Академический Документы

Профессиональный Документы

Культура Документы

SF - 2002-05 Equipment Record Card - AIR-COOLED HEAT EXCHANGER

Загружено:

hwang2Исходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

SF - 2002-05 Equipment Record Card - AIR-COOLED HEAT EXCHANGER

Загружено:

hwang2Авторское право:

Доступные форматы

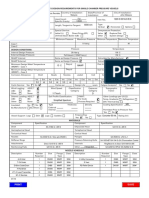

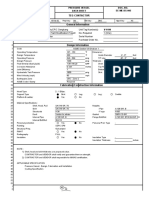

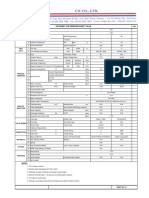

LOCATION AND DUTY AIR-COOLED HEAT EXCHANGER PLANT NO.

LOCATION DUTY MEDIUM

GENERAL INFORMATION

Purchase order No. Date

INTENDED OPERATING CONDITIONS PERMITTED OPERATING RANGE Maker Type

MINIMUM MAXIMUM Year of fabrication Serial No.

OUTSIDE

TUBES

Air temp. inlet °C Design book page No. Size

Fabrication report No. MESC No.

Air temp. outlet °C NOTE: This equipment is safeguarded against overpressure by: Mass kg

Relief valve No. Date in operation

INSIDE TUBES

Working temp. inlet °C P & I drawing Ref. No.

Working temp. outlet °C ENGINEERING

Working press. inlet bar (ga) Constructed acc. To

Working press. outlet bar (ga) Design pressure (see note above) bar (ga)

Hyd. test pressure (new and cold) bar (ga)

Normal capacity Design temperature °C

Max. capacity Header nozzles (per element) INLET OUTLET

Heat transferred Diam. mm

Over design Flange standard/size ASA series

Construction of header

Cooling surface (outside bare) m2 Corrosion allow. of headers mm

Cooling surface (total finned) m2 Volume of water for testing dm3

Radiographed/ultrasonic tested yes/no

MATERIALS Stress relieved yes/no

No. PART SIZE SPECIFICATION MESC No.

Tubes

Headers DRAWING REFERENCE

Sheet No. 1

Plenums General arrangement No.

Supports Requisition No.

Fan shaft DESCRIPTION AND TUBES ARRANGEMENT

This cooler consists oNo. of elements parallel

Fan blades No. of elements in series

Hub For inspection purposes the elements are marked as indicated on the attached sheet

Plugs The elements consits of tubes in rows

Total number of tubes

O.D. of tubes mm ISWG No.

Length of tubes mm

Connection in headers: expanded/welded/flated/exp. and sealwelded

Number of passes

Number of fins per m

Fin height mm

Fin thickness mm

INFORMATION COMPILED BY DATE CHECKED ON SITE BY

CHECKED BY DATE REFINERY

DEP 31.21.70.80-Gen., sheet 1/1 dated 05/2002

Вам также может понравиться

- Form U-Dr-1 User'S Design Requirements For Single Chamber Pressure VesselsДокумент2 страницыForm U-Dr-1 User'S Design Requirements For Single Chamber Pressure VesselsAmit Sharma100% (1)

- 250 Conversation StartersДокумент28 страниц250 Conversation StartersmuleОценок пока нет

- Heat Transfer in Jacketed Vessels: Customary US SIДокумент60 страницHeat Transfer in Jacketed Vessels: Customary US SIDHAVALESH AMОценок пока нет

- Damper Datasheet FormДокумент1 страницаDamper Datasheet FormharishcsharmaОценок пока нет

- BOMA - Office Building Standard Methods of Measurement AppendixДокумент41 страницаBOMA - Office Building Standard Methods of Measurement Appendixxavest100% (7)

- Data Sheet EjectorДокумент4 страницыData Sheet EjectorGunturMudaAliAkbarОценок пока нет

- Spherical TankДокумент6 страницSpherical Tankhgag selimОценок пока нет

- Bagi CHAPT 7 TUGAS INGGRIS W - YAHIEN PUTRIДокумент4 страницыBagi CHAPT 7 TUGAS INGGRIS W - YAHIEN PUTRIYahien PutriОценок пока нет

- Data Sheet TEG Contactor (V-1100)Документ2 страницыData Sheet TEG Contactor (V-1100)Elias EliasОценок пока нет

- Design Notes and AssumptionsДокумент19 страницDesign Notes and AssumptionsDarshan PanchalОценок пока нет

- Mechanical Data SheetДокумент7 страницMechanical Data SheetktejankarОценок пока нет

