Академический Документы

Профессиональный Документы

Культура Документы

Hbe-Cw: High Build Liquid Coating For Low Temperature Applications

Загружено:

Mohammad Mehdi JafariОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Hbe-Cw: High Build Liquid Coating For Low Temperature Applications

Загружено:

Mohammad Mehdi JafariАвторское право:

Доступные форматы

HBE-CW

High build liquid coating for low

temperature applications

The HBE-CW is an advanced liquid coating specifically designed

for cold weather application. The high build formulation is capable

of curing fast when applied to colder substrates at colder ambient

temperatures – even down to subzero conditions of -20°C (-4°F).

Applied to bare steel, the HBE-CW coating is used for protection of

pipeline field joint girth welds, valves and fittings, as a holiday repair

material on FBE coated mainline pipe or for pipeline coating

rehabilitation.

Cures in the Winter Applications

• The HBE-CW coating will cure in the Winter season without the

requirement of external heat. Just apply it and leave it. No Oil & Gas

preheating or post heating necessary.

Superior Corrosion Resistance

• Canusa’s HBE-CW coating has proven to outperform Repair & Rehab

competitive equivalents in a variety of different test methods

including cathodic disbondment, hot water soak and impact resis-

tance. Low Temperature

Saves Time

• The fast cure formulation allows for quick handling and quick

backfilling for an efficient end-to-end coating process.

High Build in Single Coat

• A single pass application direct-to-metal will achieve a high

igh build

coating thickness of 20-40 mils (500-1000 microns)

Variety of Uses

• Field joint girth welds, valves and fittings, holiday repair

material on FBE mainline pipe, pipeline rehabilitation or

new construction.

PRODUCT DATA SHEET canusacps.com

The product information

shown here is intended as a

HBE-CW guide for standard products.

Consult your Canusa

representative for specific

High build liquid coating for low temperature projects or unique

applications applications.

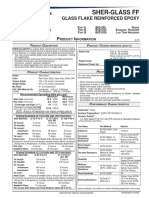

Performance All performance testing followed CSA-Z245.20-10 unless specified.

Service Temp. Up to 65°C (150°F)

Typical Thickness > 25 mils (635 microns)

Mixing Ratio 12.5:1 (by volume)

Percent Solids 100%

Base: 1.45

Specific Gravity

Cure: 1.58

Hardness (ASTM D2240) > 87 Shore D

Adhesion to Steel (ASTM D4541) 3200 psi

Adhesion to FBE (ASTM D4541) 3000 psi

Cathodic Disbondment @ 28 days, 23°C 4.1 mm

Canusa-CPS

Cathodic Disbondment @ 28 days, 50°C 10.0 mm A division of Shawcor Ltd.

Impact Resistance @ 0°C > 3.0 J

Head Office

Impact Resistance @ -40°C > 3.0 J 25 Bethridge Road

Toronto, ON, Canada M9W 1M7

Hot Water Immersion @ 28 days, 50°C Rating 1 Tel: +1 416 743 7111

Fax: +1 416 743 5927

Hot Water Immersion @ 28 days, 65°C Rating 1

Canada

Hot Water Immersion @ 28 days, 95°C Rating 1 Dome Tower St. 2200, 333-7th Avenue SW

Calgary, AB, Canada T2P 2Z1

Minimum Curing Temperature (Surface) -20°C

Tel: +1 403 218 8207

6 months when stored in original packaging be- Fax: +1 403 264 3649

Shelf Life

tween 0.5°C – 27°C. Americas

Pot Life/Gel Time (100 g Sample) 5875 N. Sam Houston Pkwy W., Suite 200

Houston, TX, USA 77086

Pot Life/Gel Time @ 23°C (73°F) 13 minutes Tel: +1 281 886 2350

Fax: +1 281 886 2353

Pot Life/Gel Time @ 0°C (32°F) 35 minutes

Middle East

Pot Life/Gel Time @ -10°C (14°F) 55 minutes ADPC - Mussafah Port, P.O. Box 2621

Abu Dhabi, UAE

Pot Life increases as temperature decreases

Tel: +971 2 496 3500

Fax: +971 2 496 3501

Typical Kit Size Required by Pipe Diameter1

Europe, Africa & Russia

4.5” – 26” 0.8 Liter Kit

Dellaertweg 9-E, Gebouw “Le Carrefour”

