Академический Документы

Профессиональный Документы

Культура Документы

WIweld01 Co2 Welding Rev 01

Загружено:

Gautam KumarОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

WIweld01 Co2 Welding Rev 01

Загружено:

Gautam KumarАвторское право:

Доступные форматы

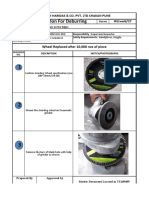

ANANDJI HARIDAS & CO PVT LTD CHAKAN PUNE

WORK

INSTRUCTION WI/weld /01

Work Instructions for usage of Anti Spray NO

1.0 Purpose : To under stand How we can used anti Spatter Spray

2.0 Scope : All Co2 Welding /MIG welding

3.0 Record: Co2 welding Inspection report

Associated Co2 MIG Welding Process Inspection Report , Control Plan

4.0 Documents :

5.0 Responsibility Welding prod In charge , Co2/MIG Welder

6.0 Anti Spray bottle SPRAYMOULD : Silcon Spray

Safety RequiremHand gloves

Anti Spray : It is ideal compund for all ferrous parts . It is excellent corrosion resistance & useful aid to prevent flying metla

8.0 spraks form sticking to the metal thus avoiding further Grinding Deburring Operations

This is also suitable to useon welding gun nozzle which which will leave a film on a nozzle.this film prevents flying

metal sparks from sticking to the gun increses life of Gun

Directions Of Use

9.0

9.1 Refer Mfg Date of Mfg & ensures that date should not be more than 18 months

9.2 Shake can gently before use

9.3 Spray On the Gun Nozzle and inside the Nozzle over contact Tip before start of welding

9.4

Repeat the procedure after 4 Hours

Clean accummulated Spatter inside the Nozlle & clean

9.5

Spray on the job nearthe weld before welding Operations

9.6

9.7 Clean the spatter with easily without grinder

10.0 CAUTION

10.1 Do not Kept the bottle in the sun

10.2 Do not kept near Fire or heat

10.3 Do not punchure the empty bottle

If bottle is found in leaked conditons informed supervisor for dispsoal

10.4

Point no 9.3 is added based on

3/15/2016 Paresh Gowardhan Ulhas Kavathekar

1 customer compalints

0 12/15/2015 New released Paresh Gowardhan Ulhas Kavathekar

Rev No Rev Date Details of Revision Prepared By Approved By

Вам также может понравиться

- Powder Coating: A How-to Guide for Automotive, Motorcycle, and Bicycle PartsОт EverandPowder Coating: A How-to Guide for Automotive, Motorcycle, and Bicycle PartsРейтинг: 4.5 из 5 звезд4.5/5 (17)

- Aws C1.5 2015Документ2 страницыAws C1.5 2015SARATH KRISHNAKUMAR0% (3)

- Power INSPECTДокумент229 страницPower INSPECTmaruti mishra100% (4)

- Nike Case StudyДокумент6 страницNike Case Studyapi-361156846100% (1)

- VBC Fl-10W: Water Insoluble Punching Fluid FL-10W Is Designed To Be Suitable For Aluminum Fin Press and CopperДокумент1 страницаVBC Fl-10W: Water Insoluble Punching Fluid FL-10W Is Designed To Be Suitable For Aluminum Fin Press and CopperSinh LeОценок пока нет

- All Work InstructionsДокумент7 страницAll Work InstructionsAmine Chahi100% (1)

- Procedure For Liquid Penetrant ExaminationДокумент12 страницProcedure For Liquid Penetrant ExaminationShashank ParmarОценок пока нет

- WI-02 Thermal CuttingДокумент16 страницWI-02 Thermal CuttingPrakash RajОценок пока нет

- Compressor Oil SДокумент2 страницыCompressor Oil SQuy CocanhОценок пока нет

- CompressorДокумент2 страницыCompressorQuy CocanhОценок пока нет

- PDS - AEROL SYNTHETIC S (EN) Rev.18-00Документ2 страницыPDS - AEROL SYNTHETIC S (EN) Rev.18-00Toppy ToppyОценок пока нет

- MOLYKOTE CO220 Oil IДокумент2 страницыMOLYKOTE CO220 Oil ILuz Angela GuerreroОценок пока нет

- Project Work InstructionДокумент5 страницProject Work InstructionRAJU RAJPUTОценок пока нет

- VBC Finedraw 1900K: DescriptionДокумент1 страницаVBC Finedraw 1900K: DescriptionSinh LeОценок пока нет

- Interzinc 2280 Application Guidelines UkДокумент9 страницInterzinc 2280 Application Guidelines UkTrần minh ngọcОценок пока нет

