Академический Документы

Профессиональный Документы

Культура Документы

ENGINE SENSORS 32 Hal

Загружено:

Dian Idawati100%(1)100% нашли этот документ полезным (1 голос)

170 просмотров32 страницыThe document describes various sensors used in an electronic control module for a construction equipment engine. It discusses 11 sensors that provide input to the ECM including sensors for intake manifold pressure and temperature, engine speed and position, coolant temperature, barometric pressure, fuel pressure, oil pressure, and camshaft position. It also describes the functions of the ECM, fuel injectors, fuel pump actuator, intake air heater, and water-in-fuel sensor.

Исходное описание:

Engine sensor

Оригинальное название

(6)ENGINE SENSORS 32 Hal

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документThe document describes various sensors used in an electronic control module for a construction equipment engine. It discusses 11 sensors that provide input to the ECM including sensors for intake manifold pressure and temperature, engine speed and position, coolant temperature, barometric pressure, fuel pressure, oil pressure, and camshaft position. It also describes the functions of the ECM, fuel injectors, fuel pump actuator, intake air heater, and water-in-fuel sensor.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

100%(1)100% нашли этот документ полезным (1 голос)

170 просмотров32 страницыENGINE SENSORS 32 Hal

Загружено:

Dian IdawatiThe document describes various sensors used in an electronic control module for a construction equipment engine. It discusses 11 sensors that provide input to the ECM including sensors for intake manifold pressure and temperature, engine speed and position, coolant temperature, barometric pressure, fuel pressure, oil pressure, and camshaft position. It also describes the functions of the ECM, fuel injectors, fuel pump actuator, intake air heater, and water-in-fuel sensor.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 32

QSC/QSL CM850

Electronic Components

REF. ; CD-Presentation ISL elec recall

Page1 Construction Equipment

When a diagnostic fault code is recorded

in the ECM, the ECM input and output

data is recorded from all sensors and

switches.

1. Intake manifold pressure sensor

2. Intake manifold air temperature sensor

3. Engine speed and position sensor

4. Engine coolant temperature sensor

5. Barometric pressure sensor

6. Camshaft position sensor

7. Engine oil pressure switch

8. Fuel pump actuator

9. OEM Water-in-fuel sensor

10. Turbocharger speed sensor

11. Rail fuel pressure sensor.

Page2 Construction Equipment

Intake Manifold

Temperature

Sensor

The intake manifold air temperature sensor

monitors intake manifold air temperature and

passes the information to the electronic control

module (ECM) through the engine harness.

Derate:Torque-93℃(FC2964), RPM-127℃(155)

Page3 Construction Equipment

Intake Manifold

Pressure

Sensor

The intake manifold pressure sensor monitors

intake manifold pressure and passes the

information to the electronic control module (ECM)

through the engine harness. If intake manifold

pressure becomes too low, it will cause a derate

condition.

Page4 Construction Equipment

Barometric Air

Pressure

Sensor

The barometric pressure sensor is used by the

electronic control module (ECM) to monitor the

barometric pressure. This value is one of many

inputs used by the ECM to maintain the correct

air to fuel ratio for proper engine operation.

The air intake manifold provides a

location for the TMAP sensor and

the Ambient Air Pressure (AAP)

sensor. (no longer strapped to the

wiring harness)

Page5 Construction Equipment

T-MAP sensor

• QSB 4.5 and 6.7 product

uses a TMAP (Temperature TMAP sensor

and Manifold Air Pressure)

combo

sensor(example;engine oil,

intake air, fuel), instead of

the separate thread intake

manifold temperature

sensor and thread intake

manifold air pressure

sensor on ISB’02

• Euro 3 product used this

sensor.

Page6 Construction Equipment

Coolant

Temperature

Sensor

The engine coolant temperature sensor is used by

the electronic control module (ECM) to monitor the

engine coolant temperature.

The ECM monitors the voltage on the signal pin

and converts this to a temperature value.

The engine coolant temperature value is used by

the ECM for the engine protection system and

engine emissions control.

Derate:Torque-104℃(none),-107℃(FC146), RPM-112℃(151)

Page7 Construction Equipment

Common Rail

Fuel Pressure

Sensor

The rail fuel pressure sensor is used by

the electronic control module (ECM) to

monitor fuel pressure in the common rail.

