Академический Документы

Профессиональный Документы

Культура Документы

CPS Meeting-Ie

Загружено:

Mohammad KamruzzamanОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

CPS Meeting-Ie

Загружено:

Mohammad KamruzzamanАвторское право:

Доступные форматы

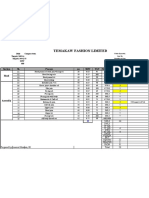

TEMAKAW FASHION LTD.

CPS MEETING

Industrial Engineering Department

DATE: 07.05.2015

S.N AGENDA LAST WEEK NEXT WEEK Risk Analysis Action Plan Remarks

1 Daily Dash Board

A. Plan Vs Actual Plan Actual Plan Target 1. Defective Qty 2. 1. Defective garment need check & need decision

Kanban Wip 3. quickly 2.

Alter Rectify 4. Kanban alter need hourly Rectify 3.

Cutting Parts change Cutting part change issue need serious

5 . Feeding down time 4. New style quality & technical issue solve

6. New style quality & technical very earliar.

Sewing 10127 14089 21800 down time more. 5. New style production need last body previous style

7. Finishing garments spot issue 6. for input

8. Input problem for size set issue 9. issue, PPM need ok by first cutt size set sample

Seam Number Shading 10. 7. Fabric inspection

Needle mark 11. need properly for shading. Need Shad blanket & tube

Oil Mark 12. system maintain properly. 8.

Supply issue (button washar, poly, Need more council for needle mark 9.

button issue) Regular Machine maintenance for oil mark 10.

Productivity increase by hourly problem solved.

Finishing 8690 8751 20560

B. Bonus 2000 5000

This week Bonus Incresed Everest- Line 04,

3000 TK

1.Need m/c routine cheek and proper repairing,

This week Lost time mechanic be attentive on the floor.

1.Machine Breakdown (6688 Min) 2. 2.Input issue we need pre-action. 3.Quaility

C.Loss Time 5785 MIN 7382 MIN Increased 1597 min, Alteration Rectifying (612 Min) 3. should maintain in layout time & kanban QC maintain

Compare with last week. Material Supply Issue ( 82 Min ) properly QC chek system.

4. must control Finishing WIP

This week Manhour

D. Manhour 37107 HRS 47444 HRS

Incresed 10337 TK

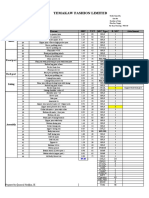

2 MIS(WIP)

Sewing 4707 PCS 5817 PCS

Last Week Finishing WIP Last Week Sewing WIP Increased 1110 1. Need proper follow up2.&must

maintain capacity.

maintain style closing

Increased 4980 PCS. PCS.

summary report every style

Finishing 7449 PCS 12429 PCS

Last Week Manpower

3 Manpower 612 635 Increased 23 Person.

1. Need SOP maintain time to time properly

2. size set issue need more

4 Input Plan Everest ( Line 8 ) Sekano(Line 12) 1. Size set no maintain on time sincerely 3. Fabric & cutting need more

serious

1. Need more sincer technical, machine, CAD & cutting

5 Line Feeding Everest ( Line 8 ) Sekano(Line 12)

1. Risk Analysis Meeting 2. Machine & folder Arange 3.

6 Operation Bulletin Everest ( Line 8 ) Sekano(Line 12)

Size set issue 4. Fabric inspection properly

Already Grading system started like-

7 Skill Matrix 450 470 500 A,B,C,D & Trainee. (Grade A(110),B(190),C(95),D(50)&Trainee(25).

Abajur, Star, pass, Uniform,

Discover, Brasil, TT-70, Bali & 1. Need proper work station, 2.

8 SMV Database Serit, Kass. Kalanor, Katie-print, Everest Need proper work management, 3. Database folder make with process video .

Adil, Akgul, Asmali, Amorti, Maintain bundle system.