28” to 50” 1.5 Liter Kit 2316 WZ Leiden, The Netherlands (NL)

Tel: +31 71 80 802 70

1 Based on 400 mm coating width, 25 mils (635 micron) average thickness and 50% wastage factor. Fax: +31 71 80 802 71

Asia-Pacific

101 Thomson Road, #11-03 United Square

307591 Singapore

Tel: +65 6749 8918

Safety Fax: +65 6749 8919

Handle with care. Before and during use, observe all safety labels on packaging Quality Management system

containers, consult with Canusa-CPS Material Safety Data Sheets and abide by all registered to ISO 9001

local or national safety regulations. Canusa warrants that the product conforms to

its chemical and physical description and is

appropriate for the use stated on the product data

sheet when used in compliance with Canusa’s

written instructions. Since many installation

factors are beyond our control, the user shall

determine the suitability of the products for the

intended use and assume all risks and liabilities in

connection therewith. Canusa’s liability is stated

in the standard terms and conditions of sale.

Canusa makes no other warranty either expressed

or implied. All information contained in this data

sheet is to be used as a guide and is subject to

change without notice. This data sheet supersedes

all previous data sheets on this product. E&OE

Since 1967, Canusa-CPS has been a leading developer and manufacturer of specialty pipeline coatings

for the sealing and corrosion protection of pipeline joints and other substrates. Canusa-CPS high PDS_HBE-CW_rev017

performance products are manufactured to the highest quality standards and are available in a number

of configurations to accommodate many specific project applications.

Вам также может понравиться

- Basic Hydraulic SystemsДокумент128 страницBasic Hydraulic Systemsbeau04297% (35)

- Work MeasurementДокумент15 страницWork MeasurementBalaji BabuОценок пока нет

- Geotechnical Engineering Notes 333Документ40 страницGeotechnical Engineering Notes 333TinaОценок пока нет

- Welding Rod Selection 2 PDFДокумент1 страницаWelding Rod Selection 2 PDFPrior Drake89% (9)

- 2009 Separator CalcsДокумент18 страниц2009 Separator CalcsneelОценок пока нет

- Instrument Air CalculationДокумент11 страницInstrument Air CalculationMohammad Mehdi Jafari67% (3)

- Epofine 556 FR/ FInehard 951Документ3 страницыEpofine 556 FR/ FInehard 951Karishma Prabhu100% (1)

- The Big Bang Never HappenedДокумент3 страницыThe Big Bang Never HappenedIvan Vule Fridman100% (1)

- Alkali Boil Out ProcedureДокумент7 страницAlkali Boil Out Procedureismail karmanaОценок пока нет

- Design of Shell & Tube HXДокумент45 страницDesign of Shell & Tube HXAnonymous yLPPdPwОценок пока нет

- Drawing Management StandardДокумент25 страницDrawing Management StandardMohammad Mehdi JafariОценок пока нет

- ASME - Performance Test CodesДокумент1 страницаASME - Performance Test CodesanoopkntpcОценок пока нет

- TR2400 HF SSB Transceiver FeaturesДокумент4 страницыTR2400 HF SSB Transceiver FeaturesAravind VinduОценок пока нет

- Advances in High Voltage Insulation and Arc Interruption in SF6 and VacuumОт EverandAdvances in High Voltage Insulation and Arc Interruption in SF6 and VacuumОценок пока нет

- Kta50 G3Документ2 страницыKta50 G3zzapieche0% (1)

- Kta50 G3Документ2 страницыKta50 G3zzapieche0% (1)

- Kta50 G3Документ2 страницыKta50 G3zzapieche0% (1)

- 2 Phase Separator Sizing Spreadsheet: Client Proj No Project Calc No Subject SheetДокумент1 страница2 Phase Separator Sizing Spreadsheet: Client Proj No Project Calc No Subject SheetMohammad Mehdi JafariОценок пока нет

