Академический Документы

Профессиональный Документы

Культура Документы

LADWER ASME V April 2017

Загружено:

Luthfi ArdiansyahИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

LADWER ASME V April 2017

Загружено:

Luthfi ArdiansyahАвторское право:

Доступные форматы

The topics discussed herewith are summarized from ASME Section V – 2013 Edition

The highlighted points are as per outline in the body of knowledge API 510 Pressure Vessel Inspector

Certification examination issued May and September 2016 and January 2017 (Replaces May 2015)

ASME V

NONDESTRUCTIVE EXAMINATION

ARTICLE 1 GENERAL REQUIREMENTS

T-150 PROCEDURE

c) When a referencing Code Section requires an examination to be performed in accordance

with the requirements of this Section, it shall be the responsibility of the Manufacturer,

fabricator, or installer to establish nondestructive examination procedures and personnel

qualification and certification procedures conforming to the referenced requirements.

T-160 CALIBRATION

a) The Manufacturer, fabricator, or installer shall assure that all equipment calibrations required by

Subsection A and / or Subsection B are performed

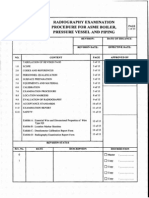

ARTICLE 2 RADIOGRAPHIC EXAMINATION

T-220 GENERAL REQUIREMENTS

T-221 Procedure Requirements. Each procedure shall include at least the following information, as

applicable:

(a) material type and thickness range

(b) isotope or maximum X-ray voltage used

(c) source-to-object distance (D in T-274.1)

(d) distance from source side of object to film (d in T-274.1)

(e) source size (F in T-274.1)

(f) film brand and designation

(g) screens used

T-221.2 Procedure Demonstration. Demonstration of the density and image quality indicator (IQI)

image requirements of the written procedure on production or technique radiographs shall be

considered satisfactory evidence of compliance with that procedure.

T-223 Backscatter Radiation. A lead symbol “B”, with minimum dimensions of ½ in. (13 mm) in

height and 1/16 in. (1.5 mm) in thickness, shall be attached to the back of each film holder during

each exposure to determine if backscatter radiation is exposing the film.

T-225 Monitoring Density Limitations of Radiographs. Either a densitometer or step wedge

comparison film shall be used for judging film density.

T-232 Intensifying Screens. Intensifying screens may be used when performing radiographic

examination in accordance with this Article.

T-233.1 Standard IQI Design. IQIs shall be either in hole type or the wire type.

Table T-233.2 WIRE IQI DESIGNATION, WIRE DIAMETER, AND WIRE IDENTITY

T-234 Facilities for Viewing of Radiographs. The viewing conditions shall be such that light from

around the outer edge of the radiograph or coming through low-density portions of the radiograph does

not interfere with interpretation.

ASME V for API 510, ALW 4/7/2017 11:29 PM Page 1 of 7

The topics discussed herewith are summarized from ASME Section V – 2013 Edition

The highlighted points are as per outline in the body of knowledge API 510 Pressure Vessel Inspector

Certification examination issued May and September 2016 and January 2017 (Replaces May 2015)

T-260 CALIBRATION

T-261 Source Size

T-261.1 Verification of Source Size. The equipment manufacturer’s or supplier’s publications, such as

technical manuals, decay curves, or written statements documenting the actual or maximum source

size or focal spot, shall be acceptable as source size verification.

T-261.2 Determination of Source Size. When manufacturer’s or supplier’s publications are not

available, source size may be determined as follows:

(a) X-Ray Machines. For X-ray machines operating at 500 kV and less, the focal spot size may be

determined by the pinhole method,1 or in accordance with SE-1165, Standard Test Method for

Measurement of Focal Spots of Industrial X-Ray Tubes by Pinhole Imaging.

(b) Iridium-192 Sources. For Iridium-192, the source size may be determined in accordance with SE-

1114, Standard Test Method for Determining the Focal Size of Iridium-192 Industrial

Radiographic Sources.

T-262 Densitometer and Step Wedge Comparison Film

T-262.1 Densitometers. Densitometers shall be calibrated at least every 90 days during use as

follows:

(a) Traceable to a national standard last year by comparison with a national standard.

(b) The densitometer manufacturer’s step-by-step instructions for the operation of the densitometer

shall be followed.