- Mud Gate Valve Manual PDFДокумент11 страницMud Gate Valve Manual PDFParag PadoleОценок пока нет

- Project Work Instruction BackupДокумент4 страницыProject Work Instruction BackupRAJU RAJPUTОценок пока нет

- Specialty Lubricants: Molykote® G-Rapid PlusДокумент2 страницыSpecialty Lubricants: Molykote® G-Rapid PlusD CОценок пока нет

- Staburags Nbu 4 12Документ4 страницыStaburags Nbu 4 12Imam SyahputraОценок пока нет

- TL E90 Anti Spatter SprayTDS ENGДокумент2 страницыTL E90 Anti Spatter SprayTDS ENGEmin MešićОценок пока нет

- VBC Press Ex-85V: Punching FluidДокумент1 страницаVBC Press Ex-85V: Punching FluidSinh LeОценок пока нет

- Pvi PDFДокумент3 страницыPvi PDFBharat ChatrathОценок пока нет

- Interzinc 22 Application Guidelines UkДокумент10 страницInterzinc 22 Application Guidelines Ukapde06Оценок пока нет

- Examination Procedures For Vacuum TestДокумент9 страницExamination Procedures For Vacuum TestOsilonya HenryОценок пока нет

- Aircol PD RangeДокумент2 страницыAircol PD RangecarmaОценок пока нет

- Bharat Heavy Electricals Limited: Tiruchirappalli-620 014 Fuel Systems/PE (FB)Документ7 страницBharat Heavy Electricals Limited: Tiruchirappalli-620 014 Fuel Systems/PE (FB)bmanojkumar16Оценок пока нет

- 4) Liquid Penetrant Examination PDFДокумент3 страницы4) Liquid Penetrant Examination PDFAmit AcharyaОценок пока нет

- TDS Shell Gadus S2 OGH 0 00 TDS Open GearДокумент2 страницыTDS Shell Gadus S2 OGH 0 00 TDS Open GearBenedict KargboОценок пока нет

- Cleaning Fuel Injector NozzlesДокумент6 страницCleaning Fuel Injector NozzlesRay DutchmanОценок пока нет

- Corrosion KING HBE (Primer All User) Tech. DataДокумент2 страницыCorrosion KING HBE (Primer All User) Tech. Datamuhamadrafie1975Оценок пока нет

- VBC FL-2000: Water Insoluble Punching FluidДокумент1 страницаVBC FL-2000: Water Insoluble Punching FluidSinh LeОценок пока нет

- IOM - Gas Detector - AE - AIYI - EN Manual-AG200 Series Fixed Gas Detector - AnrN - AnrSДокумент24 страницыIOM - Gas Detector - AE - AIYI - EN Manual-AG200 Series Fixed Gas Detector - AnrN - AnrSamielОценок пока нет

- MOLYKOTE L-1668FM Synthetic Blend Vacuum Pump Oil 80-8456A-01 PDFДокумент2 страницыMOLYKOTE L-1668FM Synthetic Blend Vacuum Pump Oil 80-8456A-01 PDFFajar EkoОценок пока нет

- SMF&W 851-01-07 Manual Arc Welding 220319Документ9 страницSMF&W 851-01-07 Manual Arc Welding 220319Shahid RazaОценок пока нет

- TDS - Motul VIS 46 - ENДокумент2 страницыTDS - Motul VIS 46 - ENnghiaОценок пока нет

- Service Manual GX270Документ183 страницыService Manual GX270Aditya ReleОценок пока нет

- Salt Spray ReportДокумент1 страницаSalt Spray ReportaslamОценок пока нет

- Ambersil Copper High Temperature Anti Seize Paste TDSДокумент2 страницыAmbersil Copper High Temperature Anti Seize Paste TDSjawnuolisОценок пока нет

- Liquid Dye Penetration Examination: 1.0 ScopeДокумент3 страницыLiquid Dye Penetration Examination: 1.0 Scopesuria qaqc100% (1)

- Approvals - Listofproducts - Siemens 2019 PDFДокумент3 страницыApprovals - Listofproducts - Siemens 2019 PDFHussain SyedОценок пока нет

- NBC 2016-Vol.1 PDFДокумент26 страницNBC 2016-Vol.1 PDFMangesh KorpeОценок пока нет

- Shell Gadus S2 - OGHДокумент2 страницыShell Gadus S2 - OGHputel_ajaОценок пока нет

- Assembly Fluid 1Документ1 страницаAssembly Fluid 1Rifki AndriyanОценок пока нет

- Surface Preparation & Painting ProcedureДокумент9 страницSurface Preparation & Painting ProcedureRam ThevarОценок пока нет

