Академический Документы

Профессиональный Документы

Культура Документы

Forging - Mechanical Test SA 105 SA 266 SA 350 SA 765

Загружено:

manisami70360 оценок0% нашли этот документ полезным (0 голосов)

126 просмотров3 страницыComparison of test location

Оригинальное название

Forging mechanical test

Авторское право

© © All Rights Reserved

Доступные форматы

DOCX, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документComparison of test location

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

126 просмотров3 страницыForging - Mechanical Test SA 105 SA 266 SA 350 SA 765

Загружено:

manisami7036Comparison of test location

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 3

Forging – Mechanical Test

SA 105 SA 266 SA 350 SA 765

SPECIFICATION FOR Standard Specification for SPECIFICATION FOR SPECIFICATION FOR

CARBON STEEL FORGINGS, Carbon Steel Forgings for CARBON AND LOW-ALLOY CARBON STEEL AND LOW-

FOR PIPING APPLICATIONS Pressure Vessel Components STEEL FORGINGS, ALLOY STEEL PRESSURE-

REQUIRING NOTCH VESSEL-COMPONENT

TOUGHNESS TESTING FOR FORGINGS WITH

PIPING COMPONENTS MANDATORY TOUGHNESS

REQUIREMENTS

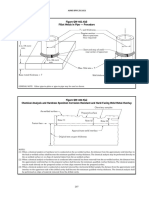

7.2 For normalized, normalized and 8.1.1.1 The longitudinal axis of the 7.1.3.1 For forgings or test blanks 6.2.1 Method 1—Forgings with 2 in. [50

tempered, or quenched and tempered specimen shall be located midway having a maximum heat-treated mm] maximum thickness. The

forgings, the central axis of the test between the parallel surfaces of the test thickness, T, of 2 in. [50 mm] or less, specimens shall have their longitudinal

specimen shall correspond to the 1⁄4 T extension if added to the periphery of the longitudinal axis of the test axis at the midthickness or the center of

plane or deeper position, where T is disks or midway between the center and specimen shall be taken at the cross section and with the

the maximum heat-treated thickness surface of solid forgings. mid-thickness and its mid-length shall midlength of the specimen at least 2 in.

of the represented forging. In addition, For hollow forgings, the longitudinal be at least 2 in. [50 mm] from a [50 mm] from any

for quenched and axis of the specimens shall be located second heat treated surface, exclusive second surface.

midway

tempered forgings, the midlength of of the T dimension surfaces. (This is

between the center and outer surfaces of

the test specimen shall be at least T normally referred to as 1⁄2 T

the wall. When

from any second heat-treated surface. separately forged test blocks are by 2 in. [50 mm]).

When section thickness does not employed as defined in 8.1.3,

permit this positioning, the test the tension test specimens shall be taken

specimen shall be positioned as near from a location that

as possible to the prescribed location. represents the midwall of the heaviest

section of the production

forgings. When specimens are required

from opposite ends,

they shall be taken from the diagonal

corners of an axial plane.

7.1.3.2 For forgings or test blanks 6.2.2 Method 2—Grade I and Grade II

having a maximum heat-treated forgings with thicknesses

thickness, T, greater than 2 in. [50 greater than 2 in. up to 4 in. [50 to 100

mm], the central axis of the test mm] inclusive, or Grade III and IV

specimen shall be taken at least forgings with thicknesses greater than 2

1⁄4 T from the nearest heat-treated in. up to 6 in. [50 to 150 mm] inclusive.

surface and at least T or The specimens shall have their

longitudinal axis at least 1⁄4 T of

4 in. [100 mm], whichever is less, maximum heat-treated

from any second heat treated thickness from any surface and with the

surface. For quenched and tempered midlength of the specimen at least one T

forgings, the midlength of the test from any second surface. This is

specimen shall be at least T from any normally referred to as 1⁄4 T by T when

second heat-treated surface. See Fig. 1 T is the maximum heat-treated thickness.

for test specimen location in

separately forged test blanks for

quenched and tempered forgings.

