchase of a hydraulic quick

coupling is complete without the selection of an appropriate

dust plug and cap. See pages noted in Table of Contents for

dust plugs and caps for the Parker full line of hydraulic

couplings.

Specifications

ANSI/ISO Pressure Rating: Dynamic applications with normal to moderate hydraulic Low Cycle, Non-pulsating Pressure Rating: Applications with lower cycle

shocks such as general industrial equipment, hydraulic presses, agricultural equip- life and no severe cyclic pressure fluctuations, essentially steady pressure during

ment, etc. Impulse tested at a multiple (125% to 133%) of rated pressure. an operating cycle. Typical applications include hydraulic jacks, mine roof

support systems, and high pressure fluid transfer (pumping water or slurry in

oil wells). Minor pump ripple is considered non-pulsating. Impulse tested at rated

pressure.

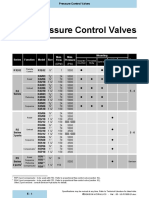

Body Size (in.) 1/8 1/4 3/8 1/2 3/4 1 1 1/2 2 1/2 1/8 1/4 3/8 1/2 3/4 1 1 1/2 2 1/2

Rated Pressure (PSI) Rated Pressure (PSI)

Brass 1000 1000 1000 1000 1000 1000 800 800 3000 3700 2700 3500 2200 1500 1500 1200

Stainless steel 2000 2000 1500 1500 1500 1000 1000 1000 5000 5000 5000 5000 3000 3000 1500 1500

Steel 5000 5000 4000 4000 2500 2000 1000 1000 5000 5000 4000 4000 2500 2000 1500 1500

Steel w / HD N/A 5000 4000 4000 3000 3000 N/A N/A 5000 5000 4000 4000 3000 3000 N/A N/A

nipple

Temperature Range: Standard seals (Buna-N) -40° to +250° F Optional Viton seals -10° to +400° F

Vacuum Data: 27.4 inches Hg. both connected and disconnected (1-1/2" and 2-1/2" body size 60 Series couplings are not reccommended for service in diconnected mode)

Note: Read the Safety Guide for Selecting and Using Quick Action Couplings and Related Accessories before making a coupling selection. It may be found in

Parker Hannifin Quick Coupling Divison catalogs and is available as Parker Publication No. 3800-B1.0.

Body Size (in.) 1/8 1/4 3/8 1/2 3/4 1 1 1/2 2 1/2

Rated Flow (GPM) .8 3 6 12 28 50 100 200

Quick Coupling Division

8145 Lewis Road • Minneapolis, MN 55427

B-5 www.parker.com/quickcouplings

General Purpose Couplings

Hydraulic Quick Couplings 60 Series

4. Hardened nipples and sleeves (steel) and solid barstock

4 construction make for a quality coupling with maximum re-

6 sistance to damage from hydraulic and mechanical shock.

5. The seal is designed to withstand high pressures and pro-

vide reliable sealing. A wide selection of optional seal ma-

terials are available, see Fluid Compatibility Chart at end

2 of this catalog for selection assistance. Steel versions fea-

9

1 ture Teflon™ back-up rings that support mating seals for

high pressure applications. Brass couplers have a double

O-ring seal for redundancy in low pressure, vacuum and

steam applications.

3 5 1 6. Durable ball-locking mechanism assures reliable connec-

tion, every time. A large number of locking balls distributes

7 2 the work load evenly while providing alignment and swivel-

ing action to reduce hose torque and prolong hose life.

7. Manufactured from brass, steel and stainless steel as

Features

standard materials. A wide range of seals allow these

1. Large flow areas machined into the body of the coupler couplings to be used with a broad range of media.

and nipple facilitate flow around the valve, for a high flow 8. Industry-wide interchangeability. Parker 60 Series couplers

capacity. and nipples are the “Industrial Interchange” design and

2. Positive valve stop. The perch maintains valve alignment meet the dimensional requirements of Series B in ISO

and provides metal to metal valve stop to ensure that the 7241-1.

valves open fully, every time. 9. Also available with a Straight Thread (ORB) end configura-

3. Captive valve seal assures “bubble tight” poppet sealing. tion available as standard, for reduced leakage.

The valve seal is positively captured by the metal poppet to

minimize seal washout or damage from high velocity fluid.

