Академический Документы

Профессиональный Документы

Культура Документы

Custom Castings: Multi-Dimensional / Tree-Node Column Casting Example

Загружено:

aams_sИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Custom Castings: Multi-Dimensional / Tree-Node Column Casting Example

Загружено:

aams_sАвторское право:

Доступные форматы

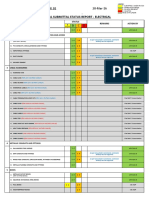

HOW TO SPECIFY: GETTING READY: Download

CAST CONNEX CUSTOM CASTING SPECIFICATION (Casting Specification)

innova� ve co mpo ne nt s for i n s p i red d esi g n s CUSTOM CASTINGS From www.castconnex.com/products/custom-components

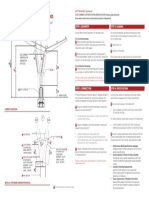

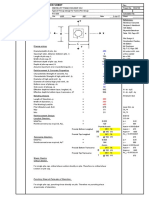

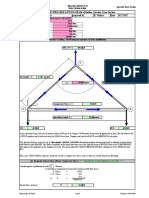

Multi- Dimensional / Tree-Node Column Casting Example

STEP 1: GEOMETRY STEP 2: LOADING

1B GRID 4A 2B

SEE DETAIL B CAST CONNEX MAX LRFD LOADS Clearly define external geometry of cast steel node. On structural drawings, provide governing axial, shear

FOR MEMBER CUSTOM CAST Z AT TOP ARM

GRID GRID STEEL NODE, Pu = 62 KIPS

and moments at the workpoint locations both in- and

SIZES 1B Z

REFER TO SPECS. Z Vu,x = 12 KIPS On structural drawings: out-of-plane using:

(SEE ADJACENT Y Y Vu,y = 18 KIPS 1A Define centerline geometry with workpoints, and

DETAILS FOR X X Mu,x = 52 K-FT

B X dimension their locations using vertical and horizontal 2A Tabular form, or

ADDT’L Mu,y = 41 K-FT

4A INFORMATION) Y dimensions and/or with angles.

CAST CONNEX 2B 2B Callouts on the detail.

CUSTOM MAX LRFD LOADS

CAST STEEL A,C Y Y 1B Dimension key structural features* including size of

AT ANGULAR ARMS

NODE, REFER

W0 (TYP. 1 OF 4) connecting members, length of cast steel arms, shape and Note: these loads are used to price the cast steel node.

TO SPECS. Pu = 46 KIPS (C) thickness of cast base plate, and other structural features. Once the project is awarded, Cast Connex may request

W.P. 3B X X

8 KIPS (T) Z Z

Vu,x = 25 KIPS equilibrated load combinations to complete structural

Vu,y = 56 KIPS On architectural drawings: analysis of cast steel node; see Casting Specification for

1B 1A Mu,x = 50 K-FT 1C Dimension key architectural features* including delegated design of steel castings.

Mu,y = 12 K-FT

X

any curvature or radii that define the form of the casting.

2B

MAX LRFD LOADS Y

AT BASE ARM *Contact a Cast Connex representative to help identify

FINISH FLOOR Pu = 182 KIPS key architectural and structural features prior to issuing drawings.

ELEV. Vu,x = 64 KIPS Z

Vu,y = 58 KIPS

Mu,x = 62 K-FT

Mu,y = 57 K-FT NOTE: STEP 3: CONNECTION STEP 4: SPECIFICATION

1) SPECIFIED FORCES RELATE TO GEOMETRY

OF EACH INDIVIDUAL ARM.