7.1.3.5 With prior purchaser approval, 6.2.3 Method 3—For forgings thicker

tests may be taken at a depth (t) than described in Method 2 (6.2.2):

corresponding to the distance from the 6.2.3.1 Prior to heat treatment the

area of significant loading to the forging shall be machined to a purchaser

nearest heat treated surface and at least supplied or approved drawing that

twice this distance (2t) from any indicates the

second surface. However, the test locations of significant in-service

depth shall not be nearer to one loading in the finished part.

The mechanical test specimens shall be

treated surface than 3⁄4 in. [19 mm]

located as an integral

and to the second treated part of the forging such that the mid-

surface than 11⁄2 in. [38 mm]. This point of the gauge length

method of test location would of the tension test specimen and the area

normally apply to contour-forged under the notch of the

parts, or parts with thick cross- impact specimens are located no closer

sectional areas where 1⁄4 T _ T testing than the dimension t

(7.1.3.2) is not practical. Sketches from one heat treated surface and 2t

showing the exact test from any other heat treated

locations shall be approved by the surface where t is the dimension from

purchaser when this method is used. the area of significant

loading to the heat treated surface, or 3⁄4

in. [20 mm] whichever

is the greater.

6.2.4 Method 4—This method shall be

limited to forgings with a rough

machined weight of not more than 1000

lb [455 kg]. Separate test forging when

agreed upon between the purchaser and

the supplier. Test coupons representing

forgings from one heat and one heat

treatment lot may be taken from a

separately forged piece under the

following conditions:

Interpretations:

Standard Designation: BPV Section II Part A Edition/Addenda: 2017 Para./Fig./Table No: SA-350, Para. 7.1.3.2

Subject Description: Testing Location for Forging, Date Issued: 10/21/2019, Record Number: 18-1516 Interpretation Number : BPV II-A-19-16

Question(s) and Reply(ies):

Question 1: Does SA-350/SA-350M require mechanical testing to be performed on specimens taken from locations specified in Paragraph 7.1.3?

Reply 1: Yes

Question 2: Does SA-350/SA-350M require mechanical testing to be performed on specimens taken from locations other than what is specified in Paragraph

7.1.3?

Reply 2: No

Вам также может понравиться

- A 770 - A770m - 86 R01 - Qtc3mc04nliwmqДокумент5 страницA 770 - A770m - 86 R01 - Qtc3mc04nliwmqAdrian GonzalezОценок пока нет

- Astm A770 PDFДокумент5 страницAstm A770 PDFCristian OtivoОценок пока нет

- Through-Thickness Tension Testing of Steel Plates For Special ApplicationsДокумент5 страницThrough-Thickness Tension Testing of Steel Plates For Special Applicationsvuqar0979Оценок пока нет

- Standard HFRW PDFДокумент3 страницыStandard HFRW PDFGuidoColomboОценок пока нет

- Reg. 338 Boiler and Super Heater Tubes, Headers and Other Pressure Parts TubesДокумент4 страницыReg. 338 Boiler and Super Heater Tubes, Headers and Other Pressure Parts TubesWASIM MAKANDARОценок пока нет

- RILEM TC 162-TDF Test and Design Methods For Steel Fibre Reinforced ConcreteДокумент3 страницыRILEM TC 162-TDF Test and Design Methods For Steel Fibre Reinforced ConcreteAbdul GhaffarОценок пока нет

- Casting and Curing Concrete Specimens in Field Based On ASTM C31Документ14 страницCasting and Curing Concrete Specimens in Field Based On ASTM C31Sourabh ChougalaОценок пока нет

- Indian Standard: Methods of Test For CablesДокумент3 страницыIndian Standard: Methods of Test For CablesVatsalОценок пока нет

- TR 225 - 5-31-19Документ4 страницыTR 225 - 5-31-19anbertjonathanОценок пока нет

- TR 225 - 5-31-19 PDFДокумент4 страницыTR 225 - 5-31-19 PDFanbertjonathanОценок пока нет

- ASTM E 740 - 2003 - Standard Practice For Fracture Testing With Surface-Crack Tension SpecimensДокумент9 страницASTM E 740 - 2003 - Standard Practice For Fracture Testing With Surface-Crack Tension SpecimensPatricio G. ArrienОценок пока нет

- Microhardness of Electroplated Coatings: Standard Test Method ForДокумент2 страницыMicrohardness of Electroplated Coatings: Standard Test Method ForNEFTALI VARGAS MANDUJANOОценок пока нет

