Академический Документы

Профессиональный Документы

Культура Документы

Ansi B31.4

Загружено:

Andres Antonio Moreno CastroОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Ansi B31.4

Загружено:

Andres Antonio Moreno CastroАвторское право:

Доступные форматы

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

The American Society of

Mechanical Engineers

A N A M E R I C A N

N A T I O N A L

S T A N D A R D

PP

IELN

I ETRANSPORA ilTO

IN

SYSTEMS FOR LIQUID

HYDROCARBONS A

OTHER LIQUIDS

ASME CODE FOR PRESSURE PIPING, B31

ASME B31.4-1888 Edion

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

Date of Issuance: April 30, 1999

Mandatory Date: October 31, 1999

The 1998 Edition of this Code is being issued with an automatic update service that

includes Addenda,Interpretations,and Cases. The next Editionis scheduled for publication

in 2001.

The use of Addenda allows revisions made in response to public review comments or

committee actions to be published on a regular basis;revisions published in Addenda will

become effective 6 months after the Date of Issuance of the Addenda.

ASME issues writtenreplies to inquiries concerning interpretationsof technical aspects

of the Code. The Interpretations are published in a separate supplement.

Periodically certain actions of the ASME B31 Committee will be published as Cases.

While these Cases do not constitute formal revisions of the Code, they may be used in

specifications, or otherwise, as representing considered opinions of the Committee. The

Cases are published in a separate supplement.

The user of the Code will note that metric equivalents of U.S. Customary units appear

in many places in this Code. The values statedin U.S. Customary units are tobe regarded

as the standard, unless otherwise agreed between contracting parties.

ASME is the registered trademark of The American Society of Mechanical Engineers.

This code or standard was developed under procedures accredited as meeting the criteria for American

National Standards. The.Standards Committee that approved the code or standard was balanced to assure that

individuals from competent and concerned interests have had an opportunity to participate. The proposed code

or standard was made available for public review and comment which provides an oppoltunity for additional

public input from industry, academia, regulatory agencies, and the public-at-large.

ASME does not “approve,” “rate,” or “endorse” any item, construction, proprietary device, or activity.

ASME does not take any position with respect to the validity of any patent rights asserted in connection with

any items mentioned in this document, and does not undertake to insure anyone utilizing a standard against

liability for infringement of any applicable Letters Patent, nor assume any such liability. Users of a code or

standard are expressly advised that determination of the validity of any such patent rights, and the risk of

infringement of such rights, is entirely their own responsibility.

Participation by federal agency representative(s) or person(s) affiliated with industry is not to be interpreted

as government or industry endorsement of this code or standard.

ASME accepts responsibility for only those interpretations issued in accordance with governing ASME

procedures and policies which preclude the issuance of interpretations by individual volunteers.

No part of this document may be reproduced in any form,

in an electronic retrieval system or otherwise,

without the prior written permission of the publisher.

The American Society of Mechanical Engineers

Three Park Avenue, New York, NY 10016-5990

Copyright 0 1999 by

THE AMERICAN SOCIETY OF MECHANICAL ENGINEERS

All Rights Reserved

Printed in U.S.A.

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

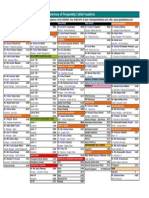

CONTENTS

Foreword ................................................................................. xi

...

Personnel ................................................................................. x111

Introduction ............................................................................... wii

Summary of Changes ...................................................................... xix

Chapter I Scope and Definitions

400 GeneralStatements ......................................................... 1

400.1 scope ..................................................................... 1

400.2 Definitions ................................................................. 2

Figures

400.1.1 DiagramShowingScope of ASME B31.4 ExcludingCarbonDioxide

PipelineSystems(SeeFig . 400.1.2) ...................................... 3

400.1.2 DiagramShowingScope of ASME B31.4 for CarbonDioxidePipeline

Systems ................................................................. 4

Chapter I1 Design

Part I Conditions and Criteria ................................................... 9

401 DesignConditions ......................................................... 9

401.1 General ................................................................... 9

401.2 Pressure ................................................................... 9

401.3 Temperature ............................................................... 9

40 1.4 AmbientInfluences ......................................................... 9

401.5 Dynamic Effects ........................................................... 9

40 1.6 Weight Effects ............................................................. 9

40 1.7 ThermalExpansionandContractionLoads .................................. 10

401.8 RelativeMovement of Connected Components ............................... 10

402 DesignCriteria ............................................................ 10

402.1 General ................................................................... 10

402.2 Pressure-TemperatureRatings for PipingComponents ........................ 10

402.3 AllowableStressesandOtherStressLimits ................................. 11

402.4 Allowances ................................................................ 14

402.5 FracturePropagationinCarbonDioxidePipelines ............................ 14

Part 2 PressureDesign of PipingComponents .................................... 14

403 Criteria for PressureDesign of PipingComponents .......................... 14

404 PressureDesign of Components ............................................ 14

404.1 StraightPipe .............................................................. 14

404.2 CurvedSegments of Pipe .................................................. 16

404.3 Intersections ............................................................... 16

404.5 PressureDesign of Flanges ................................................. 24

404.6 Reducers .................................................................. 24

404.7 PressureDesign of OtherPressureContainingComponents ................... 24

Part 3 DesignApplications of PipingComponentsSelectionand Limitations ...... 25

...

111

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

Chapter I1 Design(Cont’d)

405 Pipe ....................................................................... 25

405.2 MetallicPipe .............................................................. 25

406 Fittings.Elbows.Bends.andIntersections ................................... 25

406.1 Fittings .................................................................... 25

406.2 Bends.Miters.andElbows ................................................. 25

406.3 Couplings ................................................................. 26

406.4 Reductions ................................................................ 26

406.5 Intersections ............................................................... 26

406.6 Closures ................................................................... 26

407 Valves .................................................................... 27

407.1 General ................................................................... 27

407.8 SpecialValves ............................................................. 27

408 Flanges.Facings.Gaskets.andBolting ...................................... 27

408.1 Flanges .................................................................... 27

408.3 FlangeFacings ............................................................ 27

408.4 Gaskets ................................................................... 27

408.5 Bolting .................................................................... 28

409 Used PipingComponentsandEquipment .................................... 28

Part 4 Selection andLimitation of PipingJoints ................................. 28

41 1 WeldedJoints ............................................................. 28

41 1.2 ButtWelds ................................................................ 28

412 FlangedJoints ............................................................. 28

412.1 General ................................................................... 28

414 ThreadedJoints ............................................................ 28

414.1 General ................................................................... 28

418 Sleeve.Coupled.andOtherPatentedJoints .................................. 29

418.1 General ................................................................... 29

Part 5 Expansion.Flexibility.StructuralAttachments.Supports.and

Restraints .............................................................. 29

419 ExpansionandFlexibility ................................................... 29

419.1 General ................................................................... 29

419.5 Flexibility ................................................................. 29

419.6 Properties ................................................................. 29

419.7 Analysis ................................................................... 30

420 Loads onPipeSupportingElements ......................................... 33

420.1 General ................................................................... 33

421 DesignofPipeSupportingElements ........................................ 33

421.1 Supports.Braces.andAnchors .............................................. 33

Part 6 AuxiliaryandOtherSpecificPiping ....................................... 33

422 DesignRequirements ....................................................... 33

422.3 InstrumentandOtherAuxiliaryLiquidPetroleum or LiquidAnhydrous

AmmoniaPiping ......................................................... 33

422.6 PressureDisposalPiping ................................................... 33

Figures

404.3.1(b)(3) ReinforcedExtrudedOutlets ................................................ 17

404.3.l(c)( 1) Welding Details forOpeningsWithCompleteEncirclementTypesof

Reinforcement ........................................................... 19

WeldingDetailsforOpeningsWithLocalizedTypeReinforcement ........... 20

iv

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

Chapter I1 Design

(Cont’d)

