Академический Документы

Профессиональный Документы

Культура Документы

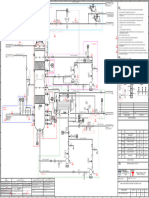

P&ID May Nghien Malt 10t-h

Загружено:

alun nguyễnИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

P&ID May Nghien Malt 10t-h

Загружено:

alun nguyễnАвторское право:

Доступные форматы

1 2 3 4 5 6 7 8 9 10 11 12

MALT DN 150 DN 50 AIR

/ / / / / /

VMI1+VSG01-Q104

FROM EXISTING MALT HANDLING DEDUSTING

VMI1+VSG01-Q101

VMI1+VSG01

-B101.GSO

A VMI1+VSG01 A

-B101.GSC

DN 40 DN 125

NO UNMALTED CEREALS

NO SOUND INSULATION

NO RAW GRAIN

14,0 m³/h

VMI1+VCI01-Q103

VMI1+GEF01

MALT HOPPER

B DOOR DOOR B

VMI1+MUE01 VMI+MUE01-S001 VMI1+MUE01 VMI1+MUE01

-K301.LSL -F391.GS -F392.GS

DN 50 / 40

VMI1+GEF01-P305 VMI1+MUE01

-B301.LE LADDERS AND PLATFORMS

VMI1+01-M201 VMI1+01-M221

DN 40 DN 40 - BY CUSTOMER -

VMI1+MUE01 VMI1+MUE01

M VMI1+MUE01

-T101.SC -K201.GI -K221.GI

VMI1+VWS01-V305 VMI1+VWS01-Q102

VMI1+01-M101 VMI1+MUE01 VMI1+MUE01

-B201.GT -B221.GT

VMI1+MUE01 VMI1+MUE01 VMI1+MUE01 M M

VMI1+MUE01

DN 25 -B401.LET -K401.LIC -B201.GE -B221.GE

M

VMI1+VCI01-Q102

14,0 m³/h

VMI1+MUE01 VMI1+MUE01 VMI1+MUE01 VMI1+MUE01

M

DN 50

-B161.ET

DN 8

REVERSIBLE -K161.EI

VMI1+01-M121 -K141.EI -B141.ET

C C

M VMI1+MUE01

-T121.SC

VMI1+01-M141

FRONTSIDE

VMI1+01-M161

DN 50 VMI1+MUE01 VMI1+MUE01

-T141.JC -T161.JC

CIP + WATER DN 65 DN 65 / 50 SOFTSTART SOFTSTART

VMI1+VWS01-Q103

80,00 C / 3,0 bar / 44,0 m^3/hr /

FROM EXISTING CIP PLANT M M

VMI1+VCI01-Q101

VMI1+MUE01 VMI1+MUE01

-B311.LE -K311.LSH

DN 50

DN 65 DN 65 / 50

VMI1+MUE01 VMI1+MUE01

-B402.LET -K402.LIC DN 80

VMI1+VWS01-Q101 DN 100 / 80 MASH

55,00 C / 1,0 bar / 90,0 m^3/hr /

FI

VMI1+VPR01-Q251

DN 8 / 1/2" TO EXISTING MASH VESSELS

VMI1+01-G301 DN 80

M VMI1+01-M301

DN 65

VMI1+VWS01-Q291 VMI1+VWS01-P395 MASH PUMP

D VMI1+WM01 VMI1+WM02 VMI1+MUE01 D

-B511.FET -B511.FET -T301.SC

VMI1+WM01 VMI1+WM02

-K511.FIC -K511.FIC

VMI1+WM02-G305

VMI1+WM01-G305

VMI1+WM01 VMI1+WM02

-B411.TET -B411.TET

VMI1+WM01 VMI1+WM02

-K411.TIC -K411.TIC

VMI1+WM01 VMI1+WM02

-K261.GC -K261.GC

DN 25 / 65 DN 65 / 50 DN 50

DN 40

VMI1+WM01-Q261 VMI1+WM02-Q261

DN 65

E VMI1+WM01 VMI1+WM02 E

-K262.GC -K262.GC

DN 40 / 65 DN 65 / 50 DN 50 / 65

PI VMI1+WM01-Q262 VMI1+WM02-Q262

COLD WATER DN 65

25,00 C / 3,5 bar / /

FROM EXISTING COLD WATER PLANT

VMI1+WM01-Q305 VMI1+WM01-V305 VMI1+WM01-R305 VMI1+WM01-P305

DN 65

PI TI

WARM WATER

80,00 C / 3,5 bar / /

FROM EXISTING WARM WATER PLANT

VMI1+WM01-Q306 VMI1+WM01-V306 VMI1+WM01-R306 VMI1+WM01-P306 VMI1+WM01-P307

F F

WATERMIXER:

