Академический Документы

Профессиональный Документы

Культура Документы

Smith Meter VDR Vertical Deaerator Specifications

Загружено:

ClarkFedele27Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Smith Meter VDR Vertical Deaerator Specifications

Загружено:

ClarkFedele27Авторское право:

Доступные форматы

Smith Meter ® Accessories

Smith Meter ® VDR Deaerator

Specifications

Issue/Rev. 0.3 (5/10) Bulletin SS01058E

The Smith Meter ® "VDR" Vertical Deaerator will sepa-

rate and release air and gas from petroleum and other

liquid products before they are metered. The deaerator

is a necessary part of any metering system, whenever

there is a possibility that air or gas can be pumped or

siphoned into the pipeline.

Features

Low pressure drop.

High efficiency air release.

Float operated automatic air release valve.

Standard Specifications

Fabricated according to DIN/EN, AD2000 specifi-

cation.

Temperature Range:

-29° to +65° C with Buna-N sealing.

Body Material: Carbon steel to EN Standard.

Flanges: Carbon steel raised face according to DIN/

EN or ANSI B16.5.

Model VDR Deaerator

Supports: Three (3) legs are standard on models 10-

100 deaerator. Four (4) legs are standard on models

130-350 deaerator. HE 2: Includes (2) factory installed liquid level con-

Sight Glass: Carbon steel with automatic air release trols with ATEX explosion proof sensor to activate

head(s). Air exhaust: 3/4" NPT. a Smith Meter Hydraulic Control Valve or the Smith

Meter Load Controller AccuLoad.

Automatic Air Release Head(s): Type "RB" - maximum

W.P. 300 psi. Type "UB" - Maximum W.P. 720 psi. HE 3: Includes (3) factory installed liquid level con-

Number of Air Release Heads per Model: VDR 10- trols with ATEX explosion proof sensor to activate

130 (1) head, VDR 180 and 240 - (2) heads, VDR 350 a Smith Meter Hydraulic Control Valve or the Smith

- (3) Heads. Meter Load Controller AccuLoad.

Drain: 1-1/2" NPT plugged, Model 10 to 60.

2" NPT plugged, Model 70 to 350. Functional Description

The removal of air from a liquid is controlled and limited

Options by the physical properties of that liquid and influenced

by a combination of pressure, temperature, flow rate,

Temperature Range:

and system design.

-12° to +65° C with Viton sealing.

Temperatures / Sealings other than specified: The presence of air or gas in a liquid system, while

consult factory. being measured by a positive displacement or turbine

meter, will result in inaccurate measurement and can

High Pressure Application: consult factory.

also damage the meter.

Special Surface Treatment: consult factory.

The deaerator is a necessary part of any metering sys-

“High Efficiency” Modification(s):

tem, whenever there is a possibility that air or gas can

HE 1: Includes (1) factory installed liquid level con- be pumped or siphoned into the pipeline.

trol with ATEX explosion proof sensor to activate a The tangentially constructed inlet and outlet connec-

Smith Meter Hydraulic Control Valve or the Smith tions (Figure 1), force the liquid into a rotational move-

Meter Load Controller AccuLoad®. ment. This centrifugal movement, in conjunction with a

The Most Trusted Name In Measurement

decrease in flow velocity and pressure will allow mass Efficiency

volumes, as well as entrained air and gas to be segre- Deaerators must release up to 30% volume of air/gas

gated from the liquid and subsequently through the float from the flowing liquid stream. Increased efficiency

operated automatic air release valve(s). A sight glass is can be achieved by installing liquid level control(s) in

installed to display the liquid. conjunction with a Smith Meter 200 Series Hydraulic

In accordance with EC Weights and Measures Regula- Control Valve.

tions, consideration must be given to the system design

to assure sufficient back pressure (min. 7.5 psi). Installation

Deaerators should be installed downstream from the

pump, as close to the meter as possible. The air release

Air Exhaust

should be piped to a vapour recovery system or to a

convenient and safe point of discharge. (Provide the end

of the air release pipe with a suitable flame arrestor.)

or Vapour

Recovery

The condensate return line can be discharged into a

System suitable container or back to storage.

