Академический Документы

Профессиональный Документы

Культура Документы

TES-P-119.06 R0 - Surge Protection

Загружено:

Mohamed EldinАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

TES-P-119.06 R0 - Surge Protection

Загружено:

Mohamed EldinАвторское право:

Доступные форматы

TRANSMISSION ENGINEERING STANDARD TES-P-119.06, Rev.

TABLE OF CONTENTS

1.0 PURPOSE AND SCOPE

2.0 GENERAL

3.0 TYPES OF SURGE PROTECTIVE DEVICES

3.1 Rod Gap

3.2 Metal Oxide Surge Arrester

4.0 ARRESTER SELECTION

4.1 Maximum Continuous Operating Voltage (MCOV)

4.2 Temporary Power Frequency Overvoltages

4.3 Switching Surges

4.4 Ambient Temperature and Solar Radiation

4.5 Protective Level

4.6 Special Installation Conditions

5.0 ARRESTER APPLICATIONS

5.1 Power Transformer

5.2 Power Transformer Tertiary Winding

5.3 Overhead Line Terminal

5.4 Underground Line Terminal

5.5 Gas Insulated Substation

5.6 Shunt Reactor

6.0 OTHER CONSIDERATIONS

6.1 Effect of Leas Wire

6.2 Mechanical Loading

6.3 Grounding

6.4 Distance to Surrounding Objects

6.5 Discharge counters and Leakage Current Indicators

6.6 Pressure Relief Device

6.7 Shielding

7.0 BIBLIOGRAPHY

TESP11906R0/KSB Date of Approval: October 16, 2006 PAGE NO. 2 OF 15

TRANSMISSION ENGINEERING STANDARD TES-P-119.06, Rev. 0

1.0 PURPOSE AND SCOPE

The purpose of this chapter is to highlight SEC practices with respect to the requirements

and application of surge arrester.

2.0 GENERAL

Surge arresters are the primary protection to make the circuit devices immune to different

types of overvoltages and spikes either atmospheric or switching. Surge arresters are

designed to limit the voltage surges by discharging or bypassing surge current and

automatically limiting the flow of system power current.

3.0 TYPES OF SURGE PROTECTIVE DEVICES

Two types of surge protective devices are generally provided:

3.1 Rod Gap

A rod gap is a spark gap comprising of two rods spaced coaxially, extending from

their supports at least one half of the gap spacing. Spark over occurs when the air is

ionized by a sufficient voltage potential across the rods. Disadvantages of rod gaps

are, it conducts at higher voltages and requires very steep rise time. Further it has

unpredictable turn-on and response characteristics.

Rod gaps shall be provided with prior SEC approval, only when found necessary for

insulation co-ordination when the phase to ground insulation distance of the

disconnect switch is 90% or more than the disconnect switch isolating distance. The

design of rod gaps for such applications shall be the responsibility of the disconnect

manufacturer.

3.2 Metal Oxide Surge Arrester

Metallic oxides surge arresters are ceramic semiconductor devices with highly non-

linear current-voltage characteristics and with an extremely good energy capability.

The voltage-current characteristics for the resistive components (Ir) and capacitive

components (Ic) currents through metal oxide discs are shown in figure 06-1. The

curve comprises of three regions namely pre-breakdown region (Region 1),

breakdown region (Region 2) and high current region (Region 3). In the pre-

breakdown region the resistivity of material depends on the temperature with

negative temperature co-efficient, in the breakdown region the temperature

dependence is very small and in the higher current region the characteristics are no

longer linear. For surge arresters capacitive peak leakage current is normally 0.2mA

to 3mA and resistive peak leakage current is 5% to 20% of capacitive leakage

current under normal operating condition.

TESP11906R0/KSB Date of Approval: October 16, 2006 PAGE NO. 3 OF 15

TRANSMISSION ENGINEERING STANDARD TES-P-119.06, Rev. 0

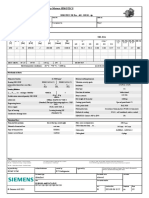

DWG TE-1906-01-00

4.0 ARRESTER SELECTION

The objective of arrester selection is to select the lowest rated surge arrester that will have a

satisfactory service life on the power system while providing adequate protection of

equipment insulation. An arrester of the minimum practical rating is generally preferred

because it provides higher margin of protection for insulation. The use of higher rating

increases the capability of the arrester to survive on the power system, but reduces the

margin of protection it provides for a specific insulation level. Thus arrester selection must

strike a balance between arrester survival and equipment protection.

