Академический Документы

Профессиональный Документы

Культура Документы

2.2 Replacing Casing Oil Seal Assembly

Загружено:

nabiАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

2.2 Replacing Casing Oil Seal Assembly

Загружено:

nabiАвторское право:

Доступные форматы

Replacing Casing Oil Seal Assembly

PREPARATION

Learning Objectives

Upon completion of this lesson, the trainee will be able to:

1. Remove worn and deteriorated packing.

2. Install new packing in accordance with manufacturer's specifications and

procedures.

3. Inspect and test for freedom of movement of the camshaft.

Reference Materials

Material Removed In Process Control Tag (SUBGEN QA Form 4355/5)

Applicable technical manual

Figures/Tables

None

Training Aids/Materials

Cam pump demonstrator

Shop tools

Deep well socket, 2-3/8 inches, 3/4-inch drive

Breaker bar, 3/4-inch drive

Self-sealing plastic bags

Studs, 3/8 inch-16 x 2-1/2 inches, with washers and nuts (2)

Allen wrench, 3/8 inch

Socket, 3/8 inch

Packing rings (four sets of three each)

Torque wrench, 0 to 50 foot-pound range

Feeler gage

O-rings (4)

Stud remover and resetter set

Special tool: packing assembly puller plate

Squirt oil can

Lube oil, Symbol 2190 TEP

Plug gaskets (4)

Torque wrench, 0 to 800 foot-pound range

Grease, MIL-G-24508

Outside micrometer, 0 to 1 inch

Shim stock, laminated

Garlock Blue-Gard gasketing, 1/32 inch or equivalent

Molykote

Packing rings, 1/4 inch, Johns Manville 255 or equivalent (8)

INTRODUCTION

Seal packing must be replaced whenever it becomes worn or deteriorated to eliminate

excessive leakoff of lubricating oil. New packing must be installed in accordance with

manufacturer's procedures to be effective and prevent loss of, and/or possible

contamination of, lube oil.

DISCUSSION

Removing worn or deteriorated packing

1. Remove push rod, gland nuts, and two rings of packing from the end plug.

2. With a socket wrench, remove the end plug from the pump cylinder.

3. Tag and bag all parts as they are removed.

4. Remove the plug gasket.

5. Install two 3/8 inch-16 x 2-1/2 inch studs to the packing compressor. Install the

puller plate, two 3/8-inch flat washers, and two 3/8 inch-16 nuts. Tighten the nuts

alternately and pull the packing assembly out straight without binding or cocking

it.

6. Remove the o-ring.

7. Remove the bolts from the cover.

8. Remove the cover.

9. Remove the plunger using a 3/8-inch Allen wrench.

10. Remove the excluder.

11. Remove the four hex head bolts and four lockwashers.

12. Remove the plunger lip seal keeper.

13. Remove the three rings of seal packing.

14. Repeat steps1 through 13 for the three remaining cylinders.

Installing new packing

1. Install and seat a new packing ring into the casing.

NOTE

These two W-shaped rings should be installed in such a manner that the larger

diameter portion of each ring is facing toward the casing.

2. Install and seat second new ring into the first ring of packing.

NOTE

When installing new seal packing, the third ring should be facing in the opposite

direction from the first two rings with the thicker diameter portion facing away from

the casing.

3. Place the third ring up against the second ring.

4. Slide the plunger into the stuffing box.

5. Reinstall the excluder and lip seal keeper onto the plunger.

6. Work the plunger through the seal packing, thread it into the slipper, and tighten

with a 3/8-inch Allen wrench.

7. Attach a 3/8-inch Allen wrench to a 050 foot-pound torque wrench and torque the

plunger to 24 foot-pounds.

8. Check the compression of the seal assembly and, if necessary, use shims to

achieve a seal compression of 0.015 inch to 0.017 inch.

