Академический Документы

Профессиональный Документы

Культура Документы

Job Safety Analysis: (Risk Assessment)

Загружено:

MarhendraИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Job Safety Analysis: (Risk Assessment)

Загружено:

MarhendraАвторское право:

Доступные форматы

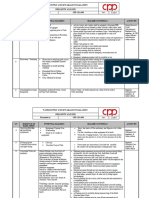

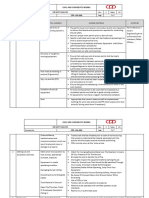

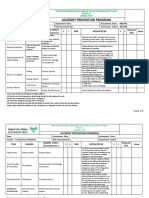

JOB SAFETY ANALYSIS

(RISK ASSESSMENT)

Area to be Access and/or Equipment Tag No. (KKS No.) : POH 2 (see attached drawings)

Work to be Done : INSTALLATION STRAUSS FOUNDATION FOR POMI COMUNITY ACADEMY BUILDING #PR148256

LOW HIGH Underwater Work Confined Space Excavation Hot Work

Risk Category Job :

Refer to Paiton Instruction : PI-05-03-01 Complex Lifting Work Working at High On Line Low & High Voltage

Work Order No. : Priority No. PAS Application No.

Work Period Date & Time Start Date & Time Finish

Operation

Applicant Health & Safety Work Parties Engineer

Supervisor

Signature :

Date : Time :

Ref. PI-05-03-01-F01 Page 1

Ref. PI-05-03-01-F01 Page 2

Work sequence Hazards Risk Control Measures

A. Prepartion

Mobilization tools, Good manual handling practices to be used (min. 2 person

equipment and materials Manual handling Musculoskeletal injuries

lift); Use hand gloves

to the work place Use mechanical aids where required

Improper electrical

Electrical tools/equipment Electrical Shock Ensure all electrical equipment in good condition

tools/equipment

Ensure all electrical equipment has been checked before use

and has valid tagging

B. Access & Ground

Proper installation and maintenance of the piling plant,

Toppling of plant causing injury

installed as per the piling platform design

or death to persons in the

Piling platform to be designed by a competent person

working area

Unstable platform Plant to be visually inspected before work daily. Inspection to

Damage to nearby

Poor work area be recorded

structures/buildings

Ramps Avoid unnecessary tracking alongside existing structures

Falling due to trip hazards from

Setting up plant / piling rig and trees

uneven mat causing injuries

Refer to method statement for all must be made available

Damage to nearby trees

throughout the works

Auger or piling rig coming into Live services survey to be carried out before

Buried services contact with buried or overhead piling commences

Overhead services cables relating in serious injury All live services to be clearly marked and diverted if

or death necessary

C. Unloading & Deliveries

All person not involved in lifting/ unloading duties to be clear

Being struck / crushed by of lifting area

moving plant possibly causing Qualified and competent slinger only to attached and detach

Plant movements fatalities loads

Offloading HIAB and Lifting Danger of slung equipment Lifting equipment to be certified and visual inspection carried

arranging storage area Storage become uncontrolled and out prior to use

Manual handling injuring personnel All plant movements on site to be supervised by slinger

Lifting without mechanical help signaller

possibly causing serious injury Any load that is deemed too heavy to lift shall be lifted using

attendant excavator/HIAB

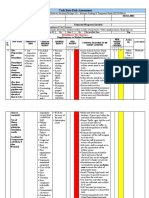

Ref. PI-05-03-01-F01 Page 3

Work sequence Hazards Risk Control Measures

Lifting to be carried out in conjunction with the Lift Plan

If lift cannot be carried out in conjunction with the Lift Plan

General public and site the AP is to be contacted

personnel being struck / crushed All deliveries/concrete to be bought onto and out of site to be