2) AXIAL LOADS SHOWN ARE COMPRESSION Structural Engineer of Record: design or delegate design to Call out steel casting on drawings and include casting

ONLY UNLESS NOTED “T” FOR TENSION.

the connection engineer the connections between the specification language within contract specification.

casting and adjacent structural elements. When relevant:

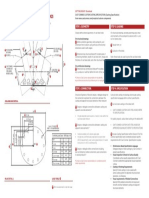

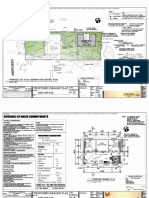

TREE COLUMN ELEVATION DETAIL A: CAST STEEL TREE NODE: ISOMETRIC VIEW 4A Call out steel casting on the detail with:

3A Design or delegate connections between casting and

adjacent concrete elements.* • CAST CONNEX CUSTOM CAST STEEL NODE, REFER

TO SPECIFICATIONS

1A 45˚ 45˚ 1A

3B PJP, AESS R = 4˚, TYP. 1C • Provide diameter and location of anchor rods within the

cast base plate feature For public projects, callout steel casting on the detail with:

W2

1B 1B 3B Design or delegate connections between casting and • CAST CONNEX CUSTOM CAST STEEL NODE OR

1B 0’-10 3/4” TYP.

(W3, W4, W5, W6) adjacent steel elements.* APPROVED EQUIVALENT, REFER TO SPECIFICATIONS

W3 W5 W6 W4

• Indicate welded joints where applicable 4B Include Casting Specification within Division 05 of the

• Include any architecturally exposed structural steel contract specification and coordinate product specific

(AESS) requirements; see Casting Specification for weld requirements with Cast Connex. Specification includes:

1B 1B instructions for AESS craftsmanship.

1B

W0 • Performance-Based Specification Language

0’-10 3/4” TYP. 3C Design or delegate other connections including, Delegate design of steel castings by Cast Connex in

(W3, W4, W5, W6) but not limited to: bolted connections, and connections project specifications.

1B

to wood products.* • Visual Inspection Criteria for Surface Quality

Coordinate surface quality expectations with Cast

1A 45˚ 45˚ 1A *Contact a Cast Connex representative to coordinate specific Connex to determine appropriate visual inspection

W1 detail requirements. criteria

4A CAST CONNEX • Coating & Finishing Requirements

CUSTOM CAST

STEEL NODE, 1B1’-10” TYP. Specify if steel casting is to be coated with

REFER TO SPECS. (W3, W4, W5, W6) same coating system of adjoined structural steel

elements, or otherwise.

DETAIL B: PLAN VIEW DETAIL C: SECTION • Visual requirements of Welded Connections

Specify AESS welded connections to be ground

smooth and flush between casting and adjacent

## Refer to associated step # on right side of page structural elements.

Вам также может понравиться

- Custom Castings: Wye-Node Column Casting ExampleДокумент1 страницаCustom Castings: Wye-Node Column Casting Exampleaams_sОценок пока нет

- Custom Castings: V-Node Column and Integrated Base Casting ExampleДокумент1 страницаCustom Castings: V-Node Column and Integrated Base Casting Exampleaams_sОценок пока нет

- Pile Cap Design OriДокумент14 страницPile Cap Design OriHoihogo Hoi100% (1)

- Masonry Shear Wall Design Based On TMS 402-16/13 & 2018 IBC (Both ASD and SD)Документ2 страницыMasonry Shear Wall Design Based On TMS 402-16/13 & 2018 IBC (Both ASD and SD)Madhusudan ShewalkarОценок пока нет

- Spreader Beam BLOCK EДокумент25 страницSpreader Beam BLOCK EDhanraj Vasanth100% (1)

- MasonryShearWall CBCДокумент2 страницыMasonryShearWall CBCMadhusudan ShewalkarОценок пока нет

- Pilecap Sizing: Bukit Keteri (Pg3-Pc1)Документ8 страницPilecap Sizing: Bukit Keteri (Pg3-Pc1)azwanОценок пока нет

- Circular Anchor Bolt Pattern ExampleДокумент1 страницаCircular Anchor Bolt Pattern ExampleSisu Stefan100% (1)

- Pdf-Caissonxlsx CompressДокумент2 страницыPdf-Caissonxlsx CompressrvmerchanОценок пока нет