Page8 Construction Equipment

Engine oil

Pres. Sensor

The engine oil pressure sensor is used by the

electronic control module (ECM) to monitor the

lubricating oil pressure. The ECM monitors the

sensor input and converts this to a pressure

value. The oil pressure value is used by the

ECM for the engine protection system.

Crancking;10psi, Idle;30psi, Rrated;70psi

Page9 Construction Equipment

Engine Speed/

Position Sensor

The engine speed sensor monitors engine

speed and position from a tone wheel mounted

on the crankshaft, then passes this information

to the electronic control module (ECM) through

the engine harness.

Primary engine speed sensor has been moved to the

crankshaft. Provides increased speed resolution for the fuel

system. Increases reliability from current product because the

primary and secondary speed sensors are reading from two

different targets.

–The tone wheel mounted on the rear of the

crankshaft, provides crankshaft speed and position

information to the ECM via the engine speed sensor.

–The crankshaft speed indicator ring will be mounted

to the vibration damper.

–The crankshaft speed indicator ring is not

serviceable. If damage or replacement is required,

the damper assembly must be replaced.

Page10 Construction Equipment

Intake Air

Heater

The intake air heater (grid heater) provides the

heated intake air in cold ambient conditions.

Start ability and white smoke control are

enhanced by the use of the intake air heater.

The ECM controls the actuation on the intake

air heater via a relay(s).

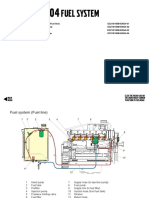

Page11 Construction Equipment

Fuel Pump

Actuator

The fuel pump actuator is used by the

electronic control module (ECM) to control

fuel pressure in the common rail. N.O type.

Page12 Construction Equipment

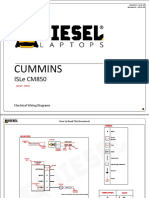

Electronic

Control Module

New Electronic Control Module (ECM) - Model

CM850

Same ECM architecture as the ISB CM850 and

ISX CM870 engines

Three connectors on the ECM

- 50-pin OEM connector

- 60-pin engine harness connector

- 4-pin ECM power supply (main power

and ground for the ECM)

ECM COOLING PLATE

Page13 Construction Equipment

Injector

The ECM controls the injector to provide the

correct timing and metering for each cylinder.

CONNECTOR – from COMMON

RAIL to INJECTOR

SOLENOID actuated at 4.7V

Page14 Construction Equipment

OEM Water in

Fuel Sensor

The water-in-fuel sensor monitors fuel for the

presence of water and passes this information to the

electronic control module (ECM) through the engine

harness.

The water-in-fuel sensor is located in the pre-filter

(OEM supplied).

Page15 Construction Equipment

Coolant Level

Sensor(N.A)

Derate : Torque-Low

coolant(FC197-Amber)

Page16 Construction Equipment

Camshaft speed/position sensor (gear cover, front)

The camshaft position sensor monitors

camshaft position from the 7 protrusions

on the back side of the cam gear, then

passes this information to the electronic

control module (ECM) through the engine

harness.

• Will be the same/similar to the ISB ’02

engines

– One change is currently being worked

on, to have a common oil pressure

switch/sensor location in the front gear

cover by the camshaft speed/position

sensor

• Will be different that ISBe3 engines

– Will house the camshaft speed/position

sensor

• Camshaft speed/position sensor

was previously located in the rear

gear housing.

– Will house the camshaft speed indicator

ring

Page17 Construction Equipment

Camshaft gear & Sensor

• Change from ISBe3 camshaft and

camshaft gear

– ISBe engines had speed/

position pick ups on the

camshaft gear. The camshaft

speed/position sensor was at the

rear of the engine

– Like ISB ’02, the camshaft will

have a camshaft speed indicator

ring mounted to the camshaft at

the front of the engine.