NO PRE-ASSEMBLING AT PLANT STEINECKER! - MOUNTING MATERIALS LIKE PIPES, PIPE

ASSEMBLING ON SITE! BENDS, T-PIECES, PIPE HOLDERS

BY CUSTOMER

- INSULATION OF PIPES

BY CUSTOMER

POWER SUPPLY - ONLY ALL FITTINGS AND VALVES OF MILL

400 V 50 HZ AND WATERMIXER

BY STEINECKER

BY CUSTOMER

G G

=BH1.L1.VMI1

VMI1+01-M101 VMI1+01-M141 VMI1+01-M201 VMI1+01-M301 Quotation No.: Saigon, Nha Trang

FEED ROLLER, UPPER CRUSHING ROLL, FRONT (F/B) MILL GAP, LEFT (O/C) MASH PUMP

Order No. :

P = 1,50 kW P = 15,00 kW P = 250,0 W P = 7,50 kW

n = 1450,0 rpm n = 1450,0 rpm n = 1450,0 rpm n = 1450,0 rpm

VT

KRONES KRONES KRONES KRONES

PDG Index Revision Date Name

PSA Transmission and duplication of this document as well

as exploitation of its contents is not permitted,

TA unless otherwise stated. Infringements result

VMI1+GEF01 VMI1+01-M121 VMI1+01-M161 VMI1+01-M221 VMI1+01-G301 PLT in claim for damages.

H All rights on patent or utility patent - with the P&ID VARIOMILL 10 T/H H

MALT HOPPER FEED ROLLER, LOWER CRUSHING ROLL, BACK MILL GAP, RIGHT (O/C) MASH PUMP GPL proviso for registration.

d = 2380,0 mm P = 1,50 kW P = 15,00 kW P = 250,0 W Q =90,0 m^3/hr

Date Name Scale Material for Page

V = 89,0 hl

CUSTOMER

n = 1450,0 rpm

KRONES

n = 1450,0 rpm

KRONES

n = 1450,0 rpm

KRONES

dp = 1,0 bar

KRONES

By 20.10.2015 1:X XXX Substitute

by VMI

Approved Drawing to be modified

Sheet Size: DIN A2 Date saved CAD only in CAD-System !!

Drawing No.

1 2 3 4 5 6 7 8 9 10 11 12

Вам также может понравиться

- Traxon Standard LKW: StromlaufplanДокумент2 страницыTraxon Standard LKW: Stromlaufplanivan oliverosОценок пока нет

- Panasonic Eb A100Документ4 страницыPanasonic Eb A100jose peresОценок пока нет

- Samyung Navis 2500/3000/3700Документ33 страницыSamyung Navis 2500/3000/3700adavit73100% (1)

- MCS 2 Block 004 - r1Документ1 страницаMCS 2 Block 004 - r1tailieutonghop97Оценок пока нет

- 8-Schematic Diagram (Ver2.0)Документ4 страницы8-Schematic Diagram (Ver2.0)Kadër Stevïe ĽfcОценок пока нет

- Carvin Schematic - KB1000 PWR Module RevEДокумент1 страницаCarvin Schematic - KB1000 PWR Module RevEdod100% (1)

- Ed 0900 PRS Pid 000 09041CДокумент1 страницаEd 0900 PRS Pid 000 09041CMohamed ArafaОценок пока нет

- I9100-Schematic PDFДокумент9 страницI9100-Schematic PDFMina BariОценок пока нет

- +HVCC: +V:FW1300/+155V FW1100/+144V FW900/+132VДокумент1 страница+HVCC: +V:FW1300/+155V FW1100/+144V FW900/+132VVesko IОценок пока нет

