Академический Документы

Профессиональный Документы

Культура Документы

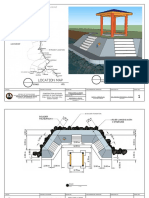

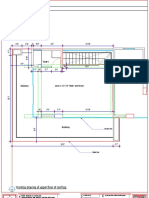

Sample Structural Plan

Загружено:

Al DrinАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Sample Structural Plan

Загружено:

Al DrinАвторское право:

Доступные форматы

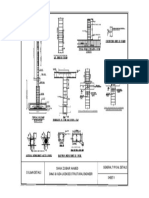

STRUCTURAL SPECIFICATIONS G) REINFORCING BARS SPLICES K) MINIMUM TIME BEFORE REMOVAL OF FORMS AFTER POURING:

A) GENERAL NOTES: K.1) WALLS ---------------------------------------

3 Days

G.1) FOR BEAMS: K.2) COLUMNS ---------------------------------------

3 Days

A.1) In the interpretation of these drawings, indicated dimensions shall govern. Distances or

All splices shall be lapped or extend a minimum of K.3) BEAMS ---------------------------------------

After Stressing for prestressed members or 21 Days for

sizes shall not be scaled for construction purposes. non-prestressed members.

40 diameters unless shown otherwise, horizontal bars

A.2) In case of conflict in details or dimensions between the architectural and engineering drawings, refer K.4) SLABS --------------------------------------- After stressing of post-tensioned beams or 21 Days for

splice location shall be staggered for beams and girders.

to the architect for final decision. non-prestressed members

Splice top bars at mid span, bottom bars at supports.

A.3) In case conflict between these drawings and specification, the working drawing shall govern. Undue superimposed dead loads should not be applied during any subsequent curing period.

A.4) All structural details unless otherwise shown in the drawings shall follow Construction Note details. G.2) FOR COLUMNS:

A.5) All concrete work shall be done in accordance with the ACI-318-95 Code in so far as they do not conflict All splices shall be welded or lapped located near the

with the Local Building Code requirements.

mid-height level. No more than 50% of the total number

H) CAMBERING:

A.6) Contractor shall coordinate with the Architect, Mechanical, Electrical, Structural Engineer plans as to Unless otherwise specified by the engineer or architect, camber are to be provided for all suspended

of main bars shall be spliced at any same level location.

exact size and location of openings thru floor slab, beams and walls. reinforced concrete members, As follows:

H.1) BEAMS --------------------------------------- 12mm PER 3.05 m.

B) CONCRETE: H.2) SLABS --------------------------------------- 12mm PER 3.05 m. (L3)

Minimum concrete strength at 28 days compressive test shall as follows H.3) CANTILEVERED BEAMS and SLAB ------------ 25mm PER 3.05 m.

H) CUT-OFF BARS

B.1) Columns, Footing Tie Beams ---------------------------------------------------------------- f'c = 21 Mpa (3,000 psi) Unless otherwise shown on structural drawings. Typical bar cut-off for beams, girders and slabs shown below

Undue superimposed dead loads should not be applied during any subsequent

B.2) Footings, Retaining walls & Stairs ---------------------------------------------------------- f'c = 21 Mpa (3,000 psi) shall be followed. Hook may be optional

curing period.

B.3) Suspended slabs, beams & girders ------------------------------------------------------ f'c = 21 Mpa (3,000 psi) L

B.4) Slab on grade ----------------------------------------------------------------------------------- f'c = 17 Mpa (2'500 psi) L/4 L/4

B.5) Others not specified ------------------------------------------------------------------------- f'c = 21 Mpa (3,000 psi)

D

Concrete shall be deposited in its final position without segregation. Re-handling or flowing. Placing shall be

.

done preferably with buggies buckets or wheelbarrows. No chutes will be allowed except to transfer concrete

from hoppers to buggies. Wheelbarrows or buckets in which case they shall not exceed six(6.00) meters in L/5 L/5

INTERIOR END

L2/5 L3/5 B

aggregate length. EXTERIOR END L1/5 L1/5 L2/5

TYPICAL FOR BEAMS

SECTION @ MIDSPAN

RIGHT SUPPORT

"Y"