Sekare

Prepared By

IE Department

Temakaw Fashion Limited

Вам также может понравиться

- (CPS) History Check-1Документ1 страница(CPS) History Check-1Andrew Dishman100% (1)

- CPS SafetyДокумент3 страницыCPS SafetyMustafaОценок пока нет

- My Family My Family My Family My FamilyДокумент9 страницMy Family My Family My Family My FamilycarolinaОценок пока нет

- I Want To Catch A Leprechaun B&W Word CardsДокумент6 страницI Want To Catch A Leprechaun B&W Word CardsKristin McGill OldhamОценок пока нет

- SPARKДокумент49 страницSPARKBibhudutta MishraОценок пока нет

- Lean Manufacturing 5SДокумент20 страницLean Manufacturing 5SÖnder HançerОценок пока нет

- ch8 Elastic Tape PDFДокумент4 страницыch8 Elastic Tape PDFAMIT PRAJAPATIОценок пока нет

- Essential auto part production bottlenecksДокумент11 страницEssential auto part production bottlenecksLaxmikant JoshiОценок пока нет

- Lean Manufacturing - TWI Case Study Model Answers PDFДокумент11 страницLean Manufacturing - TWI Case Study Model Answers PDFBianka NaulaОценок пока нет

- New Staff Training Mech. Eng - DanielДокумент2 страницыNew Staff Training Mech. Eng - DanielDaniel Garnando KristianОценок пока нет

- Weekly Performance Report Highlights Revenue, Sales, Jobs MetricsДокумент9 страницWeekly Performance Report Highlights Revenue, Sales, Jobs MetricsPhayeSoneHeinОценок пока нет

- Jay Bhart Maruti Ltd. Vithalapur, Gujarat: (Performance Evaluation)Документ15 страницJay Bhart Maruti Ltd. Vithalapur, Gujarat: (Performance Evaluation)Sharwan KumarОценок пока нет

- Meagal Stelplast: Steering A New PathДокумент7 страницMeagal Stelplast: Steering A New PathArjun JoshiОценок пока нет

- Ch 1 True False MC cost accounting concepts classificationsДокумент362 страницыCh 1 True False MC cost accounting concepts classificationsKrstnОценок пока нет

- 6 Sigma SD Shaft Dia. VariationДокумент32 страницы6 Sigma SD Shaft Dia. Variationsageershaikh100% (1)

- 04 Work Place OrganizationДокумент230 страниц04 Work Place Organizationanderson parizОценок пока нет

- Mba07220 C VsmendtermДокумент6 страницMba07220 C VsmendtermTRIBIKRAM DEBANGSHIОценок пока нет

- MSL Horn AssignmentДокумент4 страницыMSL Horn AssignmentKaushik ChopraОценок пока нет

- Kanban System Proces FlowДокумент24 страницыKanban System Proces FlowVaibhav Rakhunde0% (1)

- ReplaceДокумент9 страницReplaceAbdul MuhidОценок пока нет

- July 2020 BudgetДокумент14 страницJuly 2020 BudgetvinothОценок пока нет

- Stitching Improvement Project - UpdateДокумент15 страницStitching Improvement Project - UpdateHizkia Angga HendrayanaОценок пока нет

- 8D Problem Solving Steering ReserviorДокумент22 страницы8D Problem Solving Steering ReserviorAvinash BatraОценок пока нет

- Small Improvement Project Presentation byДокумент19 страницSmall Improvement Project Presentation byঅজানা রশ্মি Ajana rashmiОценок пока нет

- Group AssignmentДокумент8 страницGroup AssignmentMai LinhОценок пока нет

- A3 Report Vios Double Layer SobekДокумент1 страницаA3 Report Vios Double Layer SobekM Saputra Paytren PurwakartaОценок пока нет

- CO185.08 Novi-King Lead Project Closing Meeting 2018-12-29Документ29 страницCO185.08 Novi-King Lead Project Closing Meeting 2018-12-29Manmohan KumarОценок пока нет

- Email: Curriculum - VitaeДокумент3 страницыEmail: Curriculum - Vitaeritesh shrivastavОценок пока нет