WeldingDetailsforOpeningsWithoutReinforcementOther Than That

inHeaderandBranchWalls ............................................. 21

404.3.1(d)(2) ReinforcementofBranchConnections ....................................... 23

419.6.4(c) FlexibilityFactor k andStressIntensificationFactor i ........................ 31

Tables

402.3.1(a) TabulationofExamplesofAllowableStresses for Reference Use in

PipingSystemsWithintheScope of ThisCode ........................... 12

402.4.3 Weld JointFactor E ....................................................... 15

404.3.1(c) DesignCriteriaforWeldedBranchConnections ............................. 21

Chapter III Materials

423 Materials . GeneralRequirements ......................................... 35

423.1 AcceptableMaterialsandSpecifications ..................................... 35

423.2 Limitations on Materials .................................................... 35

425 MaterialsApplied to MiscellaneousParts .................................... 35

425.3 Gaskets ................................................................... 35

425.4 Bolting .................................................................... 35

Table

423.1 MaterialStandards ........................................................ 36

Chapter IV DimensionalRequirements

426 DimensionalRequirementsforStandardandNonstandardPiping

Components .............................................................. 39

426.1 StandardPipingComponents ............................................... 39

426.2 NonstandardPipingComponents ............................................ 39

426.3 Threads ................................................................... 39

Table

426.1 DimensionalStandards ..................................................... 40

Chapter V Construction.Welding.andAssembly

434 Construction ............................................................... 41

434.1 General ................................................................... 41

434.2 Inspection ................................................................. 41

434.3 RightofWay ............................................................. 41

434.4 Handling.Hauling.Stringing.andStoring ................................... 41

434.5 DamagetoFabricatedItemsandPipe ....................................... 41

434.6 Ditching ................................................................... 42

434.7 Bends.Miters.and Elbows ................................................. 42

434.8 Welding ................................................................... 43

434.9 Tie-In ..................................................................... 47

434.10 Installation of Pipe inthe Ditch ............................................ 47

434.11 Backfilling ................................................................. 47

434.12 Restoration of Right of WayandCleanup ................................... 48

434.13 SpecialCrossings .......................................................... 48

434.14 InlandCoastalWaterConstruction .......................................... 49

434.15 BlockandIsolatingValves ................................................. 49

434.16 ConnectionstoMainLines ................................................. 50

434.17 ScraperTraps .............................................................. 50

434.18 LineMarkers .............................................................. 50

434.19 CorrosionControl .......................................................... 50

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

Chapter V Construction.

Welding.

andAssembly

(Cont’d)

434.20 PumpStation.TankFarm. and TerminalConstruction ........................ 50

434.21 Storage and Working Tankage .............................................. 51

434.22 Electrical Installations ...................................................... 52

434.23 Liquid

Metering ........................................................... 52

434.24 Liquid Strainers and Filters ................................................. 52

435 Assembly of PipingComponents ............................................ 53

435.1 General ................................................................... 53

435.2 Bolting

Procedure .......................................................... 53

435.3 PumpingUnitPiping ....................................................... 53

435.4 Manifolds ................................................................. 53

435.5 AuxiliaryLiquidPetroleum. Carbon Dioxide.LiquidAnhydrous

Ammonia. or LiquidAlcoholPiping ...................................... 53

Figures

434.8.6(a)-( I ) AcceptableButtWeldedJointDesign for EqualWallThicknesses ............ 45

434.8.6(a)-(2) AcceptableButtWelded Joint DesignforUnequalWallThicknesses ......... 46

434.8.6(b) RecommendedAttachmentDetails of Flanges ................................ 48

Table

434.qa) Minimum Cover for Buried Pipelines ....................................... 43

Chapter VI InspectionandTesting

436 Inspection ................................................................. 55

436.1 General ................................................................... 55

436.2 Qualification of Inspectors .................................................. 55

436.5 Type and Extent of ExaminationRequired .................................. 55

436.6 Repair of Defects .......................................................... 56

437 Testing .................................................................... 56

437.1 General ................................................................... 56

437.4 Test Pressure .............................................................. 56

437.6 Qualification Tests ......................................................... 57

437.7 Records ................................................................... 58

Chapter VI1 OperationandMaintenanceProcedures

450 OperationandMaintenanceProcedures Affecting theSafety of Liquid

Transportation Piping Systems ............................................ 59

450.1 General ................................................................... 59

450.2 Operation andMaintenancePlansand Procedures ............................ 59

45 1 PipelineOperationand Maintenance ........................................ 60

451.1 Operating Pressure ......................................................... 60

451.2 Communications ........................................................... 60

45 1.3 Markers ................................................................... 60

45 I .4 RightofWayMaintenance ................................................. 60

451.5 Patrolling .................................................................. 60

45 1.6 PipelineRepairs ........................................................... 60

45 1.7 Derating a Pipelineto a Lower Operating Pressure .......................... 64

45 1.8 Valve Maintenance ......................................................... 64

45 1.9 Railroads andHighways Crossing Existing Pipelines ......................... 64

45 1.IO Inland Waters PlatformRisers .............................................. 65

452 PumpStation.Terminal.and Tank Farm OperationandMaintenance ......... 65

452.1 General ................................................................... 65

452.2 Controls andProtectiveEquipment .......................................... 65

vi

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

Chapter VI1 OperationandMaintenanceProcedures(Cont’d)

452.3 Storage Vessels ............................................................ 65

452.4 Storage of Combustible Materials ........................................... 65

452.5 Fencing ................................................................... 65

452.6 Signs ...................................................................... 65

452.7 PreventionofAccidentalIgnition ........................................... 65

453 Corrosion Control .......................................................... 66

454 EmergencyPlan ........................................................... 66

455 Records ................................................................... 67

456 Qualifying aPiping System for aHigher Operating Pressure ................. 67

457 AbandoningaPiping System ............................................... 67

Figure

45 1.6.2(a)(7) ParametersUsed in Analysis of the Strength of Corroded Areas .............. 62

Chapter VI11 CorrosionControl

460 General ................................................................... 69

46 1 External Corrosion Control for Buried or Submerged Pipelines ............... 69

461.1 New Installations .......................................................... 69

461.2 Existing Piping Systems .................................................... 71

461.3 Monitoring ................................................................ 71

462 Internal Corrosion Control .................................................. 72

462.1 New Installations .......................................................... 72

462.2 Existing Piping Systems .................................................... 72

462.3 Monitoring ................................................................ 72

463 External Corrosion Control for PipingExposed to Atmosphere ............... 73

463.1 New Installations .......................................................... 73

463.2 Existing Piping Systems .................................................... 73

463.3 Monitoring ................................................................ 73

464 Corrective Measures ........................................................ 73

465 Records ................................................................... 73

Chapter IX OffshoreLiquidPipeline Systems

A400 General Statememts ........................................................ 75

A400.1 scope ..................................................................... 75

A400.2 Definitions ................................................................. 75

A40 1 Design Conditions ......................................................... 76

A401.1 General ................................................................... 76

A40 1.9 Installation Design Considerations ........................................... 76

A401.10 Operational Design Considerations .......................................... 77

A401.11 Hydrostatic Test Design Considerations ...................................... 78

A401.12 Route Selection Considerations ............................................. 78

A402 Design Criteria ............................................................ 79

A402.3 Allowable Stresses and Other Stress Limits ................................. 79

A402.4 Allowances ................................................................ 83

A404 Pressure Design of Components ............................................ 83

A404.1 Straight Pipe .............................................................. 83

A404.3 Intersections ............................................................... 83

A405 Pipe ....................................................................... 83

A405.2 Metallic Pipe .............................................................. 83

A405.3 Flexible Pipe .............................................................. 84

A406 Fittings.Elbows.Bends.and Intersections ................................... 84

vii

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

Chapter IX Offshore Liquid Pipeline Systems (Cont’d)

A406.2 Bends.Miters.and Elbows ................................................. 84

A406.4 Reductions ................................................................ 84

A406.6 Closures ................................................................... 84

A407 Valves .................................................................... 84

