Академический Документы

Профессиональный Документы

Культура Документы

Icl 020a

Загружено:

Adrian0 оценок0% нашли этот документ полезным (0 голосов)

13 просмотров2 страницыОригинальное название

ICL-020A

Авторское право

© © All Rights Reserved

Доступные форматы

DOC, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOC, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

13 просмотров2 страницыIcl 020a

Загружено:

AdrianАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOC, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 2

INSTRUMENT CONSTRUCTION CHECKLIST KASHAGAN PROJECT ICL 020A

Êîíòðîëüíàÿ âåäîìîñòü ïðîâåðêè ìîíòàæíûõ ðàáîò êîíòðîëüíî-èçìåðèòåëüíûõ ïðèáîðîâ

Title: INNERDUCT / LADDER & TRAY / DRESSING Protocol ¹

TRANSITS AND FIBRE OPTIC CABLE

Ïðîòîêîë ¹

Íàçâàíèå: ÂÍÓÒ£ÅÍÍÈÉ ÊÀÁÅËÜÍÛÉ ÊÀÍÀË /

ÊÀÁÅËÜÍÛÅ ËÎÒÊÈ ÎÁÂßÇÊÈ ÊÀÁÅËÅÉ

/ÏÅ£ÅÕÎÄÛ È ÑÂÅÒÎÂÎÄÍÛÉ ÊÀÁÅËÜ

Project No.: Area/Unit:

¹ ïðîåêòà: Ó¾àñòîê/Óñòàíîâêà:

Project Title: System/Sub System: /

Íàçâàíèå ïðîåêòà: Ñèñòåìà/Ïîäñèñòåìà:

Equip. Desc.: Equip Tag No.:

Íîìåð îáîðóä:

Îïèñàíèå îáîðóäîâàíèÿ:

DESCRIPTION OF CHECK Confirm the following: Conclusion

ÎÏÈÑÀÍÈŠϣÎÂÅ£ÊÈ Ïîäòâåðäèòå ñëåäóþùåå: Çàêëþ¾åíèå

1 Check ladder/tray is installed in accordance with design requirements.

Óáåäèòüñÿ, ¾òî ëîòêè óñòàíîâëåíû â ñîîòâåòñòâèè ñ òðåáîâàíèÿìè ïðîåêòà.

2 Check ladder supports are in accordance with design requirements.

Óáåäèòüñÿ, ¾òî îïîðû ëîòêîâ ñîîòâåòñòâóþò òðåáîâàíèÿì ïðîåêòà.

3 Check ladder/tray materials meet design requirements.

Óáåäèòüñÿ, ¾òî ìàòåðèàëû ëîòêîâ ñîîòâåòñòâóþò òðåáîâàíèÿì ïðîåêòà.

4 Check ladder/tray does not present a hazard to personnel, block access ways,

or prevent removal of equipment.

Óáåäèòüñÿ, ¾òî ëîòîê íå ïðåäñòàâëÿåò îïàñíîñòè äëÿ ïåðñîíàëà, íå áëîêèðóåò

ïðîõîäû è íå ìåøàåò ïåðåìåùåíèþ îáîðóäîâàíèÿ .

5 Check that rack/tray cut edges are de-burred and smooth.

Óáåäèòüñÿ, ¾òî îáðåçàííûå êðàÿ ëîòêîâ ãëàäêè è çà¾èùåíû.

6 Where required check insulated spacers are fitted between rack and steel supports

Óáåäèòüñÿ, ¾òî ãäå íåîáõîäèìî ìåæäó ëîòêàìè è èõ ñòàëüíûìè êðåïëåíèÿìè

óñòàíîâëåíû èçîëèðóþùèå ïðîêëàäêè.

7 Check bonding/earthing of rack conforms to design requirements.

Óáåäèòüñÿ, ¾òî îáâÿçêà/çàçåìëåíèå ëîòêà ñîîòâåòñòâóåò òðåáîâàíèÿì ïðîåêòà.