Bringing deliveries /

by moving plant possibly causing accompanied by slinger signaller at all times

Concrete Wagons into and Plant movements

fatalities

out of site Deliveries to enter site in accordance with the traffic

Vehicles being struck by moving management plan

plant

Contractor to have in place traffic management plan and

gate persons if necessary

D. Riging up / de-rigging

The piling rig must be erected as stated in the manufacturers

manual by competent persons

An experienced and qualified piling rig operative will be the

Failure of the piling rig or its only person permitted to operate the piling rig

components resulting in serious 12 monthly thorough inspection certificates must be checked

Erecting the Piling Rig Machinery injuries or death to ensure the test is in date

Getting trapped in moving parts The rig pre-start checklist and daily/weekly checklist must be

causing serious injury filled out and up to date

Any previous defects in the rig to be amended before

commencement of work

Banksman must be present at all times

Safety harnesses must be used when working at height and

attached to a sturdy place

When erecting the rig, the piling A restraint lanyard must be used to restrict the piling

operative could fall from height and

Working at height Falling from height operative coming to close to the edge of the rig

cause serious injury and endanger

others around them Harnesses must be thoroughly inspected and checked prior

to use

Harnesses must be of correct fit

Working from MEWP Working from height Risk of falling from height MEWP must be tested every 6 months

(mobile elevating working Falling objects causing death or serious injury Before use, test certificates and checks shall be carried out

platform) Toppling of plant Dropping objects onto people recorded daily inspection/prior to use inspection

Failure of MEWP below MEWP causing serious All handrails shall be locked into place.

If necessary

injury If any damage to MEWP do not use and contact supplier

MEWP toppling causing serious MEWP only to be used on firm level ground (piling mat area)

injury/Death and damage to Harness to be used with fall restrain lanyard -Harness to be

plant and nearby structures used at all times and attached to the dedicated harness point

Ref. PI-05-03-01-F01 Page 4

Work sequence Hazards Risk Control Measures

If MEWP fails when a person is stuck at height emergency

services should be called for rescue

Failure of MEWP causing

Competent person only to operate MEWP

toppling of plant,

In case of MEWP failing whist carrying personnel. Somebody

potentially crushing or trapping

must be deemed competed to lower MEWP from the controls

personnel

at ground level. If unable to do so CoreTeam must be called

to ask for fire and rescue

Ref. PI-05-03-01-F01 Page 5

Work sequence Hazards Risk Control Measures

Replacing Teeth and All changes to auger teeth/pins to be carried out using the

inserting Pins into Auger Splinters of metal coming off Tungsten may fracture when struck following equipment; High impact eye protection, copper

Heads augers and teeth and seriously injury personnel hammers

All PPE must be worn correctly

E. Boring of Piles

Ensure all personnel operating the piling rig are qualified and

deemed competent

Improper operation of the piling rig Banksman to be clearly visible to rig operative at all times

Improper operation of piling

could cause serious damage to Piling rig to be operated in conjunction with the operator

Operation of Rig rig

equipment and serious injury or

Moving rig unsupervised manual

death to personnel

Banksman to be the only person to signal the movement of

the rig

All recently bored and concreted piles are to be covered with

Falling down an open or recently

grates

concreted pile could cause

Deep excavations Personnel not involved with piling should be segregated from

Open Bores serious injury or death

Open bores the piling mat area

Machinery toppling over after

Machine drivers shall back fill the open bore with hard-core

driving over an open bore

to make them safe at the end of every day

The site will have hoarding extending the full length of the

affected area or, other methods of segregating plant from the

Injury to the public

Uncontrolled personnel public

Serious damage to nearby

Piling/Boring Working near pathways Have splash guards in place if there is a significant risk of

equipment/structures

Public access falling debris to nearby buildings/pathways

Other tradesmen

Safe systems of work to be identified in the method

statement if working next to busy roads

F. Concreting and

Reinforcing piles

Lifting reinforcement cage Lifting of cages Piling operatives and/or Operatives must refer to the lift plan before any lifts take

Proximity of nearby buildings uncontrolled personnel under place

Uncontrolled personnel slung loads If the lift cannot be carried out in accordance with the lift plan

