Академический Документы

Профессиональный Документы

Культура Документы

Figure 1 Problem Geometry

Загружено:

r_zoro87Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Figure 1 Problem Geometry

Загружено:

r_zoro87Авторское право:

Доступные форматы

BEARING CAPACITY OF GROUND ANCHORS

BEARING CAPACITY OF GROUND ANCHORS

This document describes an example that has been used to verify the bearing capacity of

ground anchors in PLAXIS 3D. The test is performed with a ground anchor in loose and

dense sand. The skin friction along the grout body is considered to be either constant or

linear, in both dense and loose sand.

Used version:

• PLAXIS 3D - Version 2016.00

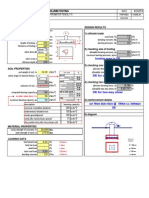

Geometry: The anchor's free length is simulated by using the Node-to-node anchor

option. The grout body has a length of 4 m. It is simulated by using the Embedded beam

option. The connection point between the embedded beam and the node-to-node anchor

should be free to move and not fixed to the adjacent soil. This is adjusted by selecting the

embedded beam and setting the option for the Connection type to Free via the Selection

explorer window. The ground anchor is attached to a concrete block with dimensions

2×2×1 m3 . The model layout is shown in Figure 1.

1m

5m

16 m

4m

16 m

16 m

Figure 1 Problem geometry

Materials: The anchor is elastic with stiffness E'A = 4.095 × 105 kN. The skin friction

properties of the ground anchor are defined as:

PLAXIS 2016 | Validation & Verification 1

VALIDATION & VERIFICATION

Loose sand:

Constant skin friction (CS): Tskin,start,max = 50 kN/m Tskin,end,max = 50 kN/m

Linear skin friction (LS): Tskin,start,max = 0 kN/m Tskin,end,max = 100 kN/m

Dense sand:

Constant skin friction (CS): Tskin,start,max = 188 kN/m Tskin,end,max = 188 kN/m

Linear skin friction (LS): Tskin,start,max = 0 kN/m Tskin,end,max = 376 kN/m

The remaining properties of the grout body are:

E = 2 × 107 kN/m2 , Diameter = 0.125 m

The concrete block is modelled as a non-porous linear elastic material:

γ = 25 kN/m3 , E = 2.80 × 107 kN/m2 , ν = 0.15

The loose sand as well as the dense sand are modelled by the Mohr-Coulomb model.

The properties of the loose sand are:

γunsat = 16 kN/m3 , γsat = 18 kN/m3 , E ' = 4.5 × 104 kN/m2 , ν ' = 0.3

c ' = 0.1 kN/m2 , ϕ' = 28 deg, ψ = 0 deg

The properties of the dense sand are:

γunsat = 17 kN/m3 , γsat = 20 kN/m3 , E ' = 10.5 × 104 kN/m2 , ν ' = 0.3

c ' = 0.1 kN/m2 , ϕ' = 35 deg, ψ = 5 deg

Meshing: The Medium option is selected for the Element distribution. A Coarseness

factor equal to 1.0 is assigned to entire model, apart from the Embedded beam and the

Node-to-node anchor, for which a Coarseness factor of 0.5 is used. The resulting

generated mesh is depicted in Figure 2. The node located at the top (8.0, 8.0, -4.0) and

the bottom (8.0, 8.0, -8.0) of the ground anchor is selected to present the results.

Attention should be payed in order to select the nodes of the Embedded beam and not

any adjacent soil node.

Calculations: The bearing capacity of the ground anchor is tested in 4 different phases,

considering constant and linear skin friction, in both loose and dense sand. A prestress

force of 1000 kN is applied via the Node-to-node anchor. In the Numerical control

parameters menu, the Tolerated error is set to 0.001 and the Max load fraction per step

is set to 0.1, for all considered calculation phases.

Output: In Figure 3 the axial force at the top of the anchor Ntop is plot against

displacements |u|, while Figure 4 illustrates the axial force at the bottom of the anchor

Nbottom over displacements |u|. The free top of the anchor moves promptly as the axial

load is applied. The bottom anchor point does not have the same behaviour due to the

axial skin resistance of the anchor. This is more apparent in case of dense sand

conditions, for which a higher value of skin resistance is assigned to the anchor.

