Академический Документы

Профессиональный Документы

Культура Документы

Trials of A New Stirrer-Less Juice Sulphiter at Experimental Sugar Factory

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Trials of A New Stirrer-Less Juice Sulphiter at Experimental Sugar Factory

Авторское право:

Доступные форматы

Volume 5, Issue 7, July – 2020 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Trials of a New Stirrer-less Juice Sulphiter at

Experimental Sugar Factory

Narendra Mohan & S. K. Trivedi

National Sugar Institute

Kanpur, India

Abstract:- In India most of the sugar factories produce II. VARIOUS DESIGNS OF JUICE SULPHITERS

plantation white sugar by Double Sulphitation process

where the most essential and critical equipment used A continuous development in the design features of

during the clarification process is “juice sulphiter”. The juice sulphiters has taken place on the basis of observations

clarification efficiency is very much dependent upon the made on their working. They may be stirrer or stirrer less or

efficiency of juice sulphiter also which in turn depends may differ in system of adding milk of lime i.e. pre liming,

upon the design features of juice sulphiter. Authors shock liming or simultaneous addition of milk of lime and

have tried one such juice sulphiter which is also sulphur dioxide gas. Various such designs of juice sulphiters

considered as energy efficient at the Experimental are in use, some of them, which are being widely used, are

Sugar Factory of the Institute with satisfactory results. discussed here below.

Keywords:- Plantation white sugar, clarification, energy. A. Nsi Design Juice Sulphiter

One of the most commonly used and adopted design in

I. INTRODUCTION the sugar industry for simultaneous liming and sulphitation

is known as NSI design. It is a cylindrical tank in which

During the sugar season 2019-20, 457 sugar factories another inverted cylindrical shell closed from top is

are in operation in the country and the expected sugar suspended. Suitable stirrers are driven through a central

production is likely to be about 26.8 million tons. During shaft which in turn is driven by a motor and reduction gear.

the previous year 2018-19, 527 sugar factories operated & Juice after passing through the absorption tower is sprayed

produced about 33.2 million tons of sugar. About 95% of over the perforated plane where squeezers are provided for

sugar so produced is plantation white sugar manufactured by keeping perforation clean. Milk of lime enters in to the tank

double sulphitation process of clarification. where gas enters through perforated coil. Depending upon

the diameter of the tank more than one milk of lime entries

As is well known, in double sulphitation process, raw is provided at equal spacing for uniform lime distribution.

juice is heated up to about 70°C and then is sent to juice The distance between the gas coil and milk of lime entry is

sulphiter for liming and sulphitation, pH of sulphited juice is essential and is generally kept 200- 250 mm. After

maintained around 7.0-7.1. The sulphited juice is again treatment, the juice overflows out of the tank through over

heated up to 102 – 103°C and sent to clarifier for settling, flow pipe. In this design of the juice sulphiter, moving and

after settling, clear juice is sent for further processing. Juice static mixers are provided in such a way to facilitate mixing

sulphiter is the vital clarification equipment for determining of lime, juice and gas without affecting the precipitate

precipitation of the non-sugars present in the juice by formed. Now a day’s gas coils generally made of SS 304 are

ensuring proper admixing of reactants i.e. milk of lime and provided so as to have trouble free and efficient working of

sulphur dioxide gas with juice, side by side ensuring that the sulphiter.

precipitate formation is not disturbed. Being a vital

equipment of the processing house, continuous efforts have B. Sparger Type Juice Sulphiter With Stirrer

been made to improve the design features so as to have A Sparger type juice sulphiter but having a small

better juice sulphitation as reflected from minimum change stirrer for juice and milk of lime mixing has reported to be

in reducing sugar/100°brix, higher colour removal and worked well in the sugar industry. In this design also milk of

purity rise etc. Efforts have also been made to develop and lime connection is so made that entire lime comes in contact

use stirrerless juice sulphiters to save on energy without immediately with juice entering the main vessel and after 5-

disturbing floc formation. Authors designed and tried one 6 seconds comes in contact with SO2 gas. The juice

such sulphiter at Experimental Sugar Factory of National sulphitation system otherwise as a whole comprises of pre

Sugar Institute which accomplishes the task with lower and shock liming arrangement for use, as and when,

energy requirements. required. For ensuring complete mixing of lime with juice, a

stirrer has been fitted at the bottom of the sulphiter by

providing double gland system, so that, any leakages of

juice from drive end do not occur.