- Heat Transfer From Rectangular Plates Inclined at Different Angles of Attack and Yaw To An Air StreamДокумент6 страницHeat Transfer From Rectangular Plates Inclined at Different Angles of Attack and Yaw To An Air StreamJovanJoksicОценок пока нет

- Inspection, Test, Marking and RecordsДокумент10 страницInspection, Test, Marking and RecordssuryaОценок пока нет

- Experiment 04 MOSLДокумент12 страницExperiment 04 MOSLRock ManОценок пока нет

- Method For Determination of Strength of Rock Materials in Triaxial CompressionДокумент8 страницMethod For Determination of Strength of Rock Materials in Triaxial CompressionSunnil JhaОценок пока нет

- Through-Thickness Tension Testing of Steel Plates For Special ApplicationsДокумент5 страницThrough-Thickness Tension Testing of Steel Plates For Special ApplicationsDarwin DarmawanОценок пока нет

- Rilem MDT D.5Документ5 страницRilem MDT D.5ankit raiОценок пока нет

- Bending Test: Final RecommendationДокумент4 страницыBending Test: Final RecommendationfarhanfiksiОценок пока нет

- Din 8075Документ11 страницDin 8075Marco Jorquera AguilarОценок пока нет

- Astm A557 A557mДокумент3 страницыAstm A557 A557mارفع راسك فوق انت يمنيОценок пока нет

- Steel TestsДокумент4 страницыSteel TestsSaradhiJannОценок пока нет

- C617Документ5 страницC617Rajesh KumarОценок пока нет

- Bend Test AceptenДокумент1 страницаBend Test AceptenArung IdОценок пока нет

- Phani Gudipati Talks Extrusion in Advanced Materials Processes Magazine 4 - 2021Документ4 страницыPhani Gudipati Talks Extrusion in Advanced Materials Processes Magazine 4 - 202118P202 - AJAY SIVARAMAN AОценок пока нет

- MIL-W-22759 Rev E - Part23Документ1 страницаMIL-W-22759 Rev E - Part23David WongОценок пока нет

- D 624 - 00 RdyynaДокумент9 страницD 624 - 00 RdyynafadjarОценок пока нет

- ASTM A 770X - Z TestДокумент5 страницASTM A 770X - Z Testharsh upadhyayОценок пока нет

- Remaining Life Assessment of Service Exposed Reheater and Superheater Tubes in A Boiler of A Thermal Power PlantДокумент13 страницRemaining Life Assessment of Service Exposed Reheater and Superheater Tubes in A Boiler of A Thermal Power PlantArdhi Angga SОценок пока нет

- Astm d624 Pdqv6897Документ9 страницAstm d624 Pdqv6897Nayth Andres GalazОценок пока нет

- Astm C1196Документ6 страницAstm C1196Lorenzo GambassiОценок пока нет

- Astm A556 A556mДокумент3 страницыAstm A556 A556macount checkОценок пока нет

- Fitness-for-Service Evaluation of A Pipe With An Incomplete Penetration FlawДокумент5 страницFitness-for-Service Evaluation of A Pipe With An Incomplete Penetration Flawamd mhmОценок пока нет

- SNI EngДокумент5 страницSNI EngSAANO SOLOMEОценок пока нет

- API Spec 7-1 Brief Material RequirementsДокумент8 страницAPI Spec 7-1 Brief Material RequirementsQuality controller100% (1)

- Ramkrishna Mahato Government Engineering College: S0Lid Mechanics LaboratoryДокумент34 страницыRamkrishna Mahato Government Engineering College: S0Lid Mechanics LaboratoryMaynak DeyОценок пока нет

- Probe TaДокумент1 страницаProbe Tajose manuel paz fernandezОценок пока нет

- Fillet - Groove Procedure Qualification RequirementsДокумент2 страницыFillet - Groove Procedure Qualification RequirementsAamer MohammedОценок пока нет

- PurposeДокумент5 страницPurposeMahmood YounsОценок пока нет

- TABLE 2 Mechanical RequirementsДокумент1 страницаTABLE 2 Mechanical RequirementsElias KapaОценок пока нет

- Con A Ning Measure : Eff C EntsДокумент8 страницCon A Ning Measure : Eff C EntsshyamavanilОценок пока нет

