Академический Документы

Профессиональный Документы

Культура Документы

PME0000 Daily Weekly Jobs Hoist#20

Загружено:

Radhe Agri Products0 оценок0% нашли этот документ полезным (0 голосов)

16 просмотров2 страницыDaily Weekly Jobs for Hoist#20

Авторское право

© © All Rights Reserved

Доступные форматы

DOC, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документDaily Weekly Jobs for Hoist#20

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOC, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

16 просмотров2 страницыPME0000 Daily Weekly Jobs Hoist#20

Загружено:

Radhe Agri ProductsDaily Weekly Jobs for Hoist#20

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOC, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 2

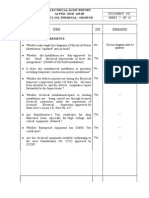

Shiv-Vani Oil & Gas Co.

LLC

Preventive Maintenance System Version 1.0

Department : ELECTICAL Hoist #20

Maintenance Frequency : PMS Code :PME0000

PMS CHECK LIST

Induction Motors (Daily)

- Check for any vibration / abnormal noise

- Check for any damaged exposed cables

- Check that ground cable is connected properly

- Check for over heating of motor or cables

- Ensure that area surrounding the equipment is reasonably clean and free

from any oil/grease spillage.

- Ensure that protective covers are in place.

- Check motors and cables for overheating

- Check motor fan intake fins are not obstructed

- Inspect surrounding for dripping oil, water, etc

Air Condition Units for Accomodations/Site(Weekly)

- Clean filters

- Wipe out grill

- Check cooling/heating operation

Rig Generators No 1 &2 (Daily)

- Check cables

- Check air suction and discharge free of obstruction.

- Check voltage/cable

- Check current/frequency

- Check battery voltage and charging

Camp Generators No 1 & 2 (Daily)

- Check the following

- Voltage/Cable

- Current

- Frequency

- Battery voltage and charging

Instrumentation at choke manifold (Daily)

- Wipe and clean the unit

- Check for proper functioning

Shale Shaker No 1 & 2 (Daily)

- Check the operation of motors

- Check the power cable and ground cable

- Check motor foundation bolts/nuts

- Check motor terminal box and cable entry gland

Intercom System (Weekly)

- Clean speaker horns and receiver units

(Daily)

- Visually check condition of cables and receiver units.

- Establish communication with each receiver unit and check the function.

Electric Welding Set (Weekly)

- Check the operation of the unit

- Check the condition of the cables

SV/PMD/01 Page 1 July 2005

Shiv-Vani Oil & Gas Co. LLC

Preventive Maintenance System Version 1.0

Rig Lighting (Weekly)

- clean the lenses of light

(Daily)

- All lights fixtures

- Lenses of all lights

- All flourescent/HPMV/bulbs are glowing

- Check condition of cables

Refrigeration/Deep Freezers (Rig & Camp) (Weekly)

- Check for proper function

+:

Kitchen Equipments

- Do not carry out internal insp/repair/maint of microwave ovens and

insetocutors.

- Check out visual inspection for proper functioning

- Check that exhaust chimney filters are cleaned (Job to be done by Camp Boss

+:

UPS SYSTEM IN OFFICES ON RIG SITE-(DAILY)

- VISUALLY INSPECT THE UNIT FOR PROPER FUNTIONING

- ENSURE THAT UNIT IS FREE FRON EXTERNAL OBSTRUCTION AND IS WELL

VENTILATED.

- ENSURE THAT ALL IN/OUT GOING CABLES ARE SECURE AND TIDY.

+

Earthing pits in camp and rig site:- (WEEKLY)

-Check for integrity of earthing pits.

- If rig/camp are on one location for more than one MONTH, check earth

resistance and ensure that present reading has not increased as compared

to previous reading.If the present reading is higher that previous reading

investigate the cause and if required fill earth pit with water.

+

Checks for all plug and sockets:-(DAILY)

- Check all plug and socket to ensure that they are NOT overhaeting.

- Check all plugs and sockets for electrical and mechanical integrity.

- Check that all plugs and sockets are free from ingress of water,

- Ensure that cables are properly terminated to plugs and sockets.

- Check and ensure that breakers connected to plugs and sockets are

functioning properly.

- Before plugging in Plugs,check plug pins and sockets for any discoloration

due overheating.Investigate cause of discoloration and change P n S.

+

-CAMP AND SITE FIRE PUMP BATTREY AND CHARGER

- CHECK BATTERY AND ENSURE THAT IT IS FULLY CHARGED TO SATRT PUMP AT

ALL TIME.