The following shall be considered during the selection of surge arrester:

• Determination of maximum continuous operating voltage with respect to system

highest operating voltage

• Determination of rated voltage with respect to temporary overvoltages

• Line discharges in switching surges

• Ambient temperature

Co-ordination of protection level of the arrester with equipment to be protected

• Selection of pressure relief requirements for the arrester with respect to system short

circuit currents

• Any special consideration

4.1 Maximum Continuous Operating Voltage (MCOV)

It is the maximum permissible r.m.s power frequency voltage applied continuously

between the arrester terminals. MCOV rating for effectively grounded system shall

be equal to or more than the system maximum line to ground power frequency

voltage under emergency operating conditions and for non-effectively grounded

system it shall be equal to or more than the system maximum line to line power

frequency voltage under emergency operating conditions.

TESP11906R0/KSB Date of Approval: October 16, 2006 PAGE NO. 4 OF 15

TRANSMISSION ENGINEERING STANDARD TES-P-119.06, Rev. 0

The recommended arrester MCOV capability is indicated in Table 06-1. MCOV

rating of the arrester is normally about 80% of arrester rated voltage and it is the

maximum permissible r.m.s value of the power frequency voltage between the

arrester terminals at which it is designed to operate correctly as established in

operating duty test.

4.2 Temporary Power Frequency Overvoltages

Temporary overvoltages (TOV) consist of lightly damped power frequency voltage

oscillations, often with harmonics, usually lasting a period of hundreds of

milliseconds or longer. Situations that may give rise to these overvoltages include

single line-to-ground faults, ferro-resonance, load rejection, loss of ground, long

unloaded transmission lines (Ferranti rise), coupled-line resonance and the

transformer in-rush.

To determine the temporary overvoltage magnitude during fault conditions the

system coefficient of grounding must be determined. The coefficient of grounding is

defined the ratio of phase-to-ground power frequency voltage on a sound phase

during fault at selected location to line-to-line power frequency voltage at the

selected location with the fault removed. A system is considered effectively

grounded if the coefficient of grounding does not exceed 80 percent, which is

generally the case when system parameters are such that 0 < X0/X1 < 3 and 0 <

R0/X1 < 1.

For non-effectively grounded system, during the ground fault the line-to-ground

voltage in the other two healthy phases may rise up to system maximum line-to-line

power frequency voltage under emergency operating condition for extended period.

The maximum temporary voltage values for 10 seconds for effectively earthed

system and non-effectively earthed system are shown in Table 06-1

Under normal operating condition there shall be a balance between the heat

generated and dissipated by the arrester elements. However overvoltage events

disturb these stable conditions by causing the elements to absorb increased levels of

energy for the time the overvoltage exceeds the normal operating voltage. The

arrester shall be capable of absorping this energy with or without prior energy

absorption due to transmission line discharges per 35-TMSS-01.

Manufacturer shall furnish TOV (power frequency versus time) curve for the arrester

with and without prior energy clearly indicating the overvoltage withstand value at 1

second and 10 seconds and the curve shall cover minimum time range of 0.1seconds

to 20 minutes. The basic requirement is the power frequency overvoltage withstand

value for the arrester shall be higher then the system TOV values for 10 seconds as

indicated in Table 06-1.

TESP11906R0/KSB Date of Approval: October 16, 2006 PAGE NO. 5 OF 15

TRANSMISSION ENGINEERING STANDARD TES-P-119.06, Rev. 0

4.3 Switching Surges

Switching surges are caused by normal line switching, high-speed autoreclosing, out

of phase switching, switching of cable circuits/capacitor banks/shunt reactors, circuit

breaker restriking, load rejection and current chopping etc.

Surge arresters dissipate switching surges by absorbing thermal energy. The amount

of energy is related to the prospective switching magnitude, its wave shape, the

system impedance, circuit topology, the arrester voltage-current characteristics, and

the number of operations. The selected arrester shall have an energy absorption

capability higher than the energy associated with expected switching surges. The

ability of metal oxide arrester to absorb system switching surges can be quantified in

terms of energy. The units generally used in quantifying this capability are kilojoules

per kV (kJ/kV) at arrester rated voltage. Arrester energy absorption capability shall

be per 35-TMSS-01.

4.4 Ambient Temperature and Solar Radiation

Higher temperature and aging of the material increases the energy of electrons in

pre-breakdown region (refer figure 06-1), causing thermal breakdown. Hence

performance and life expectancy of the arrester shall be based on the ambient

conditions per 01-TMSS-01.

4.5 Co-ordination of Protective Level

Protective level of an arrester is the maximum crest voltage that appears across the

arrester terminals under specified condition of operations. Protective level of an

arrester comprising of lightning impulse protective level (LPL), and switching

impulse protective level (SPL) shall be kept well below the equipment insulation

level of basic lightning impulse insulation level (BIL) and basic switching impulse

insulation level (BSL) respectively. Arrester protective level shall meet the

requirements of Table 06-1.