- Biema FW2400Документ6 страницBiema FW2400jefriОценок пока нет

- A294 Point To Point Diagram 1/2: AC Drive Board (PCB 10) AC Line Block ChartДокумент10 страницA294 Point To Point Diagram 1/2: AC Drive Board (PCB 10) AC Line Block ChartFábio Alessandro PereiraОценок пока нет

- 1.1.1 Z 1239083 Customer DrawingДокумент4 страницы1.1.1 Z 1239083 Customer DrawingUlises Rumiche ChungaОценок пока нет

- 19011-U-100-Pro-Pid-110-A1 NodeДокумент1 страница19011-U-100-Pro-Pid-110-A1 NodeAjay TulpuleОценок пока нет

- 4cx Master Site Electrical DiagramДокумент34 страницы4cx Master Site Electrical DiagramDean mark rey luzonОценок пока нет

- Lay OutДокумент3 страницыLay OutRobertoОценок пока нет

- Esq Net Winner (t0534602)Документ1 страницаEsq Net Winner (t0534602)Paulo CostaОценок пока нет

- Epcc05 MDR 421 STR DWG 000 0072 05Документ1 страницаEpcc05 MDR 421 STR DWG 000 0072 05RANJEET PRATAP SINGHОценок пока нет

- Matrix 1.4 Vii 120VDC4L TD Power AmpДокумент1 страницаMatrix 1.4 Vii 120VDC4L TD Power Ampsakura 835Оценок пока нет

- General Notes:: Dhi Qar Combined Cycle Power Plant ProjectДокумент1 страницаGeneral Notes:: Dhi Qar Combined Cycle Power Plant Projectmustafa1989ocОценок пока нет

- Hmc1031ms8e Eval PCB SchematicДокумент3 страницыHmc1031ms8e Eval PCB SchematicbaymanОценок пока нет

- Gem Full F FaceliftДокумент2 страницыGem Full F FaceliftIulianCiobanuОценок пока нет

- Notes: Document Review Status (By Employer / PMC)Документ1 страницаNotes: Document Review Status (By Employer / PMC)Niwrati HolkarОценок пока нет

- Beko bkl19 LWДокумент2 страницыBeko bkl19 LWcioargaОценок пока нет

- General NotesДокумент1 страницаGeneral Notesmustafa1989ocОценок пока нет

- P21020 Cit 0020 - 04Документ1 страницаP21020 Cit 0020 - 04Carlos David Hurtado MartinezОценок пока нет

- Zumo 32u4 Schematic DiagramДокумент5 страницZumo 32u4 Schematic DiagramTazОценок пока нет

- Ed 0100 PRS Pid 000 01005uДокумент1 страницаEd 0100 PRS Pid 000 01005uMohamed ArafaОценок пока нет

- Attachement-1 RFC-29-18Документ14 страницAttachement-1 RFC-29-18Mohamed ArafaОценок пока нет

- Insu - Thickness: No Open ItensДокумент1 страницаInsu - Thickness: No Open ItensGabriel PulidoОценок пока нет

- 5700 - Hydraulic Schematic 98L SystemДокумент1 страница5700 - Hydraulic Schematic 98L SystemJohn NewsomeОценок пока нет

- D038 Evs Co000 1091 - 00Документ1 страницаD038 Evs Co000 1091 - 00Mussarat BabasahebОценок пока нет

- SS-0150-TJR-DWG-ELE-004 - Auxiliary Single Line Diagram (Along With UPS) - PV2-MCRДокумент1 страницаSS-0150-TJR-DWG-ELE-004 - Auxiliary Single Line Diagram (Along With UPS) - PV2-MCRtukaram.pawarОценок пока нет

- 2 Ou T of 3 Tes Table S Afety Valve Bloc K: Steam T U RbineДокумент5 страниц2 Ou T of 3 Tes Table S Afety Valve Bloc K: Steam T U RbineRafa NisaОценок пока нет

- SET P&ID - Filter Cellar - Tibasosa PDFДокумент9 страницSET P&ID - Filter Cellar - Tibasosa PDFJairo Hernando Rojas PulidoОценок пока нет

- QL880A 器件位号图 MB V6Документ2 страницыQL880A 器件位号图 MB V6Federico Héctor UsseglioОценок пока нет

- Circuit Energi MeterДокумент2 страницыCircuit Energi MeterYusuf PranotoОценок пока нет