- Five Ess C'measures & Progress ReportДокумент24 страницыFive Ess C'measures & Progress ReportLaxmikant JoshiОценок пока нет

- Six Sigma Project to Reduce Variation in 2 Wheeler Carburetor Piston Valve ODДокумент39 страницSix Sigma Project to Reduce Variation in 2 Wheeler Carburetor Piston Valve ODAshutosh K TripathyОценок пока нет

- A3 Report RustyДокумент7 страницA3 Report RustyMarketing BonecomОценок пока нет

- BD Textile AuditДокумент13 страницBD Textile AuditMark ManОценок пока нет

- Kobelco Issues and ActionsДокумент10 страницKobelco Issues and Actionssonawaneyogesh694Оценок пока нет

- Fantastic Success: Ford Motor Company US Market Share in Japan 90%Документ19 страницFantastic Success: Ford Motor Company US Market Share in Japan 90%pritamspawarОценок пока нет

- Operation ManagmentДокумент17 страницOperation ManagmentSatheeshОценок пока нет

- Weld Width & Leg LengthДокумент1 страницаWeld Width & Leg LengthloknathОценок пока нет

- Bennett's Machine Shop Performance AnalysisДокумент16 страницBennett's Machine Shop Performance AnalysisAgAОценок пока нет

- Airport Authority, VaranashiДокумент10 страницAirport Authority, VaranashiAbhinav SinghОценок пока нет

- Oven PM Time Reduction Thru Mantle Heater Upgrade - 24th ASEMEP NATIONAL TECHNICAL SYMPOSIUM (ANTS) PDFДокумент4 страницыOven PM Time Reduction Thru Mantle Heater Upgrade - 24th ASEMEP NATIONAL TECHNICAL SYMPOSIUM (ANTS) PDFMarcelino SanicoОценок пока нет

- Pareto Analysis For Machine Stoppages & Slow RunДокумент11 страницPareto Analysis For Machine Stoppages & Slow RunEjaz AnwarОценок пока нет

- Cutting Problems & SolutionДокумент1 страницаCutting Problems & Solutionshamim hossainОценок пока нет

- SCG Lightweight Concrete Indonesia (SLCI) Downtime April 2022Документ3 страницыSCG Lightweight Concrete Indonesia (SLCI) Downtime April 2022reni krismawatiОценок пока нет

- Balling Disc Spillage Rectification ProjectДокумент5 страницBalling Disc Spillage Rectification ProjectAmit Kumar UkeОценок пока нет

- Application of Nodal System Analysis For Continuous Gas Lift Well in Nilam Field Vico Indonesia Kalimantan TimurДокумент13 страницApplication of Nodal System Analysis For Continuous Gas Lift Well in Nilam Field Vico Indonesia Kalimantan TimurIrsalina NHОценок пока нет

- Daily Report 28 - 05 Januari 2022 - 22.1.5Документ1 страницаDaily Report 28 - 05 Januari 2022 - 22.1.5muis supriyadiОценок пока нет

- CRT Production 12K (Project)Документ4 страницыCRT Production 12K (Project)agungОценок пока нет

- Summer 12Документ1 страницаSummer 12Adnan SethiОценок пока нет

- SPH Major InspectionДокумент8 страницSPH Major InspectionHENKYОценок пока нет

- Cost Accounting de Leon 20140Документ106 страницCost Accounting de Leon 20140Rommel CruzОценок пока нет

- Attachment 1684838589Документ5 страницAttachment 1684838589Yashal ZahraОценок пока нет

- Wetprocessingtechnology Internshipreport 151230113524 PDFДокумент258 страницWetprocessingtechnology Internshipreport 151230113524 PDFদীপ্তি হুমাইরাОценок пока нет

- CII Excellence in Water Management 2008 Ashok Leyland HosurIIДокумент17 страницCII Excellence in Water Management 2008 Ashok Leyland HosurIIStupidshowОценок пока нет