Page18 Construction Equipment

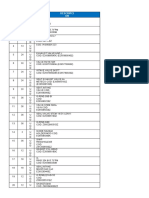

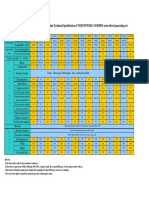

Tier-3 Electrical Specifications (QSB/C/L)

- J1939 BACKBONE RESISTANCE - SOLENOIDS

· Positive wire to negative wire ; 50 ~ 70Ω · Lift Pump ; Resistance = 1.0 ~ 1.2 Ω

· J1939 Termination Resistance ; 110 ~

130Ω · Fuel Pump Actuator(EFC) = 2.0 ~ 4.5 Ω

- ALL CONTINUITY CHECKS : · Injectors = 0.5 ~ 1.5Ω, after subtracting

· OK (no open circuit) if < 10Ω the multimeter resistance.

- ALL SHORTS TO GROUND :

· OK (no short circuit) if more than 1000kΩ

- SHORT CIRCUIT TO EXTERNAL VOLTAGE ;

OK if < 1.5VDC

- 5 VDC POWER (sensor and switch)

@ ECM/Harness ; 4.75 ~ 5.25 VDC

Page19 Construction Equipment

Tier-3 Sensor Specifications (QSB/C/L)

- OIL PRESSURE SENSOR - INTAKE MANIFOLD PRESSURE SENSOR

Pressure(kPa) Pressure(psi) Voltage(V) Pressure(mmHg) Pressure(inHg) Voltage(V)

0 0 0.42 ~ 0.58 0 0 0.90 ~ 1.06

172.37 25 1.42 ~ 1.58 381 15 1.30 ~ 1.53

344.74 50 2.42 ~ 2.58 635 25 1.57 ~ 1.84

517.11 75 3.42 ~ 3.58 1549 61 2.53 ~ 2.96

689.48 100 4.42 ~ 4.58 2057 81 3.07 ~ 3.60

2590 102 3.61 ~ 4.23

- ENGINE COOLANT TEMPERATURE SENSOR

Temperature(℃) Temperature(℉) Resistance(Ω)

0 32 30k ~ 37k - BAROMETRIC(Ambient) AIR PRES. SENSOR

25 77 9.3k ~ 10.7k Altitude(m) Altitude(ft) Voltage(V)

50 122 3.2k ~ 3.8k 0 0 3.65 ~ 4.28

80 176 1.1k ~ 1.3k 915 3000 3.06 ~ 3.50

95 203 700 ~ 800 1830 6000 2.52 ~ 2.96

2744 9000 2.01 ~ 2.36

3659 12000 1.57 ~ 1.84

- INTAKE MANIFOLD TEMPERATURE SENSOR

Temperature(℃) Temperature(℉) Resistance(Ω)

-10 14 8.7k ~ 9.7k

0 32 5.5k ~ 6.1k - WATER IN FUEL SENSOR

20 68 2.4k ~ 2.5k Description Voltage(V)

40 104 1.1k ~ 1.2k Probe in Water 0.50 ~ 3.00

70 158 418 ~ 436 Probe in Fuel 4.00 ~ 4.50

Page20 Construction Equipment

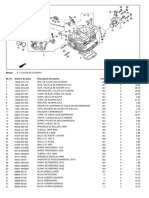

Intake Side Engine View (CM850 Control Module)

1. Air intake connection 9. Crankcase breather oil drain tube

2. Crankcase breather 10. Starter

3. Intake air heater 11. Engine oil drain plug

4. Turbocharger control valve-N.A 12. Fuel lift pump

5. Fuel rail 13. Electronic control module (ECM)

6. Fuel drain manifold 14. Air compressor

7. Fuel filter 15. Engine data plate

8. Crankcase breather draft tube 16. High-pressure pump

Page21 Construction Equipment

Exhaust Side Engine View (CM850 Control Module)

1. Exhaust manifold 8. Coolant outlet connection

2. Turbocharger (VGT shown)-적용 않됨 9. Coolant heater port

3. Variable geometry turbocharger actuator-적용 않됨 10. Coolant inlet connection

4. Crankcase breather 11. Lubricating oil cooler

5. Rocker lever cover 12. Lubricating oil filter

6. Engine oil fill 13. Dipstick location

7. Rocker lever housing 14. Flywheel housing

Page22 Construction Equipment

Wiring Diagram(Tier-2)