A407.1 General ................................................................... 84

A408 Flanges.Facings.Gaskets.andBolting ...................................... 84

A408.1 Flanges .................................................................... 84

A408.3 Flange Facings ............................................................ 84

A409 UsedPiping Components andEquipment .................................... 84

A410 Other Design Considerations ................................................ 84

A4 10.1 PigsandInternalInspection Tools .......................................... 84

A410.2 Special Components ........................................................ 84

A414 Threaded Joints ............................................................ 85

A414.1 General ................................................................... 85

A419 Expansionand Flexibility .................................................... 85

A42 1 Design of Pipe-Supporting Elements ........................................ 85

A423 Materials - General Requirements ......................................... 85

A423.1 Acceptable Materials and Specifications ..................................... 85

A423.2 Limitations on Materials .................................................... 85

A434 Construction ............................................................... 85

A434.2 Inspection ................................................................. 85

A434.3 Right-of-way .............................................................. 85

A434.4 Handling.Hauling.Stringing.and Storing ................................... 85

A434.6 Ditching ................................................................... 85

A434.7 Bends.Miters. and Elbows ................................................. 86

A434.8 Welding ................................................................... 86

A434.11 Backfilling ................................................................. 86

A434.13 Special Crossings .......................................................... 86

A434.14 Offshore Pipeline Construction .............................................. 86

A434.15 BlockandIsolatingValves ................................................. 87

A434.18 Line

Markers .............................................................. 87

A436 Inspection ................................................................. 87

A436.2 Qualification of Inspectors .................................................. 87

A436.5 Type and Extent of ExaminationRequired .................................. 87

A437 Testing .................................................................... 87

A437.1 General ................................................................... 87

A437.4 Test Pressure .............................................................. 87

A437.6 Qualification

Tests ......................................................... 87

A437.7 Records ................................................................... 88

A450 OperationandMaintenance Procedures Affecting the Safety of Liquid

Transportation Piping Systems ............................................ 88

A450.2 OperationandMaintenancePlansandProcedures ............................ 88

A45 1 PipelineOperation and Maintenance ........................................ 88

A45 1.3 Markers ................................................................... 88

A45 1.4 Right-of-way Maintenance ................................................. 88

A45 1.5 Patrolling .................................................................. 88

A45 1.6 Pipeline

Repairs ........................................................... 88

A45 1.7 Derating a Pipeline to a Lower Operating Pressure .......................... 89

A45 1.8 Valve Maintenance ......................................................... 89

A45 1.9 Railroads and Highways Crossing Existing Pipelines ......................... 89

viii

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

Chapter IX Offshore Liquid Pipeline Systems (Cont’d)

A451.10 OffshorePipelineRisers .................................................... 89

A451.11 Inspection ................................................................. 89

A452 OffshorePlatform.PumpStation.Terminal.andTank Farm Operationand

Maintenance ............................................................. 89

A452.5 Fencing ................................................................... 89

A452.7 PreventionofAccidentalIgnition ........................................... 89

A454 EmergencyPlan ........................................................... 89

A460 General ................................................................... 89

A46 1 ExternalCorrosionControlforOffshoreSubmergedPipelines ................ 90

A461.1 New Installations .......................................................... 90

A46 1.3 Monitoring ................................................................ 91

A463 ExternalCorrosionControl for OffshorePipingSystemsExposedto

AtmosphericConditions .................................................. 91

A463.1 New Installations .......................................................... 91

Table

A402.3.5(a) DesignFactorsforOffshorePipelineSystems ............................... 80

Appendices

A ReferencedStandards ....................................................... 93

B Submittal of TechnicalInquiriestotheB31PressurePipingCommittee ....... 97

Index .................................................................................... 99

ix

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

FOREWORD

Theneedfor anationalcodeforpressurepiping intensive review of the 1942 code, and a revised code

becameincreasinglyevidentfrom1915to1925.To wasapprovedandpublishedinFebruary1951with

meet this needtheAmericanEngineeringStandards thedesignation ASAB31.1-1951,whichincluded:

Committee(laterchangedtotheAmericanStandards (a) a general revision and extension of requirements

Association)initiatedProject B31inMarch 1926at toagree with practicescurrentatthetime;

therequest of TheAmericanSocietyofMechanical

Engineers, and with that society as sole sponsor. After (6) revisionofreferencestoexistingdimensional

severalyears’workbySectionalCommitteeB31and standardsandmaterialspecifications,andtheaddition

its subcommittees, a first edition was published in 1935 of referencesto new ones;and

as an American Tentative Standard Code for Pressure (c) clarification of ambiguous or conflicting require-

Piping. ments.

Arevisionoftheoriginaltentativestandardwas Supplement No. 1 to B3 1.1 was approved and pub-

begun in 1937. Several more years’ effort was given to lished in1953 as ASA B31.la-1953. This Supplement

securing uniformity between sections and to eliminating andotherapprovedrevisionswereincludedinanew

divergentrequirementsanddiscrepancies, as well as edition of B31.1 published in 1955 with the designation

tokeepingthecodeabreastofcurrentdevelopments ASAB31.1-1955.

inweldingtechnique,stresscomputations,andrefer- A review by B31 Executive and Sectional Committees

ences tonew dimensional and material standards. During in1955resultedin a decision to develop and publish

thisperiodanewsectionwasaddedonrefrigeration industrysections as separatecodedocuments of the

piping,preparedincooperationwithTheAmerican American Standard B31 Code for Pressure Piping. ASA

Society of Refrigeration Engineers and complementing B31.4-1959wasthefirstseparatecodedocument for

the American Standard Code for Mechanical Refrigera- Oil Transportation Piping Systems and superseded that

tion.

This

workculminated in the

1942

American part of Section 3 of the B3 1.1- 1955 code covering Oil

StandardCodeforPressurePiping. TransportationPipingSystems. In 1966B31.4was

Supplements 1 and 2 of the

1942 code,

which revised to expand coverage on welding, inspection, and

appearedin1944and1947,respectively,introduced testing, and to add new chapters covering construction

new dimensional and material standards, a new formula requirements and operation and maintenance procedures

forpipewallthickness,andmorecomprehensivere- affecting the safety of the piping systems. This revision

quirementsforinstrumentandcontrolpiping.Shortly was published with the designation USAS B31.4-1966,

after the 1942 code was issued, procedures were estab- Liquid Petroleum Transportation Piping Systems, since

lishedforhandlinginquiriesthatrequireexplanation theAmericanStandardsAssociationwasreconstituted

or interpretation of code requirements, and for publish- as theUnited States ofAmericaStandardsInstitute

ingsuchinquiriesandanswers in Mechanical Engi- in1966.

neering fortheinformationofallconcerned. TheUnitedStates of AmericaStandardsInstitute,

Continuing increases in the severity of service condi- Inc.,changeditsname,effectiveOctober 6, 1969,to

tions, with concurrentdevelopments ofnew materials theAmericanNationalStandardsInstitute,Inc.,and

and designs equal to meeting these higher requirements, USASB31.4-1966wasredesignated as ANSIB31.4-

hadpointedtotheneedby1948formoreextensive 1966.TheB31SectionalCommittee was redesignated

changes inthe code than could be provided by supple- as American National Standards Committee B31 Code

ments alone. The decision was reachedby the American forPressurePiping,and,becauseofthewidefield

StandardsAssociationandthesponsor to reorganize involved, more than 40 different engineering societies,

the Sectional Committee and its several subcommittees, governmentbureaus,tradeassociations,institutes,and

and to invitethevariousinterestedbodiestoreaffirm the like hadoneormore representatives on Standards

their representativesor to designate new ones. Following CommitteeB31,plusafew“IndividualMembers”

itsreorganization,SectionalCommitteeB31made an to representgeneralinterests.Codeactivitieswere

xi

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

subdividedaccordingtothescopeoftheseveralsec- Following publication of the 1986 Edition, clarifying

tions, and general direction of Code activities rested with and editorial revisions were made to improve the text.