8 Check protective kick plates installed.

Óáåäèòüñÿ, ¾òî óñòàíîâëåíû çàùèòíûå óäàðíûå ïëàñòèíû .

9 Check rack identification is correct to design requirements.

Óáåäèòüñÿ, ¾òî ìàðêèðîâêà ëîòêà ïðàâèëüíà è ñîîòâåòñòâóåò òðåáîâàíèÿì ïðîåêòà.

10 Check innerduct and fibre optic cables are routed on correct racks.

Ïðîâåðèòü, ¾òî âíóòðåííèå êàáåëüíûå êàíàëû è ñâåòîâîäíûå êàáåëè ïðîâåäåíû

ïî ñîîòâåòñòâóþùèì ëîòêàì.

11 Check that fibre optic cable segregation is correct.

Ïðîâåðèòü, ¾òî ñâåòîâîäíûå êàáåëè ëåæàò îòäåëüíî â ñîîòâåò. ñ èõ íàçíà¾åíèåì.

12 Check fibre optic cable bending radius is correct.

Ïðîâåðèòü, ¾òî ðàäèóñ èçãèáà ñâåòîâîäíîãî êàáåëÿ ñîîòâ. íîðìå.

13 Check cleating and banding neat and correct to design requirements.

Ïðîâåðèòü, ¾òî ìîíòàæ ñêîá è îáâÿçêà êàáåëåé ïðàâèëüíû è ñîîòâåòñòâóþò

òðåáîâàíèÿì ïðîåêòà.

14 Check that fibre optic cables are not resting on sharp edges.

Ïðîâåðèòü, ¾òî ñâåòîâîäíûå êàáåëè íå ðàñïîëàãàþòñÿ íà îñòðûõ êðàÿõ.

Page 1 of 2 Rev A08 31/12/08

INSTRUMENT CONSTRUCTION CHECKLIST KASHAGAN PROJECT ICL 020A

Êîíòðîëüíàÿ âåäîìîñòü ïðîâåðêè ìîíòàæíûõ ðàáîò êîíòðîëüíî-èçìåðèòåëüíûõ ïðèáîðîâ

Title: INNERDUCT / LADDER & TRAY / DRESSING Protocol ¹

TRANSITS AND FIBRE OPTIC CABLE

Ïðîòîêîë ¹

Íàçâàíèå: ÂÍÓÒ£ÅÍÍÈÉ ÊÀÁÅËÜÍÛÉ ÊÀÍÀË /

ÊÀÁÅËÜÍÛÅ ËÎÒÊÈ ÎÁÂßÇÊÈ ÊÀÁÅËÅÉ

/ÏÅ£ÅÕÎÄÛ È ÑÂÅÒÎÂÎÄÍÛÉ ÊÀÁÅËÜ

Project No.: Area/Unit:

¹ ïðîåêòà: Ó¾àñòîê/Óñòàíîâêà:

Project Title: System/Sub System: /

Íàçâàíèå ïðîåêòà: Ñèñòåìà/Ïîäñèñòåìà:

Equip. Desc.: Equip Tag No.:

Íîìåð îáîðóä:

Îïèñàíèå îáîðóäîâàíèÿ:

DESCRIPTION OF CHECK Confirm the following: Conclusion

ÎÏÈÑÀÍÈŠϣÎÂÅ£ÊÈ Ïîäòâåðäèòå ñëåäóþùåå: Çàêëþ¾åíèå

15 Check that transit frames are installed correctly.

Ïðîâåðèòü ,¾òî ïåðåõîäíûå ðàìû ïðàâèëüíî óñòàíîâëåíû.

16 Check transit identification is correct to design requirements.

Ïðîâåðèòü,¾òî ìàðêèðîâêà ïåðåõîäîâ ñîîòâåòñòâóåò òðåáîâàíèÿì ïðîåêòà.

17 Check transit material is correct.

Ïðîâåðèòü, ¾òî ìàòåðèàë ïåðåõîäîâ ñîîòâ. íîðìå.