- Estimating The Approximate Residual Circumferential Stress in Straight Thin-Walled TubingДокумент3 страницыEstimating The Approximate Residual Circumferential Stress in Straight Thin-Walled TubingAarón Escorza MistránОценок пока нет

- ASTM D412 Test Method For Vulcanized RubberДокумент13 страницASTM D412 Test Method For Vulcanized RubberElaine HuangОценок пока нет

- ThyssenKrupp - XABO 500Документ3 страницыThyssenKrupp - XABO 500Yesid Javier Martelo EllesОценок пока нет

- Determination of The Compressive Strength of Concrete Hollow BlocksДокумент54 страницыDetermination of The Compressive Strength of Concrete Hollow BlocksChrissaОценок пока нет

- Experimental Thermal and Fluid Science: Sujoy Kumar SahaДокумент10 страницExperimental Thermal and Fluid Science: Sujoy Kumar SahaAnonymous 7BQxlt8cОценок пока нет

- Asme PCCДокумент6 страницAsme PCCajaysharma_1009100% (2)

- Splitting Tensile Strength of Cylindrical Concrete SpecimensДокумент5 страницSplitting Tensile Strength of Cylindrical Concrete SpecimensmickyfelixОценок пока нет

- C496 PDFДокумент4 страницыC496 PDFpraneethaОценок пока нет

- Splitting Tensile Strength of Cylindrical Concrete SpecimensДокумент5 страницSplitting Tensile Strength of Cylindrical Concrete Specimenssayra chavezОценок пока нет

- O o Fig. 4 - Stress-Strain Curves For Steel ReinforcementДокумент1 страницаO o Fig. 4 - Stress-Strain Curves For Steel ReinforcementRonal J Clavijo RОценок пока нет

- IBR DetailsДокумент10 страницIBR Detailsreach_arindomОценок пока нет

- Splitting Tensile Strength of Cylindrical Concrete Specimens DetailedДокумент4 страницыSplitting Tensile Strength of Cylindrical Concrete Specimens DetailedYasirОценок пока нет

- Extracted Pages From ASME BPVC 2021 Section IXДокумент1 страницаExtracted Pages From ASME BPVC 2021 Section IXRoberto Carlos Arana ChumpitazОценок пока нет

- Bending Test: RILEM TC 162-TDF: Test and Design Methods For Steel Fibre Reinforced ConcreteДокумент11 страницBending Test: RILEM TC 162-TDF: Test and Design Methods For Steel Fibre Reinforced ConcreteindraОценок пока нет

- Rooler Steel chapter-2-material-2023-JAN-5Документ21 страницаRooler Steel chapter-2-material-2023-JAN-5viyfОценок пока нет

- Specific Bendability of Pipeline Coatings: Standard Test Method ForДокумент3 страницыSpecific Bendability of Pipeline Coatings: Standard Test Method Forvuqar0979Оценок пока нет

- C 408 - 88 R99 QzqwoaДокумент4 страницыC 408 - 88 R99 QzqwoaMarceloОценок пока нет

- Ncma Tek: Sampling and Testing Segmental Retaining Wall Units TEK 18-10Документ4 страницыNcma Tek: Sampling and Testing Segmental Retaining Wall Units TEK 18-10Jorge Luis Arevalo LopezОценок пока нет

- Dedication Evaluation FormДокумент5 страницDedication Evaluation Formmanisami7036100% (1)

- 2019 ASME Section V ChangesДокумент61 страница2019 ASME Section V Changesmanisami7036100% (4)

- Meditation Its EffectДокумент11 страницMeditation Its Effectmanisami7036Оценок пока нет

- Material Inspection Checklist PlugДокумент2 страницыMaterial Inspection Checklist Plugmanisami7036Оценок пока нет

- Interactive Form U-1AДокумент1 страницаInteractive Form U-1ADimas AnugrahОценок пока нет

- Sample Job #23: Finite Element Analysis (FEA) ReportДокумент17 страницSample Job #23: Finite Element Analysis (FEA) Reportmanisami7036Оценок пока нет

- Handbook For NRIs INDIANДокумент112 страницHandbook For NRIs INDIANheenamodiОценок пока нет

