Академический Документы

Профессиональный Документы

Культура Документы

Procedure Qualification Record (PQR) Form

Загружено:

Earl HarbertОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Procedure Qualification Record (PQR) Form

Загружено:

Earl HarbertАвторское право:

Доступные форматы

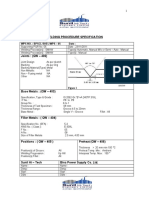

AWS CWI Practical BOS: 2017 ANNEX VIII

Specimen No. Width Thickness Area Ultimate Total Ultimate Unit Type of Failure

mm mm mm2 Load (kN) Stress (MPa) & Location

Annex VIII (Informative)

Procedure Qualification Record (PQR)

WELDING PROCESS & Type JOINTS

Process 1: Weld Type:

Process 2:Type Results Type Type:

Groove Results

Root Spacing:

BASE METALS Metal Backing:

Base Material Spec.: to Thermal Back gouging:

M-No.: Group No.: to M-No.: Group No.:

Plate or Pipe: Pipe Diameter:

Thickness:

Coating:

FILLER METALS

Specification No.:

AWS No. Classification:

F-No.:

Weld Metal Analysis A-No.: Sketch of Joint

Filler Metal Size: POSTWELD HEAT TREATMENT

Supplemental Filler: PWHT Type:

Weld Metal Deposit Thickness: PWHT Temperature:

PWHT Time:

POSITION

Position of Joint: GAS

Vertical Welding Progression: Shielding Gas:

Composition:

PREHEAT Flow:

Min. Preheat Temperature: Gas Cup Size:

Max. Inter-pass Temperature:

TECHNIQUE

ELECTRICAL Stringer or Weave:

Current & Polarity: Method of Cleaning:

Amperage Range: Oscillation:

Pulsed Current: Contact Tube to Work Distance:

Wire Feed Speed (m/min) Multi-pass or Single pass per side:

Voltage Range: Number of Electrodes:

Travel Speed (mm/min) Electrode Spacing:

Transfer Mode: Peening:

Maximum Heat Input (kJ/mm)

Tungsten Type:

Tungsten Diameter:

VISUAL EXAMINATION:

TENSILE TESTS

GUIDED-BEND TESTS

Welder’s Name Stamp or Clock No.

We certify that the statements in this record are correct and that the test welds were prepared, welded, and tested in accordance with the

requirements of the Part B Practical CWI Exam Requirements. It is intended to be used for the CWI Part B Exam only and is not intended to be used for

actual production welding or any other use without the written consent of AWS.

Вам также может понравиться

- Document Title: Welding Procedure Specification: Champion West Phase Iii Dev. Project C030005/ESP MSE BSP (ESP/2)Документ1 страницаDocument Title: Welding Procedure Specification: Champion West Phase Iii Dev. Project C030005/ESP MSE BSP (ESP/2)Ed FangОценок пока нет

- 2.QC Inspection Test Report With Procedure For MS Tank With FRP Lining - APPROVEDДокумент9 страниц2.QC Inspection Test Report With Procedure For MS Tank With FRP Lining - APPROVEDSripathi SeetharamanОценок пока нет

- Sabari Engineering PQRДокумент3 страницыSabari Engineering PQRAdvanced Quality Centre AQC100% (1)

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Документ1 страницаQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345Оценок пока нет

- Pt. Astar Testing & InspectionДокумент2 страницыPt. Astar Testing & InspectionSASIОценок пока нет

- Template BUTTДокумент1 страницаTemplate BUTTDylan TriggОценок пока нет

- Dimensional Check-Form 3TДокумент3 страницыDimensional Check-Form 3Tlempeng durianОценок пока нет

- Astm A179 PDFДокумент1 страницаAstm A179 PDFgaminОценок пока нет

- Lot Inspection Report For LPG New CylindersДокумент3 страницыLot Inspection Report For LPG New CylindersJagannath MajhiОценок пока нет

- Company Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsДокумент11 страницCompany Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsMAT-LIONОценок пока нет

- WPS for FCAW Welding of SteelДокумент2 страницыWPS for FCAW Welding of SteelHamid MansouriОценок пока нет

- ITP Fuel Fillter (J-1001) Rev10+Документ9 страницITP Fuel Fillter (J-1001) Rev10+DjokoОценок пока нет

- TCVN 9385 - 2012 - BS 6651 - 1999 - 998433 EN VerДокумент118 страницTCVN 9385 - 2012 - BS 6651 - 1999 - 998433 EN VerNam NguyenОценок пока нет

- 10.LPI. Report FormatДокумент1 страница10.LPI. Report FormatEr Sumant Kumar SinghОценок пока нет