18 Check transits are all packed correctly

Ïðîâåðèòü, ¾òî ïåðåõîäû áûëè óïëîòíåíû â ñîîòâ ñ íîðìîé

19 Check rack to transit alignments.

Ïðîâåðèòü öåíòðîâêó ëîòêà è ïåðåõîäà ïî îòíîøåíèþ äðóã ê äðóãó.

20 Check all fibre optic cables are identified on both sides of transits.

Ïðîâåðèòü, ¾òî âñå ñâåòîâîäíûå êàáåëè ïðîìàðêèðîâàíû ïî îáåèì ñòîðîíàì

ïåðåõîäîâ.

21 Check single penetrations are installed correctly.

Ïðîâåðèòü, ¾òî îäèíî¾íûå ïðîõîäû ñìîíòèðîâàíû ïðàâèëüíî.

22 Confirm ovality of innerduct does not exeed 5%. Difference in max/min outer diameter

divided by average outer diameter.

Ïîäòâåðäèòü,¾òî îâàëüíîñòü âíóòðåííåãî êàáåëüíîãî êàíàëà

íå ïðåâûøàåò 5 % . £àçíèöà ìàêñèìàëüíîãî /ìèíèìàëüíîãî íàðóæíåãî äèàìåòðà,

ðàçäåë¸ííîãî íà ñðåäíþþ âåëè¾èíó íàðóæíåãî äèàìåòðà.

23 Confirm fibre optic cable is free of visible damage.

Ïîäòâåðäèòü,¾òî ñâåòîâîäíûé êàáåëü âèçóàëüíî íå ïîâðåæä¸í.

24 Confirm fibre optic cable is correct size.

Ïîäòâåðäèòü,¾òî ñâåòîâîäíûé êàáåëü ñîîòâåòñòâóþùåãî íîðìàòèâàì ðàçìåðà.

25 Confirm pulled length of fibre optic cable and measurement method.

Ïîäòâåðäèòü, äëèíó ïðîòÿíóòîãî ñâåòîâîäíîãî êàáåëÿ è ìåòîä èçìåðåíèÿ.

Completed By Çàïîëíèë Approved By Îäîáðåíî Accepted by Ïðèíÿòî

Company Çàêàç¾èêîì

Job Title

Äîëæíîñòü

Signature

Ïîäïèñü:

Print Name

£àçáîð¾èâî:

Date

Äàòà:

Page 2 of 2 Rev A08 31/12/08

Вам также может понравиться

- MR GMAT Combinatorics+Probability 6EДокумент176 страницMR GMAT Combinatorics+Probability 6EKsifounon KsifounouОценок пока нет

- Reading Comprehension Animals Copyright English Created Resources PDFДокумент10 страницReading Comprehension Animals Copyright English Created Resources PDFCasillas ElОценок пока нет

- A Guide to Swimming Pool Maintenance and Filtration Systems: An Instructional Know-How on Everything You Need to KnowОт EverandA Guide to Swimming Pool Maintenance and Filtration Systems: An Instructional Know-How on Everything You Need to KnowОценок пока нет

- Flight Manual PDFДокумент123 страницыFlight Manual PDFAga Movsum HuseynzadeОценок пока нет

- Eclipse Phase Ghost in The ShellДокумент27 страницEclipse Phase Ghost in The ShellMeni GeorgopoulouОценок пока нет

- STSDSD QuestionДокумент12 страницSTSDSD QuestionAakash DasОценок пока нет

- Army National Guard Military Funeral Honors Soldier S Training SOP 23 Nov 15Документ203 страницыArmy National Guard Military Funeral Honors Soldier S Training SOP 23 Nov 15LuisAndresBellavista100% (1)

- Managment Book SPRДокумент54 страницыManagment Book SPRmgheisarОценок пока нет

- Heat Exchanger Inspection Checklist - QC, Inspection & Testing Engineering - Eng-TipsДокумент2 страницыHeat Exchanger Inspection Checklist - QC, Inspection & Testing Engineering - Eng-TipsdileepОценок пока нет