4.6 Special Installation Conditions

If severe ambient temperature conditions exist for a particular installation, such as

installation of a surge arrester inside an unventilated metal enclosure etc., these

conditions shall be taken into consideration before selecting appropriate arrester.

TESP11906R0/KSB Date of Approval: October 16, 2006 PAGE NO. 6 OF 15

TRANSMISSION ENGINEERING STANDARD TES-P-119.06, Rev. 0

5.0 ARRESTER APPLICATIONS

5.1 Power Transformers

5.1.1 Power Transformer HV and LV Winding

Arresters shall be located at or near all substation power transformers on both

the high and low voltage sides except in cases where the transformer

bushings are housed in cable termination boxes. The arresters shall be

mounted directly on the transformers, wherever possible. For transformer

with bushings terminating directly on to a Gas Insulated Switchgear (GIS),

GIS surge arresters shall be provided at the termination point if required per

insulation co-ordination studies.

The application of arresters for the protection of power transformers consists

of the following steps :

Step 1: Select arrester rating (preliminary).

Step 2: Determine arrester protection levels (residual voltage) :

• Protection level for a full impulse wave

• Protection level for a switching impulse (if applicable).

Step 3: Determine transformer withstand capability :

• Basic insulation level

• Basic switching insulation level.

Step 4: Plot arrester protection levels and transformer withstand capability

on a common coordinate system as shown in Figure 06-2.

Step 5: Determine protection margins between the arrester and transformer

•

Step 6: If protection margins are not higher than the recommended, select

the next lower arrester rating that is compatible with the normal

operating voltage of the system and go to step 2. Otherwise, go to

Step 7.

Step 7: Determine whether arrester has adequate energy absorption

capability for the application.

The above procedure is pertinent only for application of surge arresters at or

near the transformer.

TESP11906R0/KSB Date of Approval: October 16, 2006 PAGE NO. 7 OF 15

TRANSMISSION ENGINEERING STANDARD TES-P-119.06, Rev. 0

5.1.2 Power Transformer Tertiary Winding

For large transformer with low voltage tertiary winding surges can be

transferred through the transformer from one winding to another. The

voltages transferred through the transformers are mainly fast-front or slow-

front voltages. The transferred surge has usually both the capacitively and

inductively transferred components, which superimpose to the power

frequency voltage.

The capacitively transferred components lay typically in megahertz range and

are seen first in the transferred surge. The inductively transferred component

comes after capacitive. The magnitude of the transferred voltage depends on

the construction of transformer. Manufacturer shall furnish calculation with

methods for the transferred surges for the surge arrester sizing. It shall be

noted that not all the construction features of transformer influencing the

transferred voltages can be addressed in the calculations and calculations can

be used only as a rough estimation of surge magnitudes. The most practical

method to quantitative estimate of surge is to measure them by tests.

5.2 Overhead Line Terminals

Arrester shall be installed at the overhead line entrances to substations with rated

voltages 230kV and above. For other voltages calculations shall be carried out to

decide the requirements.

5.3 Underground Line Terminals

5.3.1 Arresters need not be installed in 11kV, 13.8kV, 33kV, 34.5kV and 69kV

substation switchgear when the line entrances are underground cables that do

not terminate at an overhead system.

5.3.2 On 110 kV and higher voltages, arresters shall be installed, if required per

insulation co-ordination studies, at both ends of underground cable which

connects two substations.

5.3.3 For all voltage levels, when the line entrances are underground cables that

terminate at an overhead system, arresters shall be installed at the

underground cable to overhead line transition point. Grounding of transition

point arresters to the substation ground through low impedance path is to be

ensured.

TESP11906R0/KSB Date of Approval: October 16, 2006 PAGE NO. 8 OF 15

TRANSMISSION ENGINEERING STANDARD TES-P-119.06, Rev. 0

5.4 Shunt Capacitors

Arresters shall be provided for all shunt capacitors. Further detailed calculation

regarding, MCOV, rated voltage, TOV, energy absorption capability etc., shall be

submitted. While installing capacitor banks for voltage improvement, existing

silicon-carbide gapped arrester, if any, shall be replaced with metal oxide surge

arrester.

5.5 Gas Insulated Substation (GIS)

GIS in general better protected than open-air substations because they have surge

impedances much lower than the overhead lines. GIS with over head line connection

through SF6 to air bushing shall be provided with surge arrester at the air to GIS

transition point. GIS with underground cables and over head line portion shall be

provided with surge arresters per clause 5.3.3. For underground cables with rated

voltage 110kV and above, connecting GIS of one substation to another substation

GIS, surge arrester shall be provided if required per insulation co-ordination studies.