- Wps Register Last Updated May 12Документ1 страницаWps Register Last Updated May 12Abdullah Al JubayerОценок пока нет

- 15-501-EP-DS-002 (IG Buffer Vessel Datasheet), Rev.2Документ4 страницы15-501-EP-DS-002 (IG Buffer Vessel Datasheet), Rev.2Umair A. KhanОценок пока нет

- Automatic Tools For High Availability in Postgresql: Camilo Andrés EcheverriДокумент9 страницAutomatic Tools For High Availability in Postgresql: Camilo Andrés EcheverriRegistro PersonalОценок пока нет

- 809-WS-ASME VIII Div 2 - Ellipsoidal Head Design - Rev0Документ2 страницы809-WS-ASME VIII Div 2 - Ellipsoidal Head Design - Rev0Sebastiano OrofinoОценок пока нет

- Spreadsheet Calculates Critical FlowДокумент8 страницSpreadsheet Calculates Critical Flowhwang20% (1)

- (Sumitomo) Abma Vs VGB For Boiler Water QualityДокумент14 страниц(Sumitomo) Abma Vs VGB For Boiler Water Qualityhwang2Оценок пока нет

- IPS-C-PM-215-Equipment Record CardДокумент1 страницаIPS-C-PM-215-Equipment Record Cardseguridadyambiente641Оценок пока нет

- CA LPG 5b STD 0 RepairedДокумент27 страницCA LPG 5b STD 0 RepairedMadiaw NajaОценок пока нет

- MDR Div-2Документ3 страницыMDR Div-2divakar.panigrahiОценок пока нет

- Data Sheet For Steam Desuperheater: Operating ConditionДокумент1 страницаData Sheet For Steam Desuperheater: Operating ConditionaquilesanchezОценок пока нет

- Datasheet Joint Isolant 4'' #300 PDFДокумент1 страницаDatasheet Joint Isolant 4'' #300 PDFseifОценок пока нет

- Wps API-mwt 2020Документ24 страницыWps API-mwt 2020afshohil anamОценок пока нет

- Ab 028 MDR For Indirect Fired Heat CoilsДокумент1 страницаAb 028 MDR For Indirect Fired Heat CoilsCubzlookОценок пока нет

- DHG Ro 20Документ3 страницыDHG Ro 20mdalt9180Оценок пока нет

- PremierДокумент2 страницыPremierShasin SolankiОценок пока нет

- Trap (HP Steam)Документ1 страницаTrap (HP Steam)khan103Оценок пока нет

- 31369093Документ2 страницы31369093mohammed8051Оценок пока нет

- Final Enquiry List For ValvesДокумент12 страницFinal Enquiry List For ValvesnikhilОценок пока нет

- Sample Test PackageДокумент18 страницSample Test PackageAKHIL RAJОценок пока нет

- Datasheet For PSVДокумент1 страницаDatasheet For PSVlãng duОценок пока нет

- Mec-Tric: Need To Select & Price Valve Needed To Size The ValveДокумент1 страницаMec-Tric: Need To Select & Price Valve Needed To Size The ValveMohamed KilanyОценок пока нет

- Hojas de Datos Planta de GasДокумент23 страницыHojas de Datos Planta de GasCarlos RinconОценок пока нет

- Anexo 4 - Dimensionamiento PSV-7004 1Документ2 страницыAnexo 4 - Dimensionamiento PSV-7004 1JairoVidalОценок пока нет

- Sar695 Cy05 000303Документ18 страницSar695 Cy05 000303Mohammad RizwanОценок пока нет

- 4823-DS-2287-0 (P-5007A&B Separated Water Submersible Pumps)Документ1 страница4823-DS-2287-0 (P-5007A&B Separated Water Submersible Pumps)Sara KhanОценок пока нет

- Air Cooled Heat Exchanger: General InformationДокумент2 страницыAir Cooled Heat Exchanger: General Informationcorey jacobsОценок пока нет

- 18105-Abg-01-Me-das-033 Rev-A Mechanical Data Sheet O2 Stripper Condense...Документ5 страниц18105-Abg-01-Me-das-033 Rev-A Mechanical Data Sheet O2 Stripper Condense...Avinash ShuklaОценок пока нет

- 31220098Документ9 страниц31220098Muhammad AliОценок пока нет

- Coil HE-1Документ13 страницCoil HE-1chemical509Оценок пока нет

- 0-WD110-EZ300-B2002 - Rev - 0 - Calculations For Safety Relief Valves and Silencers0Документ10 страниц0-WD110-EZ300-B2002 - Rev - 0 - Calculations For Safety Relief Valves and Silencers0carlos tapia bozzoОценок пока нет