(c) The density steps closest to 1.0, 2.0, 3.0, and 4.0 on the national standard step tablet or step

wedge calibration film shall be read.

(d) The densitometer is acceptable if the density readings do not vary by more than ± 0.05 density

units from the actual density stated on the national standard step tablet or step wedge calibration

film.

T-262.3 Periodic Verification

(a) Densitometers. Periodic calibrations verification checks shall be performed as described in T-

262.1 at the beginning of each shift, after 8 hours of continuous use, or after change of

apertures, whichever comes first.

T-262.4 Documentation

(a) Densitometers. Densitometer calibrations required by T-262.1 shall be documented, but the

actual readings for each step do not have to be recorded. Periodic densitometer verification checks

required by T-262.3(a) do not have to be documented.

(b) Step Wedge Calibration Films. Step wedge calibration film verifications required by T-262.1(a)

shall be documented, but the actual readings for each step do not have to be recorded.

(c) Step Wedge Comparison Films. Step wedge comparison film verifications required by T-262.2 and

T-262.3(b) shall be documented, but the actual readings for each step do not have to be recorded.

T-270 EXAMINATION

T-271.1 Single-Wall Technique. In the single-wall technique, the radiation passes through only one

wall of the weld (material), which is viewed for acceptance on the radiograph.

T-271.2 Double-Wall Technique. When it is not practical to use a single-wall technique, one of the

following double-wall techniques shall be used.

(a) Single-Wall Viewing. For materials and for welds in components, a technique may be used in

which the radiation passes through two walls and only the weld (material) on the film-side wall is

viewed for acceptance on the radiograph. When complete coverage is required for

circumferential welds (materials), a minimum of three exposures taken 120 deg to each other

shall be made.

(b) Double-Wall Viewing. For materials and for welds in components 3 ½ in. (89 mm) or less in

nominal outside diameter, a technique may be used in which the radiation passes through two

walls and the weld (material) in both walls is viewed for acceptance on the same radiograph. For

double-wall viewing, only a source-side IQI shall be used. Care should be exercised to ensure that

the required geometric unsharpness is not exceeded.

ASME V for API 510, ALW 4/7/2017 11:29 PM Page 2 of 7

The topics discussed herewith are summarized from ASME Section V – 2013 Edition

The highlighted points are as per outline in the body of knowledge API 510 Pressure Vessel Inspector

Certification examination issued May and September 2016 and January 2017 (Replaces May 2015)

T-272 Radiation Energy. The radiation energy employed for any radiographic technique shall

achieve the density an IQI image requirements of this Article.

T-273 Direction of Radiation. The direction of the central beam of radiation should be centered on

the area of interest whenever practical.

T-274 Geometric Unsharpness

T- 274.1 Geometric Unsharpness Determination. Geometric unsharpness of the radiograph

shall be determined in accordance with:

Ug = Fd / D

T-274.2 Geometric Unsharpness Limitations. Recommended maximum values for geometric

unsharpness are as follows:

Material Ug

Thickness, in. (mm) Maximum, in. (mm)

Under 2 (50) 0.020 (0.51)

2 through 3 (50–75) 0.030 (0.76)

Over 3 through 4 (75–100) 0.040 (1.02)

Greater than 4 (100) 0.070 (1.78)

T-275 Location Markers

Shall be placed on the part, not on the exposure holder / cassette. Their locations shall be

permanently marked on the surface of the part being radiographed when permitted, or on a map, in a

manner permitting the area of interest on a radiograph to be accurately traceable to its location on the

part, for the required retention period of the radiograph. Evidence shall also be provided on the

radiograph that the required coverage of the region being examined has been obtained.

T-276 IQI Selection

Material is from same alloy material group or grade per SE-1025 or from alloy material group or grade

with less radiation absorption than material being radiographed.

Table T-276 specifies required IQI.

IQI thickness based on nominal single wall thickness plus estimated reinforcement.

Backing rings or strips not considered part of weld thickness.

IQI selection of welds joining dissimilar materials or with dissimilar filler metals is based on weld

metal.