No depositing of concrete shall be allowed without the use of vibrators unless authorized in writing by the L L

FLOOR LINE WEB BAR LEFT SUPPORT MID-SPAN BOTTOM BARS

designers and only for unusual conditions where vibrations is extremely difficult to accomplish. L/4 L/4 L/4 L/4 (AS SPECIFIED) BOTTOM BARS BOTTOM BARS

SPLICING SHOULD BE LOCATED

FLOOR BEAM FLOOR BEAM

Without preliminary test data, the water-cement ratio for a given strength of concrete should not exceed the

@ MID HEIGHT OF COLUMN

.

values shown in the ACI CODE, when strength in excess of 211.0 kg/cm 2 (3KSI) are required. Strength test

"Y"

FLOOR HEIGHT

should be made.

L/7 L/7 L/7 L/7

2 TYPICAL CONVENTIONAL BEAM DETAIL

_______________________________________________________________________________

(H2)

S-1 SCALE: NTS

SPLICE

C) CONCRETE PROTECTION FOR REINFORCING BARS: TYPICAL FOR ONE-WAY SLAB

(L3)

The following shall be the clear cover concrete protections: 0.25 L1 0.25 L1 0.25 L1 0.25 L1

5 SETS TIES

A.1) Foundation ------------------------------------------------------------------- 0.08 m.

NOTE:

40 D 40 D 40 D 40 D (L) ALL TOP BARS @ SUPPORT EXTENDED

A.2) Slab on Grade ---------------------------------------------------------- 0.04 m. (WHICHEVER IS LONGER) CONTINUOUSLY TO CANTILEVERED END.

CANTILEVERED

"Y"

(UNLESS OTHERWISE SPECIFIED ON

A.3) Surface Exposed to Weather ---------------------------------------- 0.05 m. WEB BAR EXTERIOR SPAN

FLOOR LINE BEAM SCHEDULE)

(AS SPECIFIED)

A.4) Columns ------------------------------------------------------------------- 0.04 m. FLOOR BEAM FLOOR BEAM

DEPTH OF INTER-

A.5) Beams and Girders ---------------------------------------------------------- 0.04 m. CL CL CL SECTING PERPEN-

"Y"

"Y"- CLOSER SPACING OF COLUMN

A.6) Suspended Slabs and Stairs------------------------------------------------- 0.02 m. DICULAR EDGE

OF EXTERIOR SUPPORT OF INTERIOR SUPPORT OF INTERIOR SUPPORT

D

BEAM

A.7) Walls ---------------------------------------------------------------------------- 0.02 m.

TIES PER SET AS SPECIFIED

IN THE COLUMN SCHEDULE

TYPICAL DETAIL OF STAGGERED LAP SPLICES FOR SLAB BOTTOM BAR

FLOOR HEIGHT

5 SETS TIES

A.8) Post-Tensioned slab ---------------------------------------------------------- 0.03 m.

I) PIPES AND CONDUITS EMBEDDED IN CONCRETE: BOTTOM BARS B

(H1)

L 3/5 @ SUPPORT

Unless otherwise shown on structural drawings or permission of engineer. Pipes and other electrical conduits

D) SIZE OF AGGREGATES TO BE USED: SECTION @ SUPPORT

with their fittings shall not displace more than 4% of the cross-sectional area of the column.

Maximum sizes of aggregates to be used for various type of concrete construction:

J) REBARS AT CORNER SLAB AND SLAB OPENING TYPICAL CANTILEVERED

NOTE:

MINIMUM

DIMENSION

REINFORCED

CONC. WALLS

UNREINFORCED

WALLS

HEAVILY

REINFORCED

LIGHTLY

REINFORCED OR Provide extra reinforcement for corner slabs (TWO ADJACENT DISCONTINUOUS EDGES) As shown below and 3 CONVENTIONAL BEAM DETAIL

________________________________________________________________

"Y"

OF SECTION BEAMS & SLABS UNREINFORCED at ends and corner of shear walls. FLOOR LINE

COLUMN SLABS

S-1 SCALE: NTS

SLAB ON GRADE SLAB ON GRADE

2 1/2" TO 5" 1/2" TO 3/4" 3/4" 3/4" TO 1" 3/4" TO 1 1/2"