StandardsCommittee B31 officersandanExecutive Additionally, references to existing standards and mate-

Committee whose membership consisted principally of rialspecificationswererevised,andnewreferences

StandardsCommitteeofficersandchairmen of

the wereadded.Theserevisionsledtothepublicationof

SectionandTechnicalSpecialistsCommittees. an addenda toB3 1.4,which was approved and published

TheANSI B31.4-1966Code wasrevisedandpub- in 1987 as ASMWANSI B31.4a-1987.

lished in 1971 with the designation ANSI B31.4-1971. The 1989 Editionof B31.4 wasan inclusion ofthe

TheANSI B31.4-1971 Codewasrevisedand pub previouslypublishedaddendaintothe 1986 Edition.

lished in 1974 with the designation ANSI B31.4-1974. Following publication of the 1989 Edition, clarifying

InDecember 1978, AmericanNationalStandards revisions were made to improve the text. Additionally,

Committee B31 was converted to an ASME Committee references to existing standards and material specifica-

with procedures accredited by ANSI. The 1979 revision tions were revised and updated. These revisions led to

wasapprovedbyASMEandsubsequentlybyANSI thepublicationofanaddendato B31.4, whichwas

onNovember 1, 1979, withthedesignation ANSV approved and published in 1 9 9 1 as ASME B31.4a-1991.

ASME B31.4-1979. The 1992 Editionof B31.4 was an inclusion ofthe

Following publicationof the 1979 Edition, the B3 1.4 previouslypublishedaddendaintothe 1989 Edition

Section committee began work on expanding the scope and a revision to valve maintenance. The 1992 Edition

of the code to cover requirements for the transportation wasapprovedbytheAmericanNationalStandards

ofliquidalcohols.Referencestoexistingdimensional Institute onDecember 15, 1992, anddesignated as

standards and material specifications were revised, and ASME B31.4-1992 Edition.

new references were added. Other clarifying and edito- The 1998 Editionof B31.4 isan inclusion of the

rial revisions were made in order to improve the text. previouslypublishedaddendaintothe 1992 Edition.

These revisions led to the publication of two addenda Also included in this Edition are other revisions (noted

to B31.4. Addenda “b” to B31.4 was approvedand by the (98) margin notes) and the addition of Chapter

publishedin 1981 as ANSVASME B31.4b-1981.Ad- IX, Offshore Liquid Pipeline Systems. This 1998 Edition

denda “c” to B31.4 wasapprovedandpublishedin wasapprovedbytheAmericanNationalStandards

1986 as ANSVASME B31.4~-1986. Institute onNovember 11, 1998, anddesignated as

The 1986 Edition of B31.4 was an inclusion of the ASME B31.4-1998 Edition.

two previously published addenda into the1979 Edition.

xii

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

ASME CODE FOR PRESSURE PIPING, B31

OFFICERS

L. E. Hayden, Jr, Chair

D.R Frikken, Vice Chair

J. Yarmush, Secretary

COMMITTEE PERSONNEL

P. A. Bouquin, Pleasantville, New York

J. D. Byers, Mobile E & P Technology, Dallas, Texas

P. D. Flenner, Consumers Energy, Covert, Michigan

D. M.Fox, TU Electric, Dallas, Texas

D.R Frikken, Solutia Inc., St Louis, Missouri

P. H. Gudner, Wilmington, Delaware

R W. Hmpt, Pressure Piping Engineering Associates. Inc., Foster City, California

L. E. Hayden, Jr., Victaulic Company of America, Easton, Pennsylvania

R R HomOann, Federal Energy Regulatory Commission, Washington, District of Columbia

B. P. Hdbrodq D.B. Riley Inc., Worcester, Massachusetts

G. A. Jolly, Vogt Valve Co., Louisville, Kentucky

K. Kaye, West Vancouver. British Columbia, Canada

W.B. MrCebce, Houston, Texas

E. Michalopoulos, Hartford Steam Boiler Inspection and Insurance CO., Hartford. Connecticut

A. D. Nance A.D. Nance Associates, Inc., Evans, Georgia

W.V. Richards, William V. Richards, Inc., Lincolnshire, Illinois

L. J. Schmitz, Phillips Pipe Line Co., Bartlesville, Oklahoma

G. W. Spohn UI, Coleman Spohn Corp.. Cleveland, Ohio

R B. West, State of Iowa, Des Moines, Iowa

J. Yatmush, ASME International, New York, New York

B31.411 LIQUID AND SLURRY PIPING TRANSPORTATION SYSTEMS

SECTION COMMITTEE

L.J. Sehmitz, Chair, Phillips Pipe Line Co., Bartlesville, Oklahoma

K C. Bodenhamer, Vice Chair, Mid-America Pipeline Co., Tulsa, Oklahoma

P. Pertuit, UI, Vice Chair. Black Mesa Pipeline Inc., Flagstaff, Arizona

B. P. Feder, Secretory, ASME International, New York, New York

R S. BPrtield, Barfield Engineers Inc. Humble, Texas

J. P.Barrett, Conoco Inc., Ponca City, Oklahoma

L. C. Bennington Milepost Consulting Services. Inc., Mansfield, Texas

A. E. Beyer, Bechtel Corp., Houston, Texas

R R Burnett, Tulsa, Oklahoma

E. E. Cavanagh, Mustang, Engineering, Inc., Houston, Texas

J. A. Cox, Colonial Pipeline Co.. Atlanta, Georgia

R D. Denver, Deatech ConsultingCo., Houston, Texas

F. E. Fiseher, Shell Oil Products Co., Houston, Texas

E. P. Hagen, Teppco, Houston, Texas

E. G. Jones, Bechtel, San Francisco, California

D. B. Kadakia, TD Williamson Inc., Tulsa, Oklahoma

xiii

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

J. F. Kiefner, Kiefner & Associates Inc., Worthington, Ohio

A. I. MacDonald, Consulting Metallurgical Engr., Upland, California

M. H. Matheson, American Petroleum Institute. Washington, District of Columbia

T. J. O’Grady, 11, Arco Alaska Inc., Anchorage, Alaska

W. M. Olson, Gulf Interstate Engineering Co., Houston, Texas

S. R Peterson, Lakehead Pipe Line Co., Duluth, Minnesota

J. T. Powers, Parsons Energy & Chemicals, Houston, Texas

E. C. Schoenfeldt, Independence, Kansas

R. N. Tennille, Pipeline & Terminal Engineering Consultants, Houston, Texas

D. R Turner, Williams Energy Group, Tulsa, Oklahoma

L. W. Ulrich, US Department of Transportation, Washington, District of Columbia

J. E. Zimmerhanzel, Brown & Root Inc., Houston, Texas

C. Zimmeman, NTSB, Washington, District of Columbia

B31 EXECUTIVE COMMITTEE

L. E. Hayden, Jr., Chair, Victaulic Company of America, Easton, Pennsylvania

D. R Frikken, Vice Chair, Solutia, Inc.. St. Louis, Missouri

J. Yarmush, Secrerary, ASME International, New York, New York

P. D. Flenner, Consumers Energy, Covert, Michigan

A. D. Nance, A.D. Nance Associates, Inc., Evans, Georgia

B31 MATERIALS, FABRICATIONS, AND EXAMINATION TECHNICAL

COMMITTEE

P. D. Flenner, Chair, Consumers Energy, Covert, Michigan

J. Yannush, Secretary, ASME International, New York, New York

E. Michalopoulos, Hartford Steam Boiler Inspection and Insurance Company, Hartford, Connecticut

W.G. S c ~ g gE.I.