Page23 Construction Equipment

Page24 Construction Equipment

Page25 Construction Equipment

Page26 Construction Equipment

Page27 Construction Equipment

Page28 Construction Equipment

Page29 Construction Equipment

Page30 Construction Equipment

Page31 Construction Equipment

Page32 Construction Equipment

Вам также может понравиться

- Tier3 ElectricДокумент10 страницTier3 ElectricLuong Nguyen Danh100% (1)

- Cummins QSB6.7 and QSB4.5 With CM850 ECM - Sensor & Actuator LocationДокумент30 страницCummins QSB6.7 and QSB4.5 With CM850 ECM - Sensor & Actuator LocationAnders Hedlöf100% (3)

- @perkins: Electronic Controlled Governor User ManualДокумент64 страницы@perkins: Electronic Controlled Governor User ManualJohnnot PeagunОценок пока нет

- 28454-3 MID 128 PID 94 Fuel Delivery Pressure CheckДокумент6 страниц28454-3 MID 128 PID 94 Fuel Delivery Pressure CheckTun Tun Win KseОценок пока нет

- Eletronic Engines Support 7 4 0 Global GuideДокумент553 страницыEletronic Engines Support 7 4 0 Global Guidejean sanchez100% (1)

- CM850 870 875 Programming GuideДокумент155 страницCM850 870 875 Programming GuideMiguel Angel Cortes Prieto100% (1)

- Motorola Cm850: Imensione Port S.R.L - 15020 Gabiano (AL) - ITALY - Tel. +39 0142 955 201 - WEBДокумент2 страницыMotorola Cm850: Imensione Port S.R.L - 15020 Gabiano (AL) - ITALY - Tel. +39 0142 955 201 - WEBJUAN DAVID ARIAS IGUARAN100% (1)

- Tencreng0003 Ecu ControlДокумент24 страницыTencreng0003 Ecu ControlAly AbdelhamedОценок пока нет

- Cummins QSB6.7 and QSB4.5 With CM850 ECM - Components TestingДокумент15 страницCummins QSB6.7 and QSB4.5 With CM850 ECM - Components TestingAnders Hedlöf100% (5)

- 8-2 Electric System and SpecДокумент11 страниц8-2 Electric System and SpecSumitomo Laos Sumitomo LaosОценок пока нет

- Workshop Manual W3024EN2.pdf Workshop Manual W3024EN2 PDFДокумент64 страницыWorkshop Manual W3024EN2.pdf Workshop Manual W3024EN2 PDFAlexander LopezОценок пока нет

- Speed Control (Switch) - Test (RENR5096)Документ4 страницыSpeed Control (Switch) - Test (RENR5096)Josip MiškovićОценок пока нет

- Ex60-5 Elec (E)Документ1 страницаEx60-5 Elec (E)Canhoto100% (1)

- FAULT CODE 559 - Injector Metering Rail 1 Pressure - Data Valid But Below Normal Operating Range - Moderately Severe LevelДокумент8 страницFAULT CODE 559 - Injector Metering Rail 1 Pressure - Data Valid But Below Normal Operating Range - Moderately Severe LevelDylan tejadaОценок пока нет

- Throttle Information Reference Guide PDFДокумент24 страницыThrottle Information Reference Guide PDFJohn Rivera100% (1)

- Various Engine Families - ECM Code Cross Reference SheetДокумент35 страницVarious Engine Families - ECM Code Cross Reference Sheethandoko pocaОценок пока нет

- INSITE 8.7.0 Release NotesДокумент15 страницINSITE 8.7.0 Release NotesCuando NuncaОценок пока нет

- Automatic Engine Control For John Deere: Ecu-Can70BcДокумент2 страницыAutomatic Engine Control For John Deere: Ecu-Can70BcCarlos Andrés Marín ArcosОценок пока нет

- Service Bulletin Trucks: Engine Control Unit, ReplacementДокумент8 страницService Bulletin Trucks: Engine Control Unit, ReplacementLucho Volvo TronicОценок пока нет

- 385B Excavator Electrical System: Electrical Schematic Symbols and DefinitionsДокумент2 страницы385B Excavator Electrical System: Electrical Schematic Symbols and DefinitionsFlorencio MaximilianoОценок пока нет