Performance

60 Series (1/8;1/4") 60 Series (3/8;1") 60 Series (11/2;21/2")

Test Fluid: Oil - 200 SUS Test Fluid: Oil - 200 SUS Test Fluid: Oil - 200 SUS

30 30 200 200

40 40

30 30

2-1/2"

20 20 100 100

80 80

20 20

1/8" 60 60

1/4" 50 50

1/2" 1" 40 40

10 10

Pressure Drop in PSID

Pressure Drop in PSID

Pressure Drop in PSID

3/8" 3/4"

9 9 30 30

8 8 10 10

9 9 1-1/2"

7 7 8 8 20 20

6 6 7 7

5 5 6 6

5 5 10 10

4 4 8 8

4 4

3 6 6

3

5 5

3 3

4 4

2 2 3 3

2 2

2 2

1 1 1 1 1

1

.2 .3 .4 .5 .6 .7 .8 .9 1 2 3 4 1 2 3 4 5 6 7 8 910 20 40 60 80 10 20 30 40 50 60 80 100 200 300

Flow in USGPM Flow in USGPM Flow in USGPM

Quick Coupling Division

8145 Lewis Road • Minneapolis, MN 55427

B-6 www.parker.com/quickcouplings

General Purpose Couplings

Hydraulic Quick Couplings 60 Series

Couplers A

Female Thread

Body Part Part Part No. Part No. Thread Thread Dimensions (in.)

Size No. Wt. (LB.) No. Wt. (LB.) Type 303 Wt. (LB.) Type 316 Wt. (LB.) Size Size Overall Wrench Largest

(in.) Brass P/Piece Steel* P/Piece Stainless* P/Piece Stainless* P/Piece NPTF ORB Length Flats Diameter

A B C

1/8 BH1-60 0.16 H1-62 0.16 SH1-62 0.16 SSH1-62Y** 0.15 1/8-27 – 1.90 0.68 0.96

1/8 – – H1-62-T4 0.18 SH1-62-T*4 0.10 SSH1-62Y-T4 0.17 – 7/16-20 2.06 0.68 0.96

1/4 BH2-60 0.32 H2-62 0.30 SH2-62 0.30 SSH2-62Y 0.30 1/4-18 – 2.26 0.81 1.14

1/4 – – H2-62-T6 0.31 SH2-62-T6 0.31 SSH2-62Y-T6 0.31 – 9/16-18 2.41 0.81 1.14

3/8 BH3-60 0.43 H3-62 0.40 SH3-62 0.40 SSH3-62Y 0.40 3/8-18 – 2.49 0.88 1.40

3/8 – – H3-62-T8 0.51 SH3-62-T8 0.51 SSH3-62Y-T8 0.51 – 3/4-16 2.75 1.00 1.40

1/2 BH4-60 0.80 H4-62 0.73 SH4-62 0.75 SSH4-62Y 0.76 1/2-14 – 2.87 1.12 1.77

1/2 – – H4-62-T10 0.78 SH4-62-T10 0.75 SSH4-62Y-T10 0.78 – 7/8-14 3.05 1.12 1.77

3/4 BH6-60 – H6-62 1.30 SH6-62 1.31 SSH6-62Y 1.33 3/4-14 – 3.56 1.31 2.14

3/4 – – H6-62-T12 1.39 SH6-62-T12 1.34 SSH6-62Y-T12 1.40 – 1-1/16-12 3.56 1.31 2.14

1 BH8-60 – H8-62 1.95 SH8-62 1.95 SSH8-62Y 1.95 1-11 1/2 – 4.18 1.62 2.52

1 – – H8-62-T16 1.95 SH8-62-T16 1.95 SSH8-62Y-T16 1.95 – 1-5/16-12 4.18 1.62 2.52

* T = Designator for SAE Straight Thread

** Suffix 'Y' designates Viton Seal. (Contact factory for seal options)

Contact division for BSPP port availability

Nipples D

Female Thread

Body Part Part Part No. Part No. Thread Thread Dimensions (in.)

Size No. Wt. (LB.) No. Wt. (LB.) Type 303 Wt. (LB.) Type 316 Wt. (LB.) Size Size Overall Exposed Wrench Largest

(in.) Brass P/Piece Steel* P/Piece Stainless* P/Piece Stainless* P/Piece NPTF ORB Length Length Flats Diameter

