Академический Документы

Профессиональный Документы

Культура Документы

HRU Unit Base Working Final

Загружено:

Manish Gautam0 оценок0% нашли этот документ полезным (0 голосов)

24 просмотров8 страницОригинальное название

HRU Unit base working final

Авторское право

© © All Rights Reserved

Доступные форматы

XLSX, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате XLSX, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

24 просмотров8 страницHRU Unit Base Working Final

Загружено:

Manish GautamАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате XLSX, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 8

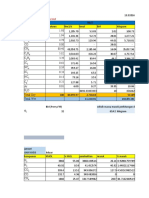

Total Purge gas flow Nm3/hr 8000

Total Feed gas to HRU Nm3/hr 7606.4

Total H2 in purge gas kgmoles/hr 216.65

Total H2 rich gas flow % 56.39

Total H2 rich gas recovered kgmoles/hr 191.37

Total Tail gas kgmoles/hr 147.99

Total H2 recovery % 83

Total NG equivalent to purge NM3/hr 2379

Total NG equivalent to tail gas NM3/hr 1106

3

Increase in NG Fuel gas for Primary reformer heat duty NM /hr 1272

Ammonia production equivalent to H2 MT/hr 2.04

Air required equivalent to H2 NM3/hr 1514.43

Current Air compressor power kW 4801.10

Current Air Flow NM3/hr 28000.00

Increase in Air compressor power kW 259.68

Total power required to pump DM water kW 21.06

Heat duty to heat purge gas Gcal/hr 0.04

Ammonia plant specific energy consumption Gcal/MT 9.376

Average ammonia production MTD 668

Ammonia plant specific energy consumption with HRU 9.133

Energy Saving Gcal/MT 0.24

Dry gas Analysis

Purge gas Purge gas H2 rich gas Tail Gas

CH4 11.51 12.11 1.50 25.82 184.6319

H2 60.7 63.84 93.80 25.1 122.3712

Ar 2.37 2.49 1.00 4.42 94.8

N2 20.5 21.56 3.70 44.66 574.328

NH3 4.92 0.00 0.00 0.00 83.79252

M.W. 10.58 10.25 3.55 18.91 1059.924

Total 100 100 100.00 100

Volumetric Flow rate

CH4 921 921 64 856

H2 4856 4856 4023 833

Ar 190 190 43 147

N2 1640 1640 159 1481

NH3 394 0 0 0

Total 8000 7606 4289 3317

Mass Flow rate

CH4 17.42 18.91 6.74 21.88

H2 11.55 12.54 53.00 2.67

Ar 8.94 9.71 11.21 9.34

N2 54.19 58.84 29.05 66.10

NH3 7.91 0.00 0.00 0.00

Total 100.00 100.00 100.00 100.00

GCV (kcal/kg) 6653.56 6763.70 18882.06 3809.62

NCV (kcal/kg)) 5738.78 5849.84 15975.78 3381.46

GCV(kcal/Nm3) 3140.7 3092.4 2992.3 3213.4

NCV (kcal/Nm3) 2708.9 2674.6 2531.7 2852.2

194.1859 24.0615 414.1786

128.7034 189.1008 50.6016

99.70551 40 176.8

604.0471 103.6592 1251.195

0 0 0

1026.642 356.8215 1892.775

`

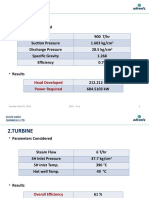

Inlet pressure of membrane 110

Outlet pressure of membrane 26

Selectivity 100

Inlet concentration of gas 100 70 99.0 Y2 + -396 Y + 296

Assuming volume of gas 85.40825 65 99.0 Y2 + -375 Y + 275

74.4719 60 99.0 Y2 + -355 Y + 254

65.96435 55 99.0 Y2 + -334 Y + 233

59.1494 50 99.0 Y2 + -313 Y + 212

53.55672 45 99.0 Y2 + -292 Y + 190

48.86872 40 99.0 Y2 + -271 Y + 169