~ , du Pont de Nemours & Co., Wilmington, Delaware

R I. Seals, Berkeley, California

R J. Silvia, Process Engineering & Constructors Inc., Wanvick, Rhode Island

W.J. Sperko, Sperko Engineering Services, Inc., Greensboro, North Carolina

E. F. Summers, Jr., Babcock & Wilcox,

I Barberton, Ohio

B31 MECHANICAL DESIGN TECHNICAL COMMITTEE

R. W.Haupt, Chair, Pressure Piping Engineering AssociatesInc., Foster City, California

J. Yannush, Secretary. ASME International, New York, New York

G. A. Antaki, Westinghouse Savannah River Co., Aiken, South Carolina

C. Becht IV,Becht Engineering Co., Liberty Corner, New Jersey

J. P. Breen, Pressure Sciences Inc., Pittsburgh, Pennsylvania

J. P. Ellenberger, WFl International Inc., Houston, Texas

D. J. Fetzner, Arc0 Alaska Inc., Anchorage, Alaska

J. A. Graziano, Tennessee Valley Authority, Chattanooga, Tennessee

J. D. Hart, SSD Engmeering ConsultantsRebis, Walnut Creek, California

B. P. Holbrook, D.B. Riley Inc., Worcester, Massachusetts

W.J. Koves, UOP LLC, Des Plaines, Illinois

P. L. Lin, Wisconsin Public Service Corp., Kewaunee, Wisconsin

G. Mayers, Naval Sea Systems Comm., Arlington, Virginia

T. Q. McCawley, Charlotte, North Carolina

E. Michalopoulos, Hartford Steam Boiler Inspection and Insurance Co., Hartford, Connecticut

J. C. Minichiello, J. C. Minnichiello Consulting Inc., Lake Bluff, Illinois

A. D. Nance, A.D. Nance Associates, Inc., Evans, Georgia

T. J. O’Grady 11, Arco Alaska Inc., Anchorage, Alaska

A. W. Paulin, Paulin Research Group, The Woodlands. Texas

P. S. Rampone, Hart Design Group, Greenville, Rhode Island

R A. Robleto, Brown & Root Inc., Houston, Texas

E. C. Rodabaugh, Dublin, Ohio

M. J. Rosenfeld, Kiefner & Associates Inc., Worthington, Ohio

xiv

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

G. Stevick, Berkeley Engineering & Research Inc., Berkeley, California

Q. N. Truong, M.W. Kellogg Co., Houston, Texas

E. A. Wais, Wais and Associates Inc., Norcross, Georgia

C. E. Woods, Houston, Texas

B31 CONFERENCE GROUP

T. A. Bell, Pipeline Safety Engineer, Olympia, Washington

M.L. Brunton, KPO, Topeka, Kansas

G. Bynog, Texas Department of Labor and Standards, Austin, Texas

R A. Coomes, Department of HousinglBoiler Section, Frankfort, Kentucky

A. W. Diamond, Department of Labour & Manpower, Saint Johns, Newfoundland, Canada

M. P. Fitzpatrick, Department of Labour & Human Resources, Fredericton, New Brunswick, Canada

J. W. Creenawalt, Jr., Oklahoma Department of Labor, Oklahoma City, Oklahoma

D. I€ Hanrath, North Carolina D.O.L., Raleigh, North Carolina

C. J. Harvey, Alabama Public Service Commission, Montgomery, Alabama

D. T. Jagger, Ohio Department of Commerce, Reynoldsburg, Ohio

M.Kotb, Regie du Batiment du Quebec, Montreal, Quebec, Canada

K. T. Lau, Alberta Boiler Safety Assoc., Edmonton, Alberta, Canada

R G. Marini, New Hampshire Public Utilities Commission, Concord, New Hampshire

1. W. Mault, Manitoba Department of Labour, Winnipeg, Manitoba, Canada

A. W. Meiring, Fire and Building Boiler and Pressure Vessel Division, Indianapolis, Indiana

R F. Mullaney, Boiler and Pressure Vessel Safety Branch, Vancouver, British Columbia,Canada

W. A. Owen, North Dakota Public Service Commission, Bismarck, North Dakota

W. M. Picardo, Department of Consumer and Regulatory Affairs, Washington, District of Columbia

P. Sher, State of Connecticut, New Britain, Connecticut

H.E. Shutt, Illinois Commerce Commission, Springfield, Illinois

M.E. Skarda, Department of Labour, Little Rock, Arkansas

R L. Smith, University of South Carolina, Columbia, South Carolina

E. L. Sparrow, Board of Public Utilities, Newark, New Jersey

D. A, Starr, Department of Labor, Lincoln, Nebraska

D. Stursma, Iowa State Department of Commerce, Des Moines, Iowa

R P.Sullivan, National Board of Boiler and Pressure Vessel Inspectors, Columbus, Ohio

J. E. Troppman, Division of LaborBoiler Inspections. Denver, Colorado

R W. Vindich, Department of Labor and Industry, Harrisburg, Pennsylvania

C. ? Walters,

I . National Board of Boiler and Pressure Vessel Inspectors. Columbus, Ohio

W. A. West, Department of Labour, Charlottetown, Prince Edward Island, Canada

T. F. Wickham, Department of Labor, Providence, Rhode Island

B31 NATIONAL INTEREST REVIEW GROUP

American Boiler Manufacturers Association - R. Fletcher

American Institute of Chemical Engineers - W. C. Carnell

American Pipe Fitting Association - H. Thielsch

American Society of Heating, Refrigeration and Air Conditioning Engineers - H. R. Komblum

Chemical Manufacturers Association - D. R. Frikken

Compressed Gas Association - M. F. Melchioris

Copper Development Association - A. Cohen

Ductile Iron Pipe Research Association - T. F. Stroud

Edison Electric Institute - R. L. Williams

International District Heating Association - G. M. Von Bargen

Manufacturers Standardization Society of the Valve and Fittings Industry - R. A. Schmidt

National Association of Plumbing-Heating-Cooling Contractors- R. E. White

National Association of Regulatory Utility Commissioners- D. W. Snyder

National certified pipe Welding Bureau - J. Hansmann

xv

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

National Fire Protection Association - T. C. Lemoff

National Fluid Power Association - H. G. Anderson

pipe Fabrication Institute - L. Katz

Slurry Transport Association - P. E. Snoek

Society of Ohio Safety Engineers - J. M. Holleran

Valve Manufacturers Association - R. A. Handschumacher

xvi

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

INTRODUCTION

The ASME B31 Code for PressurePiping consists agreement isspecificallymadebetween contracting

of a number of individuallypublished Sections, each parties to use another issue, or the regulatory body

an American National Standard. Hereafter, in this Intro- having jurisdiction imposestheuse of another issue,

ductionand in thetextofthis Code Section B31.4, the latest Edition and Addenda issued at least 6 months

where the word ‘‘Code” is used without specific identi- prior to the original contract date for the firstphase

fication, it means this Code Section. of activity covering a piping system or systems shall

The Code sets forth engineering requirements deemed bethe governing document for all design, materials,

necessary for safe design and construction of pressure fabrication, erection, examination, and testing for the

piping.While safety is thebasic consideration, this pipinguntilthecompletion of theworkandinitial

factor alone will not necessarily govern the final specifi- operation.

cations for any piping system. The designer is cautioned Users of this Code are cautioned against making use

that the Code isnot a designhandbook;it does not of Code revisions without assurance thatthey are

do away with the need for the designer or for competent acceptable to theproper authorities inthe jurisdiction

engineering judgment. where the piping is to be installed.

To the greatest possible extent, Code requirements Code userswillnotethat paragraphs in the Code

for design are stated in terms of basic design principles are notnecessarilynumbered consecutively. Such dis-

and formulas. These aresupplemented as necessary continuities resultfrom following a common outline,

with specific requirements to assure uniform application insofar as practicable, for all Code Sections. In this way,

of principles and to guide selection and application of corresponding material is correspondingly numbered in

piping elements. The Code prohibits designs and prac- most Code Sections, thus facilitating reference by those

tices known to be unsafe and contains warnings where whohaveoccasion to usemorethan one Section.

caution, butnotprohibition,iswarranted. The Code is under the direction of ASME Committee

This Code Section includes: B3 1, Code for Pressure Piping, which is organized and

(a) references to acceptable material specifications operates under procedures of The American Society of

and component standards, including dimensional re- Mechanical Engineers which have beenaccredited by

quirements and pressure-temperature ratings; the American NationalStandards Institute. The Commit-

(b) requirements for design of componentsand as- teeis a continuing one and keeps all Code Sections

semblies, including pipe supports; current withnew developments in materials, construc-

( c ) requirements and data for evaluation and limita- tion, and industrial practice.Addenda are issued periodi-

tionof stresses, reactions, and movementsassociated cally. New editions are published at intervals of 3 to

with pressure, temperature changes, andother forces; 5 years.