- PTMI Flash FilesДокумент1 страницаPTMI Flash FilesAhmer Camdzic0% (1)

- PC300-7 Elec DiagДокумент33 страницыPC300-7 Elec Diagluis eduardo corzo enriquezОценок пока нет

- Fault Code 334 Engine Coolant Temperature - Data Erratic, Intermittent, or IncorrectДокумент9 страницFault Code 334 Engine Coolant Temperature - Data Erratic, Intermittent, or IncorrectAhmedmahОценок пока нет

- Cummins: Fault Code: 141 PID: P100 SPN: 100 FMI: 4Документ4 страницыCummins: Fault Code: 141 PID: P100 SPN: 100 FMI: 4Enrrique Lara100% (1)

- DMS Help ENДокумент118 страницDMS Help ENSegundo Francisco Jauregui ValenciaОценок пока нет

- Vhp825wcu Hp935wcu Xp1050wcu Hp825wcu Xp900wcuДокумент434 страницыVhp825wcu Hp935wcu Xp1050wcu Hp825wcu Xp900wcuÖzgür Hakan Danış50% (2)

- Cummins Isb/Isc/Isl: C/W CM 850 Electronic Control ModuleДокумент1 страницаCummins Isb/Isc/Isl: C/W CM 850 Electronic Control ModuleChristian Ramirez100% (1)

- ISB/ISD6.7 CM2150 B120 Wiring Diagram: Engine Harness Connector Engine Control Module Engine Control ModuleДокумент1 страницаISB/ISD6.7 CM2150 B120 Wiring Diagram: Engine Harness Connector Engine Control Module Engine Control ModuleOmar Hernández100% (1)

- Renr1297renr1297 Sis (1) EngineДокумент2 страницыRenr1297renr1297 Sis (1) EngineAmber SmithОценок пока нет

- DG 04 003-E 08-04 Formular Communication OrderДокумент17 страницDG 04 003-E 08-04 Formular Communication OrderLuis JesusОценок пока нет

- 9U-5132 Timing and Fuel System Setting Tool GroupДокумент33 страницы9U-5132 Timing and Fuel System Setting Tool GroupmkОценок пока нет

- ENG0007 DL DV SensorДокумент23 страницыENG0007 DL DV Sensormike100% (1)

- Diaframa cm850Документ1 страницаDiaframa cm850ViniОценок пока нет

- Kit Prise HitachiДокумент45 страницKit Prise HitachiMartinezОценок пока нет

- Dearborn Protocol Adapter (Dpa) and PLC Testcon Pinouts Industry Connectors Reference GuideДокумент26 страницDearborn Protocol Adapter (Dpa) and PLC Testcon Pinouts Industry Connectors Reference GuideMateo VelezОценок пока нет

- Qual QSC - ISC-QSL - ISL CM850 Qualification 2010Документ189 страницQual QSC - ISC-QSL - ISL CM850 Qualification 2010agvass100% (5)

- FAULT CODE 187 (ISB/QSB Automotive and Industrial, ISC/QSC/ISL/QSL Automotive, Industrial, and Marine) Sensor Supply Voltage Number 2 Circuit - Voltage Below Normal, or Shorted To Low SourceДокумент11 страницFAULT CODE 187 (ISB/QSB Automotive and Industrial, ISC/QSC/ISL/QSL Automotive, Industrial, and Marine) Sensor Supply Voltage Number 2 Circuit - Voltage Below Normal, or Shorted To Low SourceAhmedmahОценок пока нет

- 05 ElectricДокумент79 страниц05 ElectriccristianОценок пока нет

- Celect Codes: A Complete List of All Celect Fault Codes For The Cummins EcmДокумент3 страницыCelect Codes: A Complete List of All Celect Fault Codes For The Cummins EcmEduardo TorresОценок пока нет

- Ems39 EngДокумент4 страницыEms39 EngDaniel AsquiОценок пока нет

- Engine Information Screen: Sumitomo (S.H.I) Construction Machinery Manufacturing Co.,LtdДокумент24 страницыEngine Information Screen: Sumitomo (S.H.I) Construction Machinery Manufacturing Co.,LtdAgus DaniОценок пока нет