IJISRT20JUL334 www.ijisrt.com 327

Volume 5, Issue 7, July – 2020 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

C. Ejector Sulphitation System III. DESIGN OF JUICE SULPHITER DEVELOPED

In an ejector sulphitation system, which is a modified AT NSI

version of “Quarez System” in the literature has also been

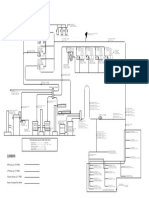

used by few sugar factories for juice sulphitation. The Trials of a stirrer less juice sulphiter (fig. 1) for the 100

system is claimed to be of a more compact design, needs TCD Experimental Sugar Factory was made during the

less steam, uses less power and hence is considered more crushing season 2019-20. The juice sulphiter was designed

energy efficient. Such system is working satisfactorily in for 4 TCH crush rate is having a retention time of about 7.0

one sugar factory in India where in sulphur melts by its own – 7.5 minutes depending upon the mixed juice % cane. The

heat of combustion and there is no need of medium pressure details of the juice sulphiter are shown in fig. no.1. It can be

steam. The sulphur burner uses induced draft air thus seen from the figure that the juice sulphiter is designed in

eliminating the air blower and compressor. such manner that milk of lime is taken upwards with

incoming juice current where SO2 gas coming out of the

sparger further creates admixing without disturbing

precipitate and subsequent floc formation.

Fig 1:- NSI Stirrer-less Juice Sulphiter

IV. MATERIAL AND METHODS

The mixed juice and clear juice samples were analyzed for brix and purity on Sucro Analyzer as per standard protocol at 589

nm, reducing sugar per 100°brix by Lane & Eynon method, CaO content by EDTA method and the colour of juices were

determined on Sucroscan Colour Analysis Kit by ICUMSA method GS-2/3-10. The samples for other parameters were analyzed

as per ICUMSA and Standard Indian protocols. The trials were conducted during the crushing season for 3 days from 1 st March,

2020 to 3rd March, 2020. Its working was compared with the existing NSI design juice sulphiter available in the Experimental

Sugar Factory. The details of analysis of mixed and clear juice for various parameters are given in the following tables:

IJISRT20JUL334 www.ijisrt.com 328

Volume 5, Issue 7, July – 2020 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

MIXED JUICE CLEAR JUICE

Date Bx. % Purity CaO content Bx. % Purity CaO content

(ppm) (ppm)

1-3-2020 12.87 79.62 730 12.90 80.02 1110

13.10 80.20 790 13.18 80.72 1220

12.60 78.90 750 12.72 79.50 1200

12.90 79.76 710 12.98 80.42 1160

2-3-2020 13.24 80.30 680 13.30 80.99 1130

13.15 80.10 710 13.19 80.81 1140

13.45 80.49 830 13.48 81.19 1250

13.20 81.20 820 13.23 81.02 1270

3-3-2020 13.10 81.40 820 13.16 81.95 1230

12.64 80.62 800 12.70 81.10 1240

12.96 81.59 670 12.98 81.99 1180

13.06 82.42 690 13.10 83.07 1100

Table 1:- Analysis of mixed juice and clear juice for Bx. %, Purity and CaO content in ppm