For transformer connected by SF6 bus duct additional surge arrester at the

transformer or at the bus may be required when the separation distance to line

entrance arresters is too long or when high voltages at the transformer are expected.

Insulation co-ordination shall be carried out to decide the requirement of surge

arresters and their location.

5.6 Shunt Reactors

Chopping of current and subsequent reignition by the shunt reactor breaker results in

significant overvoltages. Surge arrester shall be provided for suppression of peak

overvoltages.

TESP11906R0/KSB Date of Approval: October 16, 2006 PAGE NO. 9 OF 15

TRANSMISSION ENGINEERING STANDARD TES-P-119.06, Rev. 0

TESP11906R0/KSB Date of Approval: October 16, 2006 PAGE NO. 10 OF 15

TRANSMISSION ENGINEERING STANDARD TES-P-119.06, Rev. 0

6.0 OTHER CONSIDERATIONS

6.1 Effect of Lead Wires

The discharge of lightning currents through the inductance of connected lead wires

produces a voltage that adds to the arrester discharge voltage. Lead length includes

the ground lead length as well as the primary lead. The total length of these leads is

measured from the point at which the arrester line connection is made to the point

where interconnection is made between the arrester ground lead and the protected

equipment ground lead, excluding the arrester length.

The minimum protective level margin between the equipment and voltage due to

arrester discharge voltage plus voltage drop in the lead wire shall be 20%. Minimum

cross-section of lead wire between the line connection and arrester terminal shall be

per Table 06-2. As far as possible surge arrester shall be mounted nearest to the

equipment to be protected so that the distance of the equipment is within the

arrester’s protective zone.

Table 06-2 : Minimum Sizes of Arrester Lead Wire

System Nominal Voltage Lead Wire Minimum

(kV) Size

(mm2)

11 70

13.8 70

33 70

34.5 70

69 120

110 120

115 120

132 120

230 240

380 240

Note : Sizes indicated in the above table are minimum and the actual

size shall be based on voltage drop.

6.2 Mechanical Loading

The arrester shall not be used as a bus support device. The maximum permissible

mechanical loading applied to a metallic-top arrester shall be 40 percent of

manufacturer's rated cantilever strength.

TESP11906R0/KSB Date of Approval: October 16, 2006 PAGE NO. 11 OF 15

TRANSMISSION ENGINEERING STANDARD TES-P-119.06, Rev. 0

The line connection on a porcelain-top arrester (ideally suited for confined spaces,

such as cubicle mounting, where clearance between live parts are critical) shall be

made in such a way that no excessive mechanical stress is placed on the arrester.

6.3 Grounding

The lead from the ground terminal of the arrester shall be connected by the shortest

possible route to the insulated bushing of discharge counter and leakage current

indicator (if provided) by a conductor with insulation rated not less than 5 kV crest

and shall not be more than 3 meters in length, in any case, to avoid sparkover to

ground and thereon directly to a dedicated ground rod via two number 240mm2

stranded copper conductor, which shall also be connected to the station grid

conductor in the substation. The protected transformer tank shall also be connected

to the same grounding system as the arrester with as low ground resistance as

possible, one ohm or less.

The arrester shall be insulated from ground with 5kV rated standoff insulators, so

that the leakage current passes through the discharge counter and leakage current

indicator.

6.4 Distance to Surrounding Objects

To prevent outside objects affecting the voltage grading, manufacturer shall furnish

minimum distance for the objects (conducting and non-conducting type) to be

located from the arrester.

If the distances stated are not maintained, there is a risk that the value of the

discharge voltage of the arrester may differ. Also, the arrester may fail due to

unbalanced stresses on it from nearby conducting or grounded objects.

6.5 Discharge Counters and Leakage Current Indicators

All arresters for system voltages of 69 kV and above shall have a discharge counter

and a continuous AC leakage/internal current indicator. As contamination increases

on the porcelain, the leakage current increases. The level of current registered serves

as a guide to insulation cleaning frequency and abnormally high reading of counter

over a given period of time would indicate the need for inspection and checking of

arrester.

Due to the high contamination level and humid atmospheric conditions in SEC

operating areas, an ammeter with a scale range of 0-50mA Peak / √2 (nonlinear

scale) shall be provided to monitor and measure the leakage current across the

external porcelain insulator, in addition to the internal current flowing through the

arrester. The surge counter shall be non-resettable and capable of registering up to 5

discharges per second on a five digit cyclometer dial.