- Fault Code 196 (3-Wire Sensor) : Coolant Level Sensor 1 Circuit - Voltage Below Normal or Shorted To Low SourceДокумент3 страницыFault Code 196 (3-Wire Sensor) : Coolant Level Sensor 1 Circuit - Voltage Below Normal or Shorted To Low SourceHamilton MirandaОценок пока нет

- Bendix ® Gen 4 TM and Gen 5 TMДокумент48 страницBendix ® Gen 4 TM and Gen 5 TMMarcialCastroLeonidasОценок пока нет

- Fault Code 154 Intake Manifold Air Pressure/Temperature Sensor Circuit - Voltage Below Normal or Shorted To Low SourceДокумент12 страницFault Code 154 Intake Manifold Air Pressure/Temperature Sensor Circuit - Voltage Below Normal or Shorted To Low SourceAhmedmahОценок пока нет

- BE (Body Electrical System)Документ37 страницBE (Body Electrical System)RomusОценок пока нет

- Cummins: Fault Code: 222 PID: P108 SPN: 108 FMI: 4Документ6 страницCummins: Fault Code: 222 PID: P108 SPN: 108 FMI: 4Enrrique LaraОценок пока нет

- DST4400 Manual ControllerДокумент4 страницыDST4400 Manual ControllergereseОценок пока нет

- Fuel SystemДокумент37 страницFuel SystemPhan Dung100% (1)

- Wiring Diagram Tad1250veДокумент1 страницаWiring Diagram Tad1250vecochinillo1000Оценок пока нет

- Fault Code 222 Barometric Pressure Sensor Circuit - Voltage Below Normal, or Shorted To Low SourceДокумент14 страницFault Code 222 Barometric Pressure Sensor Circuit - Voltage Below Normal, or Shorted To Low SourceAhmedmahОценок пока нет

- CRI Pump & ControllerДокумент5 страницCRI Pump & Controllereko sunaryo100% (1)

- Schematic C4.4Документ8 страницSchematic C4.4Asep ShaifurrahmanОценок пока нет

- Cummins 2003-2006 Isle Cm850 Elect DiagДокумент12 страницCummins 2003-2006 Isle Cm850 Elect Diagedelsagua70Оценок пока нет

- Technical Manual: For Air-Conditioning Heating System Liebherr Excavator B-LineДокумент24 страницыTechnical Manual: For Air-Conditioning Heating System Liebherr Excavator B-LineRiza DSОценок пока нет

- GEH330-1 Spec SheetДокумент4 страницыGEH330-1 Spec SheetWai YanОценок пока нет

- Throttle Position Sensor Circuit TestДокумент8 страницThrottle Position Sensor Circuit TestDaniel AmanorОценок пока нет

- 2013-QSC8.3 & QSL9 CM850 Shop TalkДокумент6 страниц2013-QSC8.3 & QSL9 CM850 Shop Talkralph arisОценок пока нет

- 2020-ISB CM2150 Shop TalkДокумент7 страниц2020-ISB CM2150 Shop Talkralph arisОценок пока нет

- 2019-ISB CM2150 IntroductionДокумент7 страниц2019-ISB CM2150 Introductionralph arisОценок пока нет

- 2023-ISC/ISL CM2150 Fuel SystemДокумент7 страниц2023-ISC/ISL CM2150 Fuel Systemralph arisОценок пока нет

- Eec3 Electronic Engine Controls by Glendinning Installation & Operation ManualДокумент86 страницEec3 Electronic Engine Controls by Glendinning Installation & Operation ManualDian Idawati100% (1)

- CATALOG CODE: QJ50QT-2 2009 Version F01 Control Assy. NO. Code Description QTY Notes Season Old CodeДокумент25 страницCATALOG CODE: QJ50QT-2 2009 Version F01 Control Assy. NO. Code Description QTY Notes Season Old CodeDian IdawatiОценок пока нет

- Db58 G-Drive: Power RatingДокумент2 страницыDb58 G-Drive: Power RatingDian IdawatiОценок пока нет

- Indeco Kataloog PDFДокумент9 страницIndeco Kataloog PDFDian IdawatiОценок пока нет