MIXED JUICE CLEAR JUICE

0

Date Bx. % Purity RS/ 100 Bx Bx. % Purity RS/ 1000Bx

1-3-2020 12.87 79.62 5.38 12.90 80.02 5.34

13.10 80.20 5.34 13.18 80.72 5.19

12.60 78.90 5.57 12.72 79.50 5.64

12.90 79.76 5.38 12.98 80.42 5.06

2-3-2020 13.24 80.30 5.75 13.30 80.99 6.01

13.15 80.10 5.59 13.19 80.81 5.42

13.45 80.49 5.76 13.48 81.19 5.62

13.20 81.20 6.05 13.23 81.02 5.90

3-3-2020 13.10 81.40 6.27 13.16 81.95 6.20

12.64 80.62 6.41 12.70 81.10 6.16

12.96 81.59 6.19 12.98 81.99 6.33

13.06 82.42 6.12 13.10 83.07 5.70

Table 2:- Analysis of Reducing sugar /1000Brix in mixed juice and clear juice

MIXED JUICE CLEAR JUICE

Date Bx. % Purity Colour (IU) Bx. % Purity Colour (IU) %Reduction in

Colour

1-3-2020 12.87 79.62 31532 12.90 80.02 24220 23.19

13.10 80.20 30956 13.18 80.72 22595 27.00

12.60 78.90 31163 12.72 79.50 23036 26.08

12.90 79.76 29981 12.98 80.42 23745 20.80

2-3-2020 13.24 80.30 29562 13.30 80.99 20366 31.10

13.15 80.10 28673 13.19 80.81 22594 21.20

13.45 80.49 28718 13.48 81.19 22555 21.49

13.20 81.20 30142 13.23 81.02 24544 18.57

3-3-2020 13.10 81.40 30294 13.16 81.95 24211 20.08

12.64 80.62 28912 12.70 81.10 22800 21.14

12.96 81.59 29748 12.98 81.99 23114 22.30

13.06 82.42 30167 13.10 83.07 20639 31.58

Table 3:- Analysis of colour reduction% from mixed juice to clear juice

IJISRT20JUL334 www.ijisrt.com 329

Volume 5, Issue 7, July – 2020 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

V. OBSERVATIONS VI. CONCLUSION

In order to assess the efficiency of stirrer less juice The working of newly developed Stirrerless juice

sulphiter it was decided to conduct continuous trials for sulphiter was observed to be satisfactory as reflected from

duration of three consecutive days, such that, every day the analytical results. The working was observed to be better

various performance data was collected and analyzed as per than the conventional juice sulphiter as reflected from the

table No.1-3. The investigation was limited to the following: values of purity rise and colour removal. Another important

Apparent purity rise from mixed juice to clear juice consideration is that this stirrerless juice sulphiter worked

Destruction of reducing sugars well with short retention time clarifier having a retention

Rise in Cao content from mixed juice to clear juice time of about 45 minutes only. The desired clarity of clear

Colour reduction from mixed juice to clear juice juice and compactness of muddy juice could be obtained.

This stirrerless juice sulphiter besides ensuring better

A. Purity rise clarification and saving energy while working with short

It is generally accepted that the extent of purity rise retention clarifier may result in to lower unknown losses and

from mixed juice to clear juice is an indicator of good decrease in juice temperature thus lowering steam

clarification and removal of non- sugars. During the trials requirements.

the purity rise from mixed juice to clear juice was ranging

between 0.40 to 0.70 units. Only in one case decrease in ACKNOWLEDGEMENT

purity from mixed juice to clear juice was observed which

was nominal and may be due to intermittent working of Authors are thankful to the Ministry Consumer Affairs,

factory during the period. Food & Public Distribution, Department of Food & Public

Distribution for providing us the financial support and

B. Change in reducing sugar content from mixed juice to cooperation to carry out the study.

clear juice

Higher reducing sugar and ash ratio has a favorable REFERENCES

effect on reduction in sucrose purity of final molasses. It is

therefore necessary that the destruction of reducing sugars [1].Book on Clarification of sugar cane juice by Narendra

should always be avoided as far as possible. Their Mohan -2019, page No.73-77.

destruction also causes colour formation in process and is

detrimental to sugar quality. Similarly, rise in reducing

sugar content indicates inversion of sucrose, which is also

not desirable. The change in reducing sugars per 100°Bx

during the trials was about +/- 5%, which considered

normal.