- Hazardous Area Hazardous Area ClassificaДокумент106 страницHazardous Area Hazardous Area ClassificaHedi Ben MohamedОценок пока нет

- HBE COLD Weather: High Build Liquid Coating For Low Temperature ApplicationsДокумент2 страницыHBE COLD Weather: High Build Liquid Coating For Low Temperature ApplicationsolalekanОценок пока нет

- Hbe-Os: High Build Epoxy Coating For Offshore Corrosion ProtectionДокумент2 страницыHbe-Os: High Build Epoxy Coating For Offshore Corrosion Protectionsamkarthik47Оценок пока нет

- HBE-HT High Build Epoxy Coating 150°C PipelinesДокумент2 страницыHBE-HT High Build Epoxy Coating 150°C PipelinesdakidofdaboomОценок пока нет

- High Build Epoxy Coating For Pipelines: Product Data SheetДокумент2 страницыHigh Build Epoxy Coating For Pipelines: Product Data SheetChegg ChemОценок пока нет

- High Build Epoxy Coating For Pipelines: Product Data SheetДокумент2 страницыHigh Build Epoxy Coating For Pipelines: Product Data Sheetdemi bajakanОценок пока нет

- Wrapidcoat PVC: Superior Mechanical ProtectionДокумент2 страницыWrapidcoat PVC: Superior Mechanical ProtectionsenthilkumarОценок пока нет

- Wrapidcoat PVC: Superior Mechanical ProtectionДокумент2 страницыWrapidcoat PVC: Superior Mechanical ProtectionHendra AwanОценок пока нет

- Wrapidcoat PVC: Superior Mechanical ProtectionДокумент2 страницыWrapidcoat PVC: Superior Mechanical ProtectioncocoaОценок пока нет

- Pds Na Gts65Документ2 страницыPds Na Gts65Yan FerizalОценок пока нет

- Scar Guard EnglishДокумент2 страницыScar Guard EnglishVismael SantosОценок пока нет

- PDS - Na - Klon-KlnnДокумент2 страницыPDS - Na - Klon-Klnndemi bajakanОценок пока нет

- DOWSIL™ 340 Heat Sink Compound: Features & Benefits ApplicationsДокумент2 страницыDOWSIL™ 340 Heat Sink Compound: Features & Benefits ApplicationsMauricio Fernandez GuevaraОценок пока нет

- GTS-80 Provides Superior Corrosion Protection Up To 80°CДокумент2 страницыGTS-80 Provides Superior Corrosion Protection Up To 80°CZainudinОценок пока нет

- Wrapidtape: Primerless Crosslinked Protective TapeДокумент2 страницыWrapidtape: Primerless Crosslinked Protective TapeHendra AwanОценок пока нет

- Loctite Nordbak Wear Resistant Putty: Product Description MixedДокумент3 страницыLoctite Nordbak Wear Resistant Putty: Product Description MixedFurqan ShabbirОценок пока нет

- Sherglass FFДокумент4 страницыSherglass FFJhose BonillaОценок пока нет

- Technical Data Sheet Product 406: Worldwide Version, February 1996Документ3 страницыTechnical Data Sheet Product 406: Worldwide Version, February 1996Muhammad irtizaОценок пока нет

- PDS - NA - PRP Repair Data SheetДокумент2 страницыPDS - NA - PRP Repair Data SheetHendra AwanОценок пока нет

- K-Resin BK10: Styrene Butadiene Copolymer (SBC)Документ2 страницыK-Resin BK10: Styrene Butadiene Copolymer (SBC)Manikanta Sai KumarОценок пока нет

- Product 266: Technical Data SheetДокумент2 страницыProduct 266: Technical Data SheetFabio ParceroОценок пока нет

- Cardolite NX-2007: Epoxy Curing Agent Technical DatasheetДокумент2 страницыCardolite NX-2007: Epoxy Curing Agent Technical Datasheettrường phạmОценок пока нет

- Product Datasheet BiohesiveДокумент3 страницыProduct Datasheet Biohesivebolang cepuОценок пока нет