Condensate

Return Line Liquid Level Controls

Air/Gas

Inlet The Standard Smith Meter "VDR" Series Centrifugal

(tangential) Deaerator is designed and approved to release up to

30% volume of air/gas from the flowing product. When

“Effective

Liquid even greater volumes of air/gas are likely to enter into

Volume” the line, or when the highest degree of systems accu-

racy is the primary design criterion, the addition of a

Liquid Level Control L.L.C. in conjunction with a Smith

Outlet

(tangential)

Meter 200 Series multifunction hydraulic control valve

will ensure maximum deaerator efficiency.

Three (3) variations are available as factory installed

options on the "VDR" Series Deaerators.

Figure 1 – VDR Deaerator

AccuLoad III D

Computer

Printer Strainer

FMC Technologies

Loading Arm

Digital

Control

Vertical PD Meter Valve

Deaerator

Pump

Figure 2 – Typical Installation for Loading Application

Page 2 • SS01058E Issue/Rev. 0.3 (5/10)

Options

Option HE 1: Option HE3:

One (1) L.L.C. with ATEX approved explosion proof (Typical Installation for Unloading Application)

sensor, stainless steel adapter assembly, side mounted Three (3) L.L.C.’s with ATEX approved explosion proof

as high or low level control, and electrically connected sensor, stainless steel adapter assembly, side mounted

to a Smith Meter model 200-31 Solenoid Block Valve, as comprehensive level control.

provides final closure of the valve. Used exclusively with Smith Meter AccuLoad (Figure 4).

The sensor signal can also be wired into a Smith Meter Control of delivery is accomplished by three digital

model 296 Set-Stop Valve or the Smith Meter Load Con- inputs, configured as high, low and stop switch. These

troller AccuLoad, whereby the level control action tem- inputs define when to advance from high flow rate to low

porarily overrides the set-stop counter micro switches. flow rate and final closure when the liquid level drops

below the stop switch.

Option HE 2:

(typical installation for unloading application) For detailed information see following Smith Meter

Two (2) L.L.C.’s with ATEX approved explosion proof bulletins:

sensor, stainless steel adapter assembly, side mounted AccuLoad Operator Reference Manual

as high and low level control. Bulletin MN06129

Used exclusively with Smith Meter Model 296 Two Stage AccuLoad Unloading

Set-Stop Valve (Figure 3). First-stage closure (flow rate Bulletin AB06055

decreases from high flow to low flow rate) is provided

when the “high level control” switch is activated and final

closure is provided, if the liquid level continues to drop

until the “low level control” switch is activated.

Note: For application of extreme air exhaust an additional air

release valve may be fitted, which also will be controlled by the

liquid level control device.

AccuLoad

Air Release

Valve

3

Junction Box

Power Supply

3 7

Supply

3 7 Inlet

High

High Flow

High Level Level

Inlet

Control Control

Valve

Junction Box

Valve Low Flow

Junction Box

Valve Valve

NO NC

Valve NO Valve NC

Low

Low Level

Level

Control Stop Flow Valve Stem Switch

Control

Valve Stem Switch

Outlet

Outlet

Please Notice:

Please Notice: All cables are to be approved for hazardous locations.

All cables are to be approved for hazardous locations. 3, 7 is the No. of wires.

3, 7 is the No. of wires.

Figure 3 – Smith Meter Liquid Level Control Figure 4 - Smith Meter Liquid Level Control

Model 296 Set-Stop Valve Model 210 Digital Electro-Hydraulical Set-Stop Valve

Issue/Rev. 0.3 (5/10) SS01058E • Page 3

Selection Guide

Volume (Liters)

Model Designation Design Capacity* Inlet/Outlet Flange**

"VDR" (L/Min) (Std. Available) Total Effective

010 1,000 2", 2-1/2", 3" 90 54

020 2,000 2", 3", 4" 185 106

025 2,500 3", 4", 6" 288 168

030 3,000 4", 6" 455 255

040 4,000 4", 6" 480 280

060 6,000 6", 8" 1,025 622

070 7,000 6", 8" 1,860 1,068

100 10,000 8", 10" 2,090 1,292

130 13,000 8", 10" 2,360 1,421

180 18,000 10", 12" 3,765 2,356

240 24,000 10", 12", 14" 5,400 3,373

350 35,000 12", 16" 8,750 5,950

* Consult factory for design capacities above 35,000 l/min.