9. Secure the lip seal keeper with lockwashers and hex bolts.

10. Reinstall the cover.

11. Reinstall the cover bolts.

12. Install a new o-ring.

13. Lubricate the inner side of the plunger packing with a thin coat of lubricating oil.

14. Manufacture a 1/32-inch gasket for installation between the stuffing box sleeve

and throat bushing to help the o-ring seal the stuffing box sleeve.

15. Apply Molykote to the gasket and seat the gasket onto the throat bushing.

16. Install the packing cartridge onto the plunger.

17. Back out the push rod until the rod is flush with the face of the plug.

18. Install a new plug gasket.

19. Lubricate plug threads with grease.

20. Reinstall the plug to the pump cylinder.

21. Tighten the plug and torque it to 565 foot-pounds.

22. Reinstall the glands over the push rod.

23. Thread the push rod into the end plug.

24. Install two rings of 1/4-inch packing with butts 90 degrees apart.

25. Thread the gland nut into the end plug and tighten until firm.

26. Repeat steps 1 through 25 for the remaining three cylinders.

Inspecting and testing

1. Rotate the camshaft by hand.

2. Observe for proper freedom of movement.

APPLICATION

No formal test will be given. Ensuring that applicable safety precautions are followed at

all times, the instructor will observe trainees and provide applicable feedback until they

satisfactorily demonstrate the ability to:

1. Remove worn and deteriorated packing.

2. Install new packing in accordance with manufacturer's specifications and

procedures.

3. Inspect and test for freedom of movement of the camshaft.

Вам также может понравиться

- SOP 829-019 Rig Out The Mud Tanks and Pumps.Документ2 страницыSOP 829-019 Rig Out The Mud Tanks and Pumps.Anonymous XbmoAFtIОценок пока нет

- Trex 01157Документ17 страницTrex 01157OSDocs2012Оценок пока нет

- Mud Engineer Work ScopeДокумент5 страницMud Engineer Work ScopeMohamed AbozeimaОценок пока нет

- TCO - QE - Al Khor - MM-0030 - 7 Packer Retrieval +P and A + Section Mill ToolsДокумент1 страницаTCO - QE - Al Khor - MM-0030 - 7 Packer Retrieval +P and A + Section Mill ToolsrajafonsekaОценок пока нет

- Repair Side Tracking DL LGДокумент74 страницыRepair Side Tracking DL LGeleceron7919Оценок пока нет

- Well #1 - Well #1 - PROFILE PDFДокумент1 страницаWell #1 - Well #1 - PROFILE PDFHassan ZakeriОценок пока нет

- Cleaning Plan: Any Question Ask Mud Engineers (24hours) Mohamed Attwa&ahmedДокумент1 страницаCleaning Plan: Any Question Ask Mud Engineers (24hours) Mohamed Attwa&ahmedMohamed AbozeimaОценок пока нет

- Make Up TorqueДокумент1 страницаMake Up TorqueNicasio AlonzoОценок пока нет

- Mixing ProcessДокумент14 страницMixing ProcessMohammed Al-SalmiОценок пока нет

- Khurmala Field Field Department Drilling Deve. Oil Wells Project TU LocationДокумент9 страницKhurmala Field Field Department Drilling Deve. Oil Wells Project TU LocationAhmedОценок пока нет

- Synthetic-Based Mud Report No. 39: LLOG ExplorationДокумент1 страницаSynthetic-Based Mud Report No. 39: LLOG Explorationadvantage025Оценок пока нет

- Pos North1 - Basic WCR Rev0Документ874 страницыPos North1 - Basic WCR Rev0Felipe RamírezОценок пока нет

- Daily HSE Summary Report 28-03-2018Документ1 страницаDaily HSE Summary Report 28-03-2018Mahmoud Ahmed Ali AbdelrazikОценок пока нет

- 16.TDI FCR Data 9.625 43.50 PPF P110 BTC Rev.7Документ1 страница16.TDI FCR Data 9.625 43.50 PPF P110 BTC Rev.7javier monteroОценок пока нет