TESP11906R0/KSB Date of Approval: October 16, 2006 PAGE NO. 12 OF 15

TRANSMISSION ENGINEERING STANDARD TES-P-119.06, Rev. 0

The discharge counter and the leakage current indicator is to be connected between

the arrester ground terminal and the station ground and shall be installed in such a

position that reading can easily be taken.

6.6 Pressure Relief Device

Arrester pressure relief device is intended to vent internal arc gases, and prevent

violent porcelain shattering when an internal fault occurs. An arrester that has vented

shall be replaced immediately. The arrester pressure relief class to be selected for a

given application shall have a pressure relief capability greater than the maximum

short circuit current available at the intended arrester location.

6.7 Shielding

Arrester discharge current is less than direct stroke current and the provision of an

arrester is meant basically to protect substation equipments by limiting overvoltages

in the form of traveling waves due to direct strokes entering the substation over

connecting lines. Only in the case of a direct stroke very near to the terminal of

arrester where there are no flashovers before arrester operation, the arrester is called

upon to discharge most of the direct stroke lightning current. The possibility of such

a situation shall be reduced by shielding the line and substation.

6.8 Grading Ring

Performance of zinc oxide arrester depends on protective levels, temporary

overvoltage and energy discharge capabilities. Temporary overvoltage and energy

handling capabilities are closely related to temperature of zinc oxide blocks, which

in turn depends on power losses

Power losses increase rapidly with voltage stress and even distribution of voltage

stress depends on influence of stray capacitance. For short arrester even distribution

of voltage stress is possible as the self capacitance of zinc oxide block is higher than

stray capacitance. However for arrester with longer height, influence of stray

capacitance makes the voltage distribution less linear. The solution to this problem is

by using external grading rings. Grading ring shall be provided for 380kV system

arresters. For other voltages if required calculation shall be provided to prove even

distribution of voltage.

TESP11906R0/KSB Date of Approval: October 16, 2006 PAGE NO. 13 OF 15

TRANSMISSION ENGINEERING STANDARD TES-P-119.06, Rev. 0

DWG TE-1906-02-00

TESP11906R0/KSB Date of Approval: October 16, 2006 PAGE NO. 14 OF 15

TRANSMISSION ENGINEERING STANDARD TES-P-119.06, Rev. 0

7.0 BIBLIOGRAPHY

1. ANSI C62.22, “ Guide for the Application of Metal Oxide Surge Arresters

for Alternating Current Systems ”

2. IEC 60099-5, Surge Arresters-Part 5: "Selection and Application

Recommendations".

3. IEEE Transactions on Power Apparatus and Systems, Vol. PAS-100, No.5,

“Thermal Stability of the Gapless Surge Arrester ” , 1981 .

4. IEEE Transactions on Power Apparatus and Systems, Vol. PAS-101, No.6, “

Application of Metal Oxide Varistor Surge Arresters on Distribution Systems

” , 1982 .

5. REA Bulletin 65-1, “Design Guide for Rural Substations”, U.S. Department

of Agriculture, 1978 .

6. Westinghouse Electric Corporation, “Electrical Transmission and

Distribution Reference Book”, Fourth Edition, Ninth Printing, Pennsylvania,

USA, 1964 .

7. Westinghouse Electric Corporation , SA 252 , “Surge Protection of Power

Systems ”.

TESP11906R0/KSB Date of Approval: October 16, 2006 PAGE NO. 15 OF 15

Вам также может понравиться

- O & M of Sub StationДокумент94 страницыO & M of Sub StationAlbert Sekar100% (2)

- SLD 02 03 17Документ1 страницаSLD 02 03 17Hari HaranОценок пока нет

- 132kv Gis SpecsДокумент29 страниц132kv Gis Specskxalxo7637100% (2)

- Tes P 119 05 R0Документ8 страницTes P 119 05 R0boopelectraОценок пока нет

- IEEE Grounding TransformersДокумент45 страницIEEE Grounding TransformersbulmoongchiОценок пока нет

- SVL SelectionДокумент32 страницыSVL SelectionJosé100% (6)

- ANSI C57.12.10 Transformers 230kv & Below PDFДокумент36 страницANSI C57.12.10 Transformers 230kv & Below PDFkannan100% (2)

- Introduction To Batteries & UPS StandardsДокумент6 страницIntroduction To Batteries & UPS StandardsMohamed EldinОценок пока нет

- Transformer SizingДокумент15 страницTransformer SizingRaj100% (1)

- ECS 11-0006 HV Insulation TestingДокумент17 страницECS 11-0006 HV Insulation TestingEzeldeen AgoryОценок пока нет

- Bay Design, Choice of Switching Schemes, Selection & Sizing of Sub-Station EquipmentДокумент52 страницыBay Design, Choice of Switching Schemes, Selection & Sizing of Sub-Station Equipmentgaurang1111100% (2)