When no Section oftheASME Code for Pressure

(d) guidance and limitations onthe selection and

Piping specifically covers a piping system, at his discre-

applicationofmaterials,components,andjoining

tion the user may select any Section determined to be

methods;

generally applicable. However, it is cautioned that

( e ) requirements for the fabrication, assembly, and supplementary requirements to the Section chosen may

erection of piping; benecessarytoprovidefor a safe pipingsystem for

cfl requirements for examination, inspection, and the intended application. Technical limitations of the

testing of piping; various Sections, legal requirements, and possible appli-

(g) procedures for operation and maintenancethat cability of other codes or standards are someofthe

are essential topublic safety; and factors to be considered by the userin determining

(h) provisions for protecting pipelines from external the applicability ofany Section of this Code.

corrosion andinternal corrosiotderosion. The Committee has established an orderly procedure

It is intended that this Edition of Code Section B31.4 to consider requests for interpretation andrevisionof

and any subsequent Addenda not be retroactive. Unless Code requirements. To receive consideration, inquiries

xvii

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

must be in writingandmust give fullparticulars (see ever, theprovisions of a Case may be used after its

Mandatory Appendix coveting preparation of technical expiration or withdrawal, providing the Case was effec-

inquiries). tive on the original contract date or was adopted before

The approved reply to an inquiry will be sent directly completionofthework,and the contracting parties

to the inquirer. In addition, the question and reply will agree to its use.

be published as part ofan Interpretation Supplement Materials are listed in the stress tablesonly when

issuedtothe applicable Code Section. sufficient usage in piping within the scope of the Code

A Case is the prescribed form of reply to an inquiry has been shown. Materials may be covered by a Case.

whenstudyindicatesthatthe Code wordingneeds Requests forlisting shall includeevidence of satisfactory

usageandspecific data to permitestablishment of

clarification or when the reply modifiesexisting require-

allowable stresses, maximum and minimum temperature

ments ofthe Code or grants permission to usenew

limits, and other restrictions. Additional criteria can be

materials or alternative constructions. Proposed Cases

found in the guidelines foraddition ofnew materials

are published in Mechanical Engineering forpublic

in the ASME Boiler and Pressure Vessel Code, Section

review. In addition, the Case will be published as part

I1 andSectionVIII,Division 1, Appendix B. (To

of a Case Supplement issuedtothe applicable Code develop usageandgain experience, unlistedmaterials

Section. may be used in accordance with para. 423.1.)

A Case is normally issued for a limited period, after Requests for interpretation and suggestions for revi-

which it may be renewed,incorporated in the Code, sion should be addressed to the Secretary, ASMEB31

or allowed to expire if there is no indication of further Committee, Three Park Avenue, New York, NY 10016

need for therequirements covered by the Case. How-

xviii

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

SUMMARY OF CHANGES

Changes given below are identified on the pages by a margin note, (W),

placed next to the affected area.

Page Location Change

iii, v-ix reflect to Updated

Contents 98 changes

xii Foreword (1) Next-to-last paragraph revised

(2) New last paragraph added

Last Introduction xviii

400.1.1 New third paragraph added

400.1.2 Subparagraph (h) revised

400.2 (1) acckkntal W s , breakaway coupling,

buckle, cold springing, column buckling,

connectors, design life, soil liquefaction,

s p , and weight coating added

(2) nominal pipe size (NPS) revised

(3) oflshore deleted

9 401.5.6 Revised

10 402.1 Second paragraph revised

11 402.3.2 Subparagraph (e) deleted

14 404.1.1 Under subparagraph (b), nomenclature for t

revised

16 404.2.2 Subparagraph (b) revised

404.3.1 Subparagraph (aX2) revised

24 404.5.1 Subparagraphs (b) and (d) revised

404.6 Subparagraph (a) revised

25 406.1.1 Subparagraphs (a) and (b) revised

26 406.4. I Revised

406.6.2 Revised

27,28 408.1.1 Subparagraphs (b) and (d) revised

408.3.1 Revised

408.4.2 Subparagraphs (a), (d), and (e) revised

408.5. I Subparagraph (b) revised

408.5.2 Revised

xix

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

Page Location Change

27, 28 414.1 Revised

3 1-33 Fig. 419.6.4(c) (1) On p. 3 1 under Description, fourth entry

revised

(2) Extruded weld tee added

(3) Note (4) revised and Note (1 1) added

36,37 Table 423.1 (1) Under Fittings, Valves, and Flanges,

B 16.5 revised

(2) Under Structural Materials, ASTM A 537

added

40 Table 426.1 B36.1OM, B36.19M, B16.5 through B16.28,

B1.l, B1.20.1, and B1.20.3 revised

42 434.6 Subparagraph (c) revised

43 Table 434.6(a) Second and third column headings revised

44 434.8.5 Subparagraph (a)(4)(d) revised

49,50 434.13.4 Subparagraph (c) revised

434.14 Revised

434.15.1 (1) Subparagraph (c) deleted

(2) Subparagraph (d) redesignated as new (c)

434.18 Revised

51 434.20.7 Revised

52 434.21.2 Subparagraph (b) revised

434.21.3 Subparagraphs (a) and (b) revised

434.21.5 Revised

434.22.1 Revised

55 436.5.1 Subparagraphs (b)(9) and(b)( 1 1)revised

60-64 451.6.1 (1) First paragraph designated as

subparagraph (a)

(2) Subparagraph (b) added

45 I .6.2

45 1.9 Subparagraph (a) revised

65 451.10 Title revised

452.4 Revised

67 455 Subparagraphs (c) and (e) revised

69 461.1.1 (1) Subparagraph (c) deleted

(2) Subparagraph (d) redesignated as new (c)

70,71 461.1.3 Subparagraph (e) revised

xx

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

Page Location Change

70,71 461.1.5 Subparagraph (a) revised

461.3 Subparagraph (a) revised

73 465 Subparagraph (b) revised

75-9 1 Chapter IX Added

93-95 Appendix A Revised in its entirety

98 B-6 Subparagraph (a) revised

102, 103 Index (1) Existing offshore entry deleted

(2) Offshore entries to reflect Chapter IX

added

NOTES:

(1) The Interpretations to ASME B31.4 issued between January 1, 1994, and December 31, 1997,

follow the last page of this Edition as a separate supplement, InterpretationsNo. 5 .

(2) After the Interpretations, a separate supplement, CasesNo. 4,follows.

xxi

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

ASME B31.4-1998Edition 400-400.1.1

CHAPTER I

SCOPE AND DEFINITIONS

400 GENERAL STATEMENTS the development of such designs and the evaluation of

complex or combined stresses. In such cases the designer

(a) This Liquid Transportation Systems Code is one is responsible for demonstrating thevalidity of his

ofseveral sections of theASME Code for Pressure approach.