Design flow capacity of equipment for product viscosity 20 cP @ 20° C.

** Inlet and/or outlet flange sizes other than those listed, consult factory.

Pressure Drop

Based on Fluid: Kerosene, Density: 794 Kg/m3, Viscosity: 1.73 mPa•s

Pressure Drop

VDR - 130

VDR - 180

VDR - 100

VDR - 70

VDR - 10

VDR - 20

VDR - 25

VDR - 30

VDR - 40

VDR - 60

PSI Bar

1.0 VDR - 240

0.07

0.9

0.06

0.8

0.7 0.05

0.6 VDR - 350

0.04

0.5

0.4 0.03

0.3 0.02

0.2

0.01

0.1

0 0

0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180 190 200 210 220 230 LPM x 100

0 100 200 300 400 500 600 700 800 900 1000 1100 1200 1300 1400 m3/h

0 1000 2000 3000 4000 5000 6000 GPM

Figure 5 – Pressure Drop

Page 4 • SS01058E Issue/Rev. 0.3 (5/10)

Modeling

Example: VDR — 060 — 2 — 04A — A —T0 — A — H0 — L

Liquid Level Controls

Type of Equipment 0 - not required

VDR - Vertical Deaerator L - Low Level Control

H - High Level Control

VDR Model

010 - VDR-10 070 - VDR-70

Liquid Level Controls (Model L.L.C.)

020 - VDR-20 100 - VDR-100 H0 - not required

025 - VDR-25 130 - VDR-130 H1 - 1 for High or Low Level Control

030 - VDR-30 180 - VDR-180 H2 - 2 for High and Low Level Control

040 - VDR-40 240 - VDR-240 H3 - 3 for Comprehensive Level Control

060 - VDR-60 350 - VDR-350 Design Standards

Working Pressure see bulletin AB0A003E

1 - PN 10 or 150 psi

2 - PN 16 or 232 psi Elastomer Seals

3 - PN 25 or 362 psi

see bulletin AB0A003E

Flange Size

02A - 2" ANSI 02D - DN 50 DIN

25A - 2.5" ANSI 25D - DN 65 DIN Flange Arrangement and Flow Direction

03A - 3" ANSI 03D - DN 80 DIN A - Arrangement A, Right Hand Spin

04A - 4" ANSI 04D - DN 100 DIN B - Arrangement B, Right Hand Spin

06A - 6" ANSI 06D - DN 150 DIN C - Arrangement C, Right Hand Spin

08A - 8" ANSI 08D - DN 200 DIN D - Arrangement D, Left Hand Spin

10A - 10" ANSI 10D - DN 250 DIN E - Arrangement E, Left Hand Spin

12A - 12" ANSI 12D - DN 300 DIN F - Arrangement F, Left Hand Spin

14A - 14" ANSI 14D - DN 350 DIN

16A - 16" ANSI 16D - DN 400 DIN

Right Hand Spin

A B C

Left Hand Spin

D E F

Figure 6 – Flange Arrangement and Flow Direction

Issue/Rev. 0.3 (5/10) SS01058E • Page 5

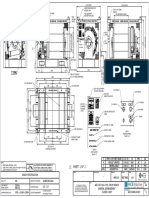

Dimensions

Model 10 to 100

Vent 3/4" NPT

120°

Air Release Head

Sight Glass

Manhole (Model 130 - 350)

30°

T

High Flow

Switch

Inlet

(Optional)

Low Flow

1/2 H

Switch

(Optional) Ø18

B (Effective Volume)

ØA

H

C*

Inspection Opening

Stop Flow

E*

VDR-20 (1x di: 50 mm)

VDR-25 to 40 (1x di: 120 mm) Switch Model 130 to 350

VDR-60 to 100 (2x di: 120 mm) (Optional)

45°

D

ØA

L

T

Outlet

F*

Drain ØA

Model 10 to 50 1 1/2" NPT

G

Model 70 to 350 2" NPT

Figure 7

* Dimensions C, E and F are subject to change on Pressure Ratings Note: NPT threaded and plugged drains are standard. Piped and

above PN 16 or on ASME coded vessels. Please consult Factory flanged drain connections available on request.

for specific informations.