- Eep 000097 0102148005 3 ST Det 0669 R02Документ1 страницаEep 000097 0102148005 3 ST Det 0669 R02Vikram DalalОценок пока нет

- Chiyuan Hdz2804-3a Rev.a Power Supply SCHДокумент2 страницыChiyuan Hdz2804-3a Rev.a Power Supply SCHSaulvcr64 PorleyОценок пока нет

- 1JNG10374D2X755 - COOLER FOUNDATION AND ROOF SHED - RevA (2 OF 2)Документ1 страница1JNG10374D2X755 - COOLER FOUNDATION AND ROOF SHED - RevA (2 OF 2)mhazarath murariОценок пока нет

- API PLAN "11" / "61" Api Plan "11" API PLAN 11/52: by VendorДокумент1 страницаAPI PLAN "11" / "61" Api Plan "11" API PLAN 11/52: by VendorTien Tran Kha Tien100% (1)

- 10083a 1X M6 Ab 00006 04Документ1 страница10083a 1X M6 Ab 00006 04wael zakariaОценок пока нет

- Notes: Investor/Operator Engineering ContractorДокумент1 страницаNotes: Investor/Operator Engineering ContractorPerviz BabazadeОценок пока нет

- CNN008311 Diagrams and DrawingsДокумент40 страницCNN008311 Diagrams and DrawingsandraОценок пока нет

- Samb108 sch0.8 - de - EfrcomДокумент8 страницSamb108 sch0.8 - de - EfrcomHotel WijayaОценок пока нет

- Slab Reinforcement DetailsДокумент1 страницаSlab Reinforcement Detailssydney augustОценок пока нет

- PORTABLE STEPS (2 STEPS) (H 550x700x700)Документ2 страницыPORTABLE STEPS (2 STEPS) (H 550x700x700)teklabimno1Оценок пока нет

- Notes:: Proposed Bridge (1) Er458 Widening of Tanah Merah Coast RoadДокумент2 страницыNotes:: Proposed Bridge (1) Er458 Widening of Tanah Merah Coast RoadasdasОценок пока нет

- Hog LHB Power CarДокумент1 страницаHog LHB Power Carpraveen_01236Оценок пока нет

- Parte Di Controllo Digitale: Altri Componenti Presenti in Sm000097Документ1 страницаParte Di Controllo Digitale: Altri Componenti Presenti in Sm000097Hazim Samer0% (1)

- Engine + Generator - Engineering Manual Rev.1 (RECIBIDO 6-11-12) PDFДокумент159 страницEngine + Generator - Engineering Manual Rev.1 (RECIBIDO 6-11-12) PDFJavier Everest50% (2)

- Point To Toint DiagramДокумент23 страницыPoint To Toint DiagramApenas MaxОценок пока нет

- 10083a 9X M6 XN 00001 01Документ1 страница10083a 9X M6 XN 00001 01wael zakariaОценок пока нет

- Pci Fonte Av3n + AmplificadorДокумент1 страницаPci Fonte Av3n + AmplificadorJeferson MazieroОценок пока нет

- D038 Evs Co000 1090 - 00Документ1 страницаD038 Evs Co000 1090 - 00Mussarat BabasahebОценок пока нет

- MCB Toilet ElevationspdfДокумент1 страницаMCB Toilet Elevationspdfjuy rose cunananОценок пока нет

- Hydraulic Diagram MM0346835 - 1Документ4 страницыHydraulic Diagram MM0346835 - 1miguel. montañoОценок пока нет

- Esquema Eletrico Aca 501 New XДокумент1 страницаEsquema Eletrico Aca 501 New XEletrônica Prime100% (2)

- بلان الدور الارضي 1-ModelДокумент1 страницаبلان الدور الارضي 1-ModelShrook Nasr AbdElKarimОценок пока нет

- Detail A: Shuqaiq 3 Independent Water ProjectДокумент1 страницаDetail A: Shuqaiq 3 Independent Water ProjectABAID ULLAHОценок пока нет

- ABB Ability Safety Plus For Hoists BrochureДокумент12 страницABB Ability Safety Plus For Hoists BrochureCarlos Bruno MatosОценок пока нет

- Ref: Bboneblk - SRM Beaglebone Black System Reference Manual Rev BДокумент125 страницRef: Bboneblk - SRM Beaglebone Black System Reference Manual Rev BhernangycОценок пока нет

