Академический Документы

Профессиональный Документы

Культура Документы

Metal Buttons Making Process

Загружено:

Zain Ali KidwaiАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Metal Buttons Making Process

Загружено:

Zain Ali KidwaiАвторское право:

Доступные форматы

Metal Buttons Making Process.

Metal buttons are manufactured using following process.

1) Material Selection.

Material Selection in button making is an important factor. Metal buttons are one of the most popular

buttons due to their surface finish, durability and decorative function. Based on the manufacturing

materials, metal buttons can be further grouped into:

1.1) Zinc Alloy Buttons.

1.2) Brass Alloy Buttons

Zinc alloy buttons and brass buttons are two of the most commonly available metal buttons on the

market. Stainless steel buttons are also popular due to their lower chances rusting as compared with the

zinc alloy buttons and brass buttons. Aluminum buttons that can achieve special effects are also

available on the market. However, iron buttons whose surface is susceptible to rusting and corruption

are seldom used.

The most Common used metal buttons are of Zinc Alloy buttons and

Brass Alloy buttons.

1.1) Zinc Alloy Buttons

Zinc alloy buttons are generally manufactured out of 5# zinc alloy (ZAMAK 5),

which is majorly comprised of zinc and aluminum. These buttons will go

through the polishing treatment following the die-casting process, which

removes the burr along the button edges or in the holes and takes care of the

surface that is not smooth before they are subjected to the electroplating

process.

2) Button Manufacturing Processes

There are two type button manufacturing Processes.

2.1) Die Casting Process.

2.2) Stamping Process.

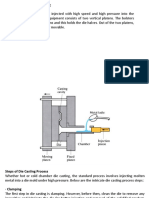

2.1) Die Casting Process.

Die casting is a manufacturing process that can

produce geometrically complex metal parts through

the use of reusable molds, called dies. The die casting

process involves the use of a furnace, metal, die

casting machine, and die. The metal, typically a non-

ferrous alloy such as aluminum or zinc, is melted in the furnace and then injected into the dies in the die

casting machine. There are two main types of die casting machines - hot chamber machines (used for

alloys with low melting temperatures, such as zinc) and cold chamber machines (used for alloys with

high melting temperatures, such as aluminum).

Production process: making mould – die casting – trimming burrs – polishing – surface treatment –

assembly – quality inspection – packaging and delivery.

2.2) Stamping Process.

Stamping process takes advantage of the plastic deformation and elastic ability of some metal materials

like copper, iron and aluminum. Metal materials will be transformed into the required shape by press

machine through pressing and punching, the state of which will not be changed during the whole

manufacturing process.

Production process: making mould – cutting raw material into strips – stamping – surface treatment –

assembly – quality inspection – packaging and delivery.

3) Alloy Button Making Procedure via Die Casting.

Step No 1: Set the dice (male part and female part) on Die Casting Machine dice holder by nut bolt and

mold setting instrument.

Step No 2: Keep the Zinc bar/ Brass Bar to the heating place of the machine. Then heat the machine at

900 degree centigrade electrically. The Zn Bar will melt at that temperature.

Step No 3: When the machine start both the part of dice closed and a nozzle push push melted Zn to

inside the dice with high pressure. The melted metal is poured into dice runner and gates.

The cycle time for pouring metal into dice depends on how many core are made in dice, and

thickness of button. Usually, the cycle time is 10 to 15 seconds. Each dice have multiple

core depending on Alloy Button sizes.

Step No 4: Now need to check the button quality after taking the button from separator/roller machine.

Automatic button sorting machine can be used for quality check or we can check the quality

manually.

Step No 5: Button coloring: After quality checking we need to send the button for electroplating bath as per

buyer require color.

Step No 6: After electroplating, again the quality of the alloy buttons is inspected following the standard

sample.

Step No 7: The inspected buttons are weighted and packed into poly bags. These packed alloy buttons

are ready for shipment or supply.