In loose sand, the maximum axial force in the anchor is 200.22 kN and 200.17 kN for a

2 Validation & Verification | PLAXIS 2016

BEARING CAPACITY OF GROUND ANCHORS

Figure 2 The resulting mesh

constant skin friction distribution (CS) and a linear skin friction distribution (LS)

respectively. This is consistent for the top and the bottom of the anchor. In dense sand,

the maximum axial force in the anchor is 753.43 kN and 753.46 kN for a constant skin

friction distribution (CS) and a linear skin friction distribution (LS) respectively. This is

consistent for the top and the bottom of the anchor as well.

800

700

600

Ntop [kN]

500

400

Dense sand [CS]

300

Dense sand [LS]

200 Loose sand [CS]

Loose sand [LS]

100

0

0 0.005 0.01 0.015 0.02 0.025 0.03

|u| [m]

Figure 3 Axial force at the top of the anchor against displacements

Verification: The theoretical solution for the total bearing capacity is presented below

(Ostermayer & Barley, 2003).

Loose sand:

Fmax = 4m × 50kN/m = 200kN

Dense sand:

Fmax = 4m × 188kN/m = 752kN

PLAXIS 2016 | Validation & Verification 3

VALIDATION & VERIFICATION

800

700

Nbottom [kN] 600

500

400

Dense sand [CS]

300

Dense sand [LS]

200 Loose sand [CS]

Loose sand [LS]

100

0

0 0.005 0.01 0.015 0.02 0.025 0.03

|u| [m]

Figure 4 Axial force at the bottom of the anchor against displacements

The results indicate an error less than 0.2% for both loose and dense sand. In both soil

materials, the ground anchor shows a softer behavior in case of a linear skin friction

distribution (LS). This is caused by early slip at the bottom of the grout body, when the

prestress is still rather low, resulting in larger displacements. In case of a constant skin

friction distribution (CS), the whole grout body remains elastic. Smaller displacements

occur until a higher value of the prestress force is reached.

REFERENCES

[1] Ostermayer, H., Barley, T. (2003). Ground anchors. Geotechnical Engineering

Handbook, 2, 169–219.

4 Validation & Verification | PLAXIS 2016

Вам также может понравиться

- Design of Manhole As Per Aashto LRFDДокумент23 страницыDesign of Manhole As Per Aashto LRFDRafique Munde100% (2)

- 2008 Seadoo Shop ManualДокумент555 страниц2008 Seadoo Shop Manualanon_846090969100% (3)

- Foundation Settlement: 8.0 SyllabusДокумент25 страницFoundation Settlement: 8.0 SyllabusAyebareОценок пока нет

- 1996 Club Car DS Golf Cart Owner's ManualДокумент48 страниц1996 Club Car DS Golf Cart Owner's Manualdriver33b60% (5)

- Hardening Soil ModelДокумент42 страницыHardening Soil ModelClaudioОценок пока нет

- Check Soil Bearing CapacityДокумент4 страницыCheck Soil Bearing CapacityKelvin LauОценок пока нет

- 1.0 General: Bored Pile 600 25000Документ24 страницы1.0 General: Bored Pile 600 25000David Sinambela100% (2)

- Load Carrying Capacity of PilesДокумент29 страницLoad Carrying Capacity of PilesMalik Rizwan100% (1)

- Calculation of Bearing Capacity From Standard Penetration Test (SPT)Документ28 страницCalculation of Bearing Capacity From Standard Penetration Test (SPT)ankitОценок пока нет

- Soil Spring Stiffness - 1.0Документ10 страницSoil Spring Stiffness - 1.0sanilОценок пока нет

- Rigid Pavements With NEW CODE PDFДокумент108 страницRigid Pavements With NEW CODE PDFdhanush gtОценок пока нет

- Comparison of Subgrade Reaction and FEM For D Wall DesignДокумент7 страницComparison of Subgrade Reaction and FEM For D Wall DesignCEG BangladeshОценок пока нет

- RCC Slab Bridge Design 10 M - 2022Документ7 страницRCC Slab Bridge Design 10 M - 2022erzahid ahmadОценок пока нет

