Академический Документы

Профессиональный Документы

Культура Документы

Excavating AND Shoring: Construction Safety Education Program

Загружено:

Yugandhar Gogula VenkataИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Excavating AND Shoring: Construction Safety Education Program

Загружено:

Yugandhar Gogula VenkataАвторское право:

Доступные форматы

CONSTRUCTION SAFETY

EDUCATION PROGRAM

#9

EXCAVATING

AND

SHORING

This education program provides a guideline for proper excavating and shoring.

It is intended to give contractors and workers practical information regarding

proper excavating and shoring techniques.

This education program contains general information. For specific regulatory

requirements, please consult the appropriate regulation(s) adopted under the

Workplace Safety and Health Act and the Canadian Safety Association

Standards (CSA).

2005 Construction Safety Association of Manitoba

www.constructionsafety.ca

EXCAVATING AND SHORING

• Shoring, or proper sloping of an excavation must be provided where a worker

is to enter an excavation that is considered to be:

− An open excavation exceeding 2.4 meters (8 ft.) in depth.

(An open excavation is any excavation that does not meet the criteria

of being a trench, shaft, caisson or tunnel.)

or

− A trench excavation exceeding 1.8 meters (6ft.) in depth.

2005 Construction Safety Association of Manitoba

www.constructionsafety.ca

BEFORE YOU START TO EXCAVATE

• *107 (1) You must be registered as an excavating contractor by WPSH.

• *108 (1) You must notify WPSH 48 hours prior to excavating in excess of 1.8

meters (6 ft.) or an open excavation exceeding 2.4 meters (*8 ft.).

• *108 (3) You must, prior to excavating, notify all utilities: telephone, hydro,

gas, etc.

REMEMBER…

Where a worker or any portion of excavating machinery or equipment may

come closer than 3 meters (10 ft.) to an overhead or underground electrical

power line, the public utility must be contacted and a permit authorization

obtained.

• Manitoba Regulations 189/85 Construction

2005 Construction Safety Association of Manitoba

www.constructionsafety.ca

SAFETY TRAINING OF EXCAVATION WORKERS

• Training must be done prior to a worker doing excavation work. This must

include but not be limited to:

Hazards involving heavy equipment near excavations:

1. If possible, plan for dive-through areas – reduces need for back-up.

2. Make personnel familiar with blind spots on equipment.

3. If required, use spotters.

Soil conditions when excavating:

1. Be aware of moisture content and soil changes when excavating.

2. Dealing with different types of soil types – hard ground, clay, granular

material, wet clay, organic deposits with high moisture content.

3. Caution when dealing with frozen soil.

Protecting workers against cave-ins. Some methods are:

1. Sloping the trench walls.

2. Trench boxes

3. Shoring

2005 Construction Safety Association of Manitoba

www.constructionsafety.ca

ENGINEERING APPROVALS REQUIRED

• Where a worker or workers are required to enter an excavation and the

following conditions apply:

* 114(1) A straight-cut trench excavation exceeding 4.5 meters (15 ft.) in

depth or 1.5 meters (5 ft.) in width.

* 114(4) If a safety and health officer in his opinion requires shoring due to

soil conditions.

* 117 Where excavation may affect adjacent building, foundation, utility

pole or other structure.

* 39(1) Where a trench cage is to be used as a shoring support structure.

* 141(1) For all deep foundations.

* 145 For all shaft and tunnel excavations.

CHECK DANGEROUS CONDITIONS

• Assessment of possible hazards such as:

* 111 Human factors – proper training

* 113(1) Locations of utilities

* 115(1) Possible flooding

(2) Explosive and toxic atmospheres, gasoline vapours

(3) Oxygen levels

* 123 Access and egress

*Manitoba Regulations 189/85 Construction

2005 Construction Safety Association of Manitoba

www.constructionsafety.ca

PROTECTING WORKERS AGAINST CAVE-INS

* 126(1) Sloping the trench walls – fully sloped

To calculate the overall

width of a sloped excavation,

use the following formula:

WIDTH – (2 X DEPTH) +

BOTTOM TRENCH WIDTH

*Manitoba Regulations 189/85 Construction

2005 Construction Safety Association of Manitoba

www.constructionsafety.ca

WORKER KNOWLEDGE OF WORK SAFE PRACTICES

1. Access/egress for workers entering an excavation usually a ladder or

stairway.

2. Ladders must extend 1 meter (3 ft.) above top of the excavation.

3. In a trench excavation a ladder must be located within 3 meters (10 ft.) of

a worker’s working position.

4. Crossover an excavation must have a proper walkway with suitable

guardrails.

5. All excavations where the public has access must have barriers and

signage to protect the public from the hazards during the work hours and

off hours.

6. First aid and emergency supplies must be kept at the excavation project at

all times.

7. It is preferable that one worker be trained in First Aid and CPR.\

8. Supervisor must be a trained excavator.

2005 Construction Safety Association of Manitoba

www.constructionsafety.ca

SOIL CATEGORIES - THREE MAIN TYPES

#1 Stiff and Firm Soils – solid soils with substantial cohesion and no water table

present (good clay, stiff clay till, medium till).