C. Rise in CaO Content:

The increase in CaO content during liming and

sulphitation results in scaling of the evaporators and

increase in molasses formation. Therefore, the increase in

CaO content from mixed juice to clear juice was also

analyzed during the duration of trials and it was observed

that the increase in CaO content varied from 400-450 mg

per liter or increase of about 40% which is considered to be

within limits.

D. Colour reduction from mixed juice to clear juice:

The mixed juice colour varied from about 28500 to

31500 IU, while colour of clear juice varied from about

20600 to 24500 IU. The colour reduction from mixed juice

to clear juice was observed to be in the range of about 20-

30% which on an average may be considered about 25%.

Such colour reduction is considered satisfactory in double

sulphitation process.

IJISRT20JUL334 www.ijisrt.com 330

Вам также может понравиться

- Caking of Raw SugarДокумент52 страницыCaking of Raw Sugarmarcelo22061970Оценок пока нет

- Syrup ClarificationДокумент14 страницSyrup ClarificationArun Gupta100% (1)

- 2000 - Smith - Some Developments in FlotationДокумент4 страницы2000 - Smith - Some Developments in FlotationmaithanhhaiОценок пока нет

- Carbonation VS Phos Floation PDFДокумент48 страницCarbonation VS Phos Floation PDFRAJKUMARОценок пока нет

- Removal of Suspended Fine Particulate Matter From Raw Juice PPT ScribdДокумент45 страницRemoval of Suspended Fine Particulate Matter From Raw Juice PPT ScribdKunchey JagadeeshОценок пока нет

- 10-Refinery Control, Aug. 09, 2017Документ12 страниц10-Refinery Control, Aug. 09, 2017jantskieОценок пока нет

- 07-Refined Sugar Boiling, Jul. 26, 2017Документ16 страниц07-Refined Sugar Boiling, Jul. 26, 2017jantskie100% (1)

- 21Документ29 страниц21Remington SalayaОценок пока нет

- Material & Energy Balance (Jaggery)Документ1 страницаMaterial & Energy Balance (Jaggery)Arif ShafiОценок пока нет

- RAPIDORRДокумент12 страницRAPIDORRKris FloraОценок пока нет

- LionnetДокумент537 страницLionnetYadav Shweta100% (2)

- Chemical Control (Ansi Sugar Tech. Third Year) : by Dr. Jahar Singh Apst NsikanpurДокумент24 страницыChemical Control (Ansi Sugar Tech. Third Year) : by Dr. Jahar Singh Apst NsikanpurSameer Agale100% (1)

- Diagrams PDFДокумент15 страницDiagrams PDFAhmed M. Abdel HamedОценок пока нет

- Chemical Control PDFДокумент85 страницChemical Control PDFHarshit Khare100% (1)

- Stirrer For Vacuum PanДокумент8 страницStirrer For Vacuum PanLong Bui ThanhОценок пока нет

- Pan Automation Presentation PDFДокумент30 страницPan Automation Presentation PDFarcher178100% (1)

- Vacuum PanДокумент7 страницVacuum Pananon_33049728Оценок пока нет

- 02 Affination Mingling Centrifugation MeltingДокумент2 страницы02 Affination Mingling Centrifugation MeltingjantskieОценок пока нет

- Quality Changes During Storage of Raw Sugar.109132625Документ9 страницQuality Changes During Storage of Raw Sugar.109132625Carlos TomeyОценок пока нет

- 2005 RefineryBoilingSchemes SKILДокумент12 страниц2005 RefineryBoilingSchemes SKILRicardo A. PolОценок пока нет

- Clarification II - Flashing + Clarifier + FiltrationДокумент48 страницClarification II - Flashing + Clarifier + FiltrationPranetr R.Оценок пока нет

- Capacity Curing Management of Continuous Centrifugal MachinesДокумент42 страницыCapacity Curing Management of Continuous Centrifugal MachinesArun GuptaОценок пока нет

- Continuous Pan Operation ManualДокумент12 страницContinuous Pan Operation Manualsandi promonoОценок пока нет