44.85675 35 99.0 Y2 + -250 Y + 148

41.33725 30 99.0 Y2 + -229 Y + 127

38.12622 25 99.0 Y2 + -208 Y + 106

34.98995 20 99.0 Y2 + -187 Y + 85

31.62667 15 99.0 Y2 + -166 Y + 63

27.62592 10 99.0 Y2 + -145 Y + 42

5 99.0 Y2 + -124 Y + 21

Solution 2

Y Yaverage permeate H2 in permTotal H2 Total permeate

= 0 0.99 0.99 14.59 14.48 14.48 14.59

= 0 0.99 0.99 10.94 10.83 25.32 25.53

= 0 0.99 0.99 8.51 8.40 33.72 34.04

= 0 0.99 0.98 6.81 6.71 40.43 40.85

= 0 0.98 0.98 5.59 5.47 45.90 46.44

= 0 0.98 0.97 4.69 4.55 50.45 51.13

= 0 0.97 0.96 4.01 3.85 54.30 55.14

= 0 0.95 0.94 3.52 3.30 57.60 58.66

= 0 0.92 0.89 3.21 2.87 60.47 61.87

= 0 0.86 0.81 3.14 2.53 63.00 65.01

= 0 0.75 0.67 3.36 2.25 65.26 68.37

= 0 0.59 0.50 4.00 1.98 67.24 72.37

= 0 0.40 0.30 5.47 1.65 68.89 77.85

= 0 0.20 0.10 0.00 0.00 77.85

% recovery

20.69

36.17

48.17

57.75

65.57

72.08

77.57

82.28

86.38

90.00

93.22

96.05

98.42

0.00

DM water pump

Total DM water flow MT/hr 4.50

suction pressure 7.00

discharge pressure 130.00

Difference kg/cm2 123.00

M.W. 18.02

density kg/m3 954.00

O

Pumping temperature C 42.00

Volume of the flue gas m3/hr 4.72

Head m 1289.31

Power required kW 15.79

Pump Efficiency 75

Exact Power required kW 21.06

Heat duty for heating purge gas

Total purge gas flow Nm3/hr 7606.4 CH4

Inlet temperature of purge gas O

C 42 H2

O

Outlet temperature of purge gas C 60 Ar

Heat capacity of purge gas Kcal/kgmoleOC 7.03358 N2

Heat duty required Gcal/hr 0.042964 NH3

4.13 4.45 4.290583 51.94006

6.65 6.67 6.66131 425.2645

4.80 4.80 4.8 11.96466

11.07 8.80 9.934176 214.1887

6.30 6.46 6.377023 0

7.03358

Вам также может понравиться

- Rich Gas and Lean GasДокумент7 страницRich Gas and Lean GasManish GautamОценок пока нет

- Jumadiao, Yra Marielle M. Exercise 9: Heat Balance and Theoretical Flame Temperature GivenДокумент4 страницыJumadiao, Yra Marielle M. Exercise 9: Heat Balance and Theoretical Flame Temperature GivenJanelle M. JumadiaoОценок пока нет

- Merged Heat BalanceДокумент56 страницMerged Heat Balancehmaza shakeel100% (2)

- Line I Heat BalanceДокумент60 страницLine I Heat Balancehmaza shakeelОценок пока нет

- DCM PFD CalculationДокумент8 страницDCM PFD CalculationManish GautamОценок пока нет

- Physical Properties of Fluids: EN IXДокумент13 страницPhysical Properties of Fluids: EN IXDiego PardoОценок пока нет

- 01 MCC Cyl Trial Calculated-1Документ270 страниц01 MCC Cyl Trial Calculated-1nps1966Оценок пока нет

- Final PDF PipeДокумент9 страницFinal PDF PipeRowena BatalunaОценок пока нет

- NerpanДокумент27 страницNerpanRoni SetiawanОценок пока нет

- Ammona Plant Parameters CO2 BalanceДокумент16 страницAmmona Plant Parameters CO2 BalanceManish Gautam0% (1)

- New GC CalibrationДокумент159 страницNew GC Calibrationapi-3728640Оценок пока нет

- New GC CalibrationДокумент110 страницNew GC Calibrationapi-3728640Оценок пока нет