T-277 Use of IQIs to Monitor Radiographic Examination

T-277.1 Placement of IQIs

(a) Source-Side IQI(s). The IQI(s) shall be placed on the source side of the part being examined,

(b) Film-Side IQI(s). Where inaccessibility prevents hand placing the IQI(s) on the source side, the

IQI(s) shall be placed on the film side in contact with the part being examined. A lead letter “F”

shall be placed adjacent to or on the IQI(s), but shall not mask the essential hole where hole IQIs

are used.

(c) IQI Placement for Welds — Wire IQIs. The IQI(s) shall be placed on the weld so that the length of

the wires is perpendicular to the length of the weld.

ASME V for API 510, ALW 4/7/2017 11:29 PM Page 3 of 7

The topics discussed herewith are summarized from ASME Section V – 2013 Edition

The highlighted points are as per outline in the body of knowledge API 510 Pressure Vessel Inspector

Certification examination issued May and September 2016 and January 2017 (Replaces May 2015)

T-277.2 Number of IQIs. When one or more film holders are used for an exposure, at least one IQI

image shall appear on each radiograph.

When a single exposure of a complete circumference is made only three IQI’s are required at 120

degrees apart.

T-280 EVALUATION

T-281 Quality of Radiographs

Must be free from mechanical, chemical or other blemishes that do not mask and are not confused

with the image of any discontinuity in the area of interest.

T-282 Radiographic Density

T-282.1 Density Limitations. Shall be 1.8 minimum for single film viewing for radiographs made with an

X-ray source and 2.0 minimum for radiographs made with a gamma ray source. For composite viewing

of multiple film exposures, each film of the composite set shall have a minimum density of 1.3. The

maximum density shall be 4.0 for either single or composite viewing. A tolerance of 0.05 in density is

allowed for variations between densitometer readings.

T-282.2 Density Variation. Density in area of interest must be within – 15% and + 30% from

density through the penetrameter otherwise an additional penetrameter shall be used.

T-284 Excessive Backscatter

If a light image of the “B,” appears on a darker background of the radiograph, protection from

backscatter is insufficient and the radiograph shall be considered unacceptable. A dark image of the “B”

on a lighter background is not cause for rejection.

T-290 DOCUMENTATION

T-291 Radiographic Technique Documentation Details

The Manufacturer shall prepare and document the radiographic technique details. As a minimum, the

following information shall be provided.

(a) the requirements

(b) identification

(c) the dimensional map (if used) of marker placement

(d) number of radiographs (exposures)

(e) X-ray voltage or isotope type used

(f) source size

(g) base material type and thickness, weld thickness, weld reinforcement thickness, as applicable

(h) source-to-object distance

(i) distance from source side of object to film

(j) film manufacturer and Manufacturer’s type/designation

(k) number of film in each film holder/cassette

(l) single- or double-wall exposure

(m) single- or double-wall viewing

ARTICLE 6 LIQUID PENETRANT EXAMINATION

T-620 GENERAL

An effective means for detecting discontinuities which are open to the surface of nonporous metals

and other materials. Typical discontinuities detectable by this method are cracks, seams, laps, cold

shuts, laminations, and porosity.

ASME V for API 510, ALW 4/7/2017 11:29 PM Page 4 of 7

The topics discussed herewith are summarized from ASME Section V – 2013 Edition

The highlighted points are as per outline in the body of knowledge API 510 Pressure Vessel Inspector

Certification examination issued May and September 2016 and January 2017 (Replaces May 2015)

T-641 Control of Contaminants (Mandatory Appendix II)

Sulfur content for nickel base alloys.

Chlorine and fluorine content for austenitic stainless steel and titanium.

T-642 Surface Preparation

(a) Surface preparation by grinding, machining, or other methods may be necessary where surface

irregularities could mask indications.

(b) Prior to each liquid penetrant examination, the surface to be examined and all adjacent areas

within at least 1 in. (25 mm) shall be dry and free of all contaminant

T-652 Techniques for Standard Temperatures

Not be below 40°F (5°C) nor above 125°F (52°C)

T-653 Techniques for Nonstandard Temperatures (Mandatory Appendix III)

Covers handling of nonstandard technique using a liquid penetrant comparator.

For temperatures less than 40oF perform examination at proposed lower temperature and compare to

the 40oF to 125oF range. This qualifies the procedure from lower temperature to 40oF.

o

For temperatures above 125 F the upper and lower limits shall be established and the procedure

qualified at these temperatures per Appendix III of this Article.