- Safe Distance For Radiographic Plan: Week Day Curie Unshielded Collimator T-Wall Collimator+T-WallДокумент1 страницаSafe Distance For Radiographic Plan: Week Day Curie Unshielded Collimator T-Wall Collimator+T-WallHarun AkkayaОценок пока нет

- Certificate of Origin Form F For China-Chile FTAДокумент2 страницыCertificate of Origin Form F For China-Chile FTAinspectormetОценок пока нет

- CV of Engineer MD Sazid Alam1Документ8 страницCV of Engineer MD Sazid Alam1Alam MD SazidОценок пока нет

- Daily structural concrete reportДокумент2 страницыDaily structural concrete reportAli RazaОценок пока нет

- AnilДокумент7 страницAnilanil kumarОценок пока нет

- Wip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreДокумент3 страницыWip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreVijayabaraniОценок пока нет

- PT Kuwera Karya Me: PanduДокумент2 страницыPT Kuwera Karya Me: PanduGalang Pratama PutraОценок пока нет

- Weld History SheetДокумент2 страницыWeld History SheetAjin S100% (1)

- Daily Fit-Up/Welding Inspection ReportДокумент7 страницDaily Fit-Up/Welding Inspection ReportRichard PeriyanayagamОценок пока нет

- T.C.L. Co. - Test & Control LaboratoriesДокумент2 страницыT.C.L. Co. - Test & Control LaboratoriesA. ΒρατσισταОценок пока нет

- Hydro TestДокумент1 страницаHydro TestMilan BanerjeeОценок пока нет

- Dimensional Inspektion ReportДокумент6 страницDimensional Inspektion Reportdidi sudiОценок пока нет

- Hardness Test Report: Test Details Machine DetailsДокумент1 страницаHardness Test Report: Test Details Machine DetailsESHWAR CHARYОценок пока нет

- Proposed Welding Procedure Specification (PWPS) : REV:A3Документ1 страницаProposed Welding Procedure Specification (PWPS) : REV:A3Shanawas Abdul RazakОценок пока нет

- Inspection RoleДокумент18 страницInspection Rolesribd9128Оценок пока нет

- PQR DT Macro 60mm Smaw Astm A 516 Gr60Документ4 страницыPQR DT Macro 60mm Smaw Astm A 516 Gr60Boran YelkenciogluОценок пока нет

- Wps PQR Spec IndexДокумент1 страницаWps PQR Spec IndexTridib DeyОценок пока нет

- PWHTДокумент1 страницаPWHTMohdBadruddinKarimОценок пока нет

- WOPQ Form English1Документ2 страницыWOPQ Form English1oaperuchenaОценок пока нет

- Ferrite Content ReportДокумент2 страницыFerrite Content ReportJawad MunirОценок пока нет

- Tank Settlement Record T-05Документ8 страницTank Settlement Record T-05Marvan Audy BurikoОценок пока нет

- FDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Документ15 страницFDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Gisela ViskaОценок пока нет

- Pretest Piping Punch List (Empty)Документ1 страницаPretest Piping Punch List (Empty)Jorge GarciaОценок пока нет

- Indt QCP RT HJ 05NДокумент14 страницIndt QCP RT HJ 05NAsad Bin Ala QatariОценок пока нет

- WPS ExampleДокумент2 страницыWPS ExampleMarcio Jr.Оценок пока нет

- Painting Report Cd3Документ15 страницPainting Report Cd3sivaОценок пока нет

- ST 37Документ7 страницST 37rendra.farisrОценок пока нет

- Mds-Sparkler Filter F-304Документ1 страницаMds-Sparkler Filter F-304Vipul Gandhi50% (2)

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateДокумент2 страницыWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateAmjad PathanОценок пока нет

- Welding Consumables Control RegisterДокумент1 страницаWelding Consumables Control RegisterAli MhaskarОценок пока нет

- Surface Preparation & Painting ProcedureДокумент9 страницSurface Preparation & Painting ProcedureRam ThevarОценок пока нет

- WPQ-1083 3G PDFДокумент2 страницыWPQ-1083 3G PDFduendex360100% (1)

- WELD DESIGN CHECK FOR ANCHOR SUPPORTДокумент8 страницWELD DESIGN CHECK FOR ANCHOR SUPPORTUmer AziqОценок пока нет

- Sample Wps Carbon Steel GTAW SMAW PDFДокумент2 страницыSample Wps Carbon Steel GTAW SMAW PDFirwanОценок пока нет

- Welding Report For Tank 1Документ1 страницаWelding Report For Tank 1Rifki HasyaОценок пока нет

- NPCIL Tube Fitting SpecificationsДокумент22 страницыNPCIL Tube Fitting Specificationssumant.c.singh1694100% (1)

- N0200003 - NEW-F201-0 - Inspection & Test PlanДокумент3 страницыN0200003 - NEW-F201-0 - Inspection & Test PlanAfiq RamliОценок пока нет