D E F G

1/8 BH1-61 0.04 H1-63 0.03 SH1-63 0.03 SSH1-63Y** 0.04 1/8-27 – 1.61 0.41 0.56 0.65

1/8 – 0.06 H1-63-T4 0.05 SH1-63-T*4 – SSH1-63Y-T4 0.06 – 7/16-20 1.32 0.57 0.69 0.79

1/4 BH2-61 0.09 H2-63 0.08 SH2-63 0.08 SSH2-63Y 0.08 1/4-18 – 1.39 0.65 0.75 0.87

1/4 – 0.11 H2-63-T6 0.10 SH2-63-T6 0.10 SSH2-63Y-T6 0.10 – 9/16-18 1.54 0.70 0.88 1.01

3/8 BH3-61 0.10 H3-63 0.12 SH3-63 0.12 SSH3-63Y 0.12 3/8-18 – 1.50 0.54 0.88 1.01

3/8 – 0.12 H3-63-T8 0.16 SH3-63-T8 0.16 SSH3-63Y-T8 0.14 – 3/4-16 1.76 0.80 1.00 1.15

1/2 BH4-61 0.25 H4-63 0.24 SH4-63 0.24 SSH4-63Y 0.24 1/2-14 – 1.75 0.69 1.12 1.30

1/2 – 0.28 H4-63-T10 0.27 SH4-63-T10 0.27 SSH4-63Y-T10 0.27 – 7/8-14 1.94 0.87 1.19 1.37

3/4 BH6-61 0.50 H6-63 0.46 SH6-63 0.45 SSH6-63Y 0.46 3/4-14 – 2.16 0.79 1.38 1.59

3/4 – 0.55 H6-63-T12 0.46 SH6-63-T12 0.50 SSH6-63Y-T12 0.50 – 1-1/16-12 2.27 0.90 1.34 1.59

1 BH8-61 0.76 H8-63 0.76 SH8-63 0.76 SSH8-63Y 0.76 1-11 1/2 – 2.91 0.99 1.62 1.88

1 – 0.80 H8-63-T16 0.80 SH8-63-T16 0.80 SSH8-63Y-T16 0.80 – 1-5/16-12 2.91 0.99 1.62 1.88*

* T = Designator for SAE Straight Thread

** Suffix 'Y' designates Viton Seal. (Contact factory for seal options)

Contact division for BSPP port availability

Optional Seals Optional Seals Suffix*

60 Series W Ethylene Propylene (EPR)

Y Standard Viton™ Seals

Z Neoprene

-264 Perfluoroelastomer (Kalrez)™

* See Ordering Information at end of Section B.

Quick Coupling Division

8145 Lewis Road • Minneapolis, MN 55427

B-7 www.parker.com/quickcouplings

General Purpose Couplings

Hydraulic Quick Couplings 60 Series

A

Couplers

Female Thread

C

Body Part Part Part No. Part No. Thread Thread Dimensions (in.)

Size No. Wt. (LB.) No. Wt. (LB.) Type 303 Wt. (LB.) Type 316 Wt. (LB.) Size Size Overall Wrench Largest

(in.) Brass P/Piece Steel* P/Piece Stainless* P/Piece Stainless* P/Piece NPTF ORB Length Flats Diameter

A B C

1 1/2 BH12-60L 4.58 H12-62L 4.70 SH12-62L 4.68 SSH12-62LY** 4.68 1 1/4-11 1/2 – 4.86 2.38‡ 3.00

1 1/2 BH12-60N 4.58 H12-62N 4.70 SH12-62N 4.68 SSH12-62NY 4.68 1 1/2-11 1/2 – 4.86 2.38‡ 3.00

1 1/2 – 4.61 H12-62-T20 4.72 SH12-62-T20 4.71 SSH12-62Y-T20 4.71 – 1 5/8-12 4.86 2.38‡ 3.00

1 1/2 – 4.61 H12-62-T24 4.72 SH12-62-T24 4.71 SSH12-62Y-T24 4.71 – 1 7/8-12 4.86 2.38‡ 3.00

2 1/2 BH2016-60 11.06 H2016-62 10.58 SH2016-62 – SSH2016-62Y – 2-11 1/2 – 5.57 3.75 4.10

2 1/2 BH2020-60 11.42 H2020-62 10.91 SH2020-62 – SSH2020-62Y – 2 1/2-8 – 6.04 3.75 4.10

2 1/2 BH2024-60 – H2024-62 – SH2024-62 – SSH2024-62Y – 3-8 – 6.96 4.00 4.35

* T = Designator for SAE Straight Thread

** Suffix 'Y' designates Viton Seal. (Consult factory for seal options)

‡Wrench Flat on 303 Stainless is 2.50 in.

Contact division for BSPP port availability

D

Nipples E

Female Thread

G

Body Part Part Part No. Part No. Thread Thread Dimensions (in.)