Вам также может понравиться

- Insulation GuideДокумент48 страницInsulation Guideguadalupe_cortes_21Оценок пока нет

- Economic Evaluation of ISO 2859 Acceptance SamplinДокумент37 страницEconomic Evaluation of ISO 2859 Acceptance SamplinSupriya RaiОценок пока нет

- Classification of Processes and Flow Chart of Foundry OperationsДокумент1 страницаClassification of Processes and Flow Chart of Foundry Operationsmann20Оценок пока нет

- Pre Construction ActivitiesДокумент1 страницаPre Construction ActivitiesrahulОценок пока нет

- MDCC Format PGCILДокумент1 страницаMDCC Format PGCILMayavan AОценок пока нет

- Woojin Plaimm Injection Molding MachineДокумент10 страницWoojin Plaimm Injection Molding MachineFauzi IskandarОценок пока нет

- F& F LAB MANUALДокумент18 страницF& F LAB MANUALJagdish Singh MehtaОценок пока нет

- V3I2IJERTV3IS21239Документ5 страницV3I2IJERTV3IS21239erwindОценок пока нет

- Material SelectionДокумент60 страницMaterial SelectionKhoa Nguyễn AnhОценок пока нет

- M - I U - 1 C P: Anufacturing Processes NIT Asting RocessesДокумент246 страницM - I U - 1 C P: Anufacturing Processes NIT Asting RocessesMahesh SalotagiОценок пока нет

- Yield of Micro FabricationДокумент5 страницYield of Micro FabricationCindy JinОценок пока нет

- SOP-FES-10 Robbery Theft Vandalism Fire Violent CustomersДокумент5 страницSOP-FES-10 Robbery Theft Vandalism Fire Violent CustomersvikramОценок пока нет

- Dis 6 W 2 HДокумент14 страницDis 6 W 2 HBalachandar SathananthanОценок пока нет

- 10 MovementДокумент26 страниц10 MovementjvanandhОценок пока нет

- Chlorokote Data Sheet and Selection GuideДокумент45 страницChlorokote Data Sheet and Selection GuideShaswat AcharyaОценок пока нет

- Wave Solder TaguchiДокумент6 страницWave Solder TaguchivictoreaОценок пока нет

- Review COSДокумент9 страницReview COSSergio AndresОценок пока нет

- Quality Inspection Assurance System - : Supplier ManagementДокумент2 страницыQuality Inspection Assurance System - : Supplier ManagementMURALIDHRA100% (1)

- Investment Casting: Expendable Mould and PatternДокумент44 страницыInvestment Casting: Expendable Mould and PatternRajumhaveri HaveriОценок пока нет

- ICAT SOP AIS - 137 - 2-Wheeler PDFДокумент325 страницICAT SOP AIS - 137 - 2-Wheeler PDFTushar Ballabh BMLОценок пока нет

- 1) Alloy Button Making Procedure Via Die CastingДокумент1 страница1) Alloy Button Making Procedure Via Die CastingZain Ali KidwaiОценок пока нет

- Report On Material Used For Making Dies For Pressure Die Casting of Alluminium Alloys.2Документ21 страницаReport On Material Used For Making Dies For Pressure Die Casting of Alluminium Alloys.2Maroof Alam100% (2)

- Metal Stamping Dies - Part One - KEY To METALS ArticleДокумент3 страницыMetal Stamping Dies - Part One - KEY To METALS Articlekumarpankaj030Оценок пока нет

- Table of ContentДокумент18 страницTable of ContentHung BuiОценок пока нет

- Manufacturing Processes For Sheetmeatl PartsДокумент2 страницыManufacturing Processes For Sheetmeatl Partsrohan zagadeОценок пока нет

- Transmission Linkages: Universidad Autónoma Del Estado de México Facultad de IngenieríaДокумент19 страницTransmission Linkages: Universidad Autónoma Del Estado de México Facultad de IngenieríaPanchitou OuuОценок пока нет

- Pressure Die-CastingДокумент12 страницPressure Die-CastingAyush PandeyОценок пока нет

- Dr. Babasaheb Ambedkar Technological University, LonereДокумент36 страницDr. Babasaheb Ambedkar Technological University, LonereNikhil PawarОценок пока нет

- 1.6.1 Die Casting (Pressure Die Casting) : Module-I of Manufacturing Science-IДокумент8 страниц1.6.1 Die Casting (Pressure Die Casting) : Module-I of Manufacturing Science-IChinmay Das100% (2)

- IC Learning Series 2013 - Sheet Metal FabricationДокумент19 страницIC Learning Series 2013 - Sheet Metal FabricationnskumarmОценок пока нет