- 21Документ4 страницы21Sarah Mae GarciaОценок пока нет

- Steel Column Slab Support MukonoДокумент3 страницыSteel Column Slab Support Mukonosoly2k12Оценок пока нет

- PE Cheat SheetДокумент5 страницPE Cheat Sheetdnl_vicars100% (1)

- Design Information: 1. Type of Structure 3. Reference CodesДокумент8 страницDesign Information: 1. Type of Structure 3. Reference CodesWin ThanОценок пока нет

- 12 Storey RC STDWGДокумент26 страниц12 Storey RC STDWGYe Min ThuОценок пока нет

- See Detail "A": Pavement Design ParametersДокумент1 страницаSee Detail "A": Pavement Design Parameterscristian gonzalesОценок пока нет

- Material Constant:: Column C1Документ5 страницMaterial Constant:: Column C1Abdullah Al MamunОценок пока нет

- Triangular BeamДокумент19 страницTriangular BeamJane MooreОценок пока нет

- CaissonДокумент2 страницыCaissonjorge01Оценок пока нет

- 2 WSD LectureДокумент21 страница2 WSD LectureJob Mikhail OceanОценок пока нет

- Base Plate - ExcelДокумент3 страницыBase Plate - Excelelmushka100% (1)

- Spreader Beam AttachmentДокумент28 страницSpreader Beam AttachmentAKSHAY BHATKAR100% (1)

- Summary Material StatusДокумент52 страницыSummary Material StatusMohamed AlaaОценок пока нет

- Crack Width L - Steps - 75mm 4.56 MДокумент22 страницыCrack Width L - Steps - 75mm 4.56 MpandianОценок пока нет

- Cmit 220046 000 SCW 15.01 0003 0Документ6 страницCmit 220046 000 SCW 15.01 0003 0Ali SalehОценок пока нет

- BERNICE MODEL QДокумент1 страницаBERNICE MODEL QOmega Chang'eОценок пока нет

- TCC15 Resistance of Retaining MembersДокумент9 страницTCC15 Resistance of Retaining MembersMelinda GordonОценок пока нет

- Machine Design1 2 FormulasДокумент9 страницMachine Design1 2 FormulasKeilah MizraimОценок пока нет

- Unlocked 189537383 Spreader Beam BLOCK EДокумент25 страницUnlocked 189537383 Spreader Beam BLOCK EWalterОценок пока нет

- Joint DetailingДокумент2 страницыJoint Detailingkukadiya127_48673372Оценок пока нет

- Borehole (Serenia Bh-27)Документ52 страницыBorehole (Serenia Bh-27)azwanОценок пока нет

- Masonry Lintel Design (MSJC)Документ2 страницыMasonry Lintel Design (MSJC)Bunkun15Оценок пока нет

- GRDSLAB - Pisodeconcreto Losa de PisoДокумент19 страницGRDSLAB - Pisodeconcreto Losa de PisoCarlos Roberto CarranzaОценок пока нет

- Mandatory Appendix 26Документ28 страницMandatory Appendix 26Sushil WadiyeОценок пока нет

- MCLДокумент4 страницыMCLDan CasuraoОценок пока нет

- Modular CNC Mini Mill Assy-01Документ1 страницаModular CNC Mini Mill Assy-01ModularCNC100% (1)

- Fully Diff Folded-Cascode Amp PaperДокумент4 страницыFully Diff Folded-Cascode Amp Paperbb11xxОценок пока нет

- Project Job No.: H H Dia ColДокумент3 страницыProject Job No.: H H Dia ColAdam HussaryОценок пока нет

- (O) If M, R: Proposed Granny FlatДокумент3 страницы(O) If M, R: Proposed Granny FlatTop hot TrendingОценок пока нет