- CHECK BATTREY CHARGER FITTED ON EACH PUMP STARTING PANEL.IF NOT

FITTED

REPORT TO PMM.

=

Note:- Do not carry out internal insp/repair/maint of TVs and PC monitors.

REMARKS

PMS EXECUTED BY __________________ DATE___________ Signature ___________

SV/PMD/01 Page 2 July 2005

Вам также может понравиться

- Pms Check List: (Daily)Документ2 страницыPms Check List: (Daily)Radhe Agri ProductsОценок пока нет

- PMD0000 Daily Weekly Jobs Hoist#20Документ3 страницыPMD0000 Daily Weekly Jobs Hoist#20Radhe Agri ProductsОценок пока нет

- Pms Check List: (1) - Travelling Block and HookДокумент3 страницыPms Check List: (1) - Travelling Block and HookRadhe Agri ProductsОценок пока нет

- Pms Check List: (1) - Travelling Block and HookДокумент3 страницыPms Check List: (1) - Travelling Block and HookRadhe Agri ProductsОценок пока нет

- Generators Expected ServicesДокумент3 страницыGenerators Expected Servicesmoaz zahidОценок пока нет

- PMM0000 Daily Weekly Check List Hoist#20Документ8 страницPMM0000 Daily Weekly Check List Hoist#20Radhe Agri ProductsОценок пока нет

- Generator MaintenanceДокумент20 страницGenerator MaintenanceZamani Mahdi100% (9)

- Maintenance Schedule For SubstationДокумент21 страницаMaintenance Schedule For SubstationSajid Shaikh100% (1)

- Annex 11 ITMSprinklersysteminspection 1649142576210Документ6 страницAnnex 11 ITMSprinklersysteminspection 1649142576210AmanОценок пока нет

- Testing & CommissioningДокумент46 страницTesting & CommissioningVuong Viet Cuong100% (1)

- Webmaster 0 Comment: Testing & Commissioning of UPS System - Method StatementДокумент3 страницыWebmaster 0 Comment: Testing & Commissioning of UPS System - Method Statementramadani bimaОценок пока нет

- Mewp Inspection ProcedureДокумент1 страницаMewp Inspection ProcedureArshad ParambilОценок пока нет

- Generator MaintenanceДокумент24 страницыGenerator MaintenancePablo Gaspar D'Agostini Amengual100% (9)

- Commissioning High Voltage Switchgear & TransformersДокумент13 страницCommissioning High Voltage Switchgear & TransformersJesus RodriguezОценок пока нет

- WORK INSTRUCTION of MPRD EQUIPMENT 2022Документ3 страницыWORK INSTRUCTION of MPRD EQUIPMENT 2022EdwardОценок пока нет

- Testing & CommissioningДокумент7 страницTesting & Commissioningpraveshkafle50% (2)

- Maintain HVDC Equipment EfficientlyДокумент19 страницMaintain HVDC Equipment EfficientlyDante FilhoОценок пока нет

- Oil Circuit BreakerДокумент15 страницOil Circuit BreakernetajibhosaleОценок пока нет

- Elevator TenderДокумент5 страницElevator TenderAmr IbrahimОценок пока нет

- RTWB Iom E4 - 1003Документ40 страницRTWB Iom E4 - 1003nairam2003100% (1)

- Gas Genset Maintenance ScheduleДокумент3 страницыGas Genset Maintenance ScheduleMutahirrasoolОценок пока нет

- Testing and Commissioning of UPS System Method StatementДокумент3 страницыTesting and Commissioning of UPS System Method StatementHumaid Shaikh100% (1)

- Land Rig Acceptance MasterДокумент17 страницLand Rig Acceptance Masterislam atif100% (1)

- Procedure For Power Receiving - pg2-13Документ12 страницProcedure For Power Receiving - pg2-13kamilОценок пока нет

- 1 - Hand Over A.Scarpete SurvilleДокумент9 страниц1 - Hand Over A.Scarpete Survillealex.verdzadze98Оценок пока нет

- Maintenance Procedures of Electrical EquipmentДокумент4 страницыMaintenance Procedures of Electrical EquipmentEdwin Cob GuriОценок пока нет

- Prefunctional ChecklistsДокумент37 страницPrefunctional Checklistsrenjithv_4100% (1)

- 2 - Hand Over I.LEFTERДокумент9 страниц2 - Hand Over I.LEFTERalex.verdzadze98Оценок пока нет

- DME Valve Gate ControllerДокумент15 страницDME Valve Gate ControllerEsteban Vanegas AlvarezОценок пока нет