- Instrumentation & Control of Continuous Vacuum Pans: by M.A. GetazДокумент28 страницInstrumentation & Control of Continuous Vacuum Pans: by M.A. GetazJavier Manuel IbanezОценок пока нет

- ClarifierДокумент3 страницыClarifierChristine FernandezОценок пока нет

- Effect of Non-PolДокумент6 страницEffect of Non-PolKevynОценок пока нет

- Comparison of Types of EvaporatorДокумент3 страницыComparison of Types of EvaporatorLon カンイェテОценок пока нет

- Mill Extraction Mangal SinghДокумент7 страницMill Extraction Mangal SinghGun SmithОценок пока нет

- 2005 Jounet Falling Film Evaporators in Cane Sugar Mills PDFДокумент12 страниц2005 Jounet Falling Film Evaporators in Cane Sugar Mills PDFnghiОценок пока нет

- Brix Curve 2022-23.Документ6 страницBrix Curve 2022-23.Mohit SrivastavaОценок пока нет

- Distillery Wastwater Treatment-CDM Project-2012Документ60 страницDistillery Wastwater Treatment-CDM Project-2012tsrinivasan5083Оценок пока нет

- KJHGДокумент18 страницKJHGSandeep Yäðäv100% (1)

- 1999 - Peaceock - Robust Designs Evaporator Station - 2 PDFДокумент14 страниц1999 - Peaceock - Robust Designs Evaporator Station - 2 PDFnghiОценок пока нет

- 03-Carbonatation, Updated July 08Документ32 страницы03-Carbonatation, Updated July 08jantskie100% (2)

- Ign Schematic Block Diagram of Sugar ProcessingДокумент1 страницаIgn Schematic Block Diagram of Sugar ProcessingTung Bui ThanhОценок пока нет

- PROCESS in RAW SUGAR Production of FFHCДокумент27 страницPROCESS in RAW SUGAR Production of FFHCTenebroso Pevie Anne100% (1)

- In Line Shredder: Keep Your CarrierДокумент2 страницыIn Line Shredder: Keep Your CarrierOmar Ahmed ElkhalilОценок пока нет

- Milk or Lime or Lime Saccharate PDFДокумент2 страницыMilk or Lime or Lime Saccharate PDFAnand Atre100% (1)

- 1972 - Guthrie - Sugar Factory Material BalanceДокумент6 страниц1972 - Guthrie - Sugar Factory Material BalanceNaeemSiddiquiОценок пока нет

- 3530 Nellikuppam Clarifier SpecДокумент62 страницы3530 Nellikuppam Clarifier Specgopalakrishnannrm1202100% (1)

- Sugar Melter Application in Sugar Factory - Sugar Melter Design Calculation2Документ1 страницаSugar Melter Application in Sugar Factory - Sugar Melter Design Calculation2Govinda DeshmukhОценок пока нет

- Quadruple Evaporator EvaluationДокумент8 страницQuadruple Evaporator EvaluationRemington SalayaОценок пока нет

- TSB ManualДокумент138 страницTSB ManualruwaaquaОценок пока нет

- Sugar Cane Juice EvaporatorДокумент9 страницSugar Cane Juice EvaporatornghiОценок пока нет

- Triple Effect Evaporators Heating Surface AreaДокумент2 страницыTriple Effect Evaporators Heating Surface AreaArif ShafiОценок пока нет

- Steam Balance Layout (TPH) ModelДокумент1 страницаSteam Balance Layout (TPH) ModelRemington SalayaОценок пока нет

- Clarke Performance IndicatorsДокумент3 страницыClarke Performance IndicatorsJavier Manuel IbanezОценок пока нет

- 1974 Murray Filtering Quallity of RAw Sugar - Mechanism of Starch Influence in CarbonatationДокумент11 страниц1974 Murray Filtering Quallity of RAw Sugar - Mechanism of Starch Influence in CarbonatationnghiОценок пока нет

- Bosch Continous Vacuum PanДокумент11 страницBosch Continous Vacuum Pancumpio425428Оценок пока нет

- Lurgi PSI Evaporator PaperДокумент13 страницLurgi PSI Evaporator PaperMariAle Droz CastroОценок пока нет