- Material and Energy Balance of Urea Reactor and Stripper Saipem ProcessДокумент20 страницMaterial and Energy Balance of Urea Reactor and Stripper Saipem ProcessBalas43100% (1)

- The Individual Gas Constant For GasesДокумент3 страницыThe Individual Gas Constant For Gasesjohn carloОценок пока нет

- Steam Reformer Mass and Energy Balance - Thermo DataДокумент5 страницSteam Reformer Mass and Energy Balance - Thermo Datau2051721Оценок пока нет

- Adiabatic Flame TemperatureДокумент4 страницыAdiabatic Flame TemperatureAdi CahyonoОценок пока нет

- Perhitungan BB Cangkang Kelapa Sawit YeayДокумент24 страницыPerhitungan BB Cangkang Kelapa Sawit YeayBillyRadianОценок пока нет

- Netralizer Koil JozДокумент44 страницыNetralizer Koil JozPradika WibowoОценок пока нет

- Raw Mill-Ball Mill Heat BalanceДокумент16 страницRaw Mill-Ball Mill Heat BalanceAbhishekОценок пока нет

- Fuels - Higher and Lower Calorific ValuesДокумент3 страницыFuels - Higher and Lower Calorific Valuesjohn100% (1)

- NM MantappisanДокумент224 страницыNM MantappisanRisky Andi0% (1)

- Comprehensive Problem: Laurito, E. R. (N.D.) - Stoichiometry of Fuel Combustion andДокумент20 страницComprehensive Problem: Laurito, E. R. (N.D.) - Stoichiometry of Fuel Combustion andVilma GaelaОценок пока нет

- Tugas Khusus Ammonia Primary Reformer (Aktual) Tugas KhususДокумент224 страницыTugas Khusus Ammonia Primary Reformer (Aktual) Tugas KhususRafi Theda PrabawaОценок пока нет

- Material and Energy BalanceДокумент8 страницMaterial and Energy BalanceSatyamGuptaОценок пока нет

- Tabel DeltaH StandarДокумент10 страницTabel DeltaH StandarPuput NurlizanОценок пока нет

- Solvent SteamДокумент3 страницыSolvent SteamvikeshkharvaОценок пока нет

- Tablas TermodinámicasДокумент9 страницTablas Termodinámicas8monsalve9Оценок пока нет

- Property Tables and Charts (Si Units) With Conversion FactorsДокумент24 страницыProperty Tables and Charts (Si Units) With Conversion Factorsnur hananiОценок пока нет

- Çengel - Thermodynamics (An Engineering Approach) 8th Ed (TABELAS) PDFДокумент91 страницаÇengel - Thermodynamics (An Engineering Approach) 8th Ed (TABELAS) PDFJorge Vieira100% (2)

- This Is Dumb 2Документ3 страницыThis Is Dumb 2Jacob ForscytheОценок пока нет

- PH Diagram: Diagram On The Right SideДокумент13 страницPH Diagram: Diagram On The Right SideAllyzon Mejia100% (1)

- Gas Condensate PVT Analysis Workbook: Written by Robert Mott, August 2003Документ43 страницыGas Condensate PVT Analysis Workbook: Written by Robert Mott, August 2003Mario HuasasquicheОценок пока нет

- Gas Liquid Separator DesignДокумент3 страницыGas Liquid Separator DesignSoheil MoradiОценок пока нет

- Debut An IzerДокумент42 страницыDebut An IzerRizadz AhmadОценок пока нет

- HMB 1Документ3 страницыHMB 1Besan LaduОценок пока нет

- HSN7471-75 R449A t0 - 35 TC 45Документ2 страницыHSN7471-75 R449A t0 - 35 TC 45KritsdaОценок пока нет

- Efficiency Boiler TrueДокумент12 страницEfficiency Boiler TruesamsОценок пока нет

- Main Combustion ChamberДокумент31 страницаMain Combustion Chambershaliq28Оценок пока нет

- Ideal Gas ConversionДокумент5 страницIdeal Gas ConversionpsaayoОценок пока нет

- Water Quality in ThailandДокумент5 страницWater Quality in ThailandpsaayoОценок пока нет