- Press Tool Operation and FunctionsДокумент25 страницPress Tool Operation and Functionsjagan89% (9)

- Metal Stamping DiesДокумент7 страницMetal Stamping DiesedpsousaОценок пока нет

- Trash Bag and Sand CastingДокумент25 страницTrash Bag and Sand CastingBirukОценок пока нет

- 43-Sheet Metal Punching MachineДокумент25 страниц43-Sheet Metal Punching MachinesathishОценок пока нет

- Bench Worh ConДокумент53 страницыBench Worh Conaragawyohannes3Оценок пока нет

- Unit IIIДокумент114 страницUnit IIIManoj Kumar SОценок пока нет

- ME3162 Part 1 SummaryДокумент5 страницME3162 Part 1 Summarytylersyt100% (1)

- Chapter IIДокумент7 страницChapter IIMuhammad Daud Abu BakarОценок пока нет

- 4.3 ExtrusionДокумент19 страниц4.3 ExtrusionSiddharth RajendranОценок пока нет

- Mechanical Process in A Distribution PanelДокумент3 страницыMechanical Process in A Distribution PanelDilanОценок пока нет

- Unit3 Part C RevisedДокумент72 страницыUnit3 Part C Revisedraymon sharmaОценок пока нет

- SID1Документ18 страницSID1Siddharth Srinivasan100% (1)

- Interview QuestionДокумент22 страницыInterview QuestionsugeshОценок пока нет

- Presstool MasterДокумент111 страницPresstool MasterRajesh Kumar100% (2)

- Al Die CastingДокумент11 страницAl Die CastingMallesh Munje100% (1)

- Selection of Manufacturing Methods For Machine Element S For Toggle JackДокумент16 страницSelection of Manufacturing Methods For Machine Element S For Toggle JackPrayag GiteОценок пока нет

- Metal Tray (Sheet Metal) : Aim: To Make A Metal Tray Out of A Given Sheet Metal of DimensionsДокумент4 страницыMetal Tray (Sheet Metal) : Aim: To Make A Metal Tray Out of A Given Sheet Metal of DimensionsVivek AnbuОценок пока нет

- DM-1 CO-1 Special Castings MaterialДокумент9 страницDM-1 CO-1 Special Castings MaterialSree vishnu Sai chandan guntupalliОценок пока нет

- Die Casting With TypesДокумент4 страницыDie Casting With TypesAdarsh TiwariОценок пока нет

- Die Casting: Mechanical Manufacturing - IIДокумент39 страницDie Casting: Mechanical Manufacturing - IIAdnan Javed100% (1)

- Casting Process: Steps of Casting AreДокумент10 страницCasting Process: Steps of Casting AreReham Emad Ezzat MohamedОценок пока нет

- Metal Swarf: Definition of ChippsДокумент10 страницMetal Swarf: Definition of ChippsabenezerОценок пока нет

- Sheet Metal Forming ProcessДокумент5 страницSheet Metal Forming ProcessAbdulbar kelilОценок пока нет

- Takele ManufacturingДокумент21 страницаTakele Manufacturingdawit solomonОценок пока нет

- واجهةДокумент10 страницواجهةAbdullah MustafaОценок пока нет

- Study and Improvement of Small Scale Industry SystemДокумент15 страницStudy and Improvement of Small Scale Industry SystemRajneesh SinghОценок пока нет

- Special Casting ProcessesДокумент25 страницSpecial Casting ProcessesV Phanindra BoguОценок пока нет

- Manufacturing Process of FlangeДокумент15 страницManufacturing Process of FlangeAbhijit Kudva100% (1)

- Sheet MetalДокумент16 страницSheet MetalYusha Patel100% (1)

- Unit 3 Part B RevisedДокумент56 страницUnit 3 Part B Revisedraymon sharmaОценок пока нет

- Tayyab CVДокумент1 страницаTayyab CVZain Ali KidwaiОценок пока нет

- ValvesДокумент68 страницValvesZain Ali KidwaiОценок пока нет

- 48 - ISO 22000 WhitepaperДокумент14 страниц48 - ISO 22000 WhitepaperZain Ali KidwaiОценок пока нет