- TES-P-119-02-R0-Basic Design AspectsДокумент29 страницTES-P-119-02-R0-Basic Design AspectsMohamed ElshafaiОценок пока нет

- O & P Setting CalculationДокумент94 страницыO & P Setting CalculationNeelakandan Masilamani67% (3)

- Gen2MR 31173Документ12 страницGen2MR 31173gtravaОценок пока нет

- Insulation Coordination in Power SystemsДокумент5 страницInsulation Coordination in Power SystemsAndrewcaesarОценок пока нет

- Grounding System For High Resistivity Limited Area Substations in Hilly Region of Himachal PradeshДокумент7 страницGrounding System For High Resistivity Limited Area Substations in Hilly Region of Himachal Pradeshostojic007Оценок пока нет

- Earthing and Lightning Protection Systems PDFДокумент88 страницEarthing and Lightning Protection Systems PDFSky LightОценок пока нет

- 132kV Cable Sizing For Ductbank in Reactor Area - R1Документ10 страниц132kV Cable Sizing For Ductbank in Reactor Area - R1Arun das100% (2)

- Technical Standards For Connectivity To The Grid (CEA)Документ14 страницTechnical Standards For Connectivity To The Grid (CEA)Sanjay RoutОценок пока нет

- Fault Current CalculationДокумент3 страницыFault Current CalculationfarhanajnОценок пока нет

- V.N PJM Design & Application of Insulation Coordination and Surge ProtectionДокумент3 страницыV.N PJM Design & Application of Insulation Coordination and Surge Protectionbkalatus1Оценок пока нет

- Resistance Grounded Systems: PurposeДокумент6 страницResistance Grounded Systems: Purposerenjithas2005Оценок пока нет

- Calculation of Induced Sheath Voltage For Transposed and Untransposed Cable ConductorsДокумент6 страницCalculation of Induced Sheath Voltage For Transposed and Untransposed Cable ConductorsPradeep PooNoorОценок пока нет

- Resistance Earthed Systems: Fault CurrentsДокумент25 страницResistance Earthed Systems: Fault CurrentsRameez Ahmed100% (1)

- Types of Neutral Earthing in Power Distribution Part 2Документ7 страницTypes of Neutral Earthing in Power Distribution Part 2shoham985Оценок пока нет

- TES-P-119-40-R0-Transformer X-R Ratio CalculationДокумент8 страницTES-P-119-40-R0-Transformer X-R Ratio CalculationZain-Ul- Abdeen100% (2)

- Estimation of Actual Maximum KVA Demand - Electrical Installation GuideДокумент2 страницыEstimation of Actual Maximum KVA Demand - Electrical Installation GuideHansika RajapakshaОценок пока нет

- 10 Insulation Co-OrdinationДокумент18 страниц10 Insulation Co-Ordinationdaegerte100% (3)

- Grounding TransformersДокумент9 страницGrounding TransformerspcelisОценок пока нет

- Typical Data Sheet Neutral Earthing ResistorДокумент2 страницыTypical Data Sheet Neutral Earthing Resistorerkamlakar2234Оценок пока нет

- As Per IEC 60071Документ22 страницыAs Per IEC 60071Saurabh Shrivastava100% (1)

- Insulation Coordination Study Report - 2019phxp0901u PDFДокумент16 страницInsulation Coordination Study Report - 2019phxp0901u PDFSudhir Ravipudi100% (1)

- Power Systems Study Specifications XXXДокумент8 страницPower Systems Study Specifications XXXharmlesdragonОценок пока нет

- QICC LV Catalogue New PDFДокумент146 страницQICC LV Catalogue New PDFSnzy DelОценок пока нет

- 132kv Malana Ekd-Section-Rev01 ModifiedДокумент1 страница132kv Malana Ekd-Section-Rev01 ModifiedannuvyasОценок пока нет

- XRRatio ABBДокумент2 страницыXRRatio ABBAshish RanjanОценок пока нет

- Presentation On Insulation CoordinationДокумент17 страницPresentation On Insulation CoordinationBhavik PrajapatiОценок пока нет

- BSF Earthing System Calculation 1Документ29 страницBSF Earthing System Calculation 1Veerasamy KarikalvalavanОценок пока нет

- Restricted Earth Fault Protection Stability & Sensitivity Test Rev01Документ9 страницRestricted Earth Fault Protection Stability & Sensitivity Test Rev01Mohamed EldinОценок пока нет

- Lightning Over Voltage Performance of 132kV GIS Substation in MalaysiaДокумент7 страницLightning Over Voltage Performance of 132kV GIS Substation in MalaysiaboopelectraОценок пока нет