- ITP For PipingДокумент5 страницITP For PipingAldeline SungahidОценок пока нет

- QAP For Ducting V1 R0Документ1 страницаQAP For Ducting V1 R0Hema NandhОценок пока нет

- Madina Trading WPS No. 017Документ12 страницMadina Trading WPS No. 017MAT-LIONОценок пока нет

- QAP Seamless PipeДокумент2 страницыQAP Seamless PipeashokkahirwarОценок пока нет

- B H e L Limited RTДокумент13 страницB H e L Limited RTbhavin17850% (2)

- Test Certificate AnalysisДокумент1 страницаTest Certificate AnalysisSagar KumarОценок пока нет

- CHG 55B2Документ1 страницаCHG 55B2Nhien ManОценок пока нет

- WPS Format For AWS D1.1 - WPS - SAWДокумент1 страницаWPS Format For AWS D1.1 - WPS - SAWThe Welding Inspections CommunityОценок пока нет

- WPS Format For AWS D1.1 - WPS - FCAWДокумент1 страницаWPS Format For AWS D1.1 - WPS - FCAWThe Welding Inspections CommunityОценок пока нет

- Tank Mounted Air CompressorДокумент26 страницTank Mounted Air CompressorEarl HarbertОценок пока нет

- 6th Central Pay Commission Salary CalculatorДокумент15 страниц6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- t200t260 Userguide en MotorolaДокумент2 страницыt200t260 Userguide en MotorolaJaime Alex RuminotОценок пока нет

- Craftsman Sabre Saw With Laser Trac - L0801036Документ28 страницCraftsman Sabre Saw With Laser Trac - L0801036Earl HarbertОценок пока нет

- English - Bolting SeminarДокумент90 страницEnglish - Bolting SeminarEarl HarbertОценок пока нет

- Tank Mounted Air CompressorДокумент26 страницTank Mounted Air CompressorEarl HarbertОценок пока нет

- Basic Welding Symbols PDFДокумент6 страницBasic Welding Symbols PDFEarl HarbertОценок пока нет

- Saltwater State Creel and Size LimitsДокумент4 страницыSaltwater State Creel and Size LimitsEarl HarbertОценок пока нет

- 1 Identification of The Substance/mixture and of The Company/undertakingДокумент5 страниц1 Identification of The Substance/mixture and of The Company/undertakingEarl HarbertОценок пока нет

- 02-05 Zuma SMДокумент217 страниц02-05 Zuma SMEarl HarbertОценок пока нет

- Welding Procedure Specification (WPS) FormДокумент2 страницыWelding Procedure Specification (WPS) FormEarl Harbert0% (1)

- Hydratight PDFДокумент40 страницHydratight PDFTamer Farahat100% (1)

- AWI Heat Input CalculatorДокумент2 страницыAWI Heat Input CalculatorEarl HarbertОценок пока нет

- Welder Qualification Test Record (WQTR) FormДокумент1 страницаWelder Qualification Test Record (WQTR) FormEarl Harbert100% (2)

- 2012 Zuma50 LIT-11626-25-31 2025Документ88 страниц2012 Zuma50 LIT-11626-25-31 2025Earl HarbertОценок пока нет

- 2012 Zuma50 LIT-11626-25-31 2025Документ88 страниц2012 Zuma50 LIT-11626-25-31 2025Earl HarbertОценок пока нет

- Dealer InformationДокумент11 страницDealer InformationEarl HarbertОценок пока нет

- XP ENV ISO 8502-1 Preparation of Steel Substrates Before Application of Paints and Related Products of Paints and Related ProductsДокумент49 страницXP ENV ISO 8502-1 Preparation of Steel Substrates Before Application of Paints and Related Products of Paints and Related ProductsEarl HarbertОценок пока нет

- Mitutoyo Absolute AOS Digital CaliperДокумент3 страницыMitutoyo Absolute AOS Digital CaliperEarl HarbertОценок пока нет

- 2008 690enduro Repair Manual PDFДокумент231 страница2008 690enduro Repair Manual PDFEarl HarbertОценок пока нет

- ITH Nut Runners Types and FeaturesДокумент12 страницITH Nut Runners Types and FeaturesEarl HarbertОценок пока нет

- Bohler MSDSДокумент9 страницBohler MSDSEarl HarbertОценок пока нет

- SRM230e Parts Catalogue 06 101911Документ95 страницSRM230e Parts Catalogue 06 101911Earl HarbertОценок пока нет

- SRM230e Parts Catalogue 06 101911Документ95 страницSRM230e Parts Catalogue 06 101911Earl HarbertОценок пока нет