- Iii. Applicable Codes & Standards For Aramco ProjectsДокумент5 страницIii. Applicable Codes & Standards For Aramco ProjectsZain Ali KidwaiОценок пока нет

- Mirza Muhammad Tayyab: Experience HighlightsДокумент1 страницаMirza Muhammad Tayyab: Experience HighlightsZain Ali KidwaiОценок пока нет

- "Company Profile": Fluid Technology International (PVT) LTDДокумент8 страниц"Company Profile": Fluid Technology International (PVT) LTDZain Ali KidwaiОценок пока нет

- Hydrosatic PresentationДокумент78 страницHydrosatic PresentationZain Ali KidwaiОценок пока нет

- Guidelines For The Use of Chlorine Bleach As A Sanitizer in Food Processing OperationsДокумент2 страницыGuidelines For The Use of Chlorine Bleach As A Sanitizer in Food Processing OperationsZain Ali KidwaiОценок пока нет

- Zain Ali Kidwai: Work ExperienceДокумент3 страницыZain Ali Kidwai: Work ExperienceZain Ali KidwaiОценок пока нет

- Materials Engineering:: Program RequirementsДокумент3 страницыMaterials Engineering:: Program RequirementsZain Ali KidwaiОценок пока нет

- Discrepancy SheetДокумент1 страницаDiscrepancy SheetZain Ali KidwaiОценок пока нет

- 1) Alloy Button Making Procedure Via Die CastingДокумент1 страница1) Alloy Button Making Procedure Via Die CastingZain Ali KidwaiОценок пока нет

- Fluid Technology International Pvt. Ltd. Monthly Activity ReportДокумент10 страницFluid Technology International Pvt. Ltd. Monthly Activity ReportZain Ali KidwaiОценок пока нет

- Self-Cleaning Filter: 1.1 Quality DossierДокумент19 страницSelf-Cleaning Filter: 1.1 Quality DossierZain Ali KidwaiОценок пока нет

- Guide For Agents: Information For Education and Migration Agents Around The WorldДокумент12 страницGuide For Agents: Information For Education and Migration Agents Around The WorldZain Ali KidwaiОценок пока нет

- Self-Cleaning Filter: 1.1 Quality DossierДокумент19 страницSelf-Cleaning Filter: 1.1 Quality DossierZain Ali KidwaiОценок пока нет

- Hydro Test ProcedureДокумент13 страницHydro Test ProcedureZain Ali KidwaiОценок пока нет

- Documents RequiredДокумент5 страницDocuments RequiredZain Ali KidwaiОценок пока нет

- ST52-3 (PLATE) Mechanical PropertiesДокумент1 страницаST52-3 (PLATE) Mechanical Propertiesistasyonbaykusu100% (1)

- Usb 3100Документ2 страницыUsb 3100terenceОценок пока нет

- 6061 Aluminum Sheet SuppliersДокумент8 страниц6061 Aluminum Sheet Supplierssanghvi overseas incОценок пока нет

- SolderingДокумент34 страницыSolderingMrinal PathakОценок пока нет

- RRSMДокумент14 страницRRSMfitrie dwi lestariОценок пока нет

- Details of Fillet Welds D15M-D15-2002 - Section - 2.1Документ40 страницDetails of Fillet Welds D15M-D15-2002 - Section - 2.1drac_dracОценок пока нет

- WX100 Fastener Finish Speecification PDFДокумент16 страницWX100 Fastener Finish Speecification PDFJulion2009Оценок пока нет

- Modified Erichsen Cupping Test For Copper, Brass, Aluminium and Stainless SteelДокумент6 страницModified Erichsen Cupping Test For Copper, Brass, Aluminium and Stainless SteelthesijОценок пока нет

- CNC QuestionsДокумент10 страницCNC QuestionsKhushant ranaОценок пока нет

- Upgrading of MN / Fe Ratio of Low-Grade Manganese Ore For Ferromanganese ProductionДокумент10 страницUpgrading of MN / Fe Ratio of Low-Grade Manganese Ore For Ferromanganese ProductionKarin AndersonОценок пока нет

- Weld RepairsДокумент24 страницыWeld RepairsLương Hồ VũОценок пока нет

- 6 Nickel Determination by ColorimetryДокумент5 страниц6 Nickel Determination by ColorimetryManni cОценок пока нет