- Selection of ArresterRatingsДокумент3 страницыSelection of ArresterRatingshaitpmОценок пока нет

- Cable SizingДокумент14 страницCable SizingAnupam0103Оценок пока нет

- Chap4-Insulation Coordination LatestДокумент41 страницаChap4-Insulation Coordination LatestAhmed TayehОценок пока нет

- Cable Damage CurveДокумент3 страницыCable Damage CurveMark-Honey Boquiron Delos ReyesОценок пока нет

- Schneider Tech Vol04Документ4 страницыSchneider Tech Vol04Sarah BreckenridgeОценок пока нет

- Rolling Sphere Tool Guide: I. II. IiiДокумент14 страницRolling Sphere Tool Guide: I. II. IiiRashad SarwarОценок пока нет

- TES-P-122.08 R0 - Survey Guidelines PDFДокумент11 страницTES-P-122.08 R0 - Survey Guidelines PDFMohamed EldinОценок пока нет

- Auto Grid ProДокумент101 страницаAuto Grid ProGokul Venugopal100% (1)

- Schneider Electric Cahier Technique 151Документ24 страницыSchneider Electric Cahier Technique 151Anonymous BwLfvuОценок пока нет

- Quick Guide On CDEGS CRДокумент28 страницQuick Guide On CDEGS CRrian0201100% (1)

- 2016 - SVL Connection at TerminationsДокумент8 страниц2016 - SVL Connection at Terminationseng_zidОценок пока нет

- Al Dhahiyah - DC Short Circuit Study-Rev AДокумент4 страницыAl Dhahiyah - DC Short Circuit Study-Rev ASomnath DasОценок пока нет

- Iec60071-1 (Ed8.0) en DДокумент7 страницIec60071-1 (Ed8.0) en Djbrwaf0% (1)

- KCGGДокумент12 страницKCGGkrluckОценок пока нет

- TES P 119 05 R0 Insulation CoordinationДокумент8 страницTES P 119 05 R0 Insulation CoordinationZain-Ul- AbdeenОценок пока нет

- Science 10 q4 Week 1Документ11 страницScience 10 q4 Week 1Jacqueline FabiaОценок пока нет

- Surge ArrestorДокумент15 страницSurge ArrestormichyimОценок пока нет

- Flowsheet T5-600PS-Continuous Dry Pretreatment With Bleaching - 11-Rev006Документ1 страницаFlowsheet T5-600PS-Continuous Dry Pretreatment With Bleaching - 11-Rev006tavocelyОценок пока нет

- 35-sdms-01 Rev.01Документ14 страниц35-sdms-01 Rev.01Mohammad FathiОценок пока нет

- Cymcap 6.1Документ37 страницCymcap 6.1daegerte0% (1)

- Winigs ReportДокумент15 страницWinigs ReportkrcdewanewОценок пока нет

- EE 741 System ProtectionДокумент25 страницEE 741 System ProtectionReymart ManablugОценок пока нет

- Circuit Breaker Ratings - A Primer For Protection EngineersДокумент13 страницCircuit Breaker Ratings - A Primer For Protection EngineersAlberto José Bermúdez AriasОценок пока нет

- IRXm Product GuideДокумент8 страницIRXm Product Guidedeepak2628Оценок пока нет

- Roc App B Tov ReportДокумент8 страницRoc App B Tov Reporthino_kaguОценок пока нет

- Product Information DIGSI4 V4.94Документ54 страницыProduct Information DIGSI4 V4.94PollОценок пока нет

- 2 - SVERKER-750-780 ManualДокумент76 страниц2 - SVERKER-750-780 ManualMohamed EldinОценок пока нет

- Product Information DIGSI4 V4.94Документ54 страницыProduct Information DIGSI4 V4.94PollОценок пока нет

- Product Information DIGSI4 V4.94Документ54 страницыProduct Information DIGSI4 V4.94PollОценок пока нет

- Product Information DIGSI4 V4.94Документ54 страницыProduct Information DIGSI4 V4.94PollОценок пока нет

- Product Information DIGSI4 V4.94Документ54 страницыProduct Information DIGSI4 V4.94PollОценок пока нет

- TP-NG-6460-002-004 Repeated Punch List Rev01Документ1 страницаTP-NG-6460-002-004 Repeated Punch List Rev01Mohamed EldinОценок пока нет

- Miniature Circuit Breaker S 200 M UC For DC and AC ApplicationsДокумент16 страницMiniature Circuit Breaker S 200 M UC For DC and AC ApplicationsMohamed EldinОценок пока нет

- DanielJacobs QuestionsДокумент79 страницDanielJacobs QuestionsJimena MedinaОценок пока нет