Slinging of the load Failure of lifting gear causing the AP must be contacted

serious injury or death Piling rig only to lift reinforcement cages

Failure of piling rig causing All other lifts to be carried out by attendant

Ref. PI-05-03-01-F01 Page 6

Work sequence Hazards Risk Control Measures

serious injury or death excavator and HIAB

Improper use of lifting gear

causing loads to fall

Damage to nearby equipment

and structures

Ref. PI-05-03-01-F01 Page 7

Work sequence Hazards Risk Control Measures

Consult method statement and COSHH (control of

substances hazardous to health) assessments for working

If concrete comes into contact

with concrete to get correct PPE

with skin it can cause serious

Concrete pump shall be checked for the inspection records

injuries

and test certificates

Pouring and pumping Concrete burns If a concrete pipe were to

Concrete hoses and fittings should be visually inspected

concrete Failure of pump/hoses burst it would cause serious

daily to check for any slices or damage to the outside

damage to property, and

Concrete hoses to be double bagged when elevated.

could cause serious injury to

The concrete pump shall be segregated from any persons

personnel

not dealing with the concreting works

Vehicles shall not drive over concrete hoses where possible

G. General

Potential run-off of harmful Ensure the use of drip trays under all plant and materials that

chemicals used in refueling and could develop a drip/leaks of harmful materials e.g. fuel

maintenance of the piling rig and bowser, agitator, pump etc.

equipment affecting the Make sure field bowsers are visually inspected DAILY to

surrounding ground identify any leaks or damage that could cause a leak

Chemicals running into Ensure all materials are kept as far away from standing

Refuelling /Greasing

watercourses resulting in water water/ flood water/ rivers as possible to reduce risk of

/Storage of harmful Gas/Oil/Fuel

course pollution contamination

materials

Leaking fuel bowsers / COSHH Spill kits must be in near vicinity to equipment that has the

stores resulting in harmful potential to cause a hazardous spill

pollution COSHH assessments must be consulted and the crew

briefed before the task is undertaken

COSHH assessments will outline the PPE required for the

task

Welding / cutting Welding equipment Welding equipment is extremely Certificate welder only

Hot works hot and can cause serious burns Correct PPE must be Worn (Fireproof overalls/welding

Abrasive wheels Areas of rig being worked on can mask) along with mandatory

also become very hot and cause PPE requirements outlined in method statement

serious burns When carrying out cutting or welding works are must be

Due to the nature of the work a segregated and screened off

fire could be caused resulting in Correct fire extinguisher to be kept in the near vicinity at all

times

serious injury or death

Gas and oxygen to be stored separately

Ref. PI-05-03-01-F01 Page 8

Work sequence Hazards Risk Control Measures

Mounting of abrasive wheels by

untrained persons causing wheel Trained operatives only to use abrasive wheels

to detach Ensure equipment is properly maintained

Wheel guards being damaged or and fit for purpose

removed causing serious injury

Ref. PI-05-03-01-F01 Page 9

Work sequence Hazards Risk Control Measures

Noise Noise of machinery can cause Hearing protection must be worn when in the specified

Working hours serious damage to hearing vicinity of the rigs (specified by noise assessments)

Noise in a sensitive community Working hours to be agreed with site management

can cause disruption among

local neighbours

Enviroment

Security of equipment and plant Unauthorized use of piling Tools must be stored away properly when not in use and

equipment while on breaks

Tools left unattended could be

picked up and used by

unauthorized personnel

Untidy work area An untidy area can cause slips The work area should be cleared of obstructions and trip

Manual handling trips and falls resulting in serious hazards

Sharp edges injury Collect excessive tying wire

Lifting heavy loads can cause Steel fixing tressels should be laid on firm level ground

Steel fixing

injuries Stack reinforcement in agreed lay down areas

Cuts and lacerations can be Use barriers to segregate from other works

obtained from shard or Use mechanical aids to lift steel bundles and heavy cages

protruding steel

Plant movement Plant movement in the vicinity Ensure yourself and your personnel are in clear view and out