T-654 Technique Restrictions

Fluorescent method shall not follow color contrast method.

Intermixing penetrant families not permitted.

T-660 Calibrations

Light meters, both visible and fluorescent shall be calibrated once a year or whenever repaired.

T-670 Examination

Includes the requirements for fluorescent penetrant examination whereby examiner must be in a

darkened area for at least 5 minute prior to performing examination.

Final interpretation is made 10 to 60 minutes after developer application.

Post emulsification penetrants divided into lipophilic and hydrophilic emulsification.

T-691 Recording of Indications

Nonrejectable and rejectable indications shall be recorded.

ARTICLE 7 MAGNETIC PARTICLE EXAMINATION

T-720 GENERAL

The magnetic particle examination method is applied to detect cracks and other discontinuities on the

surfaces of ferromagnetic materials.

ASME V for API 510, ALW 4/7/2017 11:29 PM Page 5 of 7

The topics discussed herewith are summarized from ASME Section V – 2013 Edition

The highlighted points are as per outline in the body of knowledge API 510 Pressure Vessel Inspector

Certification examination issued May and September 2016 and January 2017 (Replaces May 2015)

T-731 Examination Medium

(c) Temperature Limitations. Particles shall be used within the temperature range limitations set by the

manufacturer of the particles.

T-750 TECHNIQUE

(a) prod technique

(d) yoke technique

T-752 Prod Technique

T-752.2 Magnetizing Current. Direct or rectified magnetizing current shall be used. The current shall be

100 (minimum) amp / in. (4 amp/mm) to 125 (maximum) amp / in. (5 amp/mm) of prod spacing for

sections ¾ in. (19 mm) thick or greater. For sections less than ¾ in. (19 mm) thick, the current shall be

90 amp / in. (3.6amp / mm) to 110 amp / in. (4.4 amp / mm) of prod spacing.

T-752.3 Prod Spacing. Prod spacing shall not exceed 8 in. (200 mm).

T-755 Yoke Technique

For this technique, alternating or direct current electro- magnetic yokes, or permanent magnet yokes,

shall be used.

T-760 CALIBRATION

T-761 Frequency of Calibration

T-761.1 Magnetizing Equipment

(a) Frequency. Magnetizing equipment with an ammeter shall be calibrated at least once a year, or

whenever the equipment has been subjected to major electric repair, periodic overhaul, or damage.

If equipment has not been in use for a year or more, calibration shall be done prior to first use.

(b) Procedure. The accuracy of the unit’s meter shall be verified annually by equipment traceable to

a national standard. Comparative readings shall be taken for at least three different current

output levels encompassing the usable range.

(c) Tolerance. The unit’s meter reading shall not deviate by more than ±10% of full scale, relative to the

actual current value as shown by the test meter.

T-762 Lifting Power of Yokes

(a) The magnetizing power of all yokes shall be checked whenever the yoke has been damaged or

repaired.

(b) electromagnetic yoke shall have a lifting power of at least 10 lb (4.5 kg) at the maximum pole

spacing that will be used.

(c) permanent magnetic yoke shall have a lifting power of at least 40 lb (18 kg) at the maximum pole

spacing that will be used.

(d) Each weight shall be weighed with a scale from a reputable manufacturer and stenciled with the

applicable nominal weight prior to first use. A weight need only be verified again if damaged in a

manner that could have caused potential loss of material.

T-770 EXAMINATION

T-772 Direction of Magnetization

At least two separate examinations shall be performed on each area. During the second examination,

the lines of magnetic flux shall be approximately perpendicular to those used during the first

examination.

ASME V for API 510, ALW 4/7/2017 11:29 PM Page 6 of 7

The topics discussed herewith are summarized from ASME Section V – 2013 Edition

The highlighted points are as per outline in the body of knowledge API 510 Pressure Vessel Inspector

Certification examination issued May and September 2016 and January 2017 (Replaces May 2015)

T-773 Method of Examination

(a) Dry Particles.

(b) Wet Particles.

T-777 Interpretation

Nonfluorescent particle examination shall be performed with a minimum light intensity of 100 foot

candles (fc) or 1000 lx.

When fluorescent particles used examiner shall be in darkened area at least 5 minutes prior to

examination being performed.

Black light warm up a minimum of 5 minutes.

2.