"Y"

6" TO 11" 3/4" TO 1 1/2" 1 1/2" 1 1/2" 1 1/2" TO 3"

1000mm 2000mm

12" TO 29" 1 1/2" TO 3" 3" 1 1/2" TO 3" 3"

FTB FTB CONT. TOP BARS

30" OR MORE 1 1/2" TO 3" 6" 1 1/2" TO 3" 3" TO 6"

DEPRESSION

FTB

E) REINFORCING BARS:

"Y"

SHEAR WALL 3 SETS TIES

E.1) All reinforcing bars shall be Deformed Billet-Steel Bars in accordance with ASTM A-615

D

END OF SHEAR WALL

08

E.2) 12mmØ and smaller shall be deformed intermediate grade --------------------- fy = 227 MPa (33,000 psi)

67

0.

0.

D

E.3) 16mmØ and larger shall be deformed hard grade ------------------------------------ fy = 227 MPa (33,000 psi)

0.76

76

0.04(TYP.)

0.

30°

E.4) All reinforcing bars are weldable. BEAM COMPACTED GRAVEL BED

COMPETENT SOIL FORMATION CONT. BOTTOM BARS

D

F) STRUCTURAL STEEL:

0.04(TYP.)

F.1) All structural steel , both angles and steel plates shall conform to ASTM A36

TIED COLUMN SECTION DETAIL

0.76

BEAM

------------------------------------------------------------------------------------------------------ fy = 248MPa (36,000psi)

F.2) Welding electrodes shall be E70XX series.

0.76

0.04(TYP.)

0.76

1 SHOWING TIE OR HOOP SPACING

____________________________________________________________________ 4 BEAM DEPRESSION DETAIL

__________________________________________________________

F.3) Machine bolts and anchor bolts shall conform to ASTM a-235. S-1 SCALE: NTS S-1 SCALE: NTS

CORNER SLAB SLAB OPENING

CERTIFIED BY: PRC NO. : 0132486 SEAL : APPROVED BY: PROJECT TITLE: CAD BY: REVISIONS: SHEET NO.:

DESIGNED BY:

PTR NO. : 0418447

CHECKED BY:

CHARMAINE P. NARVADEZ

CIVIL ENGINEER

DATE :

PLACE :

T.I.N. :

01/08/19

NAGA CITY

453-268-413

MR & MRS. RODEL B. CORONO

OWNER

PROPOSED TWO-STOREY RESIDENTIAL BUILDING

LOCATION : ABELLA ST., STA.CRUZ, NAGA CITY

DATE:

APPROVED BY:

DATE:

SHEET CONTENTS:

AS SHOWN

S1

Вам также может понравиться

- Roof Slab Drawing PDFДокумент1 страницаRoof Slab Drawing PDFBãlã Ð Chøçølãtě Røměø100% (1)

- Truss Design PDFДокумент1 страницаTruss Design PDFAbby De pedroОценок пока нет

- QLD TMR Design Criteria For Bridges and Other StructuresДокумент215 страницQLD TMR Design Criteria For Bridges and Other Structuresyyanan1118Оценок пока нет

- AS 404 – STEEL AND TIMBER DESIGN CODEДокумент4 страницыAS 404 – STEEL AND TIMBER DESIGN CODEJoshua VicenteОценок пока нет

- CEE Purlin Dead Load CalculationДокумент5 страницCEE Purlin Dead Load CalculationShealtiel Regine Cinco-AyalaОценок пока нет

- Tabulation of Design StandardsДокумент7 страницTabulation of Design StandardsVincent EullaranОценок пока нет

- Sample Structural PlanДокумент1 страницаSample Structural PlanJeric Sarte100% (1)

- Floor Plan Roof Plan: Legend 1 2 3Документ7 страницFloor Plan Roof Plan: Legend 1 2 3Edelyn Lindero Ambos100% (1)

- Harvest Moon Back To Nature Prima Official Eguide PDFДокумент127 страницHarvest Moon Back To Nature Prima Official Eguide PDFcibulabula100% (4)