- Pulsation Damper Specification Form: Accumulator Type Fluids/medium Further InformationДокумент1 страницаPulsation Damper Specification Form: Accumulator Type Fluids/medium Further InformationsanthoshkumarplОценок пока нет

- (Name and Address of Manufacturer) (Name and Address of Purchaser)Документ3 страницы(Name and Address of Manufacturer) (Name and Address of Purchaser)Emma DОценок пока нет

- Data Sheet Ejector PDFДокумент2 страницыData Sheet Ejector PDFSuryaprakashОценок пока нет

- Form A-1 Manufacturer'S Data Report For Pressure Vessels As Required by The Provisions of The ASME Code Rules, Section VIII, Division 2Документ3 страницыForm A-1 Manufacturer'S Data Report For Pressure Vessels As Required by The Provisions of The ASME Code Rules, Section VIII, Division 2Emma DОценок пока нет

- Air-Cooled Heat Exchanger - Specification Sheet: Tube BundleДокумент2 страницыAir-Cooled Heat Exchanger - Specification Sheet: Tube BundlebondsivamaniОценок пока нет

- Ac001 D6000 15 MTD D XXX0009 CДокумент2 страницыAc001 D6000 15 MTD D XXX0009 Cessaessa1980Оценок пока нет

- Air-Cooled Heat Exchanger: EngineeringДокумент1 страницаAir-Cooled Heat Exchanger: EngineeringaminОценок пока нет

- D04-V-E809 Instrument Air ReceiverДокумент2 страницыD04-V-E809 Instrument Air Receiverpragnesh82011Оценок пока нет

- VLI007E1Документ1 страницаVLI007E1kais rguiguiОценок пока нет

- 45 KL Oil Storage Tank V-102: Mechanical Data Sheet For VesselДокумент4 страницы45 KL Oil Storage Tank V-102: Mechanical Data Sheet For VesselKrunalОценок пока нет

- Valvula Seguridad Serie 2700 27da23 m21 FarrisДокумент2 страницыValvula Seguridad Serie 2700 27da23 m21 Farrisesteban casanovaОценок пока нет

- Service - Cold Side Hot Side: Project: LocationДокумент1 страницаService - Cold Side Hot Side: Project: Locationmika cabelloОценок пока нет

- Trap (LP Steam)Документ1 страницаTrap (LP Steam)khan103Оценок пока нет

- Certificado Tatsa TK-500 (H2301476-H2301491)Документ3 страницыCertificado Tatsa TK-500 (H2301476-H2301491)Carlos Alonso SintiОценок пока нет

- CSY-TAM-0096-12E Data Sheet & Curve Rev01 Efecto Placo OrificioДокумент3 страницыCSY-TAM-0096-12E Data Sheet & Curve Rev01 Efecto Placo Orificioaldoacss_148400122Оценок пока нет

- 50-0RG2N-DD-021 Data Sheet For Ad-306001 (Bit)Документ3 страницы50-0RG2N-DD-021 Data Sheet For Ad-306001 (Bit)RajaramОценок пока нет

- Att. 5-1 RAPID-P028B-CMI-MEC-TDS-1450-0402 - 0Документ6 страницAtt. 5-1 RAPID-P028B-CMI-MEC-TDS-1450-0402 - 0Ranjith Kumar100% (1)

- RjyhetrsgdfzДокумент1 страницаRjyhetrsgdfzMohamed SelimОценок пока нет

- Asme Strength Calculation ManualДокумент37 страницAsme Strength Calculation ManualPrakashОценок пока нет

- Commisioning Report-Dx/Package: Project Villa No. & Type Location Report Date Customer Comm. DateДокумент1 страницаCommisioning Report-Dx/Package: Project Villa No. & Type Location Report Date Customer Comm. DateMohammed JavidОценок пока нет

- Hya 80anДокумент3 страницыHya 80anNguyễn Đình TiếnОценок пока нет

- MixerДокумент4 страницыMixerMarcelo PerettiОценок пока нет

- Verification of Capacity of Secondary Air Fan For Bagasse Fired BoilerДокумент2 страницыVerification of Capacity of Secondary Air Fan For Bagasse Fired Boilerhwang2Оценок пока нет

- Verification of Economizer ParameterДокумент2 страницыVerification of Economizer Parameterhwang2Оценок пока нет