Dimensions Model VDR

(mm) 10 20 25 30 40 60 70 100 130 180 240 350

A 356 457 508 610 650 813 1,016 1,100 1,150 1,350 1,550 1,900

B 550 650 830 910 930 1,200 1,350 1,360 1,395 1,700 1,835 2,155

C 1,536 1,716 2,006 2,156 2,186 2,707 2,952 2,952 3,122 3,602 3,883 4,275

D 600 700 900 950 950 1,100 1,250 1,300 1,400 1,600 1,800 2,200

E 1,050 1,230 1,520 1,670 1,700 2,175 2,420 2,420 2,570 3,050 3,330 3,800

F 430 440 480 500 550 600 660 680 725 750 820 925

G 200 200 200 200 200 200 200 200 200 200 200 200

T 125 160 160 210 205 280 380 390 415 460 570 700

H 360 405 570 590 630 880 1020 1020 1035 1330 1405 1665

L 300 340 400 420 440 450 460 480 510 550 610 710

Approximate Net Weight (kg)

Model VDR 10 Bar (-1) 16 Bar (-2) 25 Bar (-3) Model VDR 10 Bar (-1) 16 Bar (-2) 25 Bar (-3)

10 N/A 115 155 100 930 950 1,210

20 N/A 145 182 130 1,040 1,050 1,352

25 N/A 195 245 180 1,335 1,350 1,735

30 250 260 320 240 Consult Factory

40 275 300 380 350 Consult Factory

60 480 500 624

70 710 730 923

Page 6 • SS01058E Issue/Rev. 0.3 (5/10)

Model VDR

VDR Deaerator Standard

Issue/Rev. 0.3 (5/10) SS01058E • Page 7

Changes made to publication SS01058E Issue/Rev. 0.3 (5/10):

Editorial Change - Page 6, on figure 7

The specifications contained herein are subject to change without notice and any user of said specifications should verify from the manufacturer that the specifications are currently

in effect. Otherwise, the manufacturer assumes no responsibility for the use of specifications which may have been changed and are no longer in effect.

Contact information is subject to change. For the most current contact information, visit our website at www.fmctechnologies.com/measurementsolutions and click on the

“Contact Us” link in the left-hand column.

Headquarters:

500 North Sam Houston Parkway West, Suite 100, Houston, TX 77067 USA, Phone: +1 (281) 260 2190, Fax: +1 (281) 260 2191

Measurement Products and Equipment: Integrated Measurement Systems:

Erie, PA USA +1 (814) 898 5000 Dubai, United Arab Emirates +971 (4) 883 0303 Corpus Christi, TX USA +1 (361) 289 3400

Ellerbek, Germany +49 (4101) 3040 Los Angeles, CA USA +1 (310) 328 1236 Kongsberg, Norway +47 (32) 286700

Barcelona, Spain +34 (93) 201 0989 Melbourne, Australia +61 (3) 9807 2818 Dubai, United Arab Emirates +971 (4) 883 0303

Beijing, China +86 (10) 6500 2251 Moscow, Russia +7 (495) 5648705

Buenos Aires, Argentina +54 (11) 4312 4736 Singapore, +65 6861 3011

Burnham, England +44 (1628) 603205

Visit our website at www.fmctechnologies.com/measurementsolutions

Printed in U.S.A. © 5/10 FMC Technologies Measurement Solutions, Inc. All rights reserved. SS01058E Issue/Rev. 0.3 (5/10)

Вам также может понравиться

- Non Destructive Testing FacilityДокумент158 страницNon Destructive Testing FacilityClarkFedele27Оценок пока нет

- Williams Milton Roy V Series PumpsДокумент11 страницWilliams Milton Roy V Series PumpsIsaias Rodriguez Jimenez100% (2)

- IMT Technical Technical Specifications Specifications: Articulating Cranes Articulating CranesДокумент2 страницыIMT Technical Technical Specifications Specifications: Articulating Cranes Articulating CranesMiguel Angel Vazquez ServinОценок пока нет

- Section 34 - Sight GlassДокумент27 страницSection 34 - Sight GlasshammamiОценок пока нет

- EXAMPLE SIZING OWS Calculation Per API 421 PDFДокумент1 страницаEXAMPLE SIZING OWS Calculation Per API 421 PDFarnel_ado4412Оценок пока нет