Untidy work areas could seriously injure or cause a of the route of moving plant

Spray markers fatality Make plant operators aware that you are working in the area

Slips trips and falls could occur if Keep work area tidy at all times

Setting out

area is untidy -Refer to COSHH for working with spray paint

Fumes released from spray paint

could cause headaches and

sickness

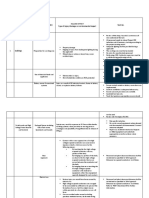

H. Foot plate foundation

and pedestal

Excavate as deep as 1,0 Ensure working tools in good condition and knowing how to

meter (dimension 1,9 x 1,9 Beaten by working tools Personal injury

use properly

meter) Provide adequate barriers, signs and warning lights to

Unauthorised access Personal injury

prevent unauthorized person entering the site

Type of soil benching :

Identify confined space and deal with them inaccordance

types of ground collapse Confined space Trapped inside the excavation

with the confined space procedur erfer to PP-05-03

risk control depending on

how deep can be Spoil Storage Overturning Make sure spoil storage areas must be clearly identified

(minimum 2 meter away from the excavation)

Ref. PI-05-03-01-F01 Page 10

Work sequence Hazards Risk Control Measures

excavate. If the deep is

more than ankle used

benching and shoring Access/Egress Fall inside the excavation Access to excavation must be by suitably safe method

(multiplex 20mm and

struts)

Sharp edge. Cut from reinforcement bar end or Rebar end and tie wire must turned down into reinforcement

Bar bending and tie wire cage

arragement rebar Sufficient rest periode between jobs and avoid repetitious

Bending rebar Stains and sprains twisting

Provide adequate shoring to hold wet concrete when pouring

Install formwork for Collapse formwork cause by

Struck down, wedge Design formwork must be based on calculation from

pedestal (400 x 400 mm) improper shoring /stager

engineering

Wearing rubber safety shoes; avoid walking backwards and

Wet concrete cover

Slip, fall, trip or twist ankle or knee make sure steel reinforcement not sags/give way because

reinforcement bar

Placing concrete not enough ties

Worm eye protection and prepare water source near work

Wet concrete splashes in eyes Eyes injury

area to flush concrete from eye/s

Additional Note :

1. Electrical isolation.

2.

3.

4.

5.

Ref. PI-05-03-01-F01 Page 11

The following test are required to assess the atmospheric conditions in the nominated space :

TEST REQUIRED

TEST FOR Permissible Exposure Limit (PEL)

YES NO

Ammonia Less than 25 ppm √

Carbon Dioxide Less than 5000 ppm √

Carbon Monoxide Less than 25 ppm √

Chlorine Less than 0.5 ppm √

Hydrogen Sulfide Less than 10 ppm √

Oxygen Greater than 19.5% & Less than 23.5% √

Ozone Less than 0.1 ppm √

Sulphur Dioxide Less than 2 ppm √

Hydrogen LEL = 4% & UEL = 75.6% √

LEL Less than/ ≤ 4% √

Note :

1. Reference (OSHA PEL – 2013)

2. For clarification on the test required to be carried out refer PI-05-03-02 (Testing of Confined Space)

Ref. PI-05-03-01-F01 Page 12

Вам также может понравиться

- JSA Painting Aut Tranformer Unit 3 OutageДокумент7 страницJSA Painting Aut Tranformer Unit 3 OutageMarhendraОценок пока нет

- HEI JHA Leakage RectificationДокумент7 страницHEI JHA Leakage RectificationJavid AaqibОценок пока нет

- Construction Risk in Operational Hospitals: Processes to Ensure Occupant Wellbeing and Minimise DisruptionsОт EverandConstruction Risk in Operational Hospitals: Processes to Ensure Occupant Wellbeing and Minimise DisruptionsОценок пока нет

- Job Safety Analysis: (Risk Assessment)Документ9 страницJob Safety Analysis: (Risk Assessment)MarhendraОценок пока нет

- Methodologies for Seismic Safety Evaluation of Existing Nuclear InstallationsОт EverandMethodologies for Seismic Safety Evaluation of Existing Nuclear InstallationsОценок пока нет