Black light intensity measured with black light meter. Minimum intensity on surface is 1000m W/cm

T-778 Demagnetization

When residual magnetization interferes with subsequent processing or usage demagnetize any time

after completion of examination.

T-792 Recording of indications

(b) Nonrejectable and rejectable indications shall be recorded.

ARTICLE 23, SE-797

STANDARD PRACTICE FOR MEASURING THICKNESS

BY MANUAL ULTRASONIC PULSE-ECHO CONTACT METHOD

1. Scope

Thickness of materials using the contact pulse-echo method at temperatures not to exceed 200°F

(93°C).

9. Technical Hazards

9.5 High-temperature materials. A rule of thumb often used is as follows: The apparent thickness

reading obtained from steel walls having elevated temperatures is high (too thick) by a factor of about

1% per 55°C (100°F). Thus, if the instrument was standardized on a piece of similar material at 20°C

(68°F), and if the reading was obtained with a surface temperature of 460°C (860°F), the apparent

reading should be reduced by 8%.

ASME V for API 510, ALW 4/7/2017 11:29 PM Page 7 of 7

Вам также может понравиться

- Lim - Asme VДокумент7 страницLim - Asme VGilang AdiОценок пока нет

- ASME Section V Art 2 SpanishДокумент8 страницASME Section V Art 2 SpanishScribdTranslationsОценок пока нет

- Ut ProcedureДокумент12 страницUt ProcedurerohithОценок пока нет

- NDT - RADIOGRAPHДокумент12 страницNDT - RADIOGRAPHDedy TriandaОценок пока нет

- Lloyd S Register Sec V 2017 Edition Key ChangesДокумент27 страницLloyd S Register Sec V 2017 Edition Key ChangesDilip VaradharajanОценок пока нет

- ASME Section V - NDE Requirements: API-653 Exam Prep Course BAY Technical Associates, Inc. (610) 594-9036Документ25 страницASME Section V - NDE Requirements: API-653 Exam Prep Course BAY Technical Associates, Inc. (610) 594-9036Anbarasan PerumalОценок пока нет

- Radiographic Testing ProcedureДокумент8 страницRadiographic Testing ProcedureRai Singh MalhiОценок пока нет

- Radiographic Testing ProcedureДокумент12 страницRadiographic Testing ProcedureJake SparrowОценок пока нет

- Radiography Examination Procedure For Asme Boiler, Pressure Vessel and PipingДокумент15 страницRadiography Examination Procedure For Asme Boiler, Pressure Vessel and PipingEko Kurniawan100% (1)

- Belajar B. InggrisДокумент2 страницыBelajar B. InggrisMario HanamiciОценок пока нет

- Ultrasonic Examination ProcedureДокумент10 страницUltrasonic Examination ProcedureJake SparrowОценок пока нет

- Sicc-Rt-01 Asme Rev 01Документ29 страницSicc-Rt-01 Asme Rev 01Enrique Campos Cannavaro100% (1)

- UT Procedure PDFДокумент23 страницыUT Procedure PDFcentaury2013Оценок пока нет

- RT ASME Art 2Документ39 страницRT ASME Art 2Florin TrОценок пока нет

- RT Procedures For WeldДокумент19 страницRT Procedures For WeldABHIJIT GIRIОценок пока нет

- Kie TP R297Документ35 страницKie TP R297Muhamad Dahlan STОценок пока нет

- RT Procedure Rev.01Документ30 страницRT Procedure Rev.01shivanshsovОценок пока нет

- Ultrasonic Testing Procedure: 1. ScopeДокумент10 страницUltrasonic Testing Procedure: 1. ScopePrashant PuriОценок пока нет

- ASME Code Case PautДокумент10 страницASME Code Case PautAnonymous kIrNuhОценок пока нет

- Asme Sec V A-2-2004 PDFДокумент39 страницAsme Sec V A-2-2004 PDFjaire esparzaОценок пока нет

- Rediographic Examination ProcedureДокумент6 страницRediographic Examination ProcedureAbank RoonyОценок пока нет

- Ut Procedure AwsДокумент23 страницыUt Procedure AwsKrishna Vacha80% (10)

- RT Procedure 10.09.16Документ9 страницRT Procedure 10.09.16mukeshsingh6Оценок пока нет