- MIDAS ChecklistДокумент27 страницMIDAS ChecklistBhagirath JoshiОценок пока нет

- Sdsadsadw DweasdДокумент44 страницыSdsadsadw DweasdChandan SharmaОценок пока нет

- Foundation SettlementДокумент25 страницFoundation SettlementBharath Kumar MОценок пока нет

- DLB @4.465Документ51 страницаDLB @4.465rvkumar3619690Оценок пока нет

- MACKINTOSH PROBE Test ReportДокумент8 страницMACKINTOSH PROBE Test ReportKrisyen Murali Tharan100% (1)

- Tension Piles C Phi SoilДокумент12 страницTension Piles C Phi SoilAhmedKarimОценок пока нет

- DLB @4.465 On Kollimerla DrainfinalДокумент55 страницDLB @4.465 On Kollimerla Drainfinalrvkumar3619690Оценок пока нет

- Slab Culvert 10m Sapn - R0Документ215 страницSlab Culvert 10m Sapn - R0Rudra SharmaОценок пока нет

- Asphalt Footing3Документ37 страницAsphalt Footing3Bert EngОценок пока нет

- Minishover Komatsu SK820-5E0Документ260 страницMinishover Komatsu SK820-5E0Jose A. Basanta H.100% (1)

- Typical Exam Questions With Answers 2Документ17 страницTypical Exam Questions With Answers 2Khadem Nuristani100% (1)

- Pile Foundation-IOE QuestionsДокумент3 страницыPile Foundation-IOE QuestionsRajesh Khadka100% (1)

- Strand7 Theoretical Manual ContentsДокумент10 страницStrand7 Theoretical Manual Contentsr_zoro87Оценок пока нет

- 6 Shallow FoundationДокумент55 страниц6 Shallow FoundationFenil ShuklaОценок пока нет

- Theory and AppliДокумент6 страницTheory and AppliDeep EngineeringОценок пока нет

- Settlements Calculations Revised For Tabuk Zone 5Документ4 страницыSettlements Calculations Revised For Tabuk Zone 5Malik AbedОценок пока нет

- National Institute of Technology, Durgapur: Structural Engineering Laboratory (CES752)Документ13 страницNational Institute of Technology, Durgapur: Structural Engineering Laboratory (CES752)AmandeepSandhuОценок пока нет

- 01 Ce Esemainstest-1 Question-1679199817621Документ16 страниц01 Ce Esemainstest-1 Question-1679199817621Vivek KumarОценок пока нет

- Iesm Mains 2023Документ275 страницIesm Mains 2023Vinod KumarОценок пока нет

- 11piling EquipmentsДокумент18 страниц11piling EquipmentsBishow KCОценок пока нет

- Exhibit 4Документ1 страницаExhibit 4Arjun Chitradurga RamachandraRaoОценок пока нет

- Tutorial ECG243 4 Consolidation - Question Guide Solution 2022 WMXДокумент78 страницTutorial ECG243 4 Consolidation - Question Guide Solution 2022 WMXMohd HasbulОценок пока нет

- Bored Pile LecДокумент29 страницBored Pile Lecmidomido121267Оценок пока нет

- MSC 18-19 Foundation TutorialДокумент3 страницыMSC 18-19 Foundation TutorialCon CanОценок пока нет

- Dipak Shrestha, DORДокумент18 страницDipak Shrestha, DORkesharinareshОценок пока нет

- 581-Article Text PDF-4636-1-10-20130303 PDFДокумент6 страниц581-Article Text PDF-4636-1-10-20130303 PDFDavid DuОценок пока нет

- H&H Culverts With Out CushionДокумент15 страницH&H Culverts With Out CushionSreedhar BhuduruОценок пока нет

- A Study On Shear Strength of Sands ReinfДокумент8 страницA Study On Shear Strength of Sands ReinfBenson Mwathi MungaiОценок пока нет

- Strength of Materials, Structural Design & DrawingsДокумент24 страницыStrength of Materials, Structural Design & Drawingsamitkap00rОценок пока нет

- Topic 2Документ88 страницTopic 2HCОценок пока нет

- M-15 PCCДокумент38 страницM-15 PCCRaj PandeyОценок пока нет

- Grafik Ka Dan Kp-ModelДокумент5 страницGrafik Ka Dan Kp-ModelBunga NabilahОценок пока нет