Size No. Wt. (LB.) No. Wt. (LB.) Type 303 Wt. (LB.) Type 316 Wt. (LB.) Size Size Overall Exposed Wrench Largest

(in.) Brass P/Piece Steel* P/Piece Stainless* P/Piece Stainless* P/Piece NPTF ORB Length Length Flats Diameter

D E F G

1 1/2 BH12-61L 2.96 H12-63L 3.10 SH12-63L 3.06 SSH12-63LY** – 1 1/4-11 1/2 – 4.76 2.69 2.38‡ 2.75†

1 1/2 BH12-61N 2.96 H12-63N 3.10 SH12-63N 3.06 SSH12-63NY – 1 1/2-11 1/2 – 4.76 2.69 2.38‡ 2.75†

1 1/2 – – H12-63-T20 3.15 SH12-63-T20 3.14 SSH12-63Y-T20 – – 1 5/8-12 4.76 2.69 2.38‡ 2.75†

1 1/2 – – H12-63-T24 3.15 SH12-63-T24 3.14 SSH12-63Y-T24 – – 1 7/8-12 4.76 2.69 2.38‡ 2.75†

2 1/2 BH2016-61 7.78 H2016-63 7.90 SH2016-63 7.92 SSH2016-63Y – 2-11 1/2 – 5.48 2.90 3.75 4.10

2 1/2 BH2020-61 8.12 H2020-63 8.16 SH2020-63 8.16 SSH2020-63Y – 2 1/2-8 – 5.95 3.37 3.75 4.10

2 1/2 BH2024-61 – H2024-63 – SH2024-63 – SSH2024-63Y – 3-8 – 6.87 4.29 4.00 4.35

* T = Designator for SAE Straight Thread

** Suffix 'Y' designates Viton Seal. (Consult factory for seal options)

† Largest diameter on Brass is 2.96" across Hex Corners

‡Hex on 303 Stainless is 2.50 in.

Contact division for BSPP port availability

Replacement Parts Repair Kits

60 Series Couplers Couplers Nipples

Body Repair Kit Used For Repair Kit Used For

Body Size (in.) O-Rings - Buna N Back-Up Rings Size (in.) Part No. Part No. Part No. Part No.

3/8 H67E-62K H3-62 H67E-63K H3-63

1/8 2-013N0674-70 H67A-28 BH67E-60K BH3-60 BH67E-61K BH3-61

1/4 2-015N0674-70 H67C-28 SH67E-62 SH3-62 SH67E-63K SH3-63

3/8 2-116N0674-70 4118007 SSH67-62K SSH3-62Y SSH67E-63K SSH3-63Y

1/2 2-213N0674-70 4128002 1/2 H67F-62K H4-62 H67F-63K H4-63

3/4 2-218N0674-70 4148001 BH67F-60K BH4-60 BH67F-61K BH4-61

1 2-222N0674-70 4158001 SH67F-62 SH4-62 SH67F-63K SH4-63

1-1/2 2-124N0674-70 2-138N0552-90 SSH67F-62K SSH4-62Y SSH67F-63K SSH4-63Y

(Valve) (Fitting) 3/4 H67G-62K H6-62 H67G-63K H6-63

2-224N0674-70 BH67G-60K BH6-60 BH67G-61K BH6-61

(Body 2 req.)

SH67G-62 SH6-62 SH67G-63K SH6-63

2-1/2 2-133N0674-70 2-234N0674-70 SSH67G-62K SSH6-62Y SSH67G-63K SSH6-63Y

(Valve) (Fitting)

1 H67J-62K H8-62 H67J-63K H8-63

2-333N0674-70

(Body)

BH67J-60K BH8-60 BH67J-61K BH8-61

SH67J-62 SH8-62 SH67J-63K SH8-63

SSH67J-62K SSH8-62Y SSH67J-63K SSH8-63Y

Quick Coupling Division

8145 Lewis Road • Minneapolis, MN 55427

B-8 www.parker.com/quickcouplings

Ordering Information

Hydraulic Quick Couplings

When ordering Parker coupler bodies and nipples, please

state the part number of each type of coupler body and each Coupling Material

type of nipple desired. List coupler bodies and nipples as • Prefix “B” for Brass

separate items rather than in combinations. Be sure to double

check thread or hose sizes of items required.

Many of Parker’s coupling products are available with unique Operation

non-standard options well suited to very specific applications. • Prefix “HD” for heavy duty nipple

Examples of unusual end use applications might include:

• Suffix “SL” for coupler sleeve-lok

high temperatures (above 250° F), extremely

caustic/corrosive solutions passing through the coupling, • Suffix “P” for poppet valve

external/environmental corrosion situations, or other high • Suffix “BP” for Push-lok hose barb

wear and tear situations such as dragging the product along • Suffix “VA” for Valve Actuator

the ground. Please see the Fluid Compatibility Chart at the

end of the catalog for a guide in selecting material for various

media. It is always recommended that the Quick Coupling Optional Seals Suffix*

Division be contacted with any questions concerning specific

product application needs. No suffix is required when ordering products with the

standard Buna-N (Nitrile) seals. When specifying an optional

Typically, a prefix or suffix is added to the base part number to

seal, refer to the following chart to determine the appropriate

specify a non-standard O-ring seal, or special option such as

suffix.**

a sleeve lock. The Optional Seals Suffix chart illustrates the

designations. Coupling Series Ethylene Fluoro- Neoprene Perfluoro-

Please Note: Certain couplings series have additional Propylene carbon elastomer

"Special Order Information" which should be referred to in 60 Series W Y Z -264

ordering those products. If applicable to the product, "Special

6600 Series W Y Z -264

Order Information" is found next to the Features and

Specifications charts. SM Series E5 E4 E12 E47

HP Series E5 E4 E12 E47

4000 Series W Y Z N/A

4200 Series W Y Z N/A

NS Series E5 E4 E12 E47

NC Series E5 E4 E12 E47

FF Series E5 E4 E12 E47

Std. is E49 (BFT)