- D D D D D D: SN54ABT640, SN74ABT640 Octal Bus Transceivers With 3-State OutputsДокумент8 страницD D D D D D: SN54ABT640, SN74ABT640 Octal Bus Transceivers With 3-State OutputsStuxnetОценок пока нет

- CH-12 600Документ10 страницCH-12 600mayank designdimensionnОценок пока нет

- Spreader Beam BLOCK EДокумент26 страницSpreader Beam BLOCK ESteve MoonОценок пока нет

- Ms Hcs (Shop Drawing) 1Документ1 страницаMs Hcs (Shop Drawing) 1Erection DepartmentОценок пока нет

- Landlite Dormitory Ee 2021sep16 E-06Документ1 страницаLandlite Dormitory Ee 2021sep16 E-06gbmmecateОценок пока нет

- Problem 1 025Документ6 страницProblem 1 025Oscar SanchezОценок пока нет

- Main Fire Station-1Документ1 страницаMain Fire Station-1Jhon CenaОценок пока нет

- Appendices: Appendix A NotationДокумент2 страницыAppendices: Appendix A NotationYASIRОценок пока нет

- Akia Terimal Arrival Revise - 2023-3Документ1 страницаAkia Terimal Arrival Revise - 2023-3marcjunalegrado28Оценок пока нет

- New Analytical Calculation Models For Compressive Arch Action in Reinforced Concrete StructuresДокумент2 страницыNew Analytical Calculation Models For Compressive Arch Action in Reinforced Concrete Structureskashif2298Оценок пока нет

- Masonry Wall Design at Horizontal Bending, Based On ACI 530-05 Input Data & Design SummaryДокумент1 страницаMasonry Wall Design at Horizontal Bending, Based On ACI 530-05 Input Data & Design Summaryazamislam726537Оценок пока нет

- Notation: Engineering With The SpreadsheetДокумент8 страницNotation: Engineering With The Spreadsheetton carolinoОценок пока нет

- Design of PT Slabs On Expansive Soil Ground Based On PTI DC10.5-12 & PTI 3rd EditionДокумент5 страницDesign of PT Slabs On Expansive Soil Ground Based On PTI DC10.5-12 & PTI 3rd Editionridho ziskaОценок пока нет

- Section B-B: Table For Non Encased PipeДокумент1 страницаSection B-B: Table For Non Encased PipeajayОценок пока нет

- Design of CorbalДокумент47 страницDesign of CorbalHussam JumahОценок пока нет

- RC Pier TabaДокумент19 страницRC Pier TabaMitiku AregieОценок пока нет

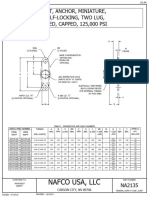

- NA2135Документ2 страницыNA2135Bogdan RusuОценок пока нет

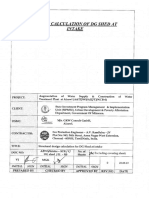

- DG ShedДокумент25 страницDG Shedepe civilОценок пока нет

- Basic Metal Buildings ExampleДокумент14 страницBasic Metal Buildings ExampleKasurika DissanayakeОценок пока нет

- OPAL Spoken PhrasesДокумент2 страницыOPAL Spoken Phrasesناصر الإسلام خليفيОценок пока нет

- OPAL - Written Phrases PDFДокумент3 страницыOPAL - Written Phrases PDFناصر الإسلام خليفيОценок пока нет

- Phrasal AcademicДокумент5 страницPhrasal AcademicCinthia Lidia Hidrogo PaulinoОценок пока нет

- OPAL - Spoken Single WordsДокумент3 страницыOPAL - Spoken Single WordsAbdulrazzak Alturki100% (1)

- Walk-Through Piping-By Ashish ShrivastavaДокумент36 страницWalk-Through Piping-By Ashish Shrivastavaaams_sОценок пока нет

- Walk-Through Piping-By Ashish ShrivastavaДокумент36 страницWalk-Through Piping-By Ashish Shrivastavaaams_sОценок пока нет