- Boeing 737NG ATA70 STANDARD PRACTICES PDFДокумент34 страницыBoeing 737NG ATA70 STANDARD PRACTICES PDFAnonymous QRVqOsa5100% (1)

- Community Tax Certificate PRINTДокумент2 страницыCommunity Tax Certificate PRINTClarenz0% (1)

- Effect of Corrosion on Steel Storage Tank Bottom Plate Integrity Assessment and RehabilitationДокумент114 страницEffect of Corrosion on Steel Storage Tank Bottom Plate Integrity Assessment and RehabilitationF GonzalezОценок пока нет

- Bolting and Unbolting ProcedureДокумент21 страницаBolting and Unbolting ProcedureMark Darrel AranasОценок пока нет

- Iracore Catalogue PDFДокумент93 страницыIracore Catalogue PDFRay100% (1)

- Tthe Sacrament of Reconciliation1Документ47 страницTthe Sacrament of Reconciliation1Rev. Fr. Jessie Somosierra, Jr.Оценок пока нет

- G G G G G G G G: Prgho# #VLI833328333U2VLI93332VLI9333U#Документ140 страницG G G G G G G G: Prgho# #VLI833328333U2VLI93332VLI9333U#Shan AhmadОценок пока нет

- Anti Viral DrugsДокумент6 страницAnti Viral DrugskakuОценок пока нет

- CES Wrong Answer SummaryДокумент4 страницыCES Wrong Answer SummaryZorg UAОценок пока нет

- BPSA 2017 Design, Control & Monitoring of Single-Use Systems For Integrity AssuranceДокумент37 страницBPSA 2017 Design, Control & Monitoring of Single-Use Systems For Integrity Assurancebio100% (1)

- HRSG InspectionДокумент4 страницыHRSG Inspection55312714Оценок пока нет

- Instrument Installation Checklist Êîíò Îëüíàß Âåäîìîñòü Óñòàíîâêè Êîíò Îëüíî-Èçìå Èòåëüíûõ Ï Èáî ÎâДокумент2 страницыInstrument Installation Checklist Êîíò Îëüíàß Âåäîìîñòü Óñòàíîâêè Êîíò Îëüíî-Èçìå Èòåëüíûõ Ï Èáî ÎâAdrianОценок пока нет

- Act On Cable Installation Facility Turnover: ECL 052AДокумент1 страницаAct On Cable Installation Facility Turnover: ECL 052AAdrianОценок пока нет

- Tubing/Hose Pressure Test/Flush Îï Åññîâêà Ò Óáîï Îâîäà/Øëàíãà Ï Îìûâêà ÑèñòåìûДокумент1 страницаTubing/Hose Pressure Test/Flush Îï Åññîâêà Ò Óáîï Îâîäà/Øëàíãà Ï Îìûâêà ÑèñòåìûAdrianОценок пока нет

- Act On Cable Inspection Before Covering: ECL 055AДокумент1 страницаAct On Cable Inspection Before Covering: ECL 055AAdrianОценок пока нет

- Èíñòðóêöèè ÏÎ Óñòàíîâêå È Ýêñïëóàòàöèè Installation and Maintenance InstructionsДокумент44 страницыÈíñòðóêöèè ÏÎ Óñòàíîâêå È Ýêñïëóàòàöèè Installation and Maintenance InstructionsDMYTRO MYRZAОценок пока нет

- Ecl 041a 2Документ1 страницаEcl 041a 2AdrianОценок пока нет

- 9120 Man Rus RevDДокумент30 страниц9120 Man Rus RevDArtem 521Оценок пока нет

- Act On Acceptance of Electrical Equipment /materials To Be InstalledДокумент1 страницаAct On Acceptance of Electrical Equipment /materials To Be InstalledAdrianОценок пока нет

- Operator Manual Ð Ó Ê Î Âîä Ñ Ò Âî ÏîëüçîâàòåëÿДокумент42 страницыOperator Manual Ð Ó Ê Î Âîä Ñ Ò Âî ÏîëüçîâàòåëÿВиктор ОбъедковОценок пока нет