- 2007 LC4 690 LC8 990 Diagnostic Measurements Failure Codes PDFДокумент49 страниц2007 LC4 690 LC8 990 Diagnostic Measurements Failure Codes PDFEarl HarbertОценок пока нет

- SRM230e Parts Catalogue 06 101911Документ38 страницSRM230e Parts Catalogue 06 101911Earl HarbertОценок пока нет

- Echo CS330T Owners Manual PDFДокумент32 страницыEcho CS330T Owners Manual PDFEarl HarbertОценок пока нет

- Mitutoyo Absolute AOS Digital CaliperДокумент3 страницыMitutoyo Absolute AOS Digital CaliperEarl HarbertОценок пока нет

- CS330Tes1112 100413 Instruction ManualДокумент48 страницCS330Tes1112 100413 Instruction ManualEarl HarbertОценок пока нет

- Selloooh X Shopee HandbookДокумент47 страницSelloooh X Shopee Handbooknora azaОценок пока нет

- Sahar NSC FixДокумент45 страницSahar NSC FixSahar AndhikaОценок пока нет

- Unit 2 - BT MLH 11 - KeyДокумент2 страницыUnit 2 - BT MLH 11 - KeyttyannieОценок пока нет

- Issues and Concerns Related To Assessment in MalaysianДокумент22 страницыIssues and Concerns Related To Assessment in MalaysianHarrish ZainurinОценок пока нет

- Dukic WarehouselayoutsДокумент14 страницDukic Warehouselayoutsrohitkamath7Оценок пока нет

- StoreFront 3.11Документ162 страницыStoreFront 3.11AnonimovОценок пока нет

- Financial Accounting & ReportingДокумент4 страницыFinancial Accounting & Reportingkulpreet_20080% (1)

- DC Rebirth Reading Order 20180704Документ43 страницыDC Rebirth Reading Order 20180704Michael MillerОценок пока нет

- Karnataka Email Id DataДокумент5 173 страницыKarnataka Email Id DataSumalatha Venkataswamy100% (6)

- Life of a VoyageurДокумент8 страницLife of a VoyageurBruce GuthrieОценок пока нет

- Aerospace & Aviation Job RolesДокумент74 страницыAerospace & Aviation Job RolesBharat JainОценок пока нет

- Calvo, G (1988) - Servicing The Public Debt - The Role of ExpectationsДокумент16 страницCalvo, G (1988) - Servicing The Public Debt - The Role of ExpectationsDaniela SanabriaОценок пока нет

- Chippernac: Vacuum Snout Attachment (Part Number 1901113)Документ2 страницыChippernac: Vacuum Snout Attachment (Part Number 1901113)GeorgeОценок пока нет

- AefiДокумент38 страницAefizedregga2Оценок пока нет

- All EscortsДокумент8 страницAll Escortsvicky19937Оценок пока нет

- Lumafusion Shortcuts LandscapeДокумент2 страницыLumafusion Shortcuts Landscapepocho clashОценок пока нет

- BIS Standards in Food SectorДокумент65 страницBIS Standards in Food SectorRino John Ebenazer100% (1)

- IT WorkShop Lab ManualДокумент74 страницыIT WorkShop Lab ManualcomputerstudentОценок пока нет

- Yoga Practice Guide: DR - Abhishek VermaДокумент26 страницYoga Practice Guide: DR - Abhishek VermaAmarendra Kumar SharmaОценок пока нет

- HiaceДокумент1 страницаHiaceburjmalabarautoОценок пока нет

- Instafin LogbookДокумент4 страницыInstafin LogbookAnonymous gV9BmXXHОценок пока нет

- M04 - Conditional Obligations and Reciprocal Obligations PDFДокумент12 страницM04 - Conditional Obligations and Reciprocal Obligations PDFTam GarciaОценок пока нет

- Credit Suisse AI ResearchДокумент38 страницCredit Suisse AI ResearchGianca DevinaОценок пока нет

- Natural Science subject curriculumДокумент15 страницNatural Science subject curriculum4porte3Оценок пока нет

- Class Homework Chapter 1Документ9 страницClass Homework Chapter 1Ela BallıoğluОценок пока нет

- Prospectus2023 24 PDFДокумент332 страницыProspectus2023 24 PDFramgharia sameerОценок пока нет

- Final Project On Employee EngagementДокумент48 страницFinal Project On Employee Engagementanuja_solanki8903100% (1)

- CH 2 Short Questions IXДокумент2 страницыCH 2 Short Questions IXLEGEND REHMAN OPОценок пока нет

- History of Early ChristianityДокумент40 страницHistory of Early ChristianityjeszoneОценок пока нет

- Maheshwar Handlooms Cluster Diagnostic StudyДокумент15 страницMaheshwar Handlooms Cluster Diagnostic Studyumang31390100% (3)