- Technical Seminar Agenda and Generator System OverviewДокумент86 страницTechnical Seminar Agenda and Generator System OverviewKenneth100% (1)

- 4 - Hand Over SIMIONДокумент9 страниц4 - Hand Over SIMIONalex.verdzadze98Оценок пока нет

- Equipment Maintenance Checklist: Operation RecordsДокумент6 страницEquipment Maintenance Checklist: Operation RecordsmaheshОценок пока нет

- PM of HT MotorДокумент30 страницPM of HT Motorshashank715100% (1)

- Testing & Commissioning of UPS System - Method StatementДокумент4 страницыTesting & Commissioning of UPS System - Method Statementvin ssОценок пока нет

- Method Statement For Battery ChargerДокумент6 страницMethod Statement For Battery ChargerUtku Can Kılıç100% (1)

- Maintenance Manual ABBДокумент9 страницMaintenance Manual ABBKARAM ZAKARIAОценок пока нет

- Heat Trace Testing Procedures1Документ18 страницHeat Trace Testing Procedures1camspsОценок пока нет

- 4 - Unit Warm Start-Up (CNK 12 M Ove Oi 112C)Документ17 страниц4 - Unit Warm Start-Up (CNK 12 M Ove Oi 112C)Your FriendОценок пока нет

- Sobreprecio 18MM: TM2500 de EPS A DerwickДокумент33 страницыSobreprecio 18MM: TM2500 de EPS A DerwickTomás LanderОценок пока нет

- 3 - Hand Over I.LEFTERДокумент9 страниц3 - Hand Over I.LEFTERalex.verdzadze98Оценок пока нет

- Testing of Electrical EquipmentsДокумент23 страницыTesting of Electrical EquipmentsPrashanth Reddy Gouni100% (5)

- F 0077 e 55Документ6 страницF 0077 e 55Bùi Cảnh TrungОценок пока нет

- Procedure for Power Receiving of Khabat Thermal Power PlantДокумент18 страницProcedure for Power Receiving of Khabat Thermal Power Plantkamil100% (1)

- Maintenace ScheduleДокумент48 страницMaintenace ScheduleRanu JanuarОценок пока нет

- 14.38.00.003.01 - Chief Engineer's Monthly Report August 2021Документ6 страниц14.38.00.003.01 - Chief Engineer's Monthly Report August 2021AkshayKumarОценок пока нет

- How to Maintain Air Circuit Breakers for Maximum UptimeДокумент2 страницыHow to Maintain Air Circuit Breakers for Maximum UptimeRoyce CunananОценок пока нет

- Procedure of Maintenance For Electrical EquipmentДокумент16 страницProcedure of Maintenance For Electrical EquipmentThức Võ100% (2)

- MCC and Panels Maintenance ProcedureДокумент15 страницMCC and Panels Maintenance ProcedureÁlvaro Manterola Lazcano100% (19)

- TechnicalspecificationДокумент15 страницTechnicalspecificationorbits1s3Оценок пока нет

- INSTRUCTION of Electrical EquipmentДокумент16 страницINSTRUCTION of Electrical EquipmentSushil KumarОценок пока нет

- 3rd Officer Duties - RemindersДокумент4 страницы3rd Officer Duties - RemindersAlexandruОценок пока нет

- Equipment Maintenance ChecklistДокумент6 страницEquipment Maintenance Checklisthuonglan167hdОценок пока нет

- Snr. ElectДокумент17 страницSnr. ElectAhmed AbdeltawabОценок пока нет

- Testing & Commissioning of Chilled Water PumpsДокумент3 страницыTesting & Commissioning of Chilled Water Pumpsamg00733% (3)

- SOP For Pump and Gen SetДокумент10 страницSOP For Pump and Gen Setneyazy abdelmonemОценок пока нет

- Maintenanceboth Q and AДокумент46 страницMaintenanceboth Q and AMMS SОценок пока нет

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsОт EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsРейтинг: 3.5 из 5 звезд3.5/5 (3)

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGОт EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGОценок пока нет

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitОт EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitОценок пока нет

- PME0000 Daily Weekly Jobs Hoist#20Документ2 страницыPME0000 Daily Weekly Jobs Hoist#20Radhe Agri ProductsОценок пока нет

- PMM0000 Daily Weekly Check List Hoist#20Документ8 страницPMM0000 Daily Weekly Check List Hoist#20Radhe Agri ProductsОценок пока нет

- PLI Assessment ChartДокумент5 страницPLI Assessment ChartRadhe Agri ProductsОценок пока нет