- Sheet 2 FPДокумент4 страницыSheet 2 FPyehyaОценок пока нет

- Kaizen Idea CardДокумент2 страницыKaizen Idea Cardحفیظ محمدОценок пока нет

- L.G. Production MGTДокумент41 страницаL.G. Production MGTpawanmulaniОценок пока нет

- BOQ Radio Telephony PRДокумент6 страницBOQ Radio Telephony PRSravan Kumar SaradhiОценок пока нет

- Kick Off Meeting InternalДокумент26 страницKick Off Meeting Internaldeden ibnuОценок пока нет

- Develop A Modern, Well Equipped RC Mopper For Comfortable & Quicker Floor Cleaning'Документ6 страницDevelop A Modern, Well Equipped RC Mopper For Comfortable & Quicker Floor Cleaning'Nurul Ahad SayemОценок пока нет

- 3.1x1 PROBLEM SOLVINGv9 Apr8 2018Документ64 страницы3.1x1 PROBLEM SOLVINGv9 Apr8 2018Jechuuy HerreraОценок пока нет

- Computational Techniques for Chemical Engineers: International Series of Monographs in Chemical EngineeringОт EverandComputational Techniques for Chemical Engineers: International Series of Monographs in Chemical EngineeringОценок пока нет

- Startup Business Plan: (YEAR)Документ31 страницаStartup Business Plan: (YEAR)Alyssa Mae MonteverosОценок пока нет

- Movement ReportДокумент1 страницаMovement ReportMohammad KamruzzamanОценок пока нет

- Otp StatusДокумент13 страницOtp StatusMohammad KamruzzamanОценок пока нет

- Temakaw Fashion Limited: Section SL Process Sec SMV TGT M/C Type R. M/C R.Man Power SleeveДокумент3 страницыTemakaw Fashion Limited: Section SL Process Sec SMV TGT M/C Type R. M/C R.Man Power SleeveMohammad KamruzzamanОценок пока нет

- TEMAKAW FASHION LIMITED Style Cangaro teen OrderДокумент1 страницаTEMAKAW FASHION LIMITED Style Cangaro teen OrderMohammad KamruzzamanОценок пока нет

- The Lean Canvas: Problem Solution Unique Value Prop. Unfair Advantage Customer SegmentsДокумент7 страницThe Lean Canvas: Problem Solution Unique Value Prop. Unfair Advantage Customer SegmentsMohammad KamruzzamanОценок пока нет

- Abcd Checklist For Manufacturing ExcellenceДокумент24 страницыAbcd Checklist For Manufacturing ExcellenceMohammad KamruzzamanОценок пока нет

- 01 Op Name ID Process SMV M/C Type R. M/C Remarks: Learning CurveДокумент3 страницы01 Op Name ID Process SMV M/C Type R. M/C Remarks: Learning CurveMohammad KamruzzamanОценок пока нет

- Sample of ForecastingДокумент18 страницSample of ForecastingMohammad KamruzzamanОценок пока нет

- VSM Template (LEan Six Sigma)Документ8 страницVSM Template (LEan Six Sigma)DearRed FrankОценок пока нет

- Lean Manufacturing For Garments IndustryДокумент1 страницаLean Manufacturing For Garments IndustryMohammad KamruzzamanОценок пока нет

- Operation Buletin of Alfa: Section SL No Process M/C Sec SMVДокумент2 страницыOperation Buletin of Alfa: Section SL No Process M/C Sec SMVMohammad KamruzzamanОценок пока нет

- Temakaw Fashion Limited: Section SL Process SMV Target M/C Type R. M/C AttachmentДокумент1 страницаTemakaw Fashion Limited: Section SL Process SMV Target M/C Type R. M/C AttachmentMohammad KamruzzamanОценок пока нет

- TEMAKAW FASHION LIMITED Style Cangaro teen OrderДокумент1 страницаTEMAKAW FASHION LIMITED Style Cangaro teen OrderMohammad KamruzzamanОценок пока нет