- Geotechnical Investigation Advanced ReportДокумент7 страницGeotechnical Investigation Advanced ReportGicco CastorОценок пока нет

- Slab Design DR Zahid Ahmad SiddiqiДокумент6 страницSlab Design DR Zahid Ahmad SiddiqiFahad IqbalОценок пока нет

- National Institute of Technology, Durgapur: Structural Engineering Laboratory (Ces752)Документ13 страницNational Institute of Technology, Durgapur: Structural Engineering Laboratory (Ces752)AmandeepSandhuОценок пока нет

- Some Practical and Theoretical Aspects of Grouted Soil AnchorДокумент12 страницSome Practical and Theoretical Aspects of Grouted Soil AnchorGeorge HaileОценок пока нет

- Outline of Foundation Cast-In-Place RC Pile - Pile Diameter:d 1.5m - Pile Length: L 40.0m - Unit Weight of RC Concrete: 24.5 KN/MДокумент121 страницаOutline of Foundation Cast-In-Place RC Pile - Pile Diameter:d 1.5m - Pile Length: L 40.0m - Unit Weight of RC Concrete: 24.5 KN/MDevendrasinh PadhiyarОценок пока нет

- Designing Stone Columns To Control Horizontal and Vertical PDFДокумент6 страницDesigning Stone Columns To Control Horizontal and Vertical PDFZOUABIОценок пока нет

- Structural Design ReportДокумент208 страницStructural Design Reportmohan sundarОценок пока нет

- Cve431 Course Work.Документ12 страницCve431 Course Work.Ifiokobong AkpanОценок пока нет

- Reinforced Concrete Design Analysis of A Proposed Five (5) Storey Mini-Hotel BuildingДокумент15 страницReinforced Concrete Design Analysis of A Proposed Five (5) Storey Mini-Hotel Buildinghonesto reynaОценок пока нет

- Buoyancy Control For Pipelines Buoyancy Control For PipelinesДокумент12 страницBuoyancy Control For Pipelines Buoyancy Control For PipelinesMukiara LuffyОценок пока нет

- Assignment # 4Документ2 страницыAssignment # 4Anonymous Vx9KTkM8nОценок пока нет

- Finite Difference Method: Table 1: Typical Ks Values For Stiff Clays (Terzaghi, 1995)Документ10 страницFinite Difference Method: Table 1: Typical Ks Values For Stiff Clays (Terzaghi, 1995)Western Ang'ong'aОценок пока нет

- Slab Design DR - Zahid Ahmad SiddiqiДокумент6 страницSlab Design DR - Zahid Ahmad SiddiqiNoor MohdОценок пока нет

- Clasificación de Suelos Blandos PDFДокумент2 страницыClasificación de Suelos Blandos PDFHanafiahHamzahОценок пока нет

- Recitation 2 Field Load Test-SettlementДокумент12 страницRecitation 2 Field Load Test-SettlementCemre CaglarОценок пока нет

- Reference Material II Piled Raft DesiДокумент42 страницыReference Material II Piled Raft Desiabdulajeej salluОценок пока нет

- 7.7.1.4 Trusses SpecificationsДокумент3 страницы7.7.1.4 Trusses Specificationsishaan choudharyОценок пока нет

- Prism Compressive Strength Prism Testing - C1314: F E F E F EДокумент4 страницыPrism Compressive Strength Prism Testing - C1314: F E F E F EMarco PalmaОценок пока нет

- Application of Cyclic CBR Test To Approximation of Subgrade Displacement in Road PavementДокумент11 страницApplication of Cyclic CBR Test To Approximation of Subgrade Displacement in Road Pavementزھرة ٱلبيلسآنОценок пока нет

- BC-10 - 11 Method AДокумент3 страницыBC-10 - 11 Method Ar_zoro87Оценок пока нет

- 295-R ZiaieMoayedandM AliBolandiДокумент4 страницы295-R ZiaieMoayedandM AliBolandir_zoro87Оценок пока нет

- ACI 318 - Interaction Diagram P - M: Material PropertiesДокумент25 страницACI 318 - Interaction Diagram P - M: Material Propertiesr_zoro87Оценок пока нет