- Wilcom E2Документ1 133 страницыWilcom E2Soporte De AccesoОценок пока нет

- Product Catalogue Êàòàëîã ÏðîäóêöèèДокумент8 страницProduct Catalogue Êàòàëîã ÏðîäóêöèèGusarov VyacheslavОценок пока нет

- FX Programming ManualДокумент480 страницFX Programming ManualMohammad ZakoutОценок пока нет

- sjzl20084045 ZXMSG 9000 v1005 Media Gateway Product Description ManualДокумент90 страницsjzl20084045 ZXMSG 9000 v1005 Media Gateway Product Description ManualkingtakОценок пока нет

- MAN Diesel: Service LetterДокумент5 страницMAN Diesel: Service LetterAKINMOLADUN OMOLADEОценок пока нет

- Gost R Iso 7250-2007 RussianДокумент32 страницыGost R Iso 7250-2007 Russiancnavarro51Оценок пока нет

- Etem StatikДокумент161 страницаEtem StatikatalayyОценок пока нет

- Contractors Classification Application FormДокумент11 страницContractors Classification Application FormGasser GoudaОценок пока нет

- Manual Book 7075Документ86 страницManual Book 7075margono akurasiОценок пока нет

- Sjzl20084045-ZXMSG 9000 (V1.0.05) Media Gateway Product Description ManualДокумент90 страницSjzl20084045-ZXMSG 9000 (V1.0.05) Media Gateway Product Description ManualRuban Vijaya Singh100% (1)

- WELDING INSTRUCTION FOR PROCESSДокумент8 страницWELDING INSTRUCTION FOR PROCESSUmesh SakhareliyaОценок пока нет

- Optimization of Screw Cap Process For E & J Gallo WineryДокумент52 страницыOptimization of Screw Cap Process For E & J Gallo Wineryryan brionesОценок пока нет

- 620 Series Installation ManualДокумент46 страниц620 Series Installation ManualcentellitaОценок пока нет

- Hopoocolor Ohsp 350f BF SFДокумент47 страницHopoocolor Ohsp 350f BF SFPedro MorenoОценок пока нет

- Válvula Arrestallamas Serie 5000Документ5 страницVálvula Arrestallamas Serie 5000Alegal03Оценок пока нет

- Opel 91Документ348 страницOpel 91galia.roh123Оценок пока нет

- Final Project Plan and SowДокумент13 страницFinal Project Plan and Sowapi-252682011Оценок пока нет

- Hyundai Engine D6AB Fuel SystemДокумент70 страницHyundai Engine D6AB Fuel SystemBigfair HD78100% (2)

- Airstream-AHC AVC D-User and Service Manual-V4.3-Jul 2013 ArdanaДокумент80 страницAirstream-AHC AVC D-User and Service Manual-V4.3-Jul 2013 Ardanadwi aryanto100% (1)

- 16-OM-QC-PL-MS-06 - MS FLOATING HEAD TYPE EXCHANGER'S INSPECTION & CLEANING (IRIS, ECT) (Rev.00)Документ7 страниц16-OM-QC-PL-MS-06 - MS FLOATING HEAD TYPE EXCHANGER'S INSPECTION & CLEANING (IRIS, ECT) (Rev.00)SANDEEPОценок пока нет

- Report On BSTIДокумент16 страницReport On BSTIRaselAhmed082100% (1)

- Cosmetics Mobile App Proposal - 290421Документ49 страницCosmetics Mobile App Proposal - 290421Abdulelah HamadОценок пока нет

- Comprehensive Guide To ActionДокумент108 страницComprehensive Guide To ActionMoodi SejiniОценок пока нет

- Product Catalogue: ConnectionsДокумент72 страницыProduct Catalogue: ConnectionsRusu AndreiОценок пока нет