- Publication - Painting, Coating & Corrosion Protection - AkzoNobel - International Paints - Mining and Minerals ApplicationsДокумент44 страницыPublication - Painting, Coating & Corrosion Protection - AkzoNobel - International Paints - Mining and Minerals Applicationszinha_alОценок пока нет

- Ams 5537H PDFДокумент6 страницAms 5537H PDFR Krishna KumarОценок пока нет

- THE PEROIDIC TABLE Answer Key 2dd55 61635c8cДокумент1 страницаTHE PEROIDIC TABLE Answer Key 2dd55 61635c8cbhagat johnsonОценок пока нет

- Mecon Limited: Indian Iron Ore Scenario: Low Grade Iron Ore BeneficiationДокумент19 страницMecon Limited: Indian Iron Ore Scenario: Low Grade Iron Ore BeneficiationKalai SelvanОценок пока нет

- Kwitansi Toko EmasДокумент4 страницыKwitansi Toko EmasFrizky AriaОценок пока нет

- Astm 1008Документ10 страницAstm 1008Waqas Raja100% (1)

- Corrosion Effects of MgCl2 and NaClДокумент91 страницаCorrosion Effects of MgCl2 and NaClandrebrezolin100% (1)

- Corrosion: Introduction - Definitions and TypesДокумент13 страницCorrosion: Introduction - Definitions and TypesGuru PrasadОценок пока нет

- Panasonic SwitchesДокумент16 страницPanasonic SwitchesMohamed MostafaОценок пока нет

- Aluminium Alloy U Channel - : Astm B221 / Astm B557Документ2 страницыAluminium Alloy U Channel - : Astm B221 / Astm B557fery indrawanОценок пока нет

- Taiwan Hardware SHOWROOMS - Fastener Manufacturer Directory Self Drilling ScrewДокумент6 страницTaiwan Hardware SHOWROOMS - Fastener Manufacturer Directory Self Drilling ScrewSorinBologaОценок пока нет

- DIN en 10085 2001 Nitriding SteelsДокумент27 страницDIN en 10085 2001 Nitriding SteelsjorgeОценок пока нет

- 12-Carburising of Low-Carbon Steel Using Carbon BlackДокумент8 страниц12-Carburising of Low-Carbon Steel Using Carbon BlackEnriqe PuentesОценок пока нет

- Stainless Lifting Bolts - Male: MetricДокумент3 страницыStainless Lifting Bolts - Male: MetricShreenidhiОценок пока нет

- Iso 22778-2006Документ22 страницыIso 22778-2006Kali AbdennourОценок пока нет

- Metal CastingДокумент11 страницMetal Castingআজিজুর রহমান চৌধুরীОценок пока нет

- Aluminium 6061Документ1 страницаAluminium 6061shubhamОценок пока нет

- Comparison of The Use of Rutile and Cellulosic Electrodes - Job Knowledge 142Документ5 страницComparison of The Use of Rutile and Cellulosic Electrodes - Job Knowledge 142tuanОценок пока нет

- Crochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiОт EverandCrochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiРейтинг: 4 из 5 звезд4/5 (3)

- Crochet with London Kaye: Projects and Ideas to Yarn Bomb Your LifeОт EverandCrochet with London Kaye: Projects and Ideas to Yarn Bomb Your LifeРейтинг: 5 из 5 звезд5/5 (2)

- Edward's Menagerie New Edition: Over 50 easy-to-make soft toy animal crochet patternsОт EverandEdward's Menagerie New Edition: Over 50 easy-to-make soft toy animal crochet patternsОценок пока нет

- House Rules: How to Decorate for Every Home, Style, and BudgetОт EverandHouse Rules: How to Decorate for Every Home, Style, and BudgetОценок пока нет

- The Martha Manual: How to Do (Almost) EverythingОт EverandThe Martha Manual: How to Do (Almost) EverythingРейтинг: 4 из 5 звезд4/5 (11)

- 100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiОт Everand100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiРейтинг: 5 из 5 звезд5/5 (2)

- Crochet Creatures of Myth and Legend: 19 Designs Easy Cute Critters to Legendary BeastsОт EverandCrochet Creatures of Myth and Legend: 19 Designs Easy Cute Critters to Legendary BeastsРейтинг: 4.5 из 5 звезд4.5/5 (10)