- Technical Submittal - PF-K & Er-VДокумент50 страницTechnical Submittal - PF-K & Er-VClarkFedele27Оценок пока нет

- HAT Horiz Vessel VolДокумент1 страницаHAT Horiz Vessel VolAnonymous JWI6rqtОценок пока нет

- Knockout DrumДокумент9 страницKnockout Drumgautam_96948069Оценок пока нет

- Wedding Song ChordsДокумент13 страницWedding Song ChordsClarkFedele27Оценок пока нет

- Retention TimeДокумент10 страницRetention TimealexnomitaОценок пока нет

- AI 10 Prompts WorksheetsДокумент8 страницAI 10 Prompts WorksheetsSafeelloОценок пока нет

- Constructability Review ChecklistДокумент3 страницыConstructability Review ChecklistAnyanele Nnamdi FelixОценок пока нет

- 2000 High Speed CMOS Data DL129-D c20000324Документ408 страниц2000 High Speed CMOS Data DL129-D c20000324Dara Nyara Ricardo SocorroОценок пока нет

- Ace 02380 001 R8 PDFДокумент1 страницаAce 02380 001 R8 PDFClarkFedele27Оценок пока нет

- Well Test Standards Section 3.30 Chemical Injection Pumps: Global StandardДокумент8 страницWell Test Standards Section 3.30 Chemical Injection Pumps: Global StandardEmmanuelОценок пока нет

- Presentation 2009oil and GasДокумент102 страницыPresentation 2009oil and Gasmalik1000Оценок пока нет

- 1.0 Severn Glocon CV Sizing Selection ManualДокумент104 страницы1.0 Severn Glocon CV Sizing Selection Manualkoushik420000% (1)

- KO DrumДокумент3 страницыKO DrumArynda Dimas SadewoОценок пока нет

- Screw Pump 197131EДокумент59 страницScrew Pump 197131EJeffrey BaldwinОценок пока нет

- Real Separator Guide - HysysДокумент23 страницыReal Separator Guide - Hysysfri_13thОценок пока нет

- FAT Precedure - R 072 Nitrogen PackageДокумент10 страницFAT Precedure - R 072 Nitrogen PackageBudi UtomoОценок пока нет

- Centrifugal CompressorДокумент5 страницCentrifugal CompressorDeliaChiaОценок пока нет

- Installation, Operation & Maintenance Manual: Virgo Engineers LimitedДокумент47 страницInstallation, Operation & Maintenance Manual: Virgo Engineers LimitedSreenivasОценок пока нет

- DeaeratorДокумент8 страницDeaeratorfjoesandiОценок пока нет

- Cpi O&m ManualДокумент36 страницCpi O&m Manualprasad336Оценок пока нет

- TSV and PSV PDFДокумент5 страницTSV and PSV PDFMetoo ChyОценок пока нет

- Installation Procedure - 1200AДокумент18 страницInstallation Procedure - 1200AHarshkumar PatelОценок пока нет

- Ammonia BookletДокумент71 страницаAmmonia Bookletrao_consultantОценок пока нет

- Introduction To Fiscal MeteringДокумент24 страницыIntroduction To Fiscal MeteringAliОценок пока нет

- Ambient Crude Oil StorageДокумент13 страницAmbient Crude Oil StorageSrihari KodimelaОценок пока нет

- Reciprocating Compressor 11p Vs 618Документ4 страницыReciprocating Compressor 11p Vs 618karehmanОценок пока нет

- Valve Inspection and Test PlanДокумент1 страницаValve Inspection and Test PlanClarkFedele27100% (1)

- Compressor Troubleshooting: Problem Cause SolutionДокумент11 страницCompressor Troubleshooting: Problem Cause SolutionPatrickioОценок пока нет

- Vacuum EjectorДокумент6 страницVacuum EjectorAmol KadamОценок пока нет

- Actuator Maintenance ServicesДокумент7 страницActuator Maintenance ServicesKevin MuhalingОценок пока нет

- Hydrocyclone SeparatorДокумент2 страницыHydrocyclone Separatorgautam_96948069100% (1)

- 3, Promass F300 - TI01221DEN - 1022-00Документ134 страницы3, Promass F300 - TI01221DEN - 1022-00tlakiri100% (2)