- JSA Epoxy Coating Machine ShopДокумент10 страницJSA Epoxy Coating Machine ShopMarhendra100% (1)

- 004 Piling JSAДокумент4 страницы004 Piling JSAIdada EzekielОценок пока нет

- Hot Work Gift Gift / Near Gis SEPCOO III Early Comb: Job Hazard Analysis (Jha) WorksheetДокумент4 страницыHot Work Gift Gift / Near Gis SEPCOO III Early Comb: Job Hazard Analysis (Jha) Worksheet王志伟Оценок пока нет

- JSA Additional Lamp Paiton 3Документ10 страницJSA Additional Lamp Paiton 3MarhendraОценок пока нет

- JS A For Compressor Shelter SGSДокумент3 страницыJS A For Compressor Shelter SGSwhtez0neОценок пока нет

- JSA For Errection of Batching PlantДокумент4 страницыJSA For Errection of Batching Plantasamrat582Оценок пока нет

- Method Statement For Access Road & Platform Construction in Hill Area (HSE)Документ5 страницMethod Statement For Access Road & Platform Construction in Hill Area (HSE)Rajesh100% (1)

- 004 Piling JSAДокумент5 страниц004 Piling JSAmidozotyОценок пока нет

- JSA Install Automatic Parking GateДокумент6 страницJSA Install Automatic Parking GateMarhendraОценок пока нет

- Job Hazard Analysis (JHA) Worksheet: Jerp # 3, Aromatics Unit CompanyДокумент9 страницJob Hazard Analysis (JHA) Worksheet: Jerp # 3, Aromatics Unit CompanyTeodoro Esquillo100% (1)

- Overhauling of Centrifugal Pump HEI-LEPCL-HSE-JHA-003Документ5 страницOverhauling of Centrifugal Pump HEI-LEPCL-HSE-JHA-003Javid AaqibОценок пока нет

- Excavations: Job Safety AnalysisДокумент5 страницExcavations: Job Safety AnalysisJICKОценок пока нет

- Jsa For Drilling WellДокумент5 страницJsa For Drilling WellAnna JisabaОценок пока нет

- Jha Lifting Permit - Tower CraneДокумент3 страницыJha Lifting Permit - Tower CraneJohn Ralph Vega100% (1)

- 021 Manual Excavation JSA For FLS SiteДокумент3 страницы021 Manual Excavation JSA For FLS SiteViron BaxhiaОценок пока нет

- JSA Column Errection, Shuttering, Casting, Deshuttering Raw Material Ware HouseДокумент9 страницJSA Column Errection, Shuttering, Casting, Deshuttering Raw Material Ware Houseradeep100% (1)

- Jsa CheckДокумент2 страницыJsa CheckAbhi SandiОценок пока нет

- JHSA Water Supply and Sewer InstallationДокумент4 страницыJHSA Water Supply and Sewer InstallationAnna JisabaОценок пока нет

- JSA-Piling or Concreting For Foundations & BuildingДокумент2 страницыJSA-Piling or Concreting For Foundations & BuildingSanjeet SinghОценок пока нет

- 5. job-safety Equipment and electrical panels设备服务和电箱工作安全分析Документ5 страниц5. job-safety Equipment and electrical panels设备服务和电箱工作安全分析ADEN LIUОценок пока нет

- 5.19 JSP Electrical Power InstallationДокумент4 страницы5.19 JSP Electrical Power InstallationDarius DsouzaОценок пока нет

- Excavations JSA Final 2015Документ5 страницExcavations JSA Final 2015jithin shankarОценок пока нет

- Housekeeping JsaДокумент9 страницHousekeeping JsaShahid BhattiОценок пока нет

- JSA - Structural Steel Errection Anerrection and DismantlingДокумент5 страницJSA - Structural Steel Errection Anerrection and DismantlingSwaroop CherryОценок пока нет

- Jsa - ExcavationДокумент7 страницJsa - ExcavationNOOR AISYA AMIRA ZUKAFLI100% (1)