- QC - 06 Surface Preparation & Painting 2Документ6 страницQC - 06 Surface Preparation & Painting 2mahendraОценок пока нет

- A110 210 Ä Éaëpò 201117Документ1 страницаA110 210 Ä Éaëpò 201117Phan Trong ThucОценок пока нет

- RSH 270.00 PadeyesДокумент3 страницыRSH 270.00 PadeyesmanikandanОценок пока нет

- MOLYKOTE HSC Plus Paste 71-0212H-01Документ2 страницыMOLYKOTE HSC Plus Paste 71-0212H-01Vendy KurniawanОценок пока нет

- WSX ND24C User ManualДокумент19 страницWSX ND24C User ManualAndrejОценок пока нет

- Molykote® SK-623Документ2 страницыMolykote® SK-623If ChenОценок пока нет

- DR Fixit Instant Leak Plug 67 1Документ2 страницыDR Fixit Instant Leak Plug 67 1Gurumoorthy SОценок пока нет

- KSVB - Manual Installation Operation Maintenance Repair Manual - Oil Lubricated, Rotary Vane Vacuum PumpДокумент24 страницыKSVB - Manual Installation Operation Maintenance Repair Manual - Oil Lubricated, Rotary Vane Vacuum PumpahmedОценок пока нет

- How To Use Desoldering WickДокумент9 страницHow To Use Desoldering WickjackОценок пока нет

- DC-3522-TD Dow Corning 3522Документ2 страницыDC-3522-TD Dow Corning 3522nakul164Оценок пока нет

- Nevastane AW PDFДокумент1 страницаNevastane AW PDFsteve liamluntunganОценок пока нет

- Molykote® P-37 Datasheet Eng PDFДокумент2 страницыMolykote® P-37 Datasheet Eng PDFBib GmzОценок пока нет

- Isuzu 4le1t Shop OpmДокумент210 страницIsuzu 4le1t Shop OpmYogi PurchasingОценок пока нет

- Ca1101 TdsДокумент2 страницыCa1101 TdsJosevi Jiménez MerinoОценок пока нет

- BIX Dye Penetrant ProcedureДокумент7 страницBIX Dye Penetrant ProcedureEduard Abastillas100% (1)

- Vtv-3281-Lit-9511-Pp-Doc-034 R3Документ13 страницVtv-3281-Lit-9511-Pp-Doc-034 R3VIVEK TIWARIОценок пока нет

- Steelshield Ve: Product DescriptionДокумент2 страницыSteelshield Ve: Product DescriptionMoin AltafОценок пока нет

- B2 AIR 24200 Catalogue Sheet EN 05 21Документ2 страницыB2 AIR 24200 Catalogue Sheet EN 05 21bulentОценок пока нет

- TDS Food Grade Chain LubeДокумент2 страницыTDS Food Grade Chain LubeJavier PinzonОценок пока нет

- CH4 2 Welding Joint PreparationДокумент46 страницCH4 2 Welding Joint PreparationMatija BušićОценок пока нет

- Welding Defects PresentationДокумент40 страницWelding Defects PresentationGautam KumarОценок пока нет

- Welding DefectsДокумент13 страницWelding DefectsVinay Kumar SharmaОценок пока нет

- Welding DefectsДокумент32 страницыWelding DefectsJayesh100% (3)

- Welding Procedure PreparationДокумент122 страницыWelding Procedure Preparationthe_badass1234100% (21)

- ISO 2553 Weld SymbolsДокумент63 страницыISO 2553 Weld SymbolsSudip100% (4)

- WIweld09 Carbon Impression Testing Rev 01Документ1 страницаWIweld09 Carbon Impression Testing Rev 01Gautam KumarОценок пока нет

- WIweld04 Weld Penetration Rev 01Документ1 страницаWIweld04 Weld Penetration Rev 01Gautam KumarОценок пока нет

- WIWELD11 Torsional Test DraftДокумент1 страницаWIWELD11 Torsional Test DraftGautam KumarОценок пока нет

- WIWeld27 Deburring Rev 00Документ2 страницыWIWeld27 Deburring Rev 00Gautam KumarОценок пока нет

- WIWeld21 Welding Defect Repair Rev 00Документ4 страницыWIWeld21 Welding Defect Repair Rev 00Gautam KumarОценок пока нет

- WIweld05 Nugget Test Rev 00Документ4 страницыWIweld05 Nugget Test Rev 00Gautam KumarОценок пока нет

- WIweld10 Dye Penetrant Examination Rev 00Документ3 страницыWIweld10 Dye Penetrant Examination Rev 00Gautam KumarОценок пока нет