- Manta Canusa - GTS65 - en InglesДокумент2 страницыManta Canusa - GTS65 - en IngleserwinvillarОценок пока нет

- Tideguard 182: Product Data/ Application InstructionsДокумент2 страницыTideguard 182: Product Data/ Application InstructionsPablo Ahumada G.Оценок пока нет

- Liquid Epoxy Type E: Force-Cure Epoxy For Superior 3-Layer Corrosion ProtectionДокумент2 страницыLiquid Epoxy Type E: Force-Cure Epoxy For Superior 3-Layer Corrosion ProtectionamirhosseinОценок пока нет

- Parche CRP 65 - Ficha Técnica - en InglesДокумент2 страницыParche CRP 65 - Ficha Técnica - en IngleserwinvillarОценок пока нет

- TDS L2057216Документ3 страницыTDS L2057216erolsarОценок пока нет

- NC-558 TDS enДокумент2 страницыNC-558 TDS enniteshacharya100% (1)

- My T Bond 1161 TDS Structural Adhesive For Low Surface Energy PlasticsДокумент2 страницыMy T Bond 1161 TDS Structural Adhesive For Low Surface Energy PlasticsShabarish KeshavОценок пока нет

- Protective & Marine Coatings: DTM Acrylic Primer/FinishДокумент4 страницыProtective & Marine Coatings: DTM Acrylic Primer/FinishAna CabreraОценок пока нет

- Loctite PC 7227™: Technical Data SheetДокумент3 страницыLoctite PC 7227™: Technical Data SheetMohsin ModiОценок пока нет

- Fluteck P7500 CA v01.19Документ2 страницыFluteck P7500 CA v01.19fprovitaliОценок пока нет

- NorylДокумент1 страницаNorylAnonymous P8Bt46mk5IОценок пока нет

- CANUSA Wrapid TapeДокумент2 страницыCANUSA Wrapid TapeHalimОценок пока нет

- Loctite PC 7222: Technical Data SheetДокумент3 страницыLoctite PC 7222: Technical Data Sheetfrancisca ferrerОценок пока нет

- 4070-4072 Product InfoДокумент2 страницы4070-4072 Product InfoCesar Marcello Cordova GuerreroОценок пока нет

- Spectrasyn™ 10: Polyalphaolefin (Pao) FluidДокумент2 страницыSpectrasyn™ 10: Polyalphaolefin (Pao) FluidMaram YasserОценок пока нет

- Dow Corning Electronics FT Sc102Документ2 страницыDow Corning Electronics FT Sc102Bijyendra KumarОценок пока нет

- Dow CorningДокумент2 страницыDow Corningwardoyoclp75Оценок пока нет

- Protective DTM Acrylic Primer/Finish Product DescriptionДокумент4 страницыProtective DTM Acrylic Primer/Finish Product DescriptionVernon Jiménez FonsecaОценок пока нет

- Tds Ral 7037 Haa Hfhr02s8Документ1 страницаTds Ral 7037 Haa Hfhr02s8Jaskaran SinghОценок пока нет

- 7-2500 FbeДокумент3 страницы7-2500 FbejleonosОценок пока нет

- K-Resin Styrene-Butadiene Copolymers (SBC) : Customer Benefits Typical ApplicationsДокумент1 страницаK-Resin Styrene-Butadiene Copolymers (SBC) : Customer Benefits Typical ApplicationssumherilОценок пока нет

- Product Data Sheet: No-Tox HD Food Grade GreaseДокумент3 страницыProduct Data Sheet: No-Tox HD Food Grade GreaseDaniel ColinsОценок пока нет

- Superseal: Heat Shrinkable Sleeve For Protection of Pre-Insulated Pipe JointsДокумент2 страницыSuperseal: Heat Shrinkable Sleeve For Protection of Pre-Insulated Pipe JointsPer Bagus HandokoОценок пока нет

- Novolastic Subsea Thermal InsulationДокумент3 страницыNovolastic Subsea Thermal InsulationCarloBardoliОценок пока нет

- 521+technical Data Sheet V-6Документ2 страницы521+technical Data Sheet V-6TeenTeen GaMingОценок пока нет