- AT4 - Gioi ThieuДокумент6 страницAT4 - Gioi ThieuDiêm Công ViệtОценок пока нет

- University of Baghdad Fluid Mechanics Research ReportsДокумент6 страницUniversity of Baghdad Fluid Mechanics Research ReportsAnmar HamidОценок пока нет

- PlanДокумент50 страницPlanEsteban MurilloОценок пока нет

- My Project Plan-Identifying Project TaskДокумент49 страницMy Project Plan-Identifying Project Task008816Оценок пока нет

- Production of Disposable Surgical and Medical Face Mask-67739 PDFДокумент68 страницProduction of Disposable Surgical and Medical Face Mask-67739 PDFMuralidharОценок пока нет

- CPAA Draft Guidelines v2Документ48 страницCPAA Draft Guidelines v2manish_mokalОценок пока нет

- Mos-Replacement Gasket For PP Piping - 2024Документ6 страницMos-Replacement Gasket For PP Piping - 2024habibullah.centroironОценок пока нет

- Murutu ProjectДокумент17 страницMurutu Projectmurutu CollinsОценок пока нет

- NAAS Rating Scientific Journals 2012Документ4 страницыNAAS Rating Scientific Journals 2012Abhay KumarОценок пока нет

- Future Pipe Assembly Instructions UkДокумент22 страницыFuture Pipe Assembly Instructions UkAngelevОценок пока нет

- Solder Balls or Solder Balling On A PCB - Wave Soldering DefectsДокумент5 страницSolder Balls or Solder Balling On A PCB - Wave Soldering DefectsasdfОценок пока нет

- WMS For Field Pipeline BendingДокумент19 страницWMS For Field Pipeline BendingWalid TLTОценок пока нет

- Home and Legacy Test Plan TemplateДокумент9 страницHome and Legacy Test Plan TemplateFlorescu StefanОценок пока нет

- Hoá Học 11 p1-Đã GộpДокумент69 страницHoá Học 11 p1-Đã Gộpme ImОценок пока нет

- Column Punching Shear CheckДокумент27 страницColumn Punching Shear CheckLawrence Kevin FrencillanoОценок пока нет

- Ecl 041a 2Документ1 страницаEcl 041a 2AdrianОценок пока нет

- Ecl 041a 2Документ1 страницаEcl 041a 2AdrianОценок пока нет

- Ecl 005aДокумент1 страницаEcl 005aAdrianОценок пока нет

- Ecl 005aДокумент1 страницаEcl 005aAdrianОценок пока нет

- Cable Drum Inspection Protocol For Measurements of Power Cables Up To 1000 V Insulation Resistance On The DrumsДокумент1 страницаCable Drum Inspection Protocol For Measurements of Power Cables Up To 1000 V Insulation Resistance On The DrumsAdrianОценок пока нет

- Ecl 005aДокумент1 страницаEcl 005aAdrianОценок пока нет

- Ecl 005aДокумент1 страницаEcl 005aAdrianОценок пока нет

- Ecl 005aДокумент1 страницаEcl 005aAdrianОценок пока нет

- Ecl 005aДокумент1 страницаEcl 005aAdrianОценок пока нет

- Ecl 005aДокумент1 страницаEcl 005aAdrianОценок пока нет

- Act On Acceptance of Electrical Equipment /materials To Be InstalledДокумент1 страницаAct On Acceptance of Electrical Equipment /materials To Be InstalledAdrianОценок пока нет

- Rital Data Sheet KE01-00-990-AG-T-TD-0601-000-D04Документ97 страницRital Data Sheet KE01-00-990-AG-T-TD-0601-000-D04AdrianОценок пока нет

- Ecl 005aДокумент1 страницаEcl 005aAdrianОценок пока нет

- Ecl 005aДокумент1 страницаEcl 005aAdrianОценок пока нет

- Oman India Fertilizer ProjectДокумент9 страницOman India Fertilizer ProjectAdrianОценок пока нет

- Item Checklist No. DescriptionДокумент7 страницItem Checklist No. DescriptionAdrianОценок пока нет