- JSA Crack Injection at Scruber Basin Unit 3Документ6 страницJSA Crack Injection at Scruber Basin Unit 3MarhendraОценок пока нет

- Job Safety & Environmental Analysis WorksheetДокумент2 страницыJob Safety & Environmental Analysis WorksheetCherry BetonioОценок пока нет

- Jsa For Concreate and CivilworksДокумент7 страницJsa For Concreate and CivilworksAnna JisabaОценок пока нет

- Form JSA Lifting CraneДокумент6 страницForm JSA Lifting CraneYeti Srinurhayati100% (1)

- Hard BarricationДокумент3 страницыHard BarricationViron BaxhiaОценок пока нет

- 3.JOB SAFETY ANALYSIS Hot Work Project Title Installation of Wet Sprinkler System at Main WarehouseДокумент5 страниц3.JOB SAFETY ANALYSIS Hot Work Project Title Installation of Wet Sprinkler System at Main WarehouseMuhammad Umar Gondal100% (1)

- JHA - Civil Work - Excavation (Manual & Mechanical), Form Work & Concreting For Marlin ProjectДокумент9 страницJHA - Civil Work - Excavation (Manual & Mechanical), Form Work & Concreting For Marlin ProjectKelvin TanОценок пока нет

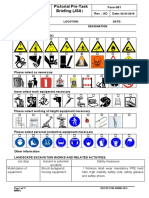

- Landscape Form-051-Pictorial Pre-Task Briefing (JSA) 19 Oct 2019 - FinalДокумент17 страницLandscape Form-051-Pictorial Pre-Task Briefing (JSA) 19 Oct 2019 - FinalJohn Vincent Macatangay Cleofe100% (1)

- SS JSP - 063 Testing and Pre-Commissioning WorksДокумент9 страницSS JSP - 063 Testing and Pre-Commissioning WorksBarkat UllahОценок пока нет

- Picmw, Inc.: Job Safety Analysis WorksheetДокумент13 страницPicmw, Inc.: Job Safety Analysis WorksheetBryleQuintОценок пока нет

- Tie - in Mechanical Installation JHAДокумент7 страницTie - in Mechanical Installation JHAmalik jahanОценок пока нет

- Jsa For Concreate and CivilworksДокумент7 страницJsa For Concreate and CivilworksAnna JisabaОценок пока нет

- 20-RAS-Transformer InstallationДокумент2 страницы20-RAS-Transformer InstallationWalid MarhabaОценок пока нет

- Use of Power ToolsДокумент3 страницыUse of Power ToolsNisanth ThulasidasОценок пока нет

- Jsa For Lifting Crane 016Документ6 страницJsa For Lifting Crane 016kiran kumar100% (1)

- 1 RA 1410 Demolition & Site ClearanceДокумент11 страниц1 RA 1410 Demolition & Site ClearanceMuhammad Shahid Iqbal100% (5)

- JSA For Construction of E - P WorkshopДокумент5 страницJSA For Construction of E - P Workshopm.rehanhseОценок пока нет

- Jsa Cooling TowerДокумент5 страницJsa Cooling TowerRavi thokalОценок пока нет

- Risk Assesment Excavation & BackfillingДокумент5 страницRisk Assesment Excavation & BackfillingMuhammad Jamshid100% (3)

- 0017 JS A Hot Job (Welding, Grinding & Cutting)Документ4 страницы0017 JS A Hot Job (Welding, Grinding & Cutting)midozotyОценок пока нет

- ISLA JHA LiftingДокумент1 страницаISLA JHA Liftingaasafety06Оценок пока нет

- 029 Fire Water Line JSA ISOM AreaДокумент4 страницы029 Fire Water Line JSA ISOM AreaViron BaxhiaОценок пока нет

- 0017 JS A Hot Job (Welding, Grinding & Cutting)Документ4 страницы0017 JS A Hot Job (Welding, Grinding & Cutting)Positivesolution100% (2)