#2 Soils likely to crack or crumble – soils that can be excavated by hand tools,

show signs of cracking after excavating, and possess a low medium moisture

content (heavily seamed silty clays, compacted clayey fill, and mixtures of

clays and silts).

#3 Soft and loose soils – soils easily excavated by hand with little or no cohesion

(i.e. sand, gravel, silt, organic soil, soft and wet clay and loose fill).

2005 Construction Safety Association of Manitoba

www.constructionsafety.ca

REAL FACTS ABOUT EXCAVATIONS

• Since 1976 twenty-four workers have died in unprotected excavations. These

workers ranged in experience from two days to twenty-nine years and ranged

in age from sixteen to sixty-one years. One thing all these fatalities had in

common – EACH WORKER THOUGHT HE WAS SAFE.

• Cave-ins happen unexpectedly, a common occurrence is wall failure. The dirt

slides into the trench pinning the worker. He is then helpless as dirt falls on

him.

• The weight of dirt distributed on your back and chest at a depth of two feet is

about 700 lbs. So even if a worker’s face and shoulders are exposed he will

not be able to breathe.

• An unnecessary fatality occurred at an excavation which was dug by hand.

There was a sewer line to be augured under a roadway. A property dispute

arose and the trench was put on hold. Due to the legal aspects the trench

was left unattended. The accident victim, unaware of the excavation, fell in

and was unable to right himself and drowned in a pool of water.

• This is a hazard of an unprotected hazard – never leave an excavation

unprotected.

• Workplace Safety and Health officers have forwarded reported violations of

the Act to the Crown Attorney’s office resulting in the following fines:

− A worker was fined $400 for working in an unshored excavation.

− A supervisor was fined $700 for letting a worker ride in the bucket of an

excavator.

− Worker/rider fined $200.

− Workers failing to take protective measures to protect themselves and

other workers fined $300.

* These are criminal offenses and require court appearances.

2005 Construction Safety Association of Manitoba

www.constructionsafety.ca

EMPLOYER RESPONSIBILITY FOR DANGEROUS CONDITIONS

* 115(1) If other hazardous conditions such as potential flooding of the

excavation exists, then the employer must establish a safe working

procedure. This may include provision of safety harnesses and

lifelines to allow workers to be removed from the excavation

immediately, should the hazardous condition develop.

* 115(3) The employer must test the atmosphere prior to entry into the

excavation. If an unsafe atmosphere exists, ventilation must be

provided to maintain safe working conditions.

* 115(4) If it is impossible to maintain a safe atmosphere by providing

engineering controls and a worker must enter the excavation, then a

proper supplied air respirator and emergency excavation procedures

must be provided.

For detailed information, check Workplace Safety and Health Division

“Guidelines for Confined Entry Work”.

*Manitoba Regulations 189/85 Excavation.

2005 Construction Safety Association of Manitoba

www.constructionsafety.ca

PROPER SHORING PROCEDURES

2005 Construction Safety Association of Manitoba

www.constructionsafety.ca

• When installing shoring within a trench-type excavation, proper methods and

procedures must be followed to provide for a safe excavation.

• When shoring is in progress, the bucket of the excavation machine must be

placed in the trench directly in front of the shoring being installed. The bucket

will serve as additional protection if a cave-in occurs.

• As the diagram on the opposite page shows, it is essential that shoring

struts/jacks be installed from the top down. It is important that the top

(first) strut/jack be placed approximately .5 meters (18”) below the surface,

then the second strut/jack placed according to the shoring table. The

installation of the first and second strut/jack to support the vertical uprights is

very important as it stabilizes the excavation walls.

• When removing shoring, the reverse procedure is used. That is, the struts

are removed from the bottom to the top. Remember, there must never be

less than two sets of uprights in place and the worker must always remain

within the shoring in place for protection.

• It is preferable to have the worker who installed the struts to be the one who

removes them. That worker will know if there has been a change in

conditions, undue pressure on struts or other potentially dangerous

conditions.

2005 Construction Safety Association of Manitoba

www.constructionsafety.ca

SEQUENCE FOR THE INSTALLATION

AND REMOVAL OF SHORING

2005 Construction Safety Association of Manitoba

www.constructionsafety.ca

2005 Construction Safety Association of Manitoba

www.constructionsafety.ca

TRENCH SHORING TABLES

The following shoring tables indicate the allowable size and spacing of wood

shoring for particular classifications of soil in Manitoba.

2005 Construction Safety Association of Manitoba

www.constructionsafety.ca

CAUTION

• An open excavation may become a trench excavation as the project

proceeds. A concrete basement wall constructed in an open excavation 2

meters (6.6 ft.) deep, now requires shoring or veeing-out if workers are

required to work on the outside wall between the concrete and the earth.

2005 Construction Safety Association of Manitoba

www.constructionsafety.ca

EXCAVATION AND SHORING

REVIEW QUESTIONS

NAME _____________________________

DATE __________________

T / F 1. You can predict if an excavation is safe to enter without a proper

support structure being provided.