- Thames Trader EngineДокумент1 страницаThames Trader EngineIanОценок пока нет

- WisecochartДокумент15 страницWisecochartVitОценок пока нет

- Nissan VQ EngineДокумент14 страницNissan VQ EngineRoberto Ortega Micalizzi33% (3)

- Russian Moto Evol Part I Engine TypesДокумент90 страницRussian Moto Evol Part I Engine TypesAna Starciuc100% (3)

- 16L Workshop ManualДокумент164 страницы16L Workshop ManualMTK2016100% (12)

- Advanced Ic Engine Full NotesДокумент200 страницAdvanced Ic Engine Full NotesBhagavathi ShankarОценок пока нет

- Daihatsu Spare PartsДокумент5 страницDaihatsu Spare PartsJacques LopezОценок пока нет

- A50 JUNIOR Brochure EnglishДокумент12 страницA50 JUNIOR Brochure EnglishSaeid MirОценок пока нет

- Principles of CarburetionДокумент38 страницPrinciples of CarburetionArpit SinghaiОценок пока нет

- Connector C41 PIN Circuit Volt Connector C42 PIN Circuit VoltДокумент2 страницыConnector C41 PIN Circuit Volt Connector C42 PIN Circuit VoltEduRoi90% (10)

- TE-I Lesson PlanДокумент6 страницTE-I Lesson PlanArunkumar MunimathanОценок пока нет

- Indian Standard: Code of Practice For Use of Screed Board Concrete VibratorsДокумент10 страницIndian Standard: Code of Practice For Use of Screed Board Concrete VibratorsRajashekar.PОценок пока нет

- VPC Chongqing CumminsДокумент1 страницаVPC Chongqing CumminspngchanhОценок пока нет

- Echnica : Improvement of Turbocharger Life For Diesel and Gasoline EnginesДокумент12 страницEchnica : Improvement of Turbocharger Life For Diesel and Gasoline EnginessamanaveenОценок пока нет

- AirSource Plus JD 4024 Rec - SparesДокумент3 страницыAirSource Plus JD 4024 Rec - SparesEder DoriaОценок пока нет

- Air Compressor ProblemsДокумент10 страницAir Compressor ProblemslynОценок пока нет

- Toyota ExpadДокумент2 страницыToyota ExpadIsihaka SuleimanОценок пока нет

- Manual DetroitDieselandFreightliner DieselTech PDFДокумент38 страницManual DetroitDieselandFreightliner DieselTech PDFGreg Pulido100% (1)

- s46mcc8 PDFДокумент385 страницs46mcc8 PDFvivekt5100% (1)

- ValmetДокумент52 страницыValmetEndra100% (1)

- Mitsubishi SU KUДокумент2 страницыMitsubishi SU KUMd ShОценок пока нет

- Honda PC 800 Pacific Coast Illustrated Parts ListДокумент221 страницаHonda PC 800 Pacific Coast Illustrated Parts ListTimbo6808100% (1)

- Despiece Motor XR 200Документ45 страницDespiece Motor XR 200Cristian AlfonsoОценок пока нет

- Diagram - HTML: Fuse Box in The Engine CompartmentДокумент20 страницDiagram - HTML: Fuse Box in The Engine CompartmentaakritichОценок пока нет

- 5 - 12 Section 5 - Diagnosis J-1 ECM Connector Identification (1 of 2 J-1)Документ8 страниц5 - 12 Section 5 - Diagnosis J-1 ECM Connector Identification (1 of 2 J-1)MyBriggsОценок пока нет

- Turbocharged Direct Injection Is Engine Oils Next Big Hurdle PDFДокумент5 страницTurbocharged Direct Injection Is Engine Oils Next Big Hurdle PDFMishu MarcelОценок пока нет

- 1 5141403013855838489 PDFДокумент5 страниц1 5141403013855838489 PDFJefferson SilvaОценок пока нет

- VWvortex Forums - DIY - Oil Breather - Catch CanДокумент34 страницыVWvortex Forums - DIY - Oil Breather - Catch Canapi-3739501100% (1)

- FORD D FaultCodes 0366 PDFДокумент1 страницаFORD D FaultCodes 0366 PDFIacob MargineanОценок пока нет

- Fault Detection and DiagnosisДокумент20 страницFault Detection and DiagnosisjudarangocaОценок пока нет