- Jsa For Lifting Activities With Mechanical EquipmentДокумент4 страницыJsa For Lifting Activities With Mechanical EquipmentMuhammad Umar GondalОценок пока нет

- Gas Cutting JsaДокумент4 страницыGas Cutting JsaMohammed Minhaj100% (1)

- Sunmow Jha 001Документ3 страницыSunmow Jha 001Douglas DellyОценок пока нет

- Job Safety AnalysisДокумент6 страницJob Safety AnalysisMuhammad TariqОценок пока нет

- Task No. Task Name Hazards Identified Hazard Effect Type of Injury/damage or Environmental Impact Task NoДокумент6 страницTask No. Task Name Hazards Identified Hazard Effect Type of Injury/damage or Environmental Impact Task NotharwatОценок пока нет

- Sika Injection 201 CE Part A - MSDSДокумент9 страницSika Injection 201 CE Part A - MSDSMarhendraОценок пока нет

- Sikaflex - 221Документ2 страницыSikaflex - 221MarhendraОценок пока нет

- Sika Injection 201 CE Part B - MSDSДокумент10 страницSika Injection 201 CE Part B - MSDSMarhendraОценок пока нет

- SikaGrout 215 SDS en - MYДокумент9 страницSikaGrout 215 SDS en - MYMarhendraОценок пока нет

- BA - KLARIFIKASI PR171982 Effluent Water New Piping System Line To Boiler 78 - PPMДокумент4 страницыBA - KLARIFIKASI PR171982 Effluent Water New Piping System Line To Boiler 78 - PPMMarhendraОценок пока нет

- JSA Crack Injection at Scruber Basin Unit 3Документ6 страницJSA Crack Injection at Scruber Basin Unit 3MarhendraОценок пока нет

- Additional Drawing Excitation Spare Trafo Rev01-1Документ1 страницаAdditional Drawing Excitation Spare Trafo Rev01-1MarhendraОценок пока нет

- 2.LINE 1,2 GAExistingSealBoosterAirFanДокумент1 страница2.LINE 1,2 GAExistingSealBoosterAirFanMarhendraОценок пока нет

- Schedule Booster FanДокумент1 страницаSchedule Booster FanMarhendraОценок пока нет

- Design Calculation Rail 350 X 175 For PTW PreparationДокумент9 страницDesign Calculation Rail 350 X 175 For PTW PreparationMarhendraОценок пока нет

- JSA Install Automatic Parking GateДокумент6 страницJSA Install Automatic Parking GateMarhendraОценок пока нет

- JSA Replace Exsisting Strainer at FGD 8Документ8 страницJSA Replace Exsisting Strainer at FGD 8MarhendraОценок пока нет

- BoQ of Additional Lamps For Some P3 Area 2020 - R1Документ3 страницыBoQ of Additional Lamps For Some P3 Area 2020 - R1MarhendraОценок пока нет

- JSA Additional Lamp Paiton 3Документ10 страницJSA Additional Lamp Paiton 3MarhendraОценок пока нет

- METHOD STATMENT Shelter For Gas InsulatedДокумент5 страницMETHOD STATMENT Shelter For Gas InsulatedMarhendraОценок пока нет

- Method Statement Bundwall GSUT Spare Unit 3Документ4 страницыMethod Statement Bundwall GSUT Spare Unit 3MarhendraОценок пока нет

- Library of Standard BQ Descriptions For Malaysian Civil Engineering SДокумент218 страницLibrary of Standard BQ Descriptions For Malaysian Civil Engineering SSharina Sulaiman94% (33)

- Chapter 3Документ8 страницChapter 3LambertoTalplacidoJr.Оценок пока нет

- Work Procedure For The Concrete Pouring of Remaining Operating Deck SlabДокумент28 страницWork Procedure For The Concrete Pouring of Remaining Operating Deck SlabResearcherОценок пока нет

- Building Design-PWD GuidelinesДокумент71 страницаBuilding Design-PWD GuidelinesPrayas SubediОценок пока нет