T / F 2. Water helps in controlling the soil of a trench.

T / F 3. An excavation should be considered a confined space and appropriate

evaluation and controls undertaken to ensure workers are not exposed

to contaminated atmosphere.

T / F 4. Clay is easier to handle when dried by the sun.

T / F 5. You do not have to call the public utility if hydro lines are overhead.

T / F 6. You can enter an unprotected trench if you are only going to be in it for

a short period of time and a ladder is in place.

T / F 7. If the soil is frozen, shoring is not required.

T / F 8. The supervisor is the only person allowed into an unprotected trench.

T / F 9. Struts are removed from the top down.

T / F 10.The minimum distance between the edge of the trench and the

excavated material is 3 feet.

T / F 11. Worker training is done onsite.

T / F 12.You must register as an excavating contractor with the City or

Municipality.

2005 Construction Safety Association of Manitoba

www.constructionsafety.ca

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Numerical Analysis of Composite Steel Concrete Structural Shear Walls With Steel Encased ProfilesДокумент12 страницNumerical Analysis of Composite Steel Concrete Structural Shear Walls With Steel Encased ProfilesAnonymous mcHqIfbnV1Оценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Distribution of Shear Force in Concrete Slabs: Poja Shams HakimiДокумент94 страницыDistribution of Shear Force in Concrete Slabs: Poja Shams HakimiAndrey SemjonovОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Ind Nifty50Документ2 страницыInd Nifty50Anonymous mcHqIfbnV1Оценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Wcee2012 1232Документ9 страницWcee2012 1232Ajayvidyanand SharmaОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Pile 2Документ1 страницаPile 2Anonymous mcHqIfbnV1Оценок пока нет

- Counterweight CastingДокумент7 страницCounterweight CastingAnonymous mcHqIfbnV1Оценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Spreadsheets To BS 8110etc: (Default Ult MT / Non-Factored MT.) ('+' Tension at Bottom Face)Документ1 страницаSpreadsheets To BS 8110etc: (Default Ult MT / Non-Factored MT.) ('+' Tension at Bottom Face)Anonymous mcHqIfbnV1100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Bridge Slab DesignДокумент24 страницыBridge Slab DesignAnonymous mcHqIfbnV1Оценок пока нет

- 01 - Eigelaar, E.MДокумент159 страниц01 - Eigelaar, E.MAhmad Hussein EnayatОценок пока нет

- Svs Tiara Price ListДокумент1 страницаSvs Tiara Price ListAnonymous mcHqIfbnV1Оценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- 9 ExcavatingandShoringДокумент17 страниц9 ExcavatingandShoringAnonymous mcHqIfbnV1Оценок пока нет

- Design Shear WallДокумент26 страницDesign Shear WallCaoTrungThành100% (2)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Rev StaircaseДокумент6 страницRev StaircaseD SRINIVASОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Purlin DesignДокумент6 страницPurlin DesignAnonymous mcHqIfbnV1Оценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Plain Concrete FootingДокумент6 страницPlain Concrete FootingAnonymous mcHqIfbnV1Оценок пока нет

- Is12778 2004Документ16 страницIs12778 2004ershekarОценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Design of Pier FinalДокумент5 страницDesign of Pier FinalAnonymous mcHqIfbnV1100% (1)

- Rigid CalculationДокумент66 страницRigid CalculationMotasem BMОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- 1145-4C-Gr FLR Beam Calculation Comments-12!09!14Документ1 страница1145-4C-Gr FLR Beam Calculation Comments-12!09!14Anonymous mcHqIfbnV1Оценок пока нет

- Post Tension Flat SlabsДокумент14 страницPost Tension Flat Slabsrahulgehlot2008Оценок пока нет

- Is 456Документ26 страницIs 456Tommy JohnsonОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Design of Continuous Column & Beams According To ACI-codeДокумент11 страницDesign of Continuous Column & Beams According To ACI-codeShanker Lal Meghwar100% (2)

- AsrdeДокумент4 страницыAsrdeAnonymous mcHqIfbnV1Оценок пока нет

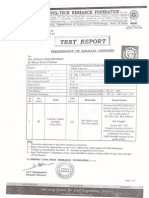

- 684 32mm Test ReportДокумент1 страница684 32mm Test ReportAnonymous mcHqIfbnV1Оценок пока нет

- Ri TL: - Ii - FQ - LДокумент2 страницыRi TL: - Ii - FQ - LAnonymous mcHqIfbnV1Оценок пока нет

- Post Tension Flat SlabsДокумент14 страницPost Tension Flat Slabsrahulgehlot2008Оценок пока нет

- Post Tension Flat SlabsДокумент14 страницPost Tension Flat Slabsrahulgehlot2008Оценок пока нет

- Second Floor-13.03.2014Документ1 страницаSecond Floor-13.03.2014Anonymous mcHqIfbnV1Оценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Shoring Failure 384 794Документ2 страницыShoring Failure 384 794Ahmed Y. AlsahharОценок пока нет

- Is 9459Документ13 страницIs 9459Anonymous mcHqIfbnV1Оценок пока нет