- Mizzen L-11 - End of Well Report - INV - 032042 642 PDFДокумент1 страницаMizzen L-11 - End of Well Report - INV - 032042 642 PDFKevin MuellerОценок пока нет

- SD-24P Bit Record 2Документ1 страницаSD-24P Bit Record 2Them Bui XuanОценок пока нет

- Morning Report 19 - 24 April 2012Документ3 страницыMorning Report 19 - 24 April 2012tolstoy potemkinОценок пока нет

- String Diagram Toot Deep-1 OGDCL DST-6 - 3Документ1 страницаString Diagram Toot Deep-1 OGDCL DST-6 - 3Aadil HaroonОценок пока нет

- DDR 27-10Документ1 страницаDDR 27-10GPCОценок пока нет

- Job Pertamina-Petrochina East Java: Wahdanadi, ErikДокумент2 страницыJob Pertamina-Petrochina East Java: Wahdanadi, Erikuli ulinuhaОценок пока нет

- Goldenman Petroluem Equipment Co., Limited: Quotation ListДокумент4 страницыGoldenman Petroluem Equipment Co., Limited: Quotation ListEstuardo AlvaradoОценок пока нет

- Alaska Drilling and Wells Recommended Practice: CTD Drilling FluidДокумент4 страницыAlaska Drilling and Wells Recommended Practice: CTD Drilling FluidAdel Ahmed AlkhaligyОценок пока нет

- Montara H1 ST1 Well ReleaseДокумент62 страницыMontara H1 ST1 Well Releasemack_eausОценок пока нет

- Copia de Bha de PozoДокумент18 страницCopia de Bha de PozoBertha Julieth Lopez ParraОценок пока нет

- Anti CollisionДокумент5 страницAnti CollisionJaime A PolancoОценок пока нет

- Tdi FCR Data 9 625 47ppf n80 BTC Rev 6Документ1 страницаTdi FCR Data 9 625 47ppf n80 BTC Rev 6Villalba XavichoОценок пока нет

- Well Data Summary ProgramДокумент13 страницWell Data Summary ProgramTemitope BelloОценок пока нет

- CT Coveyed PerforatingДокумент4 страницыCT Coveyed PerforatingAdel Ahmed AlkhaligyОценок пока нет

- Well Control Kill Sheet (Low Angle Wells) : (BBLS) Drillstring Volume Annular Volume (BBLS)Документ2 страницыWell Control Kill Sheet (Low Angle Wells) : (BBLS) Drillstring Volume Annular Volume (BBLS)scrbdgharaviОценок пока нет

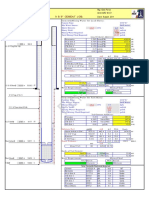

- Comp Tally W.P#14Документ3 страницыComp Tally W.P#14nabiОценок пока нет

- AFPC Lithology DescriptionДокумент9 страницAFPC Lithology DescriptionDaneskumar ManogaranОценок пока нет

- Manifold ValvesДокумент3 страницыManifold ValvesberrouiОценок пока нет

- Notes 4Документ18 страницNotes 4Ruben ChirinosОценок пока нет

- DDR N°02 - Sydnw1 - Enf57 - 24122019Документ3 страницыDDR N°02 - Sydnw1 - Enf57 - 24122019Kenaouia Bahaa100% (1)

- 37 - Primary CementationДокумент2 страницы37 - Primary CementationscrbdgharaviОценок пока нет

- Vibration Corrective Action Chart: Observation Typical Environment Short Term Corrective Action Long Term Counter MeasureДокумент1 страницаVibration Corrective Action Chart: Observation Typical Environment Short Term Corrective Action Long Term Counter Measuresaeed65Оценок пока нет

- Completion (Natural Flow)Документ3 страницыCompletion (Natural Flow)Mohammed Ali YoussefОценок пока нет