FE Series E5 E4 E12 E47

FH Series E5 E4 E12 E47

FS Series E5 STD E12 E47

6100 Series W Y Z N/A

5000 Series W Y Z N/A

8200 Series W Y Z N/A

9200 Series W Y Z N/A

3000 Series Available with Polyurethane only (no suffix needed)

TC Series Available with Fluorocarbon only (no suffix needed)

1141 Series Available with Polyurethane only (no suffix needed)

ST Series W Y Z

Water Service Available with Buna-N only

WB Series E5 E4 E12 N/A

HO Series E5 E4 E12 N/A

Moldmate Series N/A Y*** N/A N/A

Std. is Silicone

*To select proper seal materials, see Fluid Compatibility Chart in Appendices

section, or contact your Parker Quick Coupling Distributor.

**N/A = Not Available; STD = Standard (No Suffix Needed)

*** Viton™ seal available for use only with oil based media, not water glycol.

Quick Coupling Division

8145 Lewis Road • Minneapolis, MN 55427

B-64 www.parker.com/quickcouplings

Вам также может понравиться

- Acoples Hidraulicos Serie 60 ParkerДокумент2 страницыAcoples Hidraulicos Serie 60 ParkerAntonio MoralesОценок пока нет

- Parker - Conectores RapidosДокумент6 страницParker - Conectores RapidosJimyTeránAgudeloОценок пока нет

- Pulsar CatalogДокумент192 страницыPulsar CatalogCréation PFWОценок пока нет

- Parker Quick Coupling Products 60 Series 2012Документ5 страницParker Quick Coupling Products 60 Series 2012dlanorxОценок пока нет

- Couplings Oil and GasДокумент4 страницыCouplings Oil and GasAutieri AutieriОценок пока нет

- Mediumpressure PDFДокумент104 страницыMediumpressure PDFJean DuboisОценок пока нет

- Conti USA IFS Hydraulic Hoses Fittings Catalog 2016Документ444 страницыConti USA IFS Hydraulic Hoses Fittings Catalog 2016whmidi7331Оценок пока нет

- National Reciprocating PumpsДокумент6 страницNational Reciprocating PumpsCamilo Andres Cardozo Fajardo100% (2)

- Pressure Range - 200 To 1480 PSIG: PurposeДокумент2 страницыPressure Range - 200 To 1480 PSIG: Purposesunil601Оценок пока нет

- Valves, Fittings and Tubing: Medium and High Pressure Condensed CatalogДокумент20 страницValves, Fittings and Tubing: Medium and High Pressure Condensed CatalogEnrique AssmannОценок пока нет

- Series 59 Full Port Ball ValveДокумент4 страницыSeries 59 Full Port Ball Valvekyeong cheol leeОценок пока нет

- Hoke 1700 SeriesДокумент38 страницHoke 1700 SeriesOceanexОценок пока нет

- Catalog 79352ENG HOKE Needle Valves 10.15.13Документ38 страницCatalog 79352ENG HOKE Needle Valves 10.15.13lamosy78Оценок пока нет

- Acople AutomotrizДокумент36 страницAcople AutomotrizJhon Jairo Ruiz JiménezОценок пока нет

- High Pressure FiltersДокумент92 страницыHigh Pressure FiltersThabangОценок пока нет

- 4500S VW Standard PiezometersДокумент4 страницы4500S VW Standard PiezometersShiwas JorgeОценок пока нет

- High Pressure FiltersДокумент108 страницHigh Pressure FiltersKristine ReyesОценок пока нет

- BK2004 Hydraulic HoseДокумент47 страницBK2004 Hydraulic HoseSan Lwin AungОценок пока нет

- PLN-1200-3.07-01, Iss 01 - Product Catalogue PDFДокумент12 страницPLN-1200-3.07-01, Iss 01 - Product Catalogue PDFsakscribОценок пока нет

- PLN-1200-3.07-01, Iss 01 - Product Catalogue PDFДокумент12 страницPLN-1200-3.07-01, Iss 01 - Product Catalogue PDFsakscribОценок пока нет