- S11 Electric ComponentsДокумент72 страницыS11 Electric ComponentsLiliana Rebeca Santos santosОценок пока нет

- A O Smith Meter 2 Inch Steel Model C2Документ4 страницыA O Smith Meter 2 Inch Steel Model C2RomankoОценок пока нет

- Smith Meter UPTДокумент6 страницSmith Meter UPTvalimironescuОценок пока нет

- Smith Meter Flow ComputerДокумент10 страницSmith Meter Flow Computeriky7750% (2)

- Design, Operation and Maintenance of Lact UnitsДокумент3 страницыDesign, Operation and Maintenance of Lact UnitsJose gonzalezОценок пока нет

- API Separators - SolutionsДокумент8 страницAPI Separators - SolutionsnorthstarleoОценок пока нет

- 12" Steel Model K12: Smith Meter CT Series PD Meter For Crude TransportationДокумент4 страницы12" Steel Model K12: Smith Meter CT Series PD Meter For Crude Transportationjuan carlosОценок пока нет

- PSV LPG TankДокумент8 страницPSV LPG TankyosafatedenОценок пока нет

- IPS e El 110Документ105 страницIPS e El 110alinaghibОценок пока нет

- 4" Steel Model F4: Smith Meter PD Rotary Vane MeterДокумент4 страницы4" Steel Model F4: Smith Meter PD Rotary Vane MeterVictor FreireОценок пока нет

- Den Con CatalogДокумент36 страницDen Con Catalogbaskaran vОценок пока нет

- Fuel Gas Compressor SystemДокумент64 страницыFuel Gas Compressor Systemrokan123Оценок пока нет

- Meter Linearity Turbine Meter PerspectiveДокумент3 страницыMeter Linearity Turbine Meter PerspectiveraminОценок пока нет

- Smith Meter Prime 4Документ2 страницыSmith Meter Prime 4gerosuca800Оценок пока нет

- Restrictive Orifice Straight Run RequirementДокумент2 страницыRestrictive Orifice Straight Run RequirementAbbasОценок пока нет

- 3-Phase Test Separators VVFДокумент2 страницы3-Phase Test Separators VVFPetroFisicОценок пока нет

- TechnicalДокумент3 страницыTechnicalbmanojkumar16Оценок пока нет

- Static Pressure Calculation SheetДокумент24 страницыStatic Pressure Calculation SheetMuhammad ZubairОценок пока нет

- GT Tray Tower1 PDFДокумент12 страницGT Tray Tower1 PDFJose Christian Viladegut GuzmanОценок пока нет

- Echometer Well AnalysisДокумент1 страницаEchometer Well AnalysisefrasozaОценок пока нет

- 1290 RegulatorsДокумент3 страницы1290 RegulatorsPitichai PakornrersiriОценок пока нет

- Complete Paper Technical and Economical Comparison Between Installations of Multi Phase Test Separator or Multiphase Flow Meters On Gas - LibreДокумент10 страницComplete Paper Technical and Economical Comparison Between Installations of Multi Phase Test Separator or Multiphase Flow Meters On Gas - LibrePovenesan KrishnanОценок пока нет

- National Iranian Oil Company: South Pars Gas Field Development Phase 19 Onshore FacilitiesДокумент13 страницNational Iranian Oil Company: South Pars Gas Field Development Phase 19 Onshore FacilitiesNasim MemarianОценок пока нет

- Hamdon Echometer Model E Well Analyzer BrochureДокумент4 страницыHamdon Echometer Model E Well Analyzer BrochurearispriyatmonoОценок пока нет

- QIP-PDI-G.3 - Design Instruction For Standard Pipe Support SelectionДокумент1 страницаQIP-PDI-G.3 - Design Instruction For Standard Pipe Support Selectiondimas prasetyoОценок пока нет

- Emerson Compact Prover Datasheet - Dec20Документ16 страницEmerson Compact Prover Datasheet - Dec20GUSTAVO HERNANDEZОценок пока нет

- IR HL Heatless DryerДокумент1 страницаIR HL Heatless DryerYing Kei ChanОценок пока нет

- Metal Tapered Tube Plugs: Tube Plug Sizing ChartДокумент1 страницаMetal Tapered Tube Plugs: Tube Plug Sizing ChartRaghavanОценок пока нет