- Code Case - 2235-10Документ10 страницCode Case - 2235-10Nilesh Pathare0% (1)

- Ut Procedure Selon AsmeДокумент9 страницUt Procedure Selon AsmeMajdi JerbiОценок пока нет

- PAUT General Work ProceduresДокумент16 страницPAUT General Work Proceduresdiaccessltd_1717296188% (8)

- Sop RTДокумент9 страницSop RTEddy Dwi CahyonoОценок пока нет

- Procedure: R E A (P) LДокумент19 страницProcedure: R E A (P) LPramod GrОценок пока нет

- ScopeДокумент9 страницScoperaghbirОценок пока нет

- Ut Procedure NewДокумент10 страницUt Procedure NewAmit HasanОценок пока нет

- RT ProcedureДокумент26 страницRT ProcedureKoshala Balasuriya100% (1)

- Ultrasonic Examination Procedure: Doc. No.: QUAL/UT/001: of 10 Revision: 00 Date: 25.04.05 1.0Документ10 страницUltrasonic Examination Procedure: Doc. No.: QUAL/UT/001: of 10 Revision: 00 Date: 25.04.05 1.0smsunil12345Оценок пока нет

- PAUT & TOFD Procedure For EOL, VadinarДокумент22 страницыPAUT & TOFD Procedure For EOL, Vadinarrupam100% (5)

- Ultrasonic Test ProcedureДокумент8 страницUltrasonic Test ProcedureShailendra GhaisasОценок пока нет

- RT-procedure SampleДокумент19 страницRT-procedure Sampleneelapu mahesh reddyОценок пока нет

- Radiography Testing GuideДокумент7 страницRadiography Testing GuideAmirul Asyraf100% (1)

- P-003 Ultrasonic Testing ProcedureДокумент24 страницыP-003 Ultrasonic Testing ProcedureSaheb Yadav100% (2)

- 02 ACSR ZEBRA ConductorДокумент37 страниц02 ACSR ZEBRA Conductorsanjeevchhabra100% (2)

- Understanding Article 2 ASME Sec V - Radiographic ExaminationДокумент46 страницUnderstanding Article 2 ASME Sec V - Radiographic Examinationrosli2503Оценок пока нет

- 7.5.5.2asme Sec Viii Div 2 2017Документ3 страницы7.5.5.2asme Sec Viii Div 2 2017James100% (2)

- Package SubstationДокумент9 страницPackage SubstationuddinnadeemОценок пока нет

- AWS-UT-2006 Rev 0Документ40 страницAWS-UT-2006 Rev 0Shyam Singh100% (3)

- Astm E1025-2011Документ7 страницAstm E1025-2011charles46100% (1)

- Case 2235-13 Use of Ultrasonic Examination in Lieu of Radiography Section Section XIIДокумент12 страницCase 2235-13 Use of Ultrasonic Examination in Lieu of Radiography Section Section XII나무Оценок пока нет

- Radiography Test ProcedureДокумент12 страницRadiography Test Procedurehasan_676489616100% (4)

- Irst 19 2012Документ65 страницIrst 19 2012krischaever100% (1)

- UT PROCEDURE NewДокумент10 страницUT PROCEDURE NewMeet Patel100% (3)

- TOFD Procedure For VesselДокумент12 страницTOFD Procedure For Vesselmohanraj67% (3)

- UT ProcedureДокумент14 страницUT Procedureshifa0% (1)

- Procedimiento de RadiografiaДокумент40 страницProcedimiento de Radiografiajose10001Оценок пока нет

- RT ProcДокумент14 страницRT ProcaravindanОценок пока нет

- RT Proceure Gas Pipeline Abu Humos/ El Nobaria 42" Diameter & 65 KM LengthДокумент14 страницRT Proceure Gas Pipeline Abu Humos/ El Nobaria 42" Diameter & 65 KM LengtharavindanОценок пока нет

- OPGW Cables SpecДокумент45 страницOPGW Cables SpecOffshre Eng-Solutions100% (1)

- How to prepare Welding Procedures for Oil & Gas PipelinesОт EverandHow to prepare Welding Procedures for Oil & Gas PipelinesРейтинг: 5 из 5 звезд5/5 (1)