- 2020 NEHRP Fundamentals HarrisДокумент45 страниц2020 NEHRP Fundamentals Harrisaams_sОценок пока нет

- Walk-Through Piping-By Ashish ShrivastavaДокумент36 страницWalk-Through Piping-By Ashish Shrivastavaaams_sОценок пока нет

- Walk-Through Piping-By Ashish ShrivastavaДокумент36 страницWalk-Through Piping-By Ashish Shrivastavaaams_sОценок пока нет

- Walk-Through Piping-By Ashish ShrivastavaДокумент36 страницWalk-Through Piping-By Ashish Shrivastavaaams_sОценок пока нет

- Walk-Through Piping-By Ashish ShrivastavaДокумент36 страницWalk-Through Piping-By Ashish Shrivastavaaams_sОценок пока нет

- Walk-Through Piping-By Ashish ShrivastavaДокумент36 страницWalk-Through Piping-By Ashish Shrivastavaaams_sОценок пока нет

- Walk-Through Piping-By Ashish ShrivastavaДокумент36 страницWalk-Through Piping-By Ashish Shrivastavaaams_sОценок пока нет

- Walk-Through Piping-By Ashish ShrivastavaДокумент36 страницWalk-Through Piping-By Ashish Shrivastavaaams_sОценок пока нет

- Walk-Through Piping-By Ashish ShrivastavaДокумент36 страницWalk-Through Piping-By Ashish Shrivastavaaams_sОценок пока нет

- Walk-Through Piping-By Ashish ShrivastavaДокумент36 страницWalk-Through Piping-By Ashish Shrivastavaaams_sОценок пока нет

- Walk-Through Piping-By Ashish ShrivastavaДокумент36 страницWalk-Through Piping-By Ashish Shrivastavaaams_sОценок пока нет

- Walk-Through Piping-By Ashish ShrivastavaДокумент36 страницWalk-Through Piping-By Ashish Shrivastavaaams_sОценок пока нет

- Walk-Through Piping-By Ashish ShrivastavaДокумент36 страницWalk-Through Piping-By Ashish Shrivastavaaams_sОценок пока нет

- Walk-Through Piping-By Ashish ShrivastavaДокумент36 страницWalk-Through Piping-By Ashish Shrivastavaaams_sОценок пока нет

- Walk-Through Piping-By Ashish ShrivastavaДокумент36 страницWalk-Through Piping-By Ashish Shrivastavaaams_sОценок пока нет

- Walk-Through Piping-By Ashish ShrivastavaДокумент36 страницWalk-Through Piping-By Ashish Shrivastavaaams_sОценок пока нет

- Walk-Through Piping-By Ashish ShrivastavaДокумент36 страницWalk-Through Piping-By Ashish Shrivastavaaams_sОценок пока нет

- Steel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Документ2 страницыSteel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Anonymous HYxnR9Оценок пока нет

- Galvanized Slip-Critical ConnectionsДокумент2 страницыGalvanized Slip-Critical Connectionsaams_sОценок пока нет

- Si 1 2014Документ2 страницыSi 1 2014hector diazОценок пока нет

- Si 02 2013Документ2 страницыSi 02 2013hector diazОценок пока нет

- Steel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Документ2 страницыSteel Interchange: Modern Steel's Monthly Steel Interchange Is For You!hector diazОценок пока нет

- HSS Steel AvailabilityДокумент2 страницыHSS Steel Availabilityaams_sОценок пока нет

- Steel Interchange: Fillet Weld Terminations Built-Up Column DesignДокумент2 страницыSteel Interchange: Fillet Weld Terminations Built-Up Column Designhector diazОценок пока нет

- Senarai Akta A MalaysiaДокумент8 страницSenarai Akta A MalaysiawswmadihiОценок пока нет

- Wheel Loader wl56Документ6 страницWheel Loader wl56Shahzad AliОценок пока нет

- Section 6 Novation: Study GuideДокумент11 страницSection 6 Novation: Study GuideElsha DamoloОценок пока нет