- Swatch This, 3000+ Color Palettes for Success: Perfect for Artists, Designers, MakersОт EverandSwatch This, 3000+ Color Palettes for Success: Perfect for Artists, Designers, MakersРейтинг: 3.5 из 5 звезд3.5/5 (3)

- Crochet Southwest Spirit: Over 20 Bohemian Crochet Patterns Inspired by the American SouthwestОт EverandCrochet Southwest Spirit: Over 20 Bohemian Crochet Patterns Inspired by the American SouthwestРейтинг: 5 из 5 звезд5/5 (2)

- Crochet Impkins: Over a million possible combinations! Yes, really!От EverandCrochet Impkins: Over a million possible combinations! Yes, really!Рейтинг: 4.5 из 5 звезд4.5/5 (10)

- Shetland Fine Lace Knitting: Recreating Patterns from the Past.От EverandShetland Fine Lace Knitting: Recreating Patterns from the Past.Рейтинг: 2 из 5 звезд2/5 (1)

- The Botanical Hand Lettering Workbook: Draw Whimsical & Decorative Styles & ScriptsОт EverandThe Botanical Hand Lettering Workbook: Draw Whimsical & Decorative Styles & ScriptsРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Hello Hexie!: 20 Easy Crochet Patterns from Simple Granny HexagonsОт EverandHello Hexie!: 20 Easy Crochet Patterns from Simple Granny HexagonsРейтинг: 5 из 5 звезд5/5 (3)

- Amigurumi Cats: Crochet Sweet Kitties the Japanese Way (24 Projects of Cats to Crochet)От EverandAmigurumi Cats: Crochet Sweet Kitties the Japanese Way (24 Projects of Cats to Crochet)Оценок пока нет

- Harter's Picture Archive for Collage and IllustrationОт EverandHarter's Picture Archive for Collage and IllustrationРейтинг: 4.5 из 5 звезд4.5/5 (3)

- Crochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastОт EverandCrochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastРейтинг: 5 из 5 звезд5/5 (1)

- How to Make Workbenches & Shop Storage Solutions: 28 Projects to Make Your Workshop More Efficient from the Experts at American WoodworkerОт EverandHow to Make Workbenches & Shop Storage Solutions: 28 Projects to Make Your Workshop More Efficient from the Experts at American WoodworkerРейтинг: 5 из 5 звезд5/5 (2)

- Crochet Cute Dolls with Mix-and-Match Outfits: 66 Adorable Amigurumi PatternsОт EverandCrochet Cute Dolls with Mix-and-Match Outfits: 66 Adorable Amigurumi PatternsРейтинг: 4 из 5 звезд4/5 (5)

- Crochet Lace: Techniques, Patterns, and ProjectsОт EverandCrochet Lace: Techniques, Patterns, and ProjectsРейтинг: 3.5 из 5 звезд3.5/5 (3)

- Japanese Wonder Knitting: Timeless Stitches for Beautiful Hats, Bags, Blankets and MoreОт EverandJapanese Wonder Knitting: Timeless Stitches for Beautiful Hats, Bags, Blankets and MoreРейтинг: 4 из 5 звезд4/5 (4)

- Modern Crochet Style: 15 Colourful Crochet Patterns For You and Your HomeОт EverandModern Crochet Style: 15 Colourful Crochet Patterns For You and Your HomeРейтинг: 5 из 5 звезд5/5 (1)

- Artisan Sourdough Made Simple: A Beginner's Guide to Delicious Handcrafted Bread with Minimal KneadingОт EverandArtisan Sourdough Made Simple: A Beginner's Guide to Delicious Handcrafted Bread with Minimal KneadingРейтинг: 5 из 5 звезд5/5 (4)

- Paper Cutting: Contemporary Artists, Timeless CraftОт EverandPaper Cutting: Contemporary Artists, Timeless CraftРейтинг: 5 из 5 звезд5/5 (1)

- Crochet Donut Buddies: 50 easy amigurumi patterns for collectible crochet toysОт EverandCrochet Donut Buddies: 50 easy amigurumi patterns for collectible crochet toysРейтинг: 4.5 из 5 звезд4.5/5 (7)