Piping, B31. This Section is published as a separate 0 This Code shall not be retroactive or construed

document for convenience. This Code applies to hydro- as applying to piping systems installedbefore date of

carbons, liquidpetroleum gas, anhydrous ammonia, issuance shownon document title page insofaras design,

alcohols, and carbon dioxide. Throughout this Code materials, construction, assembly, inspection, and testing

thesesystemswill be referred to as LiquidPipeline are concerned. It is intended, however, that the provi-

Systems. sions of this Code shall be applicable within 6 months

(b) The requirements of this Code are adequate for after date of issuance to the relocation, replacement,

safetyunder conditions normally encountered inthe and uprating or otherwise changing existing piping

operation of liquid pipeline systems. Requirements for systems; and to the operation, maintenance, and corro-

all abnormal or unusual conditions are not specifically sion control ofnew or existing piping systems. After

provided for, nor are all details of engineering and Code revisions are approved by ASME and ANSI, they

construction prescribed. All work performed within the may be used by agreement between contracting parties

Scope of this Code shall comply with the safety stan- beginning with the date of issuance. Revisions become

dards expressed or implied. mandatory or minimum requirements for new installa-

(c) The primary purpose of this Code is to establish tions 6 months after date of issuance except for piping

requirements for safe design, construction, inspection, installations or components contracted for or under

testing, operation, and maintenanceof liquid pipeline construction prior to the end of the 6 month period.

systems forprotection of thegeneralpublicandop- (8) The users of this Code are advised that in some

erating company personnel as well as forreasonable areas legislation may establish governmental jurisdiction

protection of the piping system against vandalism and over the subject mattercovered by this Code and are

accidental damage by others and reasonable protection cautioned against making use of revisions that are less

of the environment. restrictive than former requirements withouthaving

(d) This Code isconcernedwith employee safety assurance thattheyhavebeenacceptedbytheproper

to the extent that it is affected by basic design, quality authorities inthe jurisdiction wherethepiping isto

ofmaterialsand workmanship, and requirements for be installed. The Department of Transportation, United

construction, inspection, testing, operation, and mainte- States ofAmerica, rules governing the transportation

nanceofliquid pipeline systems. Existing industrial by pipeline in interstate andforeign commerce of

safetyregulationspertainingtowork areas, safe work petroleum, petroleum products, and liquids such as

practices,andsafety devices are not intended to be anhydrous ammonia or carbon dioxide are prescribed

supplanted by this Code. under Part 195 - Transportation of Hazardous Liquids

(e) The designer is cautioned thatthe Code isnot by Pipeline, Title 49 - Transportation, Code of Federal

a design handbook. The Code does not do awaywith Regulations.

theneed for the engineer or competent engineering

judgment. The specific design requirements of the Code 400.1 Scope

usuallyrevolvearound a simplified engineering ap-

proachto a subject. It is intendedthat a designer 400.1.1 This Code prescribes requirements for the (98)

capable of applying morecomplete and rigorous analysis design, materials, construction, assembly, inspection,

tospecial or unusualproblems shall have latitude in and testing of piping transporting liquids such as crude

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

400.1.14003 ASME B31.4-1998 E d i t h

oil, condensate,natural gasoline, naturalgasliquids, tanks, other producing facilities, and pipelines intercon-

liquefied petroleum gas, carbon dioxide, liquid alcohol, nectingthese facilities;

liquid anhydrous ammonia, and liquid petroleum prod- ( e ) petroleumrefinery,natural gasoline, gas pro-

uctsbetweenproducers’lease facilities, tank farms, cessing, ammonia, carbon dioxide processing, and bulk

natural gas processing plants, refineries,stations, ammo- plant piping, except as covered under para. 400.1.1(c);

nia plants, terminals (marine, rail, and truck), and other (f) gas transmission and distribution piping;

deliveryandreceiving points. (See Fig. 400.1.1.) ( g ) thedesignandfabrication of proprietaryitems

Piping consists of pipe, flanges,bolting,gaskets, of equipment, apparatus, or instruments, except as lim-

valves,relief devices, fittings, andthepressure con- ited by para. 423.2.4(b);

taining partsof other pipingcomponents. It also includes (h) ammoniarefrigeration piping systems provided

hangers and supports, and other equipment items neces- for in ASME B31.5, Refrigeration Piping Code;

sarytoprevent overstressing thepressure containing ( i ) carbon dioxide gathering andfield distribution

parts.It does notincludesupport structures such as system.

frames of buildings, stanchions, or foundations, or any

equipmentsuch as defined in para. 400.1.2(b). 400.2 Definitions (98)

Requirementsfor offshore pipelines are found in

Chapter IX. Some of the more common terms relating to piping

Alsoincluded within thescope of thisCodeare: are definedbelow.’

( a ) primary and associated auxiliary liquid petroleum accidentalloads: anyunplannedload or combination

and liquid anhydrous ammonia piping at pipeline termi- of unplannedloadscaused by humanintervention or

nals (marine, rail, and truck), tank farms, pump stations, naturalphenomena.

pressure reducingstations, and metering stations, includ-

ing scrapertraps, strainers, and proverloops; breakawaycoupling: a component installed in the

(6) storage andworkingtanks,includingpipe-type pipeline to allowthepipeline to separate when a

storage fabricatedfrompipe and fittings,andpiping predeterminedaxialload is applied to the coupling.

interconnectingthese facilities; buckle: a conditionwherethepipeline has undergone

(c) liquid petroleum and liquid anhydrous ammonia sufficient plastic deformation to cause permanent wrin-

pipinglocated on property which has been set aside kling inthepipewall or excessive cross-sectional

for such piping within petroleum refinery, natural gaso- deformation caused by loads acting alone or in combina-

line,gasprocessing,ammonia, andbulk plants; tionwithhydrostaticpressure.

(d) those aspects of operationandmaintenance of

LiquidPipeline Systems relating to thesafetyand carbondioxide: a fluid consisting predominantlyof

protection of the generalpublic,operatingcompany carbon dioxide compressed above its critical pressure

personnel, environment, property, andthepiping sys- and, for the purpose of this Code, shall be considered

tems [see paras. 4 0 ( c ) and (d)]. to be a liquid.

cold springing: deliberate deflection of piping, within

(98) 400.1.2 This Code does notapply

to: its yield strength, to compensate for anticipated thermal

(a) auxiliary piping, such as water, air, steam, lubri- expansion.

cating oil, gas,and fuel;

(6) pressure vessels, heat exchangers, pumps, meters, columnbuckling: buckling of a beam or pipeunder

andothersuchequipmentincludinginternalpiping compressive axialload in whichloads cause unstable

and connections forpipingexcept as limited by para. lateral deflection, also referred to as upheaval buckling.

423.2.4(b); connectors: component, exceptflanges,used for the

( c ) pipingdesignedforinternalpressures: purpose of mechanically joining two sections of pipe.

( I ) at or below 15 psi (1 bar)gagepressure

regardless of temperature; defect: animperfection of sufficient

magnitude

to

(2) above 15psi(1 bar) gagepressure if design warrantrejection.

temperature isbelowminus20°F (-30°C) or above

250°F (1 20°C);

(d) casing, tubing, or pipe used in oil wells, wellhead

’ Welding terms which agree with AWS Standard A3.0 are marked

withan asterisk(*). For welding terms used in this Code but not

assemblies, oil and gas separators, crude oil production shown here, definitions in accordance with AWS A3.0 apply.

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

ASME B31.4-1998Edition Fig. 400.1.1

..............

Production field w-’ r-1 r - 1 ’.

00 4- I -

...............

Pipeline terminal *

Tank farm andlorpump station

.-r -7’-.

*.e.

Production field

mo

-T-T-..* Petroleum refinery

L Gas processing plant

Ammonia plant

Chemical plant

Pipeline terminal

Tank farm and/orpump station

r-:

Pipe type storage

I -I Bulkplant

I L1-l

L-A

Petroleum refinery

Gas processing plant

--

Ammonia plant

Chemical plant i

- 7-l

t --A

I

&.I-

1

1 k -Tank farm,terminal,” or process area

I L’,-,L ,‘-,,J

L-1L-I

A.