- Predator: Sewer Cleaning Hose ProductsДокумент8 страницPredator: Sewer Cleaning Hose ProductsbelenОценок пока нет

- 4500MB - CH 2 - Parr - Stirred Reactors and Pressure Vessels Catalog v15 Literature PDFДокумент45 страниц4500MB - CH 2 - Parr - Stirred Reactors and Pressure Vessels Catalog v15 Literature PDFglaubersgОценок пока нет

- 4500 Series VW PiezometersДокумент4 страницы4500 Series VW PiezometersMaLik ChowОценок пока нет

- A-C-F-T Couplers PDFДокумент2 страницыA-C-F-T Couplers PDFGabriel OyedemiОценок пока нет

- NM CataloguesДокумент6 страницNM CataloguessuinpeОценок пока нет

- Solenoid Valves Parker2Документ27 страницSolenoid Valves Parker2SREENATH S.SОценок пока нет

- INH InstaLock Brochure LRДокумент8 страницINH InstaLock Brochure LRviniciusОценок пока нет

- Watsonmcdaniel WLD600 - WLD601 - LiquidDrainTrapДокумент2 страницыWatsonmcdaniel WLD600 - WLD601 - LiquidDrainTrapbudi utomoОценок пока нет

- Brochure Multi-V 60 HZДокумент44 страницыBrochure Multi-V 60 HZOmar Isaac Tuesta Llaja100% (1)

- Válvulas Solenoides ASCO 3 Vias ECIДокумент31 страницаVálvulas Solenoides ASCO 3 Vias ECIJuan Carlos Pardo RimachiОценок пока нет

- Welding - Materials Catalog (Harris) .Документ8 страницWelding - Materials Catalog (Harris) .Aneesh KBОценок пока нет

- Purgadores de VaporДокумент6 страницPurgadores de VaporPaulo CostaОценок пока нет

- Stainless Steel Pressure Filters - BrochureДокумент20 страницStainless Steel Pressure Filters - Brochureviktor_gligorovОценок пока нет

- Sour ServiceДокумент24 страницыSour ServicesundachaosОценок пока нет

- Manual Book Pompa 104G5Документ7 страницManual Book Pompa 104G5Ardi 4791Оценок пока нет

- E Series: Back Pull Out End ScutionДокумент7 страницE Series: Back Pull Out End ScutionOkello Paul100% (1)

- G and L Series DatasheetДокумент6 страницG and L Series DatasheetFilipeОценок пока нет

- Filter PDFДокумент2 страницыFilter PDFMathan Selva Kumar AОценок пока нет

- Asco8210 PDFДокумент6 страницAsco8210 PDFoscar_rent_torresОценок пока нет

- BB4-Catalogue 2015Документ11 страницBB4-Catalogue 2015nima hasanzadehОценок пока нет

- FT - 8210 - V. SolenoideДокумент6 страницFT - 8210 - V. SolenoideClaudia Patricia Carazas SarmientoОценок пока нет

- General Service Solenoid Valves: FeaturesДокумент6 страницGeneral Service Solenoid Valves: FeaturesIgnacio FranОценок пока нет

- No-Skive: Tough Cover Compact HoseДокумент2 страницыNo-Skive: Tough Cover Compact HoseleonardoОценок пока нет

- Bi-Directional Overdriven / Unstable Detonation Flame ArrestersДокумент2 страницыBi-Directional Overdriven / Unstable Detonation Flame ArrestersHector Flores MarcosОценок пока нет

- Kraissl Catalog PDFДокумент34 страницыKraissl Catalog PDFsashaОценок пока нет

- Series 681: Pressure Reducing ValvesДокумент4 страницыSeries 681: Pressure Reducing ValvesSanket SavlaОценок пока нет

- CEA-CA Series CEA (N) - CA (N) Made of AISI 316: 60 HZ 60 HZ 60 HZ 60 HZ 60 HZДокумент48 страницCEA-CA Series CEA (N) - CA (N) Made of AISI 316: 60 HZ 60 HZ 60 HZ 60 HZ 60 HZValbertОценок пока нет

- 3.2. Flowstrong Yellowbox - Product SpecsДокумент16 страниц3.2. Flowstrong Yellowbox - Product SpecsHussain Al SanonaОценок пока нет

- Vertical Flame ArresterДокумент13 страницVertical Flame ArresterKris WilliamsОценок пока нет

- 98H Series Backpressure/Relief Valves: Industrial RegulatorsДокумент4 страницы98H Series Backpressure/Relief Valves: Industrial RegulatorsDaniel ReyОценок пока нет

- Dossier Suministro de Valvulas de Seccionamiento CONTRATO No. 6000004219Документ212 страницDossier Suministro de Valvulas de Seccionamiento CONTRATO No. 6000004219Bureau VeritasОценок пока нет