- Oil Field ManagerДокумент3 страницыOil Field ManagerWalter Eloy Ramirez CarranzaОценок пока нет

- Air Blowing ProcedureДокумент11 страницAir Blowing ProcedureBhayu Eka AnggitaОценок пока нет

- Details of KO DrumДокумент7 страницDetails of KO Drumnishank soniОценок пока нет

- Deaereator CapacityДокумент8 страницDeaereator Capacityedgardiaz5519Оценок пока нет

- 100 0400Документ8 страниц100 0400Benito.camelasОценок пока нет

- Valve GADДокумент2 страницыValve GADClarkFedele27Оценок пока нет

- Sutech Valves - Product RangeДокумент5 страницSutech Valves - Product RangeClarkFedele27Оценок пока нет

- Copon EA 4-2217 Data SheetДокумент2 страницыCopon EA 4-2217 Data SheetClarkFedele27Оценок пока нет

- Carbothane 134Документ2 страницыCarbothane 134ClarkFedele27Оценок пока нет

- Venting Requirement - API 2000 5th EditionДокумент1 страницаVenting Requirement - API 2000 5th EditionClarkFedele27Оценок пока нет

- APS Business ReferencesДокумент3 страницыAPS Business ReferencesClarkFedele27Оценок пока нет

- 18B. Protegol UR 32.55R Data SheetДокумент3 страницы18B. Protegol UR 32.55R Data SheetClarkFedele27Оценок пока нет

- Cameron: Valves & Measurement General Arrangement 4"-150 CL, MODEL 211, 201 HO Safety Bleed/DtrДокумент1 страницаCameron: Valves & Measurement General Arrangement 4"-150 CL, MODEL 211, 201 HO Safety Bleed/DtrClarkFedele27Оценок пока нет

- Carbozinc 11: Selection & Specification Data Substrates & Surface PreparationДокумент2 страницыCarbozinc 11: Selection & Specification Data Substrates & Surface PreparationClarkFedele27Оценок пока нет

- Product Data: Carboguard 190 HДокумент2 страницыProduct Data: Carboguard 190 HClarkFedele27100% (1)

- APS - New Capability StatementДокумент12 страницAPS - New Capability StatementClarkFedele27Оценок пока нет

- 16 150 8811 DTR.L Ma.g Fa14 - Rev02Документ1 страница16 150 8811 DTR.L Ma.g Fa14 - Rev02ClarkFedele27Оценок пока нет

- 24 150 8811 DTR.L Go.aДокумент1 страница24 150 8811 DTR.L Go.aClarkFedele27Оценок пока нет

- Avery Hardoll Whittaker Controls 4 Inch Self Sealing Ind CouplingsДокумент2 страницыAvery Hardoll Whittaker Controls 4 Inch Self Sealing Ind CouplingsClarkFedele27Оценок пока нет

- CatalogueДокумент2 страницыCatalogueClarkFedele27Оценок пока нет

- 24 150 8811 DTR.L Ma.g Fa14Документ1 страница24 150 8811 DTR.L Ma.g Fa14ClarkFedele27Оценок пока нет

- 04 150 211 DTR.L Mat Fa10Документ1 страница04 150 211 DTR.L Mat Fa10ClarkFedele27Оценок пока нет

- 20 150 8811 DTR.L Ma.g Fa14Документ1 страница20 150 8811 DTR.L Ma.g Fa14ClarkFedele27Оценок пока нет

- Brochure Alfa 2019Документ15 страницBrochure Alfa 2019ClarkFedele27Оценок пока нет

- 9.1 Corporate Profile: SchlumbergerДокумент5 страниц9.1 Corporate Profile: SchlumbergerClarkFedele27Оценок пока нет

- Orbit Facility ProfileДокумент23 страницыOrbit Facility ProfileClarkFedele27Оценок пока нет

- COMMENTS On Sample Testing of ERW Pipes For Verification On The Material Compliance To API 5L PSL 2 and The Pipe/Coil Material Test CertificatesДокумент3 страницыCOMMENTS On Sample Testing of ERW Pipes For Verification On The Material Compliance To API 5L PSL 2 and The Pipe/Coil Material Test CertificatesClarkFedele27Оценок пока нет