- Design of Buildings for Wind: A Guide for ASCE 7-10 Standard Users and Designers of Special StructuresОт EverandDesign of Buildings for Wind: A Guide for ASCE 7-10 Standard Users and Designers of Special StructuresРейтинг: 3.5 из 5 звезд3.5/5 (2)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsОт Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsРейтинг: 4 из 5 звезд4/5 (1)

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesОт EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášОценок пока нет

- Design and Implementation of Portable Impedance AnalyzersОт EverandDesign and Implementation of Portable Impedance AnalyzersОценок пока нет

- Sesi 9 - MonopolyДокумент25 страницSesi 9 - MonopolyLuthfi ArdiansyahОценок пока нет

- Sesi 7B - Exercise 2Документ2 страницыSesi 7B - Exercise 2Luthfi ArdiansyahОценок пока нет

- Describing Supply and Demand: ElasticitiesДокумент33 страницыDescribing Supply and Demand: ElasticitiesLuthfi ArdiansyahОценок пока нет

- MM 5006 Business Economics: DR - Ir. Subiakto Soekarno Mba, QWP™, CFP®Документ53 страницыMM 5006 Business Economics: DR - Ir. Subiakto Soekarno Mba, QWP™, CFP®Luthfi ArdiansyahОценок пока нет

- Sesi 3 Exercise 1Документ4 страницыSesi 3 Exercise 1Luthfi ArdiansyahОценок пока нет

- LADWER API 510 - API RP 577 April 2017Документ7 страницLADWER API 510 - API RP 577 April 2017Luthfi ArdiansyahОценок пока нет

- Calculation Formula For API 510Документ2 страницыCalculation Formula For API 510Luthfi ArdiansyahОценок пока нет

- Chap001 Introduction OSCM-4APRIL2020Документ22 страницыChap001 Introduction OSCM-4APRIL2020Luthfi ArdiansyahОценок пока нет

- Itin&budget Japan TripДокумент4 страницыItin&budget Japan TripLuthfi ArdiansyahОценок пока нет

- ITENARY EUROPE TRIP 2016 - Rev1Документ2 страницыITENARY EUROPE TRIP 2016 - Rev1Luthfi ArdiansyahОценок пока нет

- Lifting Appliances: Sofyan Purba Bayu Pratama PurbaДокумент29 страницLifting Appliances: Sofyan Purba Bayu Pratama PurbaLuthfi ArdiansyahОценок пока нет

- Case Studies and Key QuestionsДокумент13 страницCase Studies and Key QuestionsLuthfi ArdiansyahОценок пока нет

- Chap002 Strategy-4APRIL2020Документ25 страницChap002 Strategy-4APRIL2020Luthfi ArdiansyahОценок пока нет

- Mba ItbДокумент30 страницMba ItbLuthfi ArdiansyahОценок пока нет

- Ohc AssessmentДокумент8 страницOhc AssessmentLuthfi ArdiansyahОценок пока нет

- Water Well List CompanyДокумент4 страницыWater Well List CompanyLuthfi ArdiansyahОценок пока нет

- ASME PCC-1-2000 BOLTED FLANGE (For Print Out) PDFДокумент30 страницASME PCC-1-2000 BOLTED FLANGE (For Print Out) PDFLuthfi ArdiansyahОценок пока нет

- ASME PCC-1-2000 BOLTED FLANGE (For Print Out) PDFДокумент30 страницASME PCC-1-2000 BOLTED FLANGE (For Print Out) PDFLuthfi ArdiansyahОценок пока нет

- Drivers License UV Markings Per StateДокумент2 страницыDrivers License UV Markings Per StateSome OneОценок пока нет

- Mock Test Code-BДокумент18 страницMock Test Code-BKomal VermaОценок пока нет

- Mid Coast USA HospitalДокумент14 страницMid Coast USA Hospitaljahanavi sharma100% (1)

- Colors: The Psychology and Theories of ColorsДокумент45 страницColors: The Psychology and Theories of ColorsDiana Sophia KanОценок пока нет

- UFS 15-22-40-110 UFS15J-22J-40J: Braking UnitДокумент21 страницаUFS 15-22-40-110 UFS15J-22J-40J: Braking UnitnayanОценок пока нет

- Interview QuestionsДокумент5 страницInterview QuestionsShahed HussainОценок пока нет