- Temakaw Fashion LTD.: Bulletine Sheet Style Name: CAGLA SL Area Process M/C Sec SMVДокумент4 страницыTemakaw Fashion LTD.: Bulletine Sheet Style Name: CAGLA SL Area Process M/C Sec SMVMohammad KamruzzamanОценок пока нет

- Temakaw Fashion LTD: Back PartДокумент1 страницаTemakaw Fashion LTD: Back PartMohammad KamruzzamanОценок пока нет

- Temakaw Fashion LTD.: Bulletine Sheet Style Name: CAGLA SL Area Process M/C Sec SMVДокумент4 страницыTemakaw Fashion LTD.: Bulletine Sheet Style Name: CAGLA SL Area Process M/C Sec SMVMohammad KamruzzamanОценок пока нет

- Temakaw Fashion Limited: Section SL Process SMV TGT M/C Type R. M/C AttachmentДокумент1 страницаTemakaw Fashion Limited: Section SL Process SMV TGT M/C Type R. M/C AttachmentMohammad KamruzzamanОценок пока нет

- Temakaw Fashion LTD: Operation Buletin of RCJ-6370Документ2 страницыTemakaw Fashion LTD: Operation Buletin of RCJ-6370Mohammad KamruzzamanОценок пока нет

- AsmaliДокумент2 страницыAsmaliMohammad KamruzzamanОценок пока нет

- Temakaw Fashion Limited: Section SL Process SMV TGT M/C Type R. M/C AttachmentДокумент1 страницаTemakaw Fashion Limited: Section SL Process SMV TGT M/C Type R. M/C AttachmentMohammad KamruzzamanОценок пока нет

- Temakaw Fashion Limited: Section SL Process Sec SMV TGT M/C Type R. M/CДокумент2 страницыTemakaw Fashion Limited: Section SL Process Sec SMV TGT M/C Type R. M/CMohammad KamruzzamanОценок пока нет

- SMV-LC WaikkiДокумент51 страницаSMV-LC WaikkiMohammad KamruzzamanОценок пока нет

- Temakaw Fashion LTD: Operation Buletin of CUNTIДокумент2 страницыTemakaw Fashion LTD: Operation Buletin of CUNTIMohammad KamruzzamanОценок пока нет

- SMV Analysis SummaryДокумент17 страницSMV Analysis SummaryMohammad KamruzzamanОценок пока нет

- Temakaw Fashion LTD: Operation Buletin of RCJ-6370Документ2 страницыTemakaw Fashion LTD: Operation Buletin of RCJ-6370Mohammad KamruzzamanОценок пока нет

- Temakaw Fashion Limited: Style Target Target 47 SMV 32 MP 56Документ1 страницаTemakaw Fashion Limited: Style Target Target 47 SMV 32 MP 56Mohammad KamruzzamanОценок пока нет

- TEMAKAW FASHION LIMITED production process analysisДокумент1 страницаTEMAKAW FASHION LIMITED production process analysisMohammad KamruzzamanОценок пока нет

- Temakaw Fashion Limited: Section SL Process Sec SMV TGT M/C Type R. M/C R.Man Power SleeveДокумент3 страницыTemakaw Fashion Limited: Section SL Process Sec SMV TGT M/C Type R. M/C R.Man Power SleeveMohammad KamruzzamanОценок пока нет

- Temakaw Fashion LTD: Section SL No Process SMV Target M/C Type R. M/C RemarksДокумент2 страницыTemakaw Fashion LTD: Section SL No Process SMV Target M/C Type R. M/C RemarksMohammad KamruzzamanОценок пока нет

- AIR SAFETY PROCEDURES MANUAL - IndiaДокумент141 страницаAIR SAFETY PROCEDURES MANUAL - IndiaRichard R M Thodé100% (1)

- AGAR ID 200 Series Brochure LowRes Electronic and WebДокумент2 страницыAGAR ID 200 Series Brochure LowRes Electronic and WebYareli de la CruzОценок пока нет