- Garbage IncineratorДокумент59 страницGarbage IncineratorgsdaundhОценок пока нет

- Mass ConverterДокумент18 страницMass ConverterDinesh CR7Оценок пока нет

- Furnace Design and Operation: FuelsДокумент23 страницыFurnace Design and Operation: FuelskINGОценок пока нет

- Given: Problem:: (Blank) (Blank) (Blank)Документ9 страницGiven: Problem:: (Blank) (Blank) (Blank)John Michael PioquintoОценок пока нет

- Calculo HP K-60 AbДокумент23 страницыCalculo HP K-60 Abgustavo barbozaОценок пока нет

- Appendix B PrintsДокумент27 страницAppendix B PrintsRahmandaniDwiCahyaОценок пока нет

- Validation FolderДокумент2 страницыValidation FolderPriyabrata RoyОценок пока нет

- Lee2014 Ie500110v Si 001Документ3 страницыLee2014 Ie500110v Si 001Bidesh M KirtaniaОценок пока нет

- Condensate Recovery From Gas CompositionДокумент43 страницыCondensate Recovery From Gas Compositionmakasad26Оценок пока нет

- Fertial Arzew Plant2Документ5 страницFertial Arzew Plant2Azee TitouОценок пока нет

- Ring Farem CalculatorДокумент6 страницRing Farem CalculatorRajendra ShuklaОценок пока нет

- 5 OutlputДокумент55 страниц5 Outlputnps1966Оценок пока нет

- Hexamine 1Документ66 страницHexamine 1Pradhita Ramdani HОценок пока нет

- Datos TermodinamicosДокумент9 страницDatos TermodinamicosNoelithaa Melendez AranibarОценок пока нет

- 15-12-2009 Blr#1effДокумент5 страниц15-12-2009 Blr#1effpulakjaiswal85Оценок пока нет

- (°C) (°C) (°C) (°C) : Tabel Hasil PraktikumДокумент31 страница(°C) (°C) (°C) (°C) : Tabel Hasil Praktikumraka afriantoОценок пока нет

- Temperature 320: C C C Bar M /mol KG/M atДокумент52 страницыTemperature 320: C C C Bar M /mol KG/M atJosé CarlosОценок пока нет

- Vessel'S Midnight Ullage ReportДокумент31 страницаVessel'S Midnight Ullage ReportnawhiОценок пока нет

- Production of Lime: Chemical Engineering DepartmentДокумент17 страницProduction of Lime: Chemical Engineering DepartmentDon Aries EidosОценок пока нет

- Energy Saving CalculationДокумент2 страницыEnergy Saving CalculationManish GautamОценок пока нет

- AKXA Tech - Audit Services Offer - 272 - DCM Fert - 06 Jul 2021Документ2 страницыAKXA Tech - Audit Services Offer - 272 - DCM Fert - 06 Jul 2021Manish GautamОценок пока нет

- Methanator Data - 1 Min - 03.12.2021Документ58 страницMethanator Data - 1 Min - 03.12.2021Manish GautamОценок пока нет

- Metahnator Data 26.12.2021Документ116 страницMetahnator Data 26.12.2021Manish GautamОценок пока нет

- Piping and Instrumentation For Process Industries MSMДокумент21 страницаPiping and Instrumentation For Process Industries MSMLuttpiОценок пока нет

- Ammonia Plant Simulation 25.08.2016Документ81 страницаAmmonia Plant Simulation 25.08.2016Manish Gautam100% (1)

- Regenerator Shut Down ReportДокумент2 страницыRegenerator Shut Down ReportManish GautamОценок пока нет

- Short Note On Capex ModificationДокумент2 страницыShort Note On Capex ModificationManish GautamОценок пока нет

- Manoj Bhargav Suggestion PDFДокумент1 страницаManoj Bhargav Suggestion PDFManish GautamОценок пока нет

- Ammona Plant Parameters CO2 BalanceДокумент16 страницAmmona Plant Parameters CO2 BalanceManish Gautam0% (1)