- Alex Garcia Quotation-08312019Документ16 страницAlex Garcia Quotation-08312019Al Drin100% (1)

- Detail Detail Detail: Schedule of Truss MembersДокумент6 страницDetail Detail Detail: Schedule of Truss MembersSharmane BurlazaОценок пока нет

- Project Location Map and PlansДокумент6 страницProject Location Map and PlansStephanie Maiko T. BasadaОценок пока нет

- Proposed 5 Storey Building with Roof Deck Structural DesignДокумент4 страницыProposed 5 Storey Building with Roof Deck Structural DesignAlvin SantosОценок пока нет

- Struct 2Документ1 страницаStruct 2John AndersonОценок пока нет

- Amvic ICF Installation ManualДокумент136 страницAmvic ICF Installation ManualdanОценок пока нет

- Foundation Plan Roof Plan Beam Framing Plan: Sulit PastelДокумент1 страницаFoundation Plan Roof Plan Beam Framing Plan: Sulit PastelAbegail Panang100% (1)

- Adaptive Reuse Examples in The PhilippinesДокумент3 страницыAdaptive Reuse Examples in The PhilippinescbgwnkimОценок пока нет

- Details of Footing, Tie Beam and ColumnДокумент1 страницаDetails of Footing, Tie Beam and Columnanabel montiadoraОценок пока нет

- Torsion Design Beam ExampleДокумент9 страницTorsion Design Beam ExampleKhajaОценок пока нет

- General Notes and Standard Details: Rafter DetailДокумент1 страницаGeneral Notes and Standard Details: Rafter DetailLiza MarieОценок пока нет

- Antipolo SeriesДокумент1 страницаAntipolo SeriesJonaselle FonsecaОценок пока нет

- Longitudinal Section Thru "BB" Cross Section Thru "Aa": Proposed 3 Bedroom ResidentialДокумент1 страницаLongitudinal Section Thru "BB" Cross Section Thru "Aa": Proposed 3 Bedroom ResidentialChristian Sean PaglomutanОценок пока нет

- Sample Architectural PlanДокумент1 страницаSample Architectural PlanAl DrinОценок пока нет

- Transformer Plinth For 2.1MWДокумент1 страницаTransformer Plinth For 2.1MWSarin100% (2)

- Foundation - 3-Storey With Roof Deck-Model PDFДокумент1 страницаFoundation - 3-Storey With Roof Deck-Model PDFAnjo BalucasОценок пока нет

- Covered Court PlanДокумент13 страницCovered Court PlanJohn Leonne100% (3)

- Steel Frame Design Manual SAP2000Документ197 страницSteel Frame Design Manual SAP2000Mukhlish Akhatar100% (1)

- Fundamentals of Urban Design and Community ArchitectureДокумент9 страницFundamentals of Urban Design and Community ArchitectureDerick Ramirez Dasugo100% (1)

- Proposed 2-Storey Residential House-FootingДокумент1 страницаProposed 2-Storey Residential House-FootingZiur18100% (1)

- 6 CONCRETE HOLLOW BLOCKS CEMENT PLASTER FINISH CLASS A CONTINUOUS CONCRETE FLOORINGДокумент1 страница6 CONCRETE HOLLOW BLOCKS CEMENT PLASTER FINISH CLASS A CONTINUOUS CONCRETE FLOORINGArnold DominguezОценок пока нет

- STAAD.Pro V8i Analysis and Design of Box CulvertДокумент16 страницSTAAD.Pro V8i Analysis and Design of Box CulvertSikandar KumarОценок пока нет

- Sample Blow Up PlanДокумент1 страницаSample Blow Up PlanRia Abion0% (1)

- Sanitary122333 PlanДокумент1 страницаSanitary122333 PlanJom Asagra100% (2)

- Soil Bearing Capacity (PDF) - 201412230858174905Документ1 страницаSoil Bearing Capacity (PDF) - 201412230858174905MeryL Ang100% (1)

- General Specification - Proposed Two Storey Residential HouseДокумент9 страницGeneral Specification - Proposed Two Storey Residential HouseMark RamirezОценок пока нет

- Break Pressure TankДокумент53 страницыBreak Pressure TankParomita Mukherjee Misra100% (11)