- Liquid - Liquid Heater (Condensate or Duplex Juice Heater) CalculationДокумент8 страницLiquid - Liquid Heater (Condensate or Duplex Juice Heater) CalculationYounas SardarОценок пока нет

- Issct 2013 Juice Extraction Systems PDFДокумент19 страницIssct 2013 Juice Extraction Systems PDFJeffersonPalacios100% (2)

- Vasantdada Sugar Institute PDFДокумент26 страницVasantdada Sugar Institute PDFNanasaheb PatilОценок пока нет

- Sugarcane Processing Technologies: by Md. Akram HossainДокумент16 страницSugarcane Processing Technologies: by Md. Akram HossainDeva Mk100% (1)

- Reference Control PhilosophyДокумент22 страницыReference Control PhilosophyReno MurdaОценок пока нет

- Sugar Factory DefinitionДокумент8 страницSugar Factory Definitiontsrinivasan5083100% (1)

- Short Notes For InterviewДокумент15 страницShort Notes For InterviewMuhammad Arif ShafiОценок пока нет

- What Is A Sugar Refinery?: 4th Slide The Refining ProcessДокумент2 страницыWhat Is A Sugar Refinery?: 4th Slide The Refining Processbabe0% (1)

- SSP Pumps in Sugar ProcessingДокумент44 страницыSSP Pumps in Sugar Processingverderusa100% (1)

- Study Assessing Viability of Installing 20kw Solar Power For The Electrical & Electronic Engineering Department Rufus Giwa Polytechnic OwoДокумент6 страницStudy Assessing Viability of Installing 20kw Solar Power For The Electrical & Electronic Engineering Department Rufus Giwa Polytechnic OwoInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Blockchain Based Decentralized ApplicationДокумент7 страницBlockchain Based Decentralized ApplicationInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Unmasking Phishing Threats Through Cutting-Edge Machine LearningДокумент8 страницUnmasking Phishing Threats Through Cutting-Edge Machine LearningInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Cyber Security Awareness and Educational Outcomes of Grade 4 LearnersДокумент33 страницыCyber Security Awareness and Educational Outcomes of Grade 4 LearnersInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- An Industry That Capitalizes Off of Women's Insecurities?Документ8 страницAn Industry That Capitalizes Off of Women's Insecurities?International Journal of Innovative Science and Research TechnologyОценок пока нет