- Hong Kong International Airport Instrument Approach ChartДокумент21 страницаHong Kong International Airport Instrument Approach ChartThamaroj ChansawangОценок пока нет

- Indonesia's First Maritime Service Solution Provider: Company ProfileДокумент10 страницIndonesia's First Maritime Service Solution Provider: Company Profilemuh_akbar2451Оценок пока нет

- Case Study Analysis of Apex Corporation PDFДокумент2 страницыCase Study Analysis of Apex Corporation PDFAJОценок пока нет

- Braemar ApplicationДокумент2 страницыBraemar Applicationjoemedia0% (1)

- Teoh Zi Wei 0323372 Vivian Tay 0323869 Vinnie Tan 0323706 Yeoh Sin Yuen 0323737 Tey Cheng Fern 0323912Документ22 страницыTeoh Zi Wei 0323372 Vivian Tay 0323869 Vinnie Tan 0323706 Yeoh Sin Yuen 0323737 Tey Cheng Fern 0323912api-292027950Оценок пока нет

- Omd Graviner Mk6 ManualДокумент90 страницOmd Graviner Mk6 ManualChristis SavvaОценок пока нет

- CAM Charges Working For The Month of May 2023Документ1 страницаCAM Charges Working For The Month of May 2023adnandani2882Оценок пока нет

- Revised Runway Length Discussion (20171206) - 201712211212022318Документ3 страницыRevised Runway Length Discussion (20171206) - 201712211212022318Ilham RaffiОценок пока нет

- PR-1078 - Hydrogen Sulphide Management ProcedureДокумент22 страницыPR-1078 - Hydrogen Sulphide Management Procedureromedic360% (1)

- Ch2 Snapshot 20 LightingДокумент4 страницыCh2 Snapshot 20 Lightinggarych72Оценок пока нет

- Mason Melito: EducationДокумент2 страницыMason Melito: Educationapi-568517799Оценок пока нет

- RAEX 300 DatasheetДокумент2 страницыRAEX 300 Datasheetabdulloh_99Оценок пока нет

- Dialogues in French and EnglishДокумент62 страницыDialogues in French and Englishmiki1222Оценок пока нет

- Report For Neha Lem ArchitectureДокумент17 страницReport For Neha Lem ArchitecturewafasaОценок пока нет

- Logic GatesДокумент19 страницLogic GatesblazespiritОценок пока нет

- MN5200 Issue1.1 APR2009Документ2 страницыMN5200 Issue1.1 APR2009Roger ReisОценок пока нет

- ID 2051814.1 Oracle Support Sample SetupДокумент9 страницID 2051814.1 Oracle Support Sample SetupFerasHamdanОценок пока нет

- CatalogДокумент5 страницCataloglangtu2011Оценок пока нет

- Plotting in MatlabДокумент7 страницPlotting in Matlabpride3351Оценок пока нет

- Instalación Sensor RPM TurboДокумент13 страницInstalación Sensor RPM TurboLuis Herrera MarinОценок пока нет

- Blue Solar Charge Controller MPPT: NOT AcceptedДокумент12 страницBlue Solar Charge Controller MPPT: NOT Accepted1382aceОценок пока нет

- Individual: DR Winnie Louis LeeДокумент27 страницIndividual: DR Winnie Louis Leeedn_mj1645Оценок пока нет

- Sanjay ProjectДокумент41 страницаSanjay ProjectPrynka RawatОценок пока нет

- Adirondack Life Media KitДокумент8 страницAdirondack Life Media KitJohnny LibitzОценок пока нет

- Confined Spaces: Avoiding Common Mistakes in Gas DetectionДокумент1 страницаConfined Spaces: Avoiding Common Mistakes in Gas Detectiontrravi1983Оценок пока нет

- Workover Kill Fluid Density CalculationДокумент3 страницыWorkover Kill Fluid Density CalculationSanny Astari100% (1)

- Airframe Essay QuestionsДокумент12 страницAirframe Essay QuestionsRaul DeonarainОценок пока нет

- New Approach For The Measurement of Damping Properties of Materials Using The Oberst BeamДокумент6 страницNew Approach For The Measurement of Damping Properties of Materials Using The Oberst BeamMatnSambuОценок пока нет