- Top 10 Tallest Building in The Philippines: A Comparative AnalysisДокумент10 страницTop 10 Tallest Building in The Philippines: A Comparative AnalysisTrisha LlamesОценок пока нет

- A Proposed Two Storey Residential HouseДокумент2 страницыA Proposed Two Storey Residential HouseElla Sadicon0% (2)

- Table D3.1 Shear Lag Factors For Connections To Tension MembersДокумент7 страницTable D3.1 Shear Lag Factors For Connections To Tension MembersalexОценок пока нет

- Architectural Plan of Row HouseДокумент1 страницаArchitectural Plan of Row HouseDJОценок пока нет

- Comparitive Design Study BS8110 Vs EC2Документ127 страницComparitive Design Study BS8110 Vs EC2DaGoose81100% (1)

- Footing Tie Beam DetailsДокумент3 страницыFooting Tie Beam DetailsPau Llena100% (3)

- Is-7272 Code For Productivity of ManpowerДокумент15 страницIs-7272 Code For Productivity of ManpowerAnil Kumar80% (5)

- Architectural General NotesДокумент1 страницаArchitectural General Notesczarina caranguian100% (2)

- 3 WAITING SHED FOOTING DESIGN - ModelДокумент2 страницы3 WAITING SHED FOOTING DESIGN - ModelNikita MeshramОценок пока нет

- Tabulation of Design StandardsДокумент5 страницTabulation of Design Standardsconeyqu100% (1)

- Reflection PaperДокумент4 страницыReflection PaperJay Nuestro100% (1)

- Thesis Documents FinalДокумент62 страницыThesis Documents FinalRuth Reyes0% (1)

- Factors That Contributes To The Development of Indigenous ArchitectureДокумент2 страницыFactors That Contributes To The Development of Indigenous ArchitectureVlademir PancoОценок пока нет

- Equipment SpecificationsДокумент2 страницыEquipment SpecificationsJade Barbosa100% (1)

- Architectural Bay SectionДокумент1 страницаArchitectural Bay SectionAdriel TanОценок пока нет

- PNR - LRT2 Tutuban Proposal ThesisДокумент16 страницPNR - LRT2 Tutuban Proposal ThesisTrey MarianoОценок пока нет

- Proposed Residential House Roof Framing PlanДокумент1 страницаProposed Residential House Roof Framing PlanPamela Joanne Falo Andrade0% (1)

- Adamson University: Office of The Registrar Request For Overload/Overlab/SimultaneousДокумент2 страницыAdamson University: Office of The Registrar Request For Overload/Overlab/SimultaneousClord B.Оценок пока нет

- 3-Storey Building - Design CriteriaДокумент5 страниц3-Storey Building - Design CriteriaJaycee Bareng PagadorОценок пока нет

- Legend:: Sanitary Pipe Layout Plan Water Pipe Layout PlanДокумент1 страницаLegend:: Sanitary Pipe Layout Plan Water Pipe Layout PlanAbegail PanangОценок пока нет

- Loading Combination NSCP 2010 Vs 2001Документ1 страницаLoading Combination NSCP 2010 Vs 2001lauropaniergoОценок пока нет

- Allowable Stresses of Phil WoodДокумент2 страницыAllowable Stresses of Phil WoodTos Hernando100% (2)

- NSCPДокумент53 страницыNSCPZaela EfronОценок пока нет

- Spot Detail Spot Detail: (At Second Floor) (At Fourth Floor)Документ1 страницаSpot Detail Spot Detail: (At Second Floor) (At Fourth Floor)markeesОценок пока нет

- 07.03.2021 Rev - Acu LayoutДокумент1 страница07.03.2021 Rev - Acu LayoutAldrin MacaraegОценок пока нет

- Allied Services Supplemental Architectural ServicesДокумент52 страницыAllied Services Supplemental Architectural ServicesRitzel Gaffud0% (1)

- Design and Implementation of The Proposed Two Storey Multi Purpose Green Building at Brgy. Bagong Pook Malvar Batangas PDFДокумент5 страницDesign and Implementation of The Proposed Two Storey Multi Purpose Green Building at Brgy. Bagong Pook Malvar Batangas PDFPanda BachiОценок пока нет