- MWДокумент4 страницыMWHtoo Eain LwinОценок пока нет

- Assignment No. 4 - 2020-21 PDFДокумент2 страницыAssignment No. 4 - 2020-21 PDFnikhil khanwaniОценок пока нет

- Solved 2024 Specimen Paper ICSE Class 10 ChemistryДокумент11 страницSolved 2024 Specimen Paper ICSE Class 10 ChemistrymmroyalethegreatОценок пока нет

- Computational Fluid Dynamics Analysis of Greenhouse Solar DryerДокумент19 страницComputational Fluid Dynamics Analysis of Greenhouse Solar DryerPurusothamanManiОценок пока нет

- Samsung CAC Duct S Brochure 20140729 0Документ16 страницSamsung CAC Duct S Brochure 20140729 0Callany AnycallОценок пока нет

- Lesson 8 Shear or Diagonal Tension in RC BeamsДокумент8 страницLesson 8 Shear or Diagonal Tension in RC BeamsJoshua John JulioОценок пока нет

- Hempadur 15130Документ2 страницыHempadur 15130MuthuKumarОценок пока нет

- CMT Lec&lab Notes PrelimДокумент18 страницCMT Lec&lab Notes PrelimPrincess Ela Mae CatibogОценок пока нет

- Pryda Bracing Design Guide 2022Документ32 страницыPryda Bracing Design Guide 2022benjaminsigabalavuОценок пока нет

- Presentation - Company Products - Eng (June 2012)Документ11 страницPresentation - Company Products - Eng (June 2012)Ricky Ocktavi RizkyОценок пока нет

- Form 2 Math Chapter 10Документ4 страницыForm 2 Math Chapter 10velavanОценок пока нет

- Single Core Unarmoured LV CablesДокумент1 страницаSingle Core Unarmoured LV CablesPrashanth ShastryОценок пока нет

- Sch4uc PTДокумент15 страницSch4uc PTMarwan MohamudОценок пока нет

- Edited and Compiled By: Haramaya University College of Natural and Computational Sciences Department of ChemistryДокумент158 страницEdited and Compiled By: Haramaya University College of Natural and Computational Sciences Department of Chemistrygetaneh achenifОценок пока нет

- D38999/24WD35S N D38999/20WB35S N D38999/24WB35S N D38999/26WB35P N D38999/26WC35P NДокумент49 страницD38999/24WD35S N D38999/20WB35S N D38999/24WB35S N D38999/26WB35P N D38999/26WC35P NsdfsdfОценок пока нет

- Chapter 4-Behavior Evaluation of Vehicule Materials-Lecture 2Документ44 страницыChapter 4-Behavior Evaluation of Vehicule Materials-Lecture 2roy barmoОценок пока нет

- MD Product Catalogue PROXIMITY ENGДокумент194 страницыMD Product Catalogue PROXIMITY ENGETIENNEОценок пока нет

- Dr. Fixit Prebond: Hdpe Pre Applied Fully Bonded MembraneДокумент3 страницыDr. Fixit Prebond: Hdpe Pre Applied Fully Bonded Membranevelmurug_balaОценок пока нет

- Huygens' Principle, Maxwell's Displacement CurrentДокумент7 страницHuygens' Principle, Maxwell's Displacement CurrentGalleta Galleta MetralletaОценок пока нет

- Data Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1CV3407B Simotics SD Pro - 400 - Im B3 - 4PДокумент2 страницыData Sheet For Three-Phase Squirrel-Cage-Motors SIMOTICS: Motor Type: 1CV3407B Simotics SD Pro - 400 - Im B3 - 4Pnadia perezОценок пока нет

- New Radar Technology 8 500-10 500 MHZ BandДокумент18 страницNew Radar Technology 8 500-10 500 MHZ BandChinmaya_Mishr_4215Оценок пока нет

- Laminar Flow ManualДокумент16 страницLaminar Flow ManualJOSHUA KETERОценок пока нет

- Neet 2021 Physics Paper With SolutionДокумент13 страницNeet 2021 Physics Paper With SolutionAnilОценок пока нет

- Gravitation: PSI AP B PhysicsДокумент8 страницGravitation: PSI AP B PhysicscjОценок пока нет

- TM1016 Free Forced Vibrations Datasheet 0417Документ3 страницыTM1016 Free Forced Vibrations Datasheet 0417Thiri AungОценок пока нет

- Voltage Fed Full Bridge DC-DC and DC-AC Converter For High-Frequency Inverter Using C2000Документ17 страницVoltage Fed Full Bridge DC-DC and DC-AC Converter For High-Frequency Inverter Using C2000Afonso HoversОценок пока нет