- Cardolite NX 2016Документ2 страницыCardolite NX 2016Lê TiếnОценок пока нет

- TDS - CRYOPIR50f - 202004-1Документ1 страницаTDS - CRYOPIR50f - 202004-1Nguyen Thi Bich ThuyОценок пока нет

- KilnGard - 600SCWДокумент2 страницыKilnGard - 600SCWarafatОценок пока нет

- Wrapidbond: A Visco-Elastic Adhesive Based System For Pipeline Corrosion ProtectionДокумент2 страницыWrapidbond: A Visco-Elastic Adhesive Based System For Pipeline Corrosion ProtectionHendra AwanОценок пока нет

- Wrapidbond: A Visco-Elastic Adhesive Based System For Pipeline Corrosion ProtectionДокумент2 страницыWrapidbond: A Visco-Elastic Adhesive Based System For Pipeline Corrosion ProtectionHendra AwanОценок пока нет

- Marco Material Datasheet E1097Документ3 страницыMarco Material Datasheet E1097phoenixenggworkОценок пока нет

- TDS - 7-0008 - Internal Pipe Coating - EngДокумент3 страницыTDS - 7-0008 - Internal Pipe Coating - Englong chanОценок пока нет

- Hempaline Defend 630: Product DescriptionДокумент3 страницыHempaline Defend 630: Product DescriptionJorge Alberto MontalatОценок пока нет

- An Explanation of The Echo - To-Echo Measurement TechniqueДокумент1 страницаAn Explanation of The Echo - To-Echo Measurement TechniqueMohammad Mehdi JafariОценок пока нет

- Range of Le/D (Equivalent length method) and K/f T (Crane's method) over pipe range 1"-36Документ177 страницRange of Le/D (Equivalent length method) and K/f T (Crane's method) over pipe range 1"-36Samuel OnyewuenyiОценок пока нет

- Distillation Theoretical Stages CalculatorДокумент687 страницDistillation Theoretical Stages CalculatorgrabettyОценок пока нет

- Expansion Joint: Alireza @argh53Документ33 страницыExpansion Joint: Alireza @argh53Mohammad Mehdi JafariОценок пока нет

- Crane Fluid Flow Problems Hof MasterДокумент280 страницCrane Fluid Flow Problems Hof MasterMohammad Mehdi JafariОценок пока нет

- A0V5U9 - Response To NEB IR 2 Southern Access Upstream Expansion Appendix AДокумент29 страницA0V5U9 - Response To NEB IR 2 Southern Access Upstream Expansion Appendix AMohammad Mehdi JafariОценок пока нет

- ANSI B16.5 FlangesДокумент24 страницыANSI B16.5 FlangesbrjsekarОценок пока нет

- Heat Exchanger DatasheetДокумент2 страницыHeat Exchanger DatasheetMohammad Mehdi JafariОценок пока нет

- BFW Cooler Datasheet Rev 2Документ3 страницыBFW Cooler Datasheet Rev 2Mohammad Mehdi JafariОценок пока нет

- Performance of One Unit Inlet Shell Side Outlet Inlet Tube Side OutletДокумент4 страницыPerformance of One Unit Inlet Shell Side Outlet Inlet Tube Side OutletMohammad Mehdi JafariОценок пока нет

- API Separators - Key to Refinery Wastewater TreatmentДокумент8 страницAPI Separators - Key to Refinery Wastewater TreatmentnorthstarleoОценок пока нет

- Heat Exchanger Application Data SheetДокумент2 страницыHeat Exchanger Application Data SheetMohammad Mehdi JafariОценок пока нет

- KTA50-G8 - PI734B mmj100Документ10 страницKTA50-G8 - PI734B mmj100Mohammad Mehdi JafariОценок пока нет

- Ips C Pi 410 PDFДокумент29 страницIps C Pi 410 PDFMohammad Mehdi JafariОценок пока нет

- Technical Data: 1300KW / 1625KVA 1100KW / 1375KVAДокумент5 страницTechnical Data: 1300KW / 1625KVA 1100KW / 1375KVAMohammad Mehdi JafariОценок пока нет