- Syn CompressorДокумент23 страницыSyn CompressorManish GautamОценок пока нет

- Sop Covid 19 - 12.04.21Документ53 страницыSop Covid 19 - 12.04.21Manish GautamОценок пока нет

- Manish Gautam-Scheme 1Документ1 страницаManish Gautam-Scheme 1Manish GautamОценок пока нет

- CO2 Removal From Air StrippingДокумент2 страницыCO2 Removal From Air StrippingManish GautamОценок пока нет

- Stock AnalysisДокумент16 страницStock AnalysisManish GautamОценок пока нет

- Reflux Preheater Fluid Allocation Shell Side Tube Side Fluid Name Fuild Quantity Liquid Vapor Water K COДокумент1 страницаReflux Preheater Fluid Allocation Shell Side Tube Side Fluid Name Fuild Quantity Liquid Vapor Water K COManish GautamОценок пока нет

- Alarm Management - Ammonia Plants Experience in Improving Alarm Systems With Focus On Process and Human FactorsДокумент12 страницAlarm Management - Ammonia Plants Experience in Improving Alarm Systems With Focus On Process and Human FactorsManish GautamОценок пока нет

- Effect of Primary Reformer Steam To Carbon Ratio On Ammonia Plant EfficiencyДокумент2 страницыEffect of Primary Reformer Steam To Carbon Ratio On Ammonia Plant EfficiencyManish GautamОценок пока нет

- Impact of SC On Specific EnergyДокумент33 страницыImpact of SC On Specific EnergyManish GautamОценок пока нет

- Irrigation Cooler Cooling Water Isolation ValvesДокумент2 страницыIrrigation Cooler Cooling Water Isolation ValvesManish GautamОценок пока нет

- CO2 Removal From Air StrippingДокумент2 страницыCO2 Removal From Air StrippingManish Gautam100% (1)

- Reflux Preheater Fluid Allocation Shell Side Tube Side Fluid Name Fuild Quantity Liquid Vapor Water K COДокумент1 страницаReflux Preheater Fluid Allocation Shell Side Tube Side Fluid Name Fuild Quantity Liquid Vapor Water K COManish GautamОценок пока нет

- Regenerator Shut Down ReportДокумент2 страницыRegenerator Shut Down ReportManish GautamОценок пока нет

- Ammonia Plant Simulation 25.08.2016Документ81 страницаAmmonia Plant Simulation 25.08.2016Manish GautamОценок пока нет

- Explosive Limits CalculationДокумент3 страницыExplosive Limits CalculationManish GautamОценок пока нет

- Bank Nifty Option Strategies BookletДокумент28 страницBank Nifty Option Strategies BookletMohit Jhanjee100% (1)

- Ammonia Plant Simulation 25.08.2016Документ81 страницаAmmonia Plant Simulation 25.08.2016Manish GautamОценок пока нет

- AcknowledgementДокумент6 страницAcknowledgementAjay s NairОценок пока нет

- PP ManualДокумент50 страницPP ManualMohammad RehmanОценок пока нет

- Class 11 Chemistry Revision Notes EquilibriumДокумент14 страницClass 11 Chemistry Revision Notes EquilibriumSwastika DasОценок пока нет

- Design and Operation of Double Pipe Heat Exchanger: February 2017Документ27 страницDesign and Operation of Double Pipe Heat Exchanger: February 2017tasosОценок пока нет

- Thermodynamics of H2-Bonding Mixtures. 5. GE, HE, and TSE and Zeotropy of Water + Acrylic Acid PDFДокумент5 страницThermodynamics of H2-Bonding Mixtures. 5. GE, HE, and TSE and Zeotropy of Water + Acrylic Acid PDFmurdanetap957Оценок пока нет

- Analytical Chemistry-2: Action of Alkali On Certain MetalsДокумент3 страницыAnalytical Chemistry-2: Action of Alkali On Certain MetalsManju YadavОценок пока нет

- Module J: Rubbers As Entropic Springs Example of A Silicone RubberДокумент37 страницModule J: Rubbers As Entropic Springs Example of A Silicone RubberJohn McLovenОценок пока нет