- Introduction To Urban and Regional Planning: College of Architecture and Fine ArtsДокумент22 страницыIntroduction To Urban and Regional Planning: College of Architecture and Fine ArtsDivine Grace FernandoОценок пока нет

- Analytical Land Use Factors and Emerging TheoriesДокумент19 страницAnalytical Land Use Factors and Emerging TheoriesAmyr AmyrОценок пока нет

- CITY OF LAS PIÑAS Basic ProfileДокумент2 страницыCITY OF LAS PIÑAS Basic Profilepepito manalotoОценок пока нет

- Lapping and splicing details for reinforced concrete columnsДокумент1 страницаLapping and splicing details for reinforced concrete columnsVinod Masani100% (1)

- c1f1 c1f1 WFДокумент4 страницыc1f1 c1f1 WFsicnarfoyamat1977100% (1)

- 37 Geology Sv2024 Exam-1Документ11 страниц37 Geology Sv2024 Exam-1Sonam MОценок пока нет

- MosquejДокумент12 страницMosquejdr.afroza1875Оценок пока нет

- Form 2 Science Double AwardДокумент10 страницForm 2 Science Double AwardKeabetswe MoneiОценок пока нет

- GAD For - 24.750m RCC T-BEAM-ModelДокумент1 страницаGAD For - 24.750m RCC T-BEAM-Modelalok pradhanОценок пока нет

- Sample Architectural Plan 2Документ1 страницаSample Architectural Plan 2Al DrinОценок пока нет

- Masonry From Planswift - AreaДокумент1 страницаMasonry From Planswift - AreaAl DrinОценок пока нет

- Sample Electrical PlanДокумент1 страницаSample Electrical PlanAl DrinОценок пока нет

- Sample Architectural Plan 3Документ1 страницаSample Architectural Plan 3Al DrinОценок пока нет

- Walls and FloorsДокумент35 страницWalls and FloorsAl DrinОценок пока нет

- Sample Floor PlanДокумент1 страницаSample Floor PlanAl DrinОценок пока нет

- Sample Design of SlabДокумент1 страницаSample Design of SlabAl DrinОценок пока нет

- Sample Two Storey DesignДокумент1 страницаSample Two Storey DesignAl DrinОценок пока нет

- Sample Estimate For BiddingДокумент4 страницыSample Estimate For BiddingAl DrinОценок пока нет

- Plumbing CompiledДокумент17 страницPlumbing CompiledAl DrinОценок пока нет

- List of Subcon and Suppliers - 2018 06 23Документ1 страницаList of Subcon and Suppliers - 2018 06 23Al DrinОценок пока нет

- Bn1 - A-406 - Updated Tubular Steel Finishes - 2018 06 25Документ1 страницаBn1 - A-406 - Updated Tubular Steel Finishes - 2018 06 25Al DrinОценок пока нет

- Ground Floor Plan: For Expansion For ExpansionДокумент1 страницаGround Floor Plan: For Expansion For ExpansionAl DrinОценок пока нет

- Design of Beams SampleДокумент27 страницDesign of Beams SampleAl DrinОценок пока нет

- Sample Second Floor PlanДокумент1 страницаSample Second Floor PlanAl DrinОценок пока нет

- Thursday, October 11, 2018, 12:03 PM: Page 33 of 61 D:/JDP Construction/Staad Projects/Medina Warehouse - AnlДокумент3 страницыThursday, October 11, 2018, 12:03 PM: Page 33 of 61 D:/JDP Construction/Staad Projects/Medina Warehouse - AnlAl DrinОценок пока нет

- Sample Estimate For BiddingДокумент4 страницыSample Estimate For BiddingAl DrinОценок пока нет

- Sample Staad ReportДокумент15 страницSample Staad ReportAl DrinОценок пока нет

- Sample Footing DesignДокумент1 страницаSample Footing DesignAl DrinОценок пока нет

- Sample Footing DesignДокумент1 страницаSample Footing DesignAl DrinОценок пока нет