- Pdftest2 PDFДокумент1 страницаPdftest2 PDFr_zoro87Оценок пока нет

- Mit PDFДокумент156 страницMit PDFr_zoro87Оценок пока нет

- Punching ShearДокумент10 страницPunching Shearr_zoro87Оценок пока нет

- Comparison of Various Treatment Modalities For Acute TinnitusДокумент7 страницComparison of Various Treatment Modalities For Acute Tinnitusr_zoro87Оценок пока нет

- Analysis of Double Layer Grids With Material Non-linearities!IIW - A Practical ApproachДокумент8 страницAnalysis of Double Layer Grids With Material Non-linearities!IIW - A Practical Approachr_zoro87Оценок пока нет

- Elastic AДокумент47 страницElastic Ar_zoro87Оценок пока нет

- Analysis NotesДокумент6 страницAnalysis Notesr_zoro87Оценок пока нет

- Determination of Blockage Correction in Open-Jet Wind TunnelДокумент6 страницDetermination of Blockage Correction in Open-Jet Wind Tunnelmoro1381100% (1)

- JoysticksДокумент12 страницJoysticksJuan Carlos Aragon CompiОценок пока нет

- P - Delta Effect in Reinforced Concrete Structures of Rigid Joint-LibreДокумент8 страницP - Delta Effect in Reinforced Concrete Structures of Rigid Joint-LibrePunithan PunithanОценок пока нет

- Soumitra Sattikar - CSV 2021-1Документ2 страницыSoumitra Sattikar - CSV 2021-1pavanОценок пока нет

- Hoja Técnica Roto Xtend Duty Fluid PDFДокумент2 страницыHoja Técnica Roto Xtend Duty Fluid PDFFederico Liaudat100% (2)

- Alumax - SpaceframeДокумент4 страницыAlumax - SpaceframePrasenjit AdhikaryОценок пока нет

- Komal Kumar Mallick PDFДокумент2 страницыKomal Kumar Mallick PDFKomal KumarОценок пока нет

- Stair Well Pressurization Design CriteriaДокумент2 страницыStair Well Pressurization Design CriteriaShabeer HamzaОценок пока нет

- Tut-371 No.2Документ8 страницTut-371 No.2fletusdiabloiОценок пока нет

- Techniques For Obstacle Avoidance in Mobile RoboticsДокумент7 страницTechniques For Obstacle Avoidance in Mobile RoboticsHarold Geovanny Flores CardenasОценок пока нет

- Strengthening of Reinforced Concrete Beams Using FRP Technique: A ReviewДокумент16 страницStrengthening of Reinforced Concrete Beams Using FRP Technique: A ReviewHÙNG Trần MạnhОценок пока нет

- Superhero ExampleДокумент8 страницSuperhero Exampleapi-343241309Оценок пока нет

- Landing Gear Sistem 556Документ31 страницаLanding Gear Sistem 556prasetyoОценок пока нет

- Ipc 9521Документ4 страницыIpc 9521ashu0470Оценок пока нет

- Re64555 PDFДокумент12 страницRe64555 PDFMehdi MansourianОценок пока нет

- 04 - Analisa Pondasi DangkalДокумент50 страниц04 - Analisa Pondasi DangkalWak HoОценок пока нет

- RT Report Format Rev.1 17-3-19Документ6 страницRT Report Format Rev.1 17-3-19mohd as shahiddin jafriОценок пока нет

- LR1300 PDFДокумент20 страницLR1300 PDFKazim NawazОценок пока нет

- 04 AdamsParts 71-98Документ30 страниц04 AdamsParts 71-98apuhapuh_153349Оценок пока нет

- Rock Engineering Rock Engineering Practice & Design Practice & DesignДокумент46 страницRock Engineering Rock Engineering Practice & Design Practice & DesignLuis MirandaОценок пока нет

- PPF Multimedia CatalogДокумент24 страницыPPF Multimedia Catalogalperen52Оценок пока нет

- 3D FEM Approach For Laterally Loaded Monopile DesignДокумент8 страниц3D FEM Approach For Laterally Loaded Monopile DesignSunil Ranjan MohapatraОценок пока нет

- FPS FormulasДокумент5 страницFPS FormulasthamaraikkaniОценок пока нет

- TRF InspectionДокумент15 страницTRF InspectionSonny RaymundoОценок пока нет