- Presentation On Wave Behavior: Marquez Heron Dondre SaveryДокумент10 страницPresentation On Wave Behavior: Marquez Heron Dondre SaveryMARQUEZ HERONОценок пока нет

- New Microsoft Office Word DocumentДокумент7 страницNew Microsoft Office Word DocumentsandipkadoliОценок пока нет

- Experiment 1: Crystallization of Impure Acetanilide ObjectiveДокумент4 страницыExperiment 1: Crystallization of Impure Acetanilide ObjectiveEZLYEN AZLINОценок пока нет

- Chemical Bonding - Multiple Choice QuestionsДокумент12 страницChemical Bonding - Multiple Choice QuestionsOmSilence2651Оценок пока нет

- Speciality PolymersДокумент63 страницыSpeciality PolymersChini ChineeОценок пока нет

- Solubilizing Excipients in Oral and Injectable Formulations-REVIEW-VERY IMPORTANTДокумент30 страницSolubilizing Excipients in Oral and Injectable Formulations-REVIEW-VERY IMPORTANTraju1559405Оценок пока нет

- 1.TareaParticipacion 2do - ParcialДокумент19 страниц1.TareaParticipacion 2do - ParcialLeonardo EstradaОценок пока нет

- 5 Lesson Plan On HeatДокумент4 страницы5 Lesson Plan On HeatJustine Collamar GanabОценок пока нет

- Lesson 3: Maximizing Entropy: Notes From Prof. Susskind Video Lectures Publicly Available On YoutubeДокумент56 страницLesson 3: Maximizing Entropy: Notes From Prof. Susskind Video Lectures Publicly Available On YoutubeCanan OrtayОценок пока нет

- Evaporator - Printout On Article No.: SWEP International AB Box 105, Hjalmar Brantings Väg 5 SE-261 22 Landskrona, SwedenДокумент3 страницыEvaporator - Printout On Article No.: SWEP International AB Box 105, Hjalmar Brantings Väg 5 SE-261 22 Landskrona, SwedenJОценок пока нет

- Chapter 6Документ27 страницChapter 6Pranavhari T.N.Оценок пока нет

- Tutorial CondensationДокумент5 страницTutorial CondensationKusmakarОценок пока нет

- Cathodic Protection - Wikipedia PDFДокумент62 страницыCathodic Protection - Wikipedia PDFSiddhartha Archana SharmaОценок пока нет

- Sequencing of Separation Columns: Direct Sequence Indirect SequenceДокумент18 страницSequencing of Separation Columns: Direct Sequence Indirect SequenceVidvendu GuptaОценок пока нет

- 20-06 - Valvestar - Training Examples PDFДокумент18 страниц20-06 - Valvestar - Training Examples PDFJoyОценок пока нет

- Class 10 Activitys ChemДокумент4 страницыClass 10 Activitys Chemvetha cОценок пока нет

- Test3 Ch17b Buffer Titration Equilibrium Practice Problems Answers Full 2015Документ18 страницTest3 Ch17b Buffer Titration Equilibrium Practice Problems Answers Full 2015Anas SaadОценок пока нет

- Lab Sheet Air Conditioning (Perfect Gas)Документ8 страницLab Sheet Air Conditioning (Perfect Gas)JIJENDERKUMAR A/L VIJAYAN MoeОценок пока нет

- Green ChemistryДокумент14 страницGreen ChemistryMincen RevaОценок пока нет

- Polymer PhysicsДокумент405 страницPolymer PhysicsPurushothaman100% (6)

- Solution Manual For Fluid Mechanics 1St Edition by Hibbeler Isbn 0132777622 9780132777629 Full Chapter PDFДокумент30 страницSolution Manual For Fluid Mechanics 1St Edition by Hibbeler Isbn 0132777622 9780132777629 Full Chapter PDFscott.fischer352100% (9)

- A Level Chemistry Paper 2 Exam 10Документ4 страницыA Level Chemistry Paper 2 Exam 10Anthony AndyОценок пока нет

- Radiation Crosslinking of Polyamide 610Документ4 страницыRadiation Crosslinking of Polyamide 610ecclesiОценок пока нет