- PRACTICE QUESTIONS Unit 4, 5 and 6Документ5 страницPRACTICE QUESTIONS Unit 4, 5 and 6Samrudhi PatilОценок пока нет

- Microwave InspectionДокумент10 страницMicrowave InspectionZaid TariqОценок пока нет

- LED1Документ20 страницLED1Aman Kumar DiptiОценок пока нет

- Students Dream Box Academy: Guduvanchery / Tambaram / Chrompet / SpkoilДокумент8 страницStudents Dream Box Academy: Guduvanchery / Tambaram / Chrompet / SpkoilSTUDENTS DREAM BOX - CBSEОценок пока нет

- ExperimentsДокумент25 страницExperimentsanshkourav991Оценок пока нет

- Measurement Very Fast Transient Overvoltages (Vfto) in A Gis ModuleДокумент4 страницыMeasurement Very Fast Transient Overvoltages (Vfto) in A Gis Moduleajay_kairiОценок пока нет

- Tutsheet5 SolutionsДокумент5 страницTutsheet5 SolutionsDevendra Singhaniya90% (10)

- Braking of DC MotorДокумент18 страницBraking of DC MotorBangariОценок пока нет

- Atoms & Isotopes 1 QPДокумент17 страницAtoms & Isotopes 1 QPMagd OsamaОценок пока нет

- Witricity: Devon GrecoДокумент7 страницWitricity: Devon GrecoGorishsharmaОценок пока нет

- Indian Association of Physics Teachers: National Graduate Physics Examination 2020Документ11 страницIndian Association of Physics Teachers: National Graduate Physics Examination 2020PRIYANKAОценок пока нет

- Measurement and Instrumentation Lecture NotesДокумент73 страницыMeasurement and Instrumentation Lecture NotesRakesh Thapliyal83% (6)

- Principles of Underwater AcousticsДокумент55 страницPrinciples of Underwater Acousticsadrianamasa83% (6)

- 10 - SOT Question Paper End Sem 2012Документ2 страницы10 - SOT Question Paper End Sem 2012Harsh ThakurОценок пока нет

- CAE Oxford Aviation Academy - 020 Aircraft General Knowledge 2 - Electrics and ElectronicsДокумент284 страницыCAE Oxford Aviation Academy - 020 Aircraft General Knowledge 2 - Electrics and ElectronicsMichael WarrenОценок пока нет

- General Instructions:: Effect of Force:-1. Force Can Change The State of Motion: An Object Can Be in Two StatesДокумент11 страницGeneral Instructions:: Effect of Force:-1. Force Can Change The State of Motion: An Object Can Be in Two StatesSifat MongaОценок пока нет

- Engineering Science For BS MBS3211: 3. ElectricityДокумент64 страницыEngineering Science For BS MBS3211: 3. ElectricityCool DouglasОценок пока нет

- LX6-6W-6GR Product SpecificationДокумент6 страницLX6-6W-6GR Product SpecificationAmit GorkhaliОценок пока нет

- Lab#10 Electricity - Current in A Parallel CircuitДокумент2 страницыLab#10 Electricity - Current in A Parallel CircuitTren EDWARDОценок пока нет

- BS8161 Physics Lab-Cse, Civil, Aero & RoboДокумент5 страницBS8161 Physics Lab-Cse, Civil, Aero & RoboJennifer BlevinsОценок пока нет

- PEP 2020 Phase 1 Selection Test 2 - SolutionДокумент9 страницPEP 2020 Phase 1 Selection Test 2 - SolutionMarcus PoonОценок пока нет

- Class8 Physics ASM-1 3572Документ2 страницыClass8 Physics ASM-1 3572jaz kОценок пока нет

- Automatic Water Tank Level Controller Motor Driver Circuit - Engineering Project Without Microcontroller - Circuits Gallery PDFДокумент29 страницAutomatic Water Tank Level Controller Motor Driver Circuit - Engineering Project Without Microcontroller - Circuits Gallery PDFEi Po Po AungОценок пока нет

- Finite Element Motional Electro-Magnetic Modeling of A 100kW eVTOL Permanent Magnet Motor-Esdras Lopez PDFДокумент1 страницаFinite Element Motional Electro-Magnetic Modeling of A 100kW eVTOL Permanent Magnet Motor-Esdras Lopez PDFSteph ClicheОценок пока нет