- AHMSW 8 Fiche de PhaseДокумент12 страницAHMSW 8 Fiche de PhaseBOUBAKER LOGBIОценок пока нет

- Chemical CalculationДокумент45 страницChemical CalculationGPCОценок пока нет

- Ali Ibrahim/Ali Abu Mandour: Depth GAS: 1% 30 Unit TVDДокумент1 страницаAli Ibrahim/Ali Abu Mandour: Depth GAS: 1% 30 Unit TVDMohamed Mahmoud Rezk DimoОценок пока нет

- Tech Drilling Cementing CalculationsДокумент0 страницTech Drilling Cementing Calculationsadvantage025Оценок пока нет

- Daily Drilling Monitoring Report Bibiyana-18Документ2 страницыDaily Drilling Monitoring Report Bibiyana-18shuvo134Оценок пока нет

- Drilling BHA - General AssemblyДокумент3 страницыDrilling BHA - General AssemblyAdel Ahmed AlkhaligyОценок пока нет

- WLL 087Документ32 страницыWLL 087fauzan kartiyasaОценок пока нет

- RIG: F28 Shock Sub: OD (Inch) ID (Inch) Length (M) Thread S950024 6-1/8" 9-1/2" 2-7/8" 7-5/8"Документ16 страницRIG: F28 Shock Sub: OD (Inch) ID (Inch) Length (M) Thread S950024 6-1/8" 9-1/2" 2-7/8" 7-5/8"berrouiОценок пока нет

- Drilling 12 1.4 in HoleДокумент1 страницаDrilling 12 1.4 in HoleMohamed AbozeimaОценок пока нет

- Section 11 - Drilling Mud ManualДокумент4 страницыSection 11 - Drilling Mud ManualMohamed AbozeimaОценок пока нет

- O 1 03 01Документ2 страницыO 1 03 01gplese0Оценок пока нет

- 7 X 9.625 With TSP, DWPДокумент5 страниц7 X 9.625 With TSP, DWPRahima RahoumaОценок пока нет

- 10 - Drilling 12 1.4 in HoleДокумент1 страница10 - Drilling 12 1.4 in HoleMohamed AbozeimaОценок пока нет

- 250P Series Core BarrelДокумент4 страницы250P Series Core BarrelJuan Miguel RobledoОценок пока нет

- GEOREPORT Mudlogging ExampleДокумент2 страницыGEOREPORT Mudlogging ExampleCarmen Ibeth Olivos PradaОценок пока нет

- 1995 - Ardjuna B FieldДокумент8 страниц1995 - Ardjuna B FieldGemilangОценок пока нет

- Precision "Heavy Duty" Pressure Gauges: Trade Catalogue 2005Документ38 страницPrecision "Heavy Duty" Pressure Gauges: Trade Catalogue 2005marcosОценок пока нет

- MR86L - Drilling MontageДокумент1 страницаMR86L - Drilling MontageGabriel PlazasОценок пока нет

- DDR N°40 Omf-50 TP202 Du 05092021Документ3 страницыDDR N°40 Omf-50 TP202 Du 05092021Mohamed SouidiОценок пока нет

- Casing Cutting Procedure - WFDДокумент5 страницCasing Cutting Procedure - WFDprateek132106Оценок пока нет

- By-16 Drilling Monitoring Report 05.11.2012Документ3 страницыBy-16 Drilling Monitoring Report 05.11.2012shuvo134Оценок пока нет

- 1CV Overhaul PDFДокумент15 страниц1CV Overhaul PDFsteve@air-innovations.co.zaОценок пока нет

- 1KR-FE Emission ControlДокумент105 страниц1KR-FE Emission ControlChristina Smith100% (3)

- Drilling Instruction For 26in Hole&20in CSGДокумент2 страницыDrilling Instruction For 26in Hole&20in CSGnabiОценок пока нет