- Stamford AVR SX460 PDFДокумент4 страницыStamford AVR SX460 PDFNasredine AlainОценок пока нет

- Fish Feed Composition and ProductionДокумент54 страницыFish Feed Composition and ProductionhaniffОценок пока нет

- List of MeriendasДокумент17 страницList of MeriendasKristoffer OgalinoОценок пока нет

- Hold-Up?" As He Simultaneously Grabbed The Firearm of Verzosa. WhenДокумент2 страницыHold-Up?" As He Simultaneously Grabbed The Firearm of Verzosa. WhenVener MargalloОценок пока нет

- A To Z of Architecture PDFДокумент403 страницыA To Z of Architecture PDFfaizan100% (1)

- Army National Guard Military Funeral Honors Soldier S Training SOP 23 Nov 15Документ203 страницыArmy National Guard Military Funeral Honors Soldier S Training SOP 23 Nov 15LuisAndresBellavista100% (1)

- Solving Problems Involving Simple Interest: Lesson 2Документ27 страницSolving Problems Involving Simple Interest: Lesson 2Paolo MaquidatoОценок пока нет

- Polyester Staple Fibre Product ListДокумент2 страницыPolyester Staple Fibre Product Listnunu7478Оценок пока нет

- Sach Bai Tap Tieng Anh8 - Mai Lan HuongДокумент157 страницSach Bai Tap Tieng Anh8 - Mai Lan Huongvothithao19750% (1)

- Rational design of Nile bargesДокумент8 страницRational design of Nile bargesjhairОценок пока нет

- Registration Form: Advancement in I.C.Engine and Vehicle System"Документ2 страницыRegistration Form: Advancement in I.C.Engine and Vehicle System"Weld TechОценок пока нет

- Sar Oumad Zemestoun v01b Music Score سر اومد زمستون، نت موسیقیДокумент1 страницаSar Oumad Zemestoun v01b Music Score سر اومد زمستون، نت موسیقیPayman Akhlaghi (پیمان اخلاقی)100% (3)

- Reflecting Surfaces Discussion BibliographyДокумент58 страницReflecting Surfaces Discussion BibliographyAnanthanarayananОценок пока нет

- All India Ticket Restaurant Meal Vouchers DirectoryДокумент1 389 страницAll India Ticket Restaurant Meal Vouchers DirectoryShauvik HaldarОценок пока нет

- Bill of QuantitiesДокумент25 страницBill of QuantitiesOrnelAsperas100% (2)

- Suntay V CojuancoДокумент2 страницыSuntay V CojuancoJushiОценок пока нет

- OCFINALEXAM2019Документ6 страницOCFINALEXAM2019DA FT100% (1)

- FAQs MHA RecruitmentДокумент6 страницFAQs MHA RecruitmentRohit AgrawalОценок пока нет

- Alice Corporation Pty. Ltd. v. CLS Bank International and CLS Services Ltd.Документ4 страницыAlice Corporation Pty. Ltd. v. CLS Bank International and CLS Services Ltd.Rachel PauloseОценок пока нет

- Whole Brain Lesson Plan: 3 QuarterДокумент5 страницWhole Brain Lesson Plan: 3 QuarterNieve Marie Cerezo100% (1)

- Firewalker Spell and Ability GuideДокумент2 страницыFirewalker Spell and Ability GuideRon Van 't VeerОценок пока нет

- Valmet - S Waste To Energy SolutionsДокумент14 страницValmet - S Waste To Energy SolutionsNardo LlanosОценок пока нет

- Transformers Classics: UK Vol. 3 PreviewДокумент10 страницTransformers Classics: UK Vol. 3 PreviewGraphic PolicyОценок пока нет

- Whipping Cream PowderДокумент2 страницыWhipping Cream PowderSALCON ConsultancyОценок пока нет

- Describing A CompanyДокумент3 страницыDescribing A CompanyAfnanОценок пока нет

- The Sociopath's MantraДокумент2 страницыThe Sociopath's MantraStrategic ThinkerОценок пока нет

- Tarea 1Документ36 страницTarea 1LUIS RVОценок пока нет

- Assessment - Lesson 1Документ12 страницAssessment - Lesson 1Charlynjoy AbañasОценок пока нет

- Year 7 Depth Study 2a 2020 5Документ6 страницYear 7 Depth Study 2a 2020 5api-508928238Оценок пока нет

- Doubles and Doppelgangers: Religious Meaning For The Young and OldДокумент12 страницDoubles and Doppelgangers: Religious Meaning For The Young and Old0 1Оценок пока нет

- Eng CBLДокумент2 страницыEng CBLMengTangОценок пока нет