- History of ConcreteДокумент20 страницHistory of Concreteapi-3766593100% (2)

- 7 - Deflection of Reinforced Concrete Beam and SlabДокумент23 страницы7 - Deflection of Reinforced Concrete Beam and SlabyakaОценок пока нет

- Drying Shinkage DilemmaДокумент3 страницыDrying Shinkage DilemmaCristian MeloОценок пока нет

- Slimdek Pattern BookДокумент40 страницSlimdek Pattern BookBabak WSP GroupОценок пока нет

- Experimental Investigation On Strength of Concrete by Agave Sisalana (Sisal Fibers)Документ7 страницExperimental Investigation On Strength of Concrete by Agave Sisalana (Sisal Fibers)IJRASETPublicationsОценок пока нет

- Punching ShearДокумент7 страницPunching SheardagetzОценок пока нет

- CE645 Term Paper Drilled Shafts PDFДокумент22 страницыCE645 Term Paper Drilled Shafts PDFJay PatelОценок пока нет

- The Concrete Producer Article PDF - Troubleshooting Precast Cracks in Hollow-Core SlabsДокумент4 страницыThe Concrete Producer Article PDF - Troubleshooting Precast Cracks in Hollow-Core SlabsmahmoodgulamОценок пока нет

- Cikomould Pu: Technical Data SheetДокумент2 страницыCikomould Pu: Technical Data SheetVaittianathan MahavapillaiОценок пока нет

- Supply of Precast Concrete Columns: StandardДокумент12 страницSupply of Precast Concrete Columns: Standardparallax1957Оценок пока нет

- Swastik Cements FloricultureДокумент3 страницыSwastik Cements FloriculturecvwОценок пока нет

- A Low-Cost Vernacular Improved Housing DesignДокумент8 страницA Low-Cost Vernacular Improved Housing DesignsfhousingsearchОценок пока нет

- Anchor Calculation - Case 2Документ10 страницAnchor Calculation - Case 2MdShahbazAhmedОценок пока нет

- Concrete Tank SpreadsheetДокумент3 страницыConcrete Tank SpreadsheetMai CОценок пока нет

- 3.4 Concrete Mix Design Using ACI FormatДокумент6 страниц3.4 Concrete Mix Design Using ACI FormatHella SeyumОценок пока нет

- Perilaku Lentur Balok Beton Bertulang Dengan Tulangan Rotan Dan Tulangan Besi PolosДокумент13 страницPerilaku Lentur Balok Beton Bertulang Dengan Tulangan Rotan Dan Tulangan Besi PolosHilman AbdullahОценок пока нет

- Ph.D. Course Work Syllabus in Civil Engg.Документ15 страницPh.D. Course Work Syllabus in Civil Engg.arunachelamОценок пока нет

- 1 Merged 1Документ45 страниц1 Merged 1foody_kathleenОценок пока нет

- Katalog SealentДокумент15 страницKatalog SealentWulan EgidiaОценок пока нет

- ELNASHAI Et Al-1996-Earthquake Engineering & Structural DynamicsДокумент29 страницELNASHAI Et Al-1996-Earthquake Engineering & Structural Dynamicssabareesan09Оценок пока нет

- Building in A BagДокумент5 страницBuilding in A Baghungndo100% (1)

- Gypsum Partition Check ListДокумент1 страницаGypsum Partition Check ListQAQC GCCОценок пока нет

- Colak Foamed GypsumДокумент8 страницColak Foamed GypsumOnyx XynoОценок пока нет

- RCT-ConTile BondДокумент2 страницыRCT-ConTile BondfahadОценок пока нет

- METHOD Statement For Citadel Fence and Concrete Removal at The IGRF LOPДокумент8 страницMETHOD Statement For Citadel Fence and Concrete Removal at The IGRF LOPoaklamОценок пока нет

- Protective & Marine Coatings: Heavy Duty Block FillerДокумент4 страницыProtective & Marine Coatings: Heavy Duty Block FillerAna CabreraОценок пока нет