- Pipeline terminal,* tank farm, andlor pump station

_I L

0 Marine, rail, or truck (all loading or unloading)

00 Onshore or offshore

Piping within 631.4 scope

Continuation of 831.4 scope through area

Start or end at831.4 scope w i t h i n p l o tarea

Limits of production lease or field

Plot (or platform) limitsof production, petroleum refinery, chemical plant, ammonia

plant, bulk plant,o r gas processing operating facilities

Corridor within property of petroleum refinery, chemical plant, ammonia plant,or

gas processing plant set aside for 631.4 piping

Property line of petroleum refinery, chemical plant, ammonia plant, gas processing

plant, or bulk plant

FIG.400.1.1 DIAGRAM SHOWING SCOPEOF ASME 831.4 EXCLUDING CARBON DIOXIDE

PIPELINE SYSTEMS (SEE FIG. 400.1.2)

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

Fig. 400.1.2 ASME B31.4-199%Edition

Final processing faality

tor cahon dioxide before

Um carbon dioxide is

....... ...e

. Carbon

dioxide

production

field [Note (l)]

mspotted outside the

production field.

Pipelineterminal -- Carbon dioxide

.

essing/ [Now (211and/or

pump station plant recycling

.I I

L L

Carbon dioxide

mduction

h d

Pipeline terminal

[Note (2)] and/or

pump station

Hydrocarbon

production

field for

carbon dioxide

:lo injection

I.

piping within 831.4 Scope

,

I (

4

Continuation of 831.4 Scope through area

Startorend at 831.4 Scope within plot area

----- Limitsof productionleaseor field

Plot (or platform) limitsof production, petroleum refinery,

chemical plant, carbon dioxide processing plant, or gas processing operating

hCiliti9S

NOTES

(1) Onshore or offshore.

(2) Marine, rail, or hudc (all loading or unloading).

FIG. 400.1.2 DIAGRAM SHOWING SCOPE OF ASME B31.4 FOR CARBON DIOX.IDE P'IPELINE

SYSTEMS

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

ASME B31.4-1998 Edition 480.2

designlife: aperiodoftimeusedindesign calcula- nominalpipe size (NPS): see ASME B36.10M p. 1

tions,selectedforthepurpose ofverifyingthata for definition.

replaceable or permanent component is suitable for the

anticipatedperiodofservice.Designlifedoesnot operating company: owner or agent currently responsi-

pertaintothelifeofthepipelinesystembecausea bleforthe design,construction,inspection,testing,

properly maintained and protected pipeline system can operation, and maintenance ofthepipingsystem.

provideliquidtransportationserviceinde’finitely. petroleum: crude oil, condensate, natural gasoline, nat-

uralgasliquids,liquefiedpetroleumgas.andliquid

engineeringdesign: detaileddesigndevelopedfrom

petroleumproducts.

operating requirements and conforming to Code require-

ments, including all necessary drawings and specifica- pipe: a tube, usually cylindrical, used for conveying a

tions,governingapipinginstallation. fluid or transmitting fluid pressure, normally designated

“pipe” in the applicable specification. It also includes

general corrosion: uniform or graduallyvaryingloss anysimilarcomponentdesignated as “tubing” used

of wall thickness over an area. for the same purpose. Types of pipe, according to the

methodof manufacture, are defined as follows.

girth weld: a complete circumferential butt weld join-

(a) electric resistanceweldedpipe: pipeproduced

ing pipe or components. in individuallengths or in continuouslengthsfrom

coiled skelp, having a longitudinal or spiral butt joint

imperfection: adiscontinuityorirregularitywhichis

wherein coalescence is produced bytheheatobtained

detected by inspection. fromresistance ofthe pipetothe flowof electric

currentinacircuit ofwhich thepipeisapart,and

internal design pressure: internalpressureusedin

by the application ofpressure.

calculations or analysis for pressure design of a piping

component (see para. 401.2.2). (6) furnace &p welded pipe: pipe having a longitudi-

nal lap joint madeby the forge welding process wherein

liquefied petroleum gas(es) (LPG): liquidpetroleum coalescence is produced by heating the preformed tube

composed predominantlyof the following hydrocarbons, to welding temperature and passing it over a mandrel

either by themselvesor as mixtures:butane(normal located between two welding rolls which compress and

butane or isobutane), butylene (including isomers), pro- weldtheoverlappingedges.

pane,propylene,andethane. (c) furnace butt welded pipe

( I ) furnace buttwelded pipe, bell welded: pipe

liquid alcohol: any of a group of organic compounds producedinindividuallengthsfromcut-lengthskelp,

containingonlyhydrogen,carbon,andone or more having its longitudinal butt joint forgeweldedbythe

hydroxyl radicals which will remain liquid in a moving mechanical pressure developed in drawing the furnace

stream in a pipeline. heatedskelpthroughacone-shapeddie(commonly

known as the“welding bell”) which serves as a

liquid anhydrousammonia: acompoundformedby combinedformingandweldingdie.

the combination of the two gaseous elements, nitrogen (2) furnace butt welded pipe, continuous welded:

and hydrogen, in the proportion of one part of nitrogen pipe produced in continuous lengths from coiled skelp

to three parts of hydrogen, byvolume, compressed to andsubsequentlycutintoindividuallengths,having

aliquidstate. its longitudinal buttjoint forge weldedby the mechanical

pressuredeveloped in rollingthehotformedskelp

maximumsteadystate operating pressure: maximum through a set ofroundpassweldingrolls.

pressure (sum of static head pressure, pressure required (d) electricfusion welded pipe: pipe having a longitu-

to overcome friction losses, and anybackpressure) at dinal or spiral buttjoint wherein coalescence is produced

anypointin apipingsystem whenthesystem is inthepreformedtubebymanual or automatic electric

operatingundersteadystateconditions. arcwelding.Theweldmaybesingle ordoubleand

may be made with orwithouttheuseoffillermetal.

miter: twoormorestraightsections of pipematched Spiral welded pipe is also made by the electric fusion

andjoinedonalinebisectingtheangleofjunction weldedprocesswitheitheralapjointoralock-

so as toproduceachangeindirection. seam joint.

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

400.2 ASME B31.4-1998 Edition

(e) electric f i s h welded pipe: pipe having a longitu- should: “should” or “it is recommended” is used

dinal buttjoint wherein coalescence is producedsimulta- to indicate that a provision is not mandatory but recom-

neously over the entire area of abutting surfaces by mended as good practice.

the heat obtained from resistance to the flow of electric

current between the two surfaces, and by the application soil liquefaction: a soil condition, typicallycaused by

of pressure after heatingis substantially completed. dynamic cyclic loading (e.g., earthquake, waves) where

Flashing and upsetting are accompanied by expulsion the effective shear strength of the soil is reduced such

of metalfromthe joint. thatthesoil exhibits the properties of a liquid.

(f) double submerged arc wefded pipe: pipe having spun: a sectionof pipe that is unsupported

a longitudinal or spiral butt joint produced by at least

two passes, one of which is on the inside of the pipe. temperatures: are expressed in degrees Fahrenheit (OF)

Coalescenceisproduced by heatingwith an electric unless otherwise stated.

arc or arcs between the bare metal electrode or electrodes weight coating: any coating applied to the pipeline

andthework. The welding is shielded by a blanket forthepurposeof increasing thepipelinespecific

of granular, fusible material on thework.Pressure is gravity.

notusedandfillermetalfor the inside and outside

weldsisobtainedfromthe electrode or electrodes. arc welding*: a group of weldingprocesseswherein

(g) seamless pipe: pipe produced by piercing a billet coalescence isproduced by heatingwithan electric

followed by rolling or drawing, or both. arc or arcs, with or without the application of pressure

(h) electric induction welded pipe: pipe produced in andwith or without the use of fillermetal.

individual lengths or in continuous lengths from coiled

automatic welding*: weldingwithequipmentwhich

skelp having a longitudinal or spiral butt joint wherein

performs the entire welding operation without constant

coalescence is produced by theheatobtainedfrom

observation and adjustment of the controls by an opera-

resistance ofthepipe to induced electric current, and

tor. The equipment may or may not perform the loading

by applicationofpressure.

and unloadingofthework.

pipe nominal wall thickness: thewall thickness listed

jillet weld*: a weldof approximately triangular cross

in applicablepipe specifications or dimensional stan-