- Factors Influencing The Use of Improved Maize Seed and Participation in The Seed Demonstration Program by Smallholder Farmers in Kwali Area Council Abuja, NigeriaДокумент6 страницFactors Influencing The Use of Improved Maize Seed and Participation in The Seed Demonstration Program by Smallholder Farmers in Kwali Area Council Abuja, NigeriaInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Smart Health Care SystemДокумент8 страницSmart Health Care SystemInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Insights Into Nipah Virus: A Review of Epidemiology, Pathogenesis, and Therapeutic AdvancesДокумент8 страницInsights Into Nipah Virus: A Review of Epidemiology, Pathogenesis, and Therapeutic AdvancesInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Parastomal Hernia: A Case Report, Repaired by Modified Laparascopic Sugarbaker TechniqueДокумент2 страницыParastomal Hernia: A Case Report, Repaired by Modified Laparascopic Sugarbaker TechniqueInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Visual Water: An Integration of App and Web To Understand Chemical ElementsДокумент5 страницVisual Water: An Integration of App and Web To Understand Chemical ElementsInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Smart Cities: Boosting Economic Growth Through Innovation and EfficiencyДокумент19 страницSmart Cities: Boosting Economic Growth Through Innovation and EfficiencyInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Compact and Wearable Ventilator System For Enhanced Patient CareДокумент4 страницыCompact and Wearable Ventilator System For Enhanced Patient CareInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Impact of Silver Nanoparticles Infused in Blood in A Stenosed Artery Under The Effect of Magnetic Field Imp. of Silver Nano. Inf. in Blood in A Sten. Art. Under The Eff. of Mag. FieldДокумент6 страницImpact of Silver Nanoparticles Infused in Blood in A Stenosed Artery Under The Effect of Magnetic Field Imp. of Silver Nano. Inf. in Blood in A Sten. Art. Under The Eff. of Mag. FieldInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Predict The Heart Attack Possibilities Using Machine LearningДокумент2 страницыPredict The Heart Attack Possibilities Using Machine LearningInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Air Quality Index Prediction Using Bi-LSTMДокумент8 страницAir Quality Index Prediction Using Bi-LSTMInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- The Relationship Between Teacher Reflective Practice and Students Engagement in The Public Elementary SchoolДокумент31 страницаThe Relationship Between Teacher Reflective Practice and Students Engagement in The Public Elementary SchoolInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Parkinson's Detection Using Voice Features and Spiral DrawingsДокумент5 страницParkinson's Detection Using Voice Features and Spiral DrawingsInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Investigating Factors Influencing Employee Absenteeism: A Case Study of Secondary Schools in MuscatДокумент16 страницInvestigating Factors Influencing Employee Absenteeism: A Case Study of Secondary Schools in MuscatInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Implications of Adnexal Invasions in Primary Extramammary Paget's Disease: A Systematic ReviewДокумент6 страницImplications of Adnexal Invasions in Primary Extramammary Paget's Disease: A Systematic ReviewInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Keywords:-Ibadhy Chooranam, Cataract, Kann Kasam,: Siddha Medicine, Kann NoigalДокумент7 страницKeywords:-Ibadhy Chooranam, Cataract, Kann Kasam,: Siddha Medicine, Kann NoigalInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- An Analysis On Mental Health Issues Among IndividualsДокумент6 страницAn Analysis On Mental Health Issues Among IndividualsInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Harnessing Open Innovation For Translating Global Languages Into Indian LanuagesДокумент7 страницHarnessing Open Innovation For Translating Global Languages Into Indian LanuagesInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- The Utilization of Date Palm (Phoenix Dactylifera) Leaf Fiber As A Main Component in Making An Improvised Water FilterДокумент11 страницThe Utilization of Date Palm (Phoenix Dactylifera) Leaf Fiber As A Main Component in Making An Improvised Water FilterInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- The Making of Object Recognition Eyeglasses For The Visually Impaired Using Image AIДокумент6 страницThe Making of Object Recognition Eyeglasses For The Visually Impaired Using Image AIInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Advancing Healthcare Predictions: Harnessing Machine Learning For Accurate Health Index PrognosisДокумент8 страницAdvancing Healthcare Predictions: Harnessing Machine Learning For Accurate Health Index PrognosisInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Diabetic Retinopathy Stage Detection Using CNN and Inception V3Документ9 страницDiabetic Retinopathy Stage Detection Using CNN and Inception V3International Journal of Innovative Science and Research TechnologyОценок пока нет

- The Impact of Digital Marketing Dimensions On Customer SatisfactionДокумент6 страницThe Impact of Digital Marketing Dimensions On Customer SatisfactionInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Terracing As An Old-Style Scheme of Soil Water Preservation in Djingliya-Mandara Mountains - CameroonДокумент14 страницTerracing As An Old-Style Scheme of Soil Water Preservation in Djingliya-Mandara Mountains - CameroonInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Dense Wavelength Division Multiplexing (DWDM) in IT Networks: A Leap Beyond Synchronous Digital Hierarchy (SDH)Документ2 страницыDense Wavelength Division Multiplexing (DWDM) in IT Networks: A Leap Beyond Synchronous Digital Hierarchy (SDH)International Journal of Innovative Science and Research TechnologyОценок пока нет

- Formulation and Evaluation of Poly Herbal Body ScrubДокумент6 страницFormulation and Evaluation of Poly Herbal Body ScrubInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Captive ConsumptionДокумент1 страницаCaptive Consumptionshubham shimpiОценок пока нет

- Reflection On SugarДокумент1 страницаReflection On SugarLuisa Marie CasasОценок пока нет