- Name Caliber Base Penalties DMG Rate Clip Conceal Range CostДокумент23 страницыName Caliber Base Penalties DMG Rate Clip Conceal Range CostLars Pedersen100% (1)

- Review of DMOS in CNHSДокумент54 страницыReview of DMOS in CNHSrhowee onaganОценок пока нет

- The Oxford Handbook of The Trinity (Introducción)Документ12 страницThe Oxford Handbook of The Trinity (Introducción)casandraentroya100% (1)

- 4-Malayalam InternationalДокумент51 страница4-Malayalam InternationalSASHMIRA MENONОценок пока нет

- 002 SM MP4054Документ2 009 страниц002 SM MP4054tranquangthuanОценок пока нет

- Inside The Mind of A Master ProcrastinatorДокумент5 страницInside The Mind of A Master ProcrastinatorDianaОценок пока нет

- Principles of DTP Design NotesДокумент11 страницPrinciples of DTP Design NotesSHADRACK KIRIMIОценок пока нет

- Literature Review of Quality of Healthcare Services in IndiaДокумент27 страницLiterature Review of Quality of Healthcare Services in IndiaMunnangi NagendrareddyОценок пока нет

- Rheumatoid ArthritisДокумент15 страницRheumatoid ArthritisPJHG100% (2)

- LMC - Boundary Dispute CasesДокумент12 страницLMC - Boundary Dispute CasesLR FОценок пока нет

- Start Where You Are A Journal For Self Exploration PDFДокумент1 страницаStart Where You Are A Journal For Self Exploration PDFNyemwerai Muterere22% (9)

- PMO Crossword 1Документ4 страницыPMO Crossword 1Waseem NosimohomedОценок пока нет

- Danamma Vs AmarДокумент13 страницDanamma Vs AmarParthiban SekarОценок пока нет

- Pamantasan NG Lungsod NG Valenzuela: Poblacion II, Malinta, Valenzuela CityДокумент4 страницыPamantasan NG Lungsod NG Valenzuela: Poblacion II, Malinta, Valenzuela CityAnne BustilloОценок пока нет

- Determination of Distribution Coefficient of Iodine Between Two Immiscible SolventsДокумент6 страницDetermination of Distribution Coefficient of Iodine Between Two Immiscible SolventsRafid Jawad100% (1)

- IdentifyДокумент40 страницIdentifyLeonard Kenshin LianzaОценок пока нет

- Nosocomial InfectionДокумент31 страницаNosocomial InfectionDr. Ashish Jawarkar0% (1)

- Airworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Документ4 страницыAirworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Kris Wuthrich BatarioОценок пока нет

- 2010 - V 8 - PiiДокумент149 страниц2010 - V 8 - PiiJoe KerrОценок пока нет

- 1CKCДокумент44 страницы1CKCsema2210100% (1)

- Holly Rayner - The Prince S Real Fake BrideДокумент239 страницHolly Rayner - The Prince S Real Fake BrideAbbyMac BОценок пока нет

- Earth Art Michael Heizer The CityДокумент2 страницыEarth Art Michael Heizer The Cityccxx09.cxОценок пока нет

- AbstractДокумент28 страницAbstractrobin saxenaОценок пока нет

- The Doctrine of ForgivenessДокумент6 страницThe Doctrine of ForgivenessNkor IokaОценок пока нет

- Matisse As Printmaker: Matisse'S Printmaking ProcessesДокумент2 страницыMatisse As Printmaker: Matisse'S Printmaking ProcessesWriterIncОценок пока нет

- The BoxДокумент6 страницThe BoxDemian GaylordОценок пока нет

- Karakteristik Padi Gogo Lokal Yang Diber 325acbceДокумент10 страницKarakteristik Padi Gogo Lokal Yang Diber 325acbcemuhammad arjoniОценок пока нет

- Arduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!От EverandArduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!Рейтинг: 4 из 5 звезд4/5 (3)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindОт EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindОценок пока нет

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureОт EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Artificial Intelligence: From Medieval Robots to Neural NetworksОт EverandArtificial Intelligence: From Medieval Robots to Neural NetworksРейтинг: 4 из 5 звезд4/5 (4)

- How to Survive a Robot Uprising: Tips on Defending Yourself Against the Coming RebellionОт EverandHow to Survive a Robot Uprising: Tips on Defending Yourself Against the Coming RebellionРейтинг: 3.5 из 5 звезд3.5/5 (129)

- Evil Robots, Killer Computers, and Other Myths: The Truth About AI and the Future of HumanityОт EverandEvil Robots, Killer Computers, and Other Myths: The Truth About AI and the Future of HumanityРейтинг: 4.5 из 5 звезд4.5/5 (3)

- Digital Twin Development and Deployment on the Cloud: Developing Cloud-Friendly Dynamic Models Using Simulink®/SimscapeTM and Amazon AWSОт EverandDigital Twin Development and Deployment on the Cloud: Developing Cloud-Friendly Dynamic Models Using Simulink®/SimscapeTM and Amazon AWSОценок пока нет

- SAM: One Robot, a Dozen Engineers, and the Race to Revolutionize the Way We BuildОт EverandSAM: One Robot, a Dozen Engineers, and the Race to Revolutionize the Way We BuildРейтинг: 5 из 5 звезд5/5 (5)

- Artificial Intelligence: Learning about Chatbots, Robotics, and Other Business ApplicationsОт EverandArtificial Intelligence: Learning about Chatbots, Robotics, and Other Business ApplicationsРейтинг: 5 из 5 звезд5/5 (3)

- Artificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.От EverandArtificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.Рейтинг: 4 из 5 звезд4/5 (5)

- Arduino: The ultimate Arduino guide for beginners, including Arduino programming, Arduino cookbook, tips, tricks, and more!От EverandArduino: The ultimate Arduino guide for beginners, including Arduino programming, Arduino cookbook, tips, tricks, and more!Рейтинг: 3 из 5 звезд3/5 (1)

- Building with Virtual LEGO: Getting Started with LEGO Digital Designer, LDraw, and MecabricksОт EverandBuilding with Virtual LEGO: Getting Started with LEGO Digital Designer, LDraw, and MecabricksОценок пока нет

- Practical Robotics in C++: Build and Program Real Autonomous Robots Using Raspberry Pi (English Edition)От EverandPractical Robotics in C++: Build and Program Real Autonomous Robots Using Raspberry Pi (English Edition)Оценок пока нет

- What to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationОт EverandWhat to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Artificial Intelligence: Machine Learning, Deep Learning, and Automation ProcessesОт EverandArtificial Intelligence: Machine Learning, Deep Learning, and Automation ProcessesРейтинг: 5 из 5 звезд5/5 (2)

- The Fourth Age: Smart Robots, Conscious Computers, and the Future of HumanityОт EverandThe Fourth Age: Smart Robots, Conscious Computers, and the Future of HumanityРейтинг: 3.5 из 5 звезд3.5/5 (22)

- Mastering Drones - A Beginner's Guide To Start Making Money With DronesОт EverandMastering Drones - A Beginner's Guide To Start Making Money With DronesРейтинг: 2.5 из 5 звезд2.5/5 (3)

- Atlas of AI: Power, Politics, and the Planetary Costs of Artificial IntelligenceОт EverandAtlas of AI: Power, Politics, and the Planetary Costs of Artificial IntelligenceРейтинг: 5 из 5 звезд5/5 (9)

- Comprehensive Guide to Robotic Process Automation (RPA): Tips, Recommendations, and Strategies for SuccessОт EverandComprehensive Guide to Robotic Process Automation (RPA): Tips, Recommendations, and Strategies for SuccessОценок пока нет