- Amca Publication 1011-03: Certified Ratings Program - Product Rating Manual For Acoustical Duct SilencersДокумент18 страницAmca Publication 1011-03: Certified Ratings Program - Product Rating Manual For Acoustical Duct SilencersMohammad Mehdi JafariОценок пока нет

- Smart FlangeДокумент2 страницыSmart FlangeMohammad Mehdi JafariОценок пока нет

- SamplingДокумент12 страницSamplingΔημητρηςΣαρακυρουОценок пока нет

- Podar International School Chinchwad STD Xi - (I Unit Test) Subject: Computer Science Date: 8-9-2020 Marks: 40Документ3 страницыPodar International School Chinchwad STD Xi - (I Unit Test) Subject: Computer Science Date: 8-9-2020 Marks: 40Shriniwas KulkarniОценок пока нет

- Jurnal IlmiahДокумент12 страницJurnal IlmiahROSSITAОценок пока нет

- Programming structures if, for and while loopsДокумент16 страницProgramming structures if, for and while loopsFrancisco AristizabalОценок пока нет

- Central Angles and Inscribed Angles GuideДокумент22 страницыCentral Angles and Inscribed Angles GuideEric de Guzman100% (1)

- List of Practical Cs With SolutionДокумент57 страницList of Practical Cs With SolutionArjun KalaОценок пока нет

- Artificial Intelligence in The GPs Office A Retrospective Study On Diagnostic AccuracyДокумент13 страницArtificial Intelligence in The GPs Office A Retrospective Study On Diagnostic Accuracymarj611582Оценок пока нет

- 3 - Molecules and Compounds: Practice TestДокумент2 страницы3 - Molecules and Compounds: Practice Testfamily_jvcОценок пока нет

- LEARNING GUIDE-spreadsheet (Repaired)Документ53 страницыLEARNING GUIDE-spreadsheet (Repaired)Abel ZegeyeОценок пока нет

- Activity No. 5 Capacitive Circuit ObjectivesДокумент4 страницыActivity No. 5 Capacitive Circuit ObjectivesJohn Paul BaquiranОценок пока нет

- Connector Python En.a4Документ98 страницConnector Python En.a4victor carreiraОценок пока нет

- Unit 10 - Week 9: Assignment 9Документ4 страницыUnit 10 - Week 9: Assignment 9shubhamОценок пока нет

- Fault Report - Inventory Cpf1 Vs Caño LimomДокумент37 страницFault Report - Inventory Cpf1 Vs Caño LimomJessica RiveraОценок пока нет

- Battery Testing, Test Methods and ProceduresДокумент8 страницBattery Testing, Test Methods and ProceduresMuraliKrishnaОценок пока нет

- Si™ Command Language (SCL) Software Manual: For 1240I 3540I 7080I Bl7080I Blsi7080 Si-100 Si2035 Si3540 Si5580Документ23 страницыSi™ Command Language (SCL) Software Manual: For 1240I 3540I 7080I Bl7080I Blsi7080 Si-100 Si2035 Si3540 Si5580Agenor CarvalhoОценок пока нет

- IP46 - Guide To Use BAPCO WPS & Welding ProceduresДокумент4 страницыIP46 - Guide To Use BAPCO WPS & Welding ProceduressajiОценок пока нет

- Kitchen Chemistry ExperimentДокумент7 страницKitchen Chemistry ExperimentMss FaixaОценок пока нет

- Dental Material Final ReportДокумент7 страницDental Material Final ReportAbdullah Muhammed khaleel HassanОценок пока нет

- Water Pinch PresentationДокумент14 страницWater Pinch PresentationDafiMaboОценок пока нет

- Hopper Volume CalculationДокумент1 страницаHopper Volume CalculationWael AboudОценок пока нет

- 9 CE AmplifierДокумент5 страниц9 CE AmplifierAnsh PratapОценок пока нет

- Chemical Equilibrium Updated WorksheetДокумент22 страницыChemical Equilibrium Updated Worksheetmehwish razaОценок пока нет