- Biology ReviewerДокумент15 страницBiology ReviewerIshie De GuzmanОценок пока нет

- Yema SquashДокумент6 страницYema SquashRhenzОценок пока нет

- Cane - Sugar - Manufacture - in - India Datos Sobre Producción de AzucarДокумент525 страницCane - Sugar - Manufacture - in - India Datos Sobre Producción de AzucarEnrique Lucero100% (1)

- 146 Reasons Why Sugar Is Ruining Your HealthДокумент5 страниц146 Reasons Why Sugar Is Ruining Your HealthD ARUL KUMARESANОценок пока нет

- Summary Writing ProcessДокумент5 страницSummary Writing ProcessCeciliaОценок пока нет

- Food Storage WorksheetДокумент10 страницFood Storage WorksheetGlorytraffickingОценок пока нет

- Artificial Sweeteners in PakistanДокумент4 страницыArtificial Sweeteners in PakistanQaddafi Jahangir33% (3)

- Power of The Healing Foods Diet PDFДокумент30 страницPower of The Healing Foods Diet PDFbioduny2kОценок пока нет

- Chapter 12 - ConfectioneryДокумент30 страницChapter 12 - Confectioneryninacool26100% (1)

- Scenario 1Документ4 страницыScenario 1Jay SharmaОценок пока нет

- SET 2022 Gstr1Документ1 страницаSET 2022 Gstr1birpal singhОценок пока нет

- Baking IngredientsДокумент7 страницBaking IngredientsJessica MotarОценок пока нет

- Sell Refined White Cane Sugar Grade "A" Icumsa 45Документ3 страницыSell Refined White Cane Sugar Grade "A" Icumsa 45Carlos MartinezОценок пока нет

- Sugar and Artificially Sweetened Beverages Linked To Obesity: A Systematic Review and Meta-AnalysisДокумент8 страницSugar and Artificially Sweetened Beverages Linked To Obesity: A Systematic Review and Meta-AnalysisLorena ErnstОценок пока нет

- Solutions "Experimentation"Документ46 страницSolutions "Experimentation"Lyza Manubay del RosarioОценок пока нет

- Project On MolassesДокумент131 страницаProject On Molassessekhar_jvj100% (1)

- Saturated Solution-Lesson PlanДокумент4 страницыSaturated Solution-Lesson Planapi-253890516100% (1)

- Tales of Kheer RecipeДокумент4 страницыTales of Kheer RecipeAshОценок пока нет

- Ketogenic Diet For Treating CancerДокумент85 страницKetogenic Diet For Treating Cancerzarrin77100% (6)

- Pharmaceutical Technology Pharmaceutical SyrupДокумент7 страницPharmaceutical Technology Pharmaceutical Syrupحمزة الفنينيОценок пока нет

- Narendra Mohan Director: Email: Nsikanpur@nic - In, Director - Nsi@gov - inДокумент33 страницыNarendra Mohan Director: Email: Nsikanpur@nic - In, Director - Nsi@gov - inBlessings HaraОценок пока нет

- 1993 - Schaffler - Rapid Analysis of SugarДокумент8 страниц1993 - Schaffler - Rapid Analysis of SugarOpal Priya WeningОценок пока нет

- Healthy Choices BookДокумент4 страницыHealthy Choices BookAnnye AlbuquerqueОценок пока нет

- Writing Task 1-ProcessДокумент21 страницаWriting Task 1-ProcessThị VyОценок пока нет

- Nafisa's Technical ReportДокумент56 страницNafisa's Technical ReportNafisa Ibrahim50% (2)

- SCD Lista Alimente Permise InterziseДокумент62 страницыSCD Lista Alimente Permise InterzisenicoleОценок пока нет

- CXS - 052e Capsuni Congelate PDFДокумент6 страницCXS - 052e Capsuni Congelate PDFdorinutza280Оценок пока нет

- NOVA Processed Food Classification Reference SheetДокумент4 страницыNOVA Processed Food Classification Reference Sheetdonmd98Оценок пока нет