- IPTC-21407-MS Handling High-Intensity Brine Influxes Using Flow-While-Drilling FWD Techniques in A Salt Formation in Chinarevskoye FieldДокумент15 страницIPTC-21407-MS Handling High-Intensity Brine Influxes Using Flow-While-Drilling FWD Techniques in A Salt Formation in Chinarevskoye FieldnabiОценок пока нет

- BUCS-144W Drilling Instruction For 16in Hole&13.375in CSGДокумент2 страницыBUCS-144W Drilling Instruction For 16in Hole&13.375in CSGnabiОценок пока нет

- 20in Casing TallyДокумент1 страница20in Casing TallynabiОценок пока нет

- SPE/IADC 124664 Roles of Managed Pressure Drilling Technique in Kick Detection and Wellcontrol Beginning of The New Conventional Drilling WayДокумент10 страницSPE/IADC 124664 Roles of Managed Pressure Drilling Technique in Kick Detection and Wellcontrol Beginning of The New Conventional Drilling WaynabiОценок пока нет

- 19-MPD As Well controlGOM-doneДокумент6 страниц19-MPD As Well controlGOM-donenabiОценок пока нет

- SPE/IADC-194547-MS MPD Deployment For Deepwater Drilling Operations - HSE & Risk Considerations and Mitigation, Rig Configuration Challenges and MPD Equipment Selection and StandardizationДокумент6 страницSPE/IADC-194547-MS MPD Deployment For Deepwater Drilling Operations - HSE & Risk Considerations and Mitigation, Rig Configuration Challenges and MPD Equipment Selection and StandardizationnabiОценок пока нет

- Managed Pressure Drilling Systems: Guide For Classification and Certification ofДокумент37 страницManaged Pressure Drilling Systems: Guide For Classification and Certification ofnabiОценок пока нет

- Ocean Engineering: A B A A B A B A B A BДокумент5 страницOcean Engineering: A B A A B A B A B A BnabiОценок пока нет

- Journal Pre-Proof: Process Safety and Environmental ProtectionДокумент32 страницыJournal Pre-Proof: Process Safety and Environmental ProtectionnabiОценок пока нет

- CMT Programm Spd18a-07 - 3Документ9 страницCMT Programm Spd18a-07 - 3nabiОценок пока нет

- Completion Design and EngineeringДокумент92 страницыCompletion Design and EngineeringnabiОценок пока нет

- 9 5-8'' - CMT Programme SPD18A-07 (12.5 PPG)Документ1 страница9 5-8'' - CMT Programme SPD18A-07 (12.5 PPG)nabiОценок пока нет

- 1 - Classification of CasingДокумент68 страниц1 - Classification of CasingnabiОценок пока нет

- Terminology and FormlaeДокумент7 страницTerminology and FormlaenabiОценок пока нет

- EC-Drill Eliminates Effect of Equivalent Circulating DensityДокумент3 страницыEC-Drill Eliminates Effect of Equivalent Circulating DensitynabiОценок пока нет

- Completion ComponentsДокумент28 страницCompletion ComponentsnabiОценок пока нет

- PIPE Tally Sheet 7'' Liner kB2Документ10 страницPIPE Tally Sheet 7'' Liner kB2nabiОценок пока нет

- Comp Tally W.P#14Документ3 страницыComp Tally W.P#14nabiОценок пока нет

- Wob RPM GPM PDFДокумент1 страницаWob RPM GPM PDFnabiОценок пока нет

- 13.375 CSG tALLY - DL-15Документ3 страницы13.375 CSG tALLY - DL-15nabiОценок пока нет

- Ce003 PsДокумент4 страницыCe003 PsJaimeОценок пока нет

- Toro Workman MD and MDXДокумент238 страницToro Workman MD and MDXATОценок пока нет

- TGB Blade 250 Service ManualДокумент217 страницTGB Blade 250 Service Manualyornletard100% (3)

- Zx200-5g Engine Manual 6bg1 Tier 2 Edcd-En-00Документ234 страницыZx200-5g Engine Manual 6bg1 Tier 2 Edcd-En-00ibnu malkan93% (14)