- Noriseal CatalogДокумент12 страницNoriseal CatalogRio WitcandraОценок пока нет

- EC600 X-FLEX Bend Radius 420 Bar Spiral Hydraulic HoseДокумент2 страницыEC600 X-FLEX Bend Radius 420 Bar Spiral Hydraulic HoseAutieri AutieriОценок пока нет

- Pressuretrol l404 SeriesДокумент12 страницPressuretrol l404 SeriesFreddy TamayoОценок пока нет

- Guth Non-Return Valve: A Good ChoiceДокумент4 страницыGuth Non-Return Valve: A Good ChoiceВалентин КовальчукОценок пока нет

- SB and SBO Series: Pulsation DampenersДокумент4 страницыSB and SBO Series: Pulsation DampenerssanthoshkrishnaОценок пока нет

- Asco Valve 8262h 8263h GP Spec r3Документ4 страницыAsco Valve 8262h 8263h GP Spec r3Anonymous 6VCG1YRdОценок пока нет

- Geotextiles and Geomembranes HandbookОт EverandGeotextiles and Geomembranes HandbookT.S. IngoldРейтинг: 5 из 5 звезд5/5 (1)

- Fairchild Model m10bp Precision Back Pressure Regulator 2007 ManualДокумент2 страницыFairchild Model m10bp Precision Back Pressure Regulator 2007 Manualshahrol effendy rodziОценок пока нет

- Fairchild CRN Numbers 2010Документ1 страницаFairchild CRN Numbers 2010shahrol effendy rodziОценок пока нет

- Fairchild Model 30 Midget RegulatorДокумент2 страницыFairchild Model 30 Midget Regulatorshahrol effendy rodziОценок пока нет

- Fuel in The SkyДокумент5 страницFuel in The Skyshahrol effendy rodziОценок пока нет

- ES 3.06 15M 4.06 10M/15M BOP: User ManualДокумент68 страницES 3.06 15M 4.06 10M/15M BOP: User Manualshahrol effendy rodziОценок пока нет

- Apela - Learners - Handbook - L3-L7 - 120721Документ34 страницыApela - Learners - Handbook - L3-L7 - 120721shahrol effendy rodziОценок пока нет

- SS24EX: Explosion Proof External PhotocellДокумент2 страницыSS24EX: Explosion Proof External Photocellshahrol effendy rodziОценок пока нет

- Cat19579-Tachometer Cable PDFДокумент1 страницаCat19579-Tachometer Cable PDFshahrol effendy rodziОценок пока нет

- Ss24ex DatasheetДокумент2 страницыSs24ex Datasheetshahrol effendy rodziОценок пока нет

- Texas Oil Tools: Packer Inserts & EnergizersДокумент12 страницTexas Oil Tools: Packer Inserts & Energizersshahrol effendy rodziОценок пока нет

- Service Exchange CryogenicsДокумент2 страницыService Exchange Cryogenicsshahrol effendy rodziОценок пока нет

- Series R1E02 General Description Technical Information: Pressure Relief ValvesДокумент3 страницыSeries R1E02 General Description Technical Information: Pressure Relief Valvesshahrol effendy rodziОценок пока нет

- Series R5V P2 (Flange Mounted) Technical Information General DescriptionДокумент7 страницSeries R5V P2 (Flange Mounted) Technical Information General Descriptionshahrol effendy rodziОценок пока нет

- HYDAC 2054036 Datasheet PDFДокумент5 страницHYDAC 2054036 Datasheet PDFshahrol effendy rodzi100% (1)

- Series C5V (Direct Operated) General Description Technical InformationДокумент3 страницыSeries C5V (Direct Operated) General Description Technical Informationshahrol effendy rodziОценок пока нет

- Differential Pressure Valve: Model 4143AДокумент7 страницDifferential Pressure Valve: Model 4143Ashahrol effendy rodziОценок пока нет

- Orbital Motors: Seal KitsДокумент16 страницOrbital Motors: Seal Kitsshahrol effendy rodziОценок пока нет

- Datasheet 4110 Overspeed Sensing Valve 1015 Rev1 PDFДокумент6 страницDatasheet 4110 Overspeed Sensing Valve 1015 Rev1 PDFshahrol effendy rodziОценок пока нет

- Rigsaver: Rigsaver Air Intake Shut-Off ValveДокумент2 страницыRigsaver: Rigsaver Air Intake Shut-Off Valveshahrol effendy rodziОценок пока нет

- Pressure Control Valves: Mounting Series Function Model Size Max. Flow Max. PressureДокумент3 страницыPressure Control Valves: Mounting Series Function Model Size Max. Flow Max. Pressureshahrol effendy rodziОценок пока нет