- U2000 Oss NmsДокумент27 страницU2000 Oss Nmschandan100% (1)

- Design and Safety Handbook 3001.5Документ51 страницаDesign and Safety Handbook 3001.5phankhoa83Оценок пока нет

- ROC800-Series IEC 62591 Interface: ScalabilityДокумент10 страницROC800-Series IEC 62591 Interface: ScalabilityBMОценок пока нет

- 6338d1285569848 Task Alfa 300ci SB Toner PDFДокумент3 страницы6338d1285569848 Task Alfa 300ci SB Toner PDFjosealcudiacastellas100% (1)

- Canon Ir3245 Series-PcДокумент154 страницыCanon Ir3245 Series-PcPetrescu CezarОценок пока нет

- TS1A-13A: Operation and Maintenance ManualДокумент204 страницыTS1A-13A: Operation and Maintenance ManualJavier AponteОценок пока нет

- PSC Unit 4 PPT - Part 3Документ35 страницPSC Unit 4 PPT - Part 3Rino VidОценок пока нет

- KfloppyДокумент17 страницKfloppyBhanuОценок пока нет

- Ansys Fluent 14.0: Getting StartedДокумент26 страницAnsys Fluent 14.0: Getting StartedAoife FitzgeraldОценок пока нет

- ABB MNS System GuideДокумент34 страницыABB MNS System GuideLeslie HallОценок пока нет

- Field Symbols:: Type AnyДокумент3 страницыField Symbols:: Type AnyRajesh YadavОценок пока нет

- Bob L200Документ12 страницBob L200LucyPher_Comte_7563Оценок пока нет

- Installation & Maintenance Instructions Pressure Regulator With Integral Pilot Regulator R18Документ2 страницыInstallation & Maintenance Instructions Pressure Regulator With Integral Pilot Regulator R18luis ivanОценок пока нет

- SHL Learning Resource Center List of Acquired Books for Engineering S.Y. 2012-2016Документ27 страницSHL Learning Resource Center List of Acquired Books for Engineering S.Y. 2012-2016jscansinoОценок пока нет

- COILDATAДокумент1 страницаCOILDATABarış TaşkınОценок пока нет

- 2D Vs 3D ReviewДокумент7 страниц2D Vs 3D ReviewBhasker RamagiriОценок пока нет

- Abbreviations GuideДокумент12 страницAbbreviations GuideHosein AsgariОценок пока нет

- Comment To RTДокумент32 страницыComment To RTLim Wee BengОценок пока нет

- Zit 64 BVДокумент12 страницZit 64 BVVT86Оценок пока нет

- D Screenplay DialoguesДокумент75 страницD Screenplay DialoguesReza GhalibОценок пока нет

- Cisco SD-WAN Intro SOLRST-2006 PDFДокумент10 страницCisco SD-WAN Intro SOLRST-2006 PDFffusaroОценок пока нет

- Hospital Management SystemДокумент63 страницыHospital Management Systemsanjay yadavОценок пока нет

- Condition Report SIS 16M Daily Inspection GD16M-0053 (3 May 2016)Документ4 страницыCondition Report SIS 16M Daily Inspection GD16M-0053 (3 May 2016)ahmat ramadani100% (1)

- MP3 - Equations of StateДокумент8 страницMP3 - Equations of StatePatrick ValdezОценок пока нет

- Dynamometer - 1Документ3 страницыDynamometer - 1Vishal BhattОценок пока нет

- Instruction Manual Fisher 657 Diaphragm Actuator Sizes 30 30i Through 70 70i 87 en 122366Документ32 страницыInstruction Manual Fisher 657 Diaphragm Actuator Sizes 30 30i Through 70 70i 87 en 122366APE MKTОценок пока нет

- SLD Magic 2Документ12 страницSLD Magic 2Deny Arisandi DarisandОценок пока нет

- API 5l Grade l245 PipesДокумент1 страницаAPI 5l Grade l245 PipesMitul MehtaОценок пока нет