- Ke01 00 990 Ag T HT 0601 000 C02Документ6 страницKe01 00 990 Ag T HT 0601 000 C02AdrianОценок пока нет

- Confined Space Entry Permit GuideДокумент1 страницаConfined Space Entry Permit GuideAdrianОценок пока нет

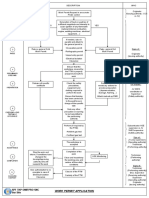

- PTW Logic DiagramДокумент1 страницаPTW Logic DiagramAdrianОценок пока нет

- Work Permit ApplicationДокумент23 страницыWork Permit ApplicationAdrianОценок пока нет

- Radiography PermitДокумент1 страницаRadiography PermitAdrianОценок пока нет

- What are plot pointsДокумент19 страницWhat are plot pointsOpeeron OpeeОценок пока нет

- Appellate Tribunal Inland Revenue Rules, 2010Документ18 страницAppellate Tribunal Inland Revenue Rules, 2010Shahbaz KhanОценок пока нет

- G.R. No. 190583 - People vs FrontrerasДокумент12 страницG.R. No. 190583 - People vs FrontrerasKaren Faye TorrecampoОценок пока нет

- 2017 Climate Survey ReportДокумент11 страниц2017 Climate Survey ReportRob PortОценок пока нет

- B1 Grammar and VocabularyДокумент224 страницыB1 Grammar and VocabularyTranhylapОценок пока нет

- SOP For Storage of Temperature Sensitive Raw MaterialsДокумент3 страницыSOP For Storage of Temperature Sensitive Raw MaterialsSolomonОценок пока нет

- Art 1207-1257 CCДокумент5 страницArt 1207-1257 CCRubz JeanОценок пока нет

- Ce QuizДокумент2 страницыCe QuizCidro Jake TyronОценок пока нет

- 3D Model of Steam Engine Using Opengl: Indian Institute of Information Technology, AllahabadДокумент18 страниц3D Model of Steam Engine Using Opengl: Indian Institute of Information Technology, AllahabadRAJ JAISWALОценок пока нет

- The Son of Man Rides The Clouds Pt. 2b - Answering Islam BlogДокумент5 страницThe Son of Man Rides The Clouds Pt. 2b - Answering Islam BlogbenciusilviuОценок пока нет

- ĐỀ MINH HỌA 15-19Документ25 страницĐỀ MINH HỌA 15-19Trung Vũ ThànhОценок пока нет

- Shell Rimula R7 AD 5W-30: Performance, Features & Benefits Main ApplicationsДокумент2 страницыShell Rimula R7 AD 5W-30: Performance, Features & Benefits Main ApplicationsAji WibowoОценок пока нет

- Leanplum - Platform Data SheetДокумент10 страницLeanplum - Platform Data SheetKiran Manjunath BesthaОценок пока нет

- Old Testament Books Bingo CardsДокумент9 страницOld Testament Books Bingo CardsSiagona LeblancОценок пока нет

- Starch Digestion by Amylase Lab ReportДокумент10 страницStarch Digestion by Amylase Lab Report햇님Оценок пока нет

- TNT Construction PLC - Tender 3Документ42 страницыTNT Construction PLC - Tender 3berekajimma100% (1)

- Connotative and Denotative, Lexical and StylisticДокумент3 страницыConnotative and Denotative, Lexical and StylisticEman Jay FesalbonОценок пока нет

- VET PREVENTIVE MEDICINE EXAMДокумент8 страницVET PREVENTIVE MEDICINE EXAMashish kumarОценок пока нет

- Revised Organizational Structure of Railway BoardДокумент4 страницыRevised Organizational Structure of Railway BoardThirunavukkarasu ThirunavukkarasuОценок пока нет

- Planned Parenthood Great NorthWestДокумент10 страницPlanned Parenthood Great NorthWestKate AndersonОценок пока нет

- Potato Tuber CropsДокумент103 страницыPotato Tuber CropsNani NazirОценок пока нет