- HT400 Water Pump: Power Drive SpecificationДокумент1 страницаHT400 Water Pump: Power Drive Specificationshahrol effendy rodziОценок пока нет

- Hoses - and - Couplers PDFДокумент4 страницыHoses - and - Couplers PDFshahrol effendy rodziОценок пока нет

- Fluid Power Design Data SheetДокумент2 страницыFluid Power Design Data Sheetshahrol effendy rodziОценок пока нет

- Business ProfileДокумент6 страницBusiness Profilerajesh kothariОценок пока нет

- Basalt Catalogue-CДокумент4 страницыBasalt Catalogue-Cdanny buiОценок пока нет

- Bollard Column Base Plate (Fixed Type)Документ15 страницBollard Column Base Plate (Fixed Type)GANESHОценок пока нет

- Powder Coating Removal Process: Mechanical (Abrasive Action) ( Explained Below in Detailed)Документ1 страницаPowder Coating Removal Process: Mechanical (Abrasive Action) ( Explained Below in Detailed)Ram TejaОценок пока нет

- General Chemistry Grade 12 ModuleДокумент86 страницGeneral Chemistry Grade 12 ModuleprincessssmtlbОценок пока нет

- Francisco Oringo, Sr. Elementary School: Cognitive DomainДокумент2 страницыFrancisco Oringo, Sr. Elementary School: Cognitive DomainPrecilla HalagoОценок пока нет

- Ce Job Mum 19 000930 003Документ18 страницCe Job Mum 19 000930 003sandeep devabhaktuniОценок пока нет

- Chemistry How To Make Stuff PDFДокумент184 страницыChemistry How To Make Stuff PDF2967449CEEОценок пока нет

- Cascade Data Sheet PDFДокумент28 страницCascade Data Sheet PDFvisutsiОценок пока нет

- CH 3 Chemical Reaction WorksheetДокумент19 страницCH 3 Chemical Reaction WorksheetStephanus AbednegoОценок пока нет

- Mineral Processing Lab ManualДокумент11 страницMineral Processing Lab ManualChimwemwe KaongaОценок пока нет

- Cal OSHA Handbook 2022Документ92 страницыCal OSHA Handbook 2022Russell SadlerОценок пока нет

- BecherДокумент7 страницBechervalholОценок пока нет

- SILVER-WPS-GESA-09 5mm To 28mm SAW BW P1.2 TO P1.2 - PQR-0052-W-18Документ2 страницыSILVER-WPS-GESA-09 5mm To 28mm SAW BW P1.2 TO P1.2 - PQR-0052-W-18Abdulmecit YetisОценок пока нет

- Copper-Brazed Steel Tubing: Standard Specification ForДокумент4 страницыCopper-Brazed Steel Tubing: Standard Specification ForSofiaJabadanEspulgar100% (1)

- International Earth Science Olympiad (IESO) : RocksДокумент14 страницInternational Earth Science Olympiad (IESO) : RocksansariОценок пока нет

- Unit-5 PTДокумент136 страницUnit-5 PTTanay NaikОценок пока нет

- KSI Discount List 2019 - SCS Filtration SpecialДокумент2 страницыKSI Discount List 2019 - SCS Filtration SpecialSebastian GanciОценок пока нет

- High Performance SeriesДокумент8 страницHigh Performance SeriesRonCarОценок пока нет

- Diamond Trainee Manual 901190 2 PDF FreeДокумент242 страницыDiamond Trainee Manual 901190 2 PDF Freeswaters98Оценок пока нет

- Advances in Materials Technology For Fossil Power PlantsДокумент1 121 страницаAdvances in Materials Technology For Fossil Power Plantsadadamovicines100% (5)

- IGCSE Prep - 4Документ17 страницIGCSE Prep - 4Yoel Friady HutabaratОценок пока нет

- Tianjin Soright Technology Product CatalogueДокумент7 страницTianjin Soright Technology Product Cataloguecacalot93Оценок пока нет

- Notes of CH 2 Is Matter Around Us Pure - Class 9th ScienceДокумент9 страницNotes of CH 2 Is Matter Around Us Pure - Class 9th SciencepjatinОценок пока нет

- Lecture 5Документ20 страницLecture 5يوسف عادل حسانينОценок пока нет

- 175 026510Документ2 страницы175 026510Abu Anas M.SalaheldinОценок пока нет

- Poly Tetra Flu Oro EthyleneДокумент15 страницPoly Tetra Flu Oro Ethylenevinod.veeranki6129Оценок пока нет

- Avt 200 #1 Aircarft StructureДокумент99 страницAvt 200 #1 Aircarft StructureStrause Vince Jansen RetuyaОценок пока нет