- Common Requirements For Bolting Intended For Use at Any Temperature From Cryogenic To The Creep RangeДокумент13 страницCommon Requirements For Bolting Intended For Use at Any Temperature From Cryogenic To The Creep RangeradziОценок пока нет

- PressureДокумент84 страницыPressureHangloque GabanoОценок пока нет

- B.E Mechanical EngineeringДокумент98 страницB.E Mechanical Engineeringmaheshbalu7Оценок пока нет

- Is 5749Документ16 страницIs 5749Anonymous b3NKZUbОценок пока нет

- Shahreza Agung AlfatihДокумент4 страницыShahreza Agung AlfatihShahreza agungОценок пока нет

- Metal Forming Pembentukan Logam 2Документ49 страницMetal Forming Pembentukan Logam 2Yoga Prdn SsflОценок пока нет

- E4 - Warm and Cold ForgingДокумент35 страницE4 - Warm and Cold ForgingRiski RamadhanОценок пока нет

- Forging: Types of Forging 1. Hot Forging 2. Cold Forging Hot ForgingДокумент22 страницыForging: Types of Forging 1. Hot Forging 2. Cold Forging Hot Forgingaman ubhiОценок пока нет

- HMCДокумент123 страницыHMCWaqas1202Оценок пока нет

- Martensitic Stainless Steel Forgings and Forging Stock For High-Temperature ServiceДокумент4 страницыMartensitic Stainless Steel Forgings and Forging Stock For High-Temperature ServiceAcácio AlvesОценок пока нет

- Characterization of INCONEL Alloy 740H For Tube, Pipe and Fittings For Advanced Supercritical CO SystemsДокумент15 страницCharacterization of INCONEL Alloy 740H For Tube, Pipe and Fittings For Advanced Supercritical CO SystemsAnonymous lmCR3SkPrKОценок пока нет

- Stainless Steel Design ManualДокумент14 страницStainless Steel Design ManualmirekwaznyОценок пока нет

- A694 F65 Product Datasheet DACooper Sons - 230621 - 110007Документ1 страницаA694 F65 Product Datasheet DACooper Sons - 230621 - 110007gawaОценок пока нет

- SIP Project ReportДокумент62 страницыSIP Project ReportNiharika MathurОценок пока нет

- Crankshaft 1Документ14 страницCrankshaft 1Shweta NarayanОценок пока нет

- Chapter 5 Die DesignДокумент129 страницChapter 5 Die Designkb89% (9)

- ST 14Документ40 страницST 14harshОценок пока нет

- ForgingДокумент56 страницForgingZulfikarUdenОценок пока нет

- MDSP 5Документ215 страницMDSP 5Caro Kan LopezОценок пока нет

- Manu - Process (Unit 1-4)Документ223 страницыManu - Process (Unit 1-4)vrinda.bhardwaj.52Оценок пока нет

- FSV03Документ24 страницыFSV03elangopi89Оценок пока нет

- Astm A370-22 PDFДокумент51 страницаAstm A370-22 PDFmehmetОценок пока нет

- Guide To Beryllium CopperДокумент46 страницGuide To Beryllium CopperJonson CaoОценок пока нет

- Forgeability of Magnesium AlloysДокумент5 страницForgeability of Magnesium AlloysIon BadoiОценок пока нет

- Compressed PDF ME 6005 PPCE Revised PDFДокумент313 страницCompressed PDF ME 6005 PPCE Revised PDFManojKumar MОценок пока нет

- Gunnebo Lifting Shackle Catalogue 2010Документ16 страницGunnebo Lifting Shackle Catalogue 2010ofitec787Оценок пока нет

- Is 904-Specification For 2-Way and 3-Way Suction Collecting Heads For Fire Fighting PurposДокумент11 страницIs 904-Specification For 2-Way and 3-Way Suction Collecting Heads For Fire Fighting PurpossanjaigОценок пока нет

- Bopp & ReutherДокумент44 страницыBopp & Reutherviveros_caos100% (1)

- Fonte PROMEXДокумент34 страницыFonte PROMEXMass GiovaniОценок пока нет

- A582A582M-12e1 Standard Specification For Free-Machining Stainless Steel BarsДокумент4 страницыA582A582M-12e1 Standard Specification For Free-Machining Stainless Steel Barstjt4779Оценок пока нет