- 4.3 1D ConnectionsДокумент82 страницы4.3 1D Connectionsjingyong123100% (1)

- Steel 1Документ25 страницSteel 1basanthi noorbashaОценок пока нет

- Technical Specification FOR 220Kv Isolators: Gujarat State Electricity Corporation LTDДокумент22 страницыTechnical Specification FOR 220Kv Isolators: Gujarat State Electricity Corporation LTDVelu SamyОценок пока нет

- TieRodsTRG Jan16revДокумент80 страницTieRodsTRG Jan16revalokОценок пока нет

- ZXMW PR10 S400&S500Документ44 страницыZXMW PR10 S400&S500Antariksha SinghОценок пока нет

- 10 Ft. X 12 FT. Steel Gazebo Assembly & Instructions ManualsДокумент9 страниц10 Ft. X 12 FT. Steel Gazebo Assembly & Instructions ManualsgillerdoitОценок пока нет

- Nissan Primastar X83 (2002-2006) Service Manual #10Документ17 страницNissan Primastar X83 (2002-2006) Service Manual #10János ZávogyánОценок пока нет

- Computer Aided Engineering GraphicsДокумент6 страницComputer Aided Engineering GraphicsVikram RaoОценок пока нет

- Front Drive Shaft2Документ10 страницFront Drive Shaft2jeremih alhegnОценок пока нет

- Service Documentation 1799-8001 - 20080307 - enДокумент7 страницService Documentation 1799-8001 - 20080307 - enFredi F FОценок пока нет

- Tle 7 Smaw TestДокумент3 страницыTle 7 Smaw TestTalakag Tnhs100% (3)

- An Anti-Loosening Screw-Fastener Innovation and Its EvaluationДокумент7 страницAn Anti-Loosening Screw-Fastener Innovation and Its EvaluationgauravmeucerОценок пока нет

- Technical Specifications CanopyДокумент5 страницTechnical Specifications CanopyNaman SharmaОценок пока нет

- D1404Документ4 страницыD1404rpajaro75Оценок пока нет

- Linelazer V 250 and 250 Self-Propelled Line Striper: Repair - PartsДокумент74 страницыLinelazer V 250 and 250 Self-Propelled Line Striper: Repair - PartsPaul Angulo CabanillasОценок пока нет

- Motoniveladora Champion Section - 2 - Circle - Drawbar - Moldboard PDFДокумент182 страницыMotoniveladora Champion Section - 2 - Circle - Drawbar - Moldboard PDFedgaralbe88% (8)

- CPI Site-Activities PDFДокумент30 страницCPI Site-Activities PDFmassive85Оценок пока нет

- 1st Moving ItemsДокумент12 страниц1st Moving Itemsshahbaz hussainОценок пока нет

- Hilti AnchoringДокумент15 страницHilti Anchoringwdavid81Оценок пока нет

- Heat Plate Exchanger - Spare PartsДокумент104 страницыHeat Plate Exchanger - Spare PartsSeekPT100% (2)

- TAD 1343 VE (Repair Manual)Документ310 страницTAD 1343 VE (Repair Manual)Riyodepitci100% (11)

- CLG200-3 Page 001-8Документ9 страницCLG200-3 Page 001-8Preett Rajin MenabungОценок пока нет

- Instruction Sheet Is Lr5005 - Style Number Lr5005Rz:: Package ContentsДокумент5 страницInstruction Sheet Is Lr5005 - Style Number Lr5005Rz:: Package Contentsdayshift5Оценок пока нет

- Sae Supra RulesДокумент9 страницSae Supra RulesPranav RandiveОценок пока нет

- Kathrein CAS 80Документ26 страницKathrein CAS 80Claudiu UscaОценок пока нет

- 980a3676 PDFДокумент49 страниц980a3676 PDFMichael Davenport0% (1)