- Welding HandbookДокумент441 страницаWelding HandbookGautam KumarОценок пока нет

- Welding HandbookДокумент441 страницаWelding HandbookGautam KumarОценок пока нет

- Automation System Integration IMTMA Pune 230311 - PPTДокумент52 страницыAutomation System Integration IMTMA Pune 230311 - PPTGautam KumarОценок пока нет

- Ressistance WeldingДокумент12 страницRessistance WeldingGautam KumarОценок пока нет

- Welding HandbookДокумент441 страницаWelding HandbookGautam KumarОценок пока нет

- Motor Load MonitorДокумент4 страницыMotor Load MonitorRenghat RumahorboОценок пока нет

- رافضیت کے معمار ج1،9 - compressedДокумент310 страницرافضیت کے معمار ج1،9 - compressedAkramОценок пока нет

- Ernest Rutherford 1Документ8 страницErnest Rutherford 1api-400268497Оценок пока нет

- 2.7 Valve Block Oil: 567802 Ref Part No Description - 08 NotesДокумент2 страницы2.7 Valve Block Oil: 567802 Ref Part No Description - 08 NotesPrinceSadhotraОценок пока нет

- Antenna Theory TutorialДокумент20 страницAntenna Theory TutorialAbhicruiserОценок пока нет

- ALUPEX BrochureДокумент5 страницALUPEX BrochureTamas PapikОценок пока нет

- Carrier Platinum I.MДокумент71 страницаCarrier Platinum I.MAndreas KalamarasОценок пока нет

- List of Practical TrainingДокумент2 страницыList of Practical TrainingБиржан МубаракОценок пока нет

- INSEKTOMORДокумент12 страницINSEKTOMORRamoОценок пока нет

- Hysil Brochure MailДокумент19 страницHysil Brochure Mailsudershan_babbarОценок пока нет

- Advanced Power System-I (Department Elective-I)Документ4 страницыAdvanced Power System-I (Department Elective-I)Palak AriwalaОценок пока нет

- 2018.11.28 - BD Net Metering Guideline 2018 (English) PDFДокумент42 страницы2018.11.28 - BD Net Metering Guideline 2018 (English) PDFChowdhury, A HasibОценок пока нет

- A320LEAP1A-B12-0008.7 Oil R1 220517Документ82 страницыA320LEAP1A-B12-0008.7 Oil R1 220517simsimsomОценок пока нет

- HYSYS Upstream GuideДокумент188 страницHYSYS Upstream GuideJahangir Malik100% (1)

- Usm Stis 2011 - Bahasa InggrisДокумент16 страницUsm Stis 2011 - Bahasa InggrisAhmad Pique Baisuni100% (1)

- Unit I Environment, Ecosystems and BiodiversityДокумент24 страницыUnit I Environment, Ecosystems and BiodiversitydeepaОценок пока нет

- JEE ChemistryДокумент4 страницыJEE Chemistryrjpatil19Оценок пока нет

- Bca SyllabusДокумент55 страницBca Syllabusapi-349492533Оценок пока нет

- Atoms, Electron Structure and Periodicity HWДокумент14 страницAtoms, Electron Structure and Periodicity HWLuke WilliamsonОценок пока нет

- PIA B2 - Module 2 (PHYSICS) SubModule 2.5 (Wave Motion and Sound) FinalДокумент17 страницPIA B2 - Module 2 (PHYSICS) SubModule 2.5 (Wave Motion and Sound) Finalsamarrana1234679Оценок пока нет

- Split Phase LV5048Документ1 страницаSplit Phase LV5048A CermenoОценок пока нет

- Infrared SpectrosДокумент3 страницыInfrared SpectrosAmanda CarvalhoОценок пока нет

- Helmholtz CoilДокумент6 страницHelmholtz CoilFieraru Ionut RaduОценок пока нет

- Kuhnke IA Series Relay DatasheetДокумент4 страницыKuhnke IA Series Relay DatasheetKishore KОценок пока нет

- C5-21B B777 CapabilitiesДокумент8 страницC5-21B B777 CapabilitiesPablo Restrepo OssaОценок пока нет

- Advances in Magnetic Pipeline InspectionДокумент5 страницAdvances in Magnetic Pipeline InspectionJohnny Walker100% (3)

- CAPEX PURCHASE POs 214Документ14 страницCAPEX PURCHASE POs 214OmkarОценок пока нет

- Fuel Cells and Its Applications (Che 694)Документ15 страницFuel Cells and Its Applications (Che 694)kolade olayodeОценок пока нет

- CIE IGCSE Forces Hookes Law OnlyДокумент22 страницыCIE IGCSE Forces Hookes Law Onlyh aОценок пока нет