- PO Box 4038, Doha, Qatar Telephone (+974) 4407 6000 / 4460 0099 /4407 6444 Fax: (+974) 4407 6498Документ12 страницPO Box 4038, Doha, Qatar Telephone (+974) 4407 6000 / 4460 0099 /4407 6444 Fax: (+974) 4407 6498ClarkFedele27Оценок пока нет

- Ace 00480 01001 R5Документ2 страницыAce 00480 01001 R5ClarkFedele27Оценок пока нет

- Test Architecture, Test RetrofitДокумент22 страницыTest Architecture, Test RetrofitReza MobashsherniaОценок пока нет

- Manual (As of 31/10/2020)Документ5 страницManual (As of 31/10/2020)Turtle GamesОценок пока нет

- Lge2121 MSДокумент1 страницаLge2121 MSPiotrОценок пока нет

- Alphabet Series Tricks - PDF: Intervals LikeДокумент7 страницAlphabet Series Tricks - PDF: Intervals LikeAbhishek A. NadgireОценок пока нет

- Unit I IntroductionДокумент15 страницUnit I IntroductionMUKILANОценок пока нет

- Understanding Commercial and Government EntityДокумент5 страницUnderstanding Commercial and Government EntitystackedaerospaceОценок пока нет

- Autonomous Landing of A VTOL UAV On A Moving Platform Using Image-Based Visual ServoingДокумент6 страницAutonomous Landing of A VTOL UAV On A Moving Platform Using Image-Based Visual Servoinglove_acОценок пока нет

- KNPC LPG Train-4 Project at MAA Refinery: For ApprovalДокумент8 страницKNPC LPG Train-4 Project at MAA Refinery: For ApprovalNeelam AhmadОценок пока нет

- Print LearnerДокумент1 страницаPrint Learnersyed mithuОценок пока нет

- Engine MountДокумент1 страницаEngine MountHarist ArdyОценок пока нет

- 4th MiningДокумент18 страниц4th MiningPrince SinghОценок пока нет

- JellДокумент1 страницаJellMuhammad DanuОценок пока нет

- ST Peter, 2014, BI-Annual DR-TB Performance Report To AAHB, 15 March 2022. JohnДокумент43 страницыST Peter, 2014, BI-Annual DR-TB Performance Report To AAHB, 15 March 2022. Johnሀይደር ዶ.ርОценок пока нет

- 3 ERP Software RFP Exhibit GДокумент575 страниц3 ERP Software RFP Exhibit GJacob YeboaОценок пока нет

- Green ComputingДокумент7 страницGreen Computingerwin.dee.cicsОценок пока нет

- PM CLINIC WB97R-5E0 SN F90001-Up 05102017Документ3 страницыPM CLINIC WB97R-5E0 SN F90001-Up 05102017efrain.hilario.86Оценок пока нет

- Solving Rational InequalityДокумент67 страницSolving Rational Inequalityjeremee balolongОценок пока нет

- Lightweight Asynchronous Snapshots For Distributed Dataflows (Flink)Документ8 страницLightweight Asynchronous Snapshots For Distributed Dataflows (Flink)SiuMing ChanОценок пока нет

- Voucher WIFI ZONE Deux Heures Up 671 07.01.21Документ5 страницVoucher WIFI ZONE Deux Heures Up 671 07.01.21kodjo ELOMОценок пока нет

- Monty 1510: Spare Parts List Tire ChangerДокумент24 страницыMonty 1510: Spare Parts List Tire ChangerJonathan FullumОценок пока нет

- Installation Guide: EV Power Chargers 3kW HEДокумент12 страницInstallation Guide: EV Power Chargers 3kW HEnikhom_dk1565Оценок пока нет

- Zero TrustДокумент10 страницZero TrustParv MethiОценок пока нет

- Problems s7Документ4 страницыProblems s7zangue billy jamesОценок пока нет

- Prateek Chotani: Contact: (+91) 9999008226 Address: H.NO-2456 Sec 16 Faridabad 121002, HaryanaДокумент2 страницыPrateek Chotani: Contact: (+91) 9999008226 Address: H.NO-2456 Sec 16 Faridabad 121002, Haryanavinay1878Оценок пока нет

- Code MSGДокумент186 страницCode MSGricardoweberОценок пока нет