- Estimate SampleДокумент3 страницыEstimate SampleAl DrinОценок пока нет

- CNC - Cad-Cam Mach - SHP FinalДокумент54 страницыCNC - Cad-Cam Mach - SHP FinalAl DrinОценок пока нет

- WSfiling and Grinding TextbookДокумент85 страницWSfiling and Grinding TextbookAl DrinОценок пока нет

- AutoCAD 2013 Tutorial - 3D Modeling WireframeДокумент26 страницAutoCAD 2013 Tutorial - 3D Modeling WireframeYa Minn AyeОценок пока нет

- Revision HistoryДокумент9 страницRevision HistoryVictOr VFОценок пока нет

- Composition Book: Edificio Polifunzionale. Studio Passarelli.Документ29 страницComposition Book: Edificio Polifunzionale. Studio Passarelli.Maria Camila Rodriguez0% (1)

- 59 Uplift CalculationsДокумент2 страницы59 Uplift CalculationsMano HarОценок пока нет

- Portal Frame Structures ExplainedДокумент2 страницыPortal Frame Structures ExplainedSohanОценок пока нет

- Slab layout of penthouse roofДокумент2 страницыSlab layout of penthouse roofAbrarОценок пока нет

- Plan of Valve Chamber Section of Valve Chamber: RCC Works: Concrete Grade: M20 Rebar Grade: Fe500Документ1 страницаPlan of Valve Chamber Section of Valve Chamber: RCC Works: Concrete Grade: M20 Rebar Grade: Fe500PraYush RajbhandariОценок пока нет

- IBSДокумент3 страницыIBSAwang HakimieОценок пока нет

- Foundation and Structural DetailsДокумент1 страницаFoundation and Structural DetailsSi Thu AungОценок пока нет

- 1722 B.arch Arch Batchno 25Документ102 страницы1722 B.arch Arch Batchno 25Ekta SharmaОценок пока нет

- Design and check of reinforced concrete according to EurocodesДокумент4 страницыDesign and check of reinforced concrete according to EurocodesMuscadin MakensonОценок пока нет

- Chapter Two 2.balconies, Loggias, Canopy and Terraces: Dire Dawa Poly Technical College Satellite ProgramДокумент12 страницChapter Two 2.balconies, Loggias, Canopy and Terraces: Dire Dawa Poly Technical College Satellite ProgramTemesgen YohannesОценок пока нет

- Chemical Action: Types of Chemical AttackДокумент14 страницChemical Action: Types of Chemical AttackSunil KumarОценок пока нет

- Estimate (PCKG 3 Group 3) 24 8 18Документ558 страницEstimate (PCKG 3 Group 3) 24 8 18Lakshmanan MarimuthuОценок пока нет

- Bid Addendum Report: 105 Road Division BiratnagarДокумент8 страницBid Addendum Report: 105 Road Division Biratnagarnitish JhaОценок пока нет

- AISC 360-16 LRFD Code Checking of Steel Beam SectionДокумент3 страницыAISC 360-16 LRFD Code Checking of Steel Beam SectionJake CortezОценок пока нет

- Build Up Rate Floor ScreedДокумент2 страницыBuild Up Rate Floor ScreedHazim ZakariaОценок пока нет

- Lecture - Malaysia Roads and Bridges Rev1Документ45 страницLecture - Malaysia Roads and Bridges Rev1Ashaari Cha-eОценок пока нет

- Calculatio SheetДокумент88 страницCalculatio SheetLe LeОценок пока нет

- CE-632 Foundation Analysis and Design: Shallow FoundationsДокумент33 страницыCE-632 Foundation Analysis and Design: Shallow FoundationsMadhu SulaniyaОценок пока нет

- Anchor Theory in Accordance To ETAG 001 Annex CДокумент71 страницаAnchor Theory in Accordance To ETAG 001 Annex Ctan zhiyuОценок пока нет

- Foundation Eng Part 1Документ334 страницыFoundation Eng Part 1Law Jia WeiОценок пока нет

- E26.To2 Steel PDFДокумент10 страницE26.To2 Steel PDFAmolsingh100Оценок пока нет

- Computation of Symmetrical Free Standing StaircasesДокумент6 страницComputation of Symmetrical Free Standing Staircaseswalaywan100% (1)