- PH Measurement and Control - Che Aug 2010Документ8 страницPH Measurement and Control - Che Aug 2010hwang2Оценок пока нет

- Design of Boiler Forced Draft FanДокумент5 страницDesign of Boiler Forced Draft Fanhwang2Оценок пока нет

- Kiln Operation AnalysisДокумент116 страницKiln Operation Analysishwang2Оценок пока нет

- IT3HWC MassEnergyBalancesДокумент34 страницыIT3HWC MassEnergyBalanceshwang2Оценок пока нет

- Boiler Performance ImproveДокумент5 страницBoiler Performance Improvehwang2Оценок пока нет

- Vertical 2 Phase FlowДокумент6 страницVertical 2 Phase Flowhwang2Оценок пока нет

- Avoid Operating ProblemДокумент6 страницAvoid Operating Problemhwang2Оценок пока нет

- Measuring Differential Pressure Mechanical or Electronic Dec16 - fr2Документ4 страницыMeasuring Differential Pressure Mechanical or Electronic Dec16 - fr2hwang2Оценок пока нет

- Specify Packaged Steam Generator Properly CEP 1996Документ6 страницSpecify Packaged Steam Generator Properly CEP 1996hwang2Оценок пока нет

- Pipe Insulation Finding The Optimal Thickness Oct15 - EPДокумент5 страницPipe Insulation Finding The Optimal Thickness Oct15 - EPhwang2Оценок пока нет

- Control Valves Jan11 - EP - SASДокумент2 страницыControl Valves Jan11 - EP - SAShwang2Оценок пока нет

- Math Cad 15Документ3 страницыMath Cad 15Kim ChanthanОценок пока нет

- Instructional Decision MakingДокумент5 страницInstructional Decision Makingapi-257693907Оценок пока нет

- Dell Inspiron 5547 15Документ7 страницDell Inspiron 5547 15Kiti HowaitoОценок пока нет

- Cascade Configuration Tool: Installation and Operations ManualДокумент22 страницыCascade Configuration Tool: Installation and Operations ManualAndrés GarciaОценок пока нет

- Review of Ventura's "An Overview of Child Psychology in The Philippines"Документ2 страницыReview of Ventura's "An Overview of Child Psychology in The Philippines"Irene CayeОценок пока нет

- Topic 4 Statistic II (Form 3)Документ2 страницыTopic 4 Statistic II (Form 3)Ct KursiahОценок пока нет

- Firststep To AlaskaДокумент28 страницFirststep To AlaskaBarbara NelsonОценок пока нет

- CIT 811 TMA 4 Quiz QuestionДокумент3 страницыCIT 811 TMA 4 Quiz QuestionjohnОценок пока нет

- RTRT User GuideДокумент324 страницыRTRT User GuideAlae Khaoua100% (3)

- Chemistry Previos Papaer 313Документ19 страницChemistry Previos Papaer 313Ashu GuptaОценок пока нет

- STRESS HealthДокумент40 страницSTRESS HealthHajra KhanОценок пока нет

- SafetyStock OverviewДокумент3 страницыSafetyStock OverviewJosue FonsecaОценок пока нет

- Lab 6 Data VisualizationДокумент8 страницLab 6 Data VisualizationRoaster GuruОценок пока нет

- Important Points in SurveyingДокумент4 страницыImportant Points in SurveyingAnand BossОценок пока нет

- Being Agile. Staying Resilient.: ANNUAL REPORT 2021-22Документ296 страницBeing Agile. Staying Resilient.: ANNUAL REPORT 2021-22PrabhatОценок пока нет

- Application of SPACE MatrixДокумент11 страницApplication of SPACE Matrixdecker444975% (4)

- User Manual PocketBookДокумент74 страницыUser Manual PocketBookmisu2001Оценок пока нет

- Livro Spectrochemical AnalysisДокумент9 страницLivro Spectrochemical AnalysisRicardo PossebonОценок пока нет

- Case Study 1 HRM in PandemicДокумент2 страницыCase Study 1 HRM in PandemicKristine Dana LabaguisОценок пока нет

- Store Docket - Wood PeckerДокумент89 страницStore Docket - Wood PeckerRakesh KumarОценок пока нет

- A B&C - List of Residents - VKRWA 12Документ10 страницA B&C - List of Residents - VKRWA 12blr.visheshОценок пока нет

- Ias Book 2015Документ49 страницIas Book 2015Rahul SharmaОценок пока нет

- Using The Words in The Box, Fill in All The GapsДокумент23 страницыUsing The Words in The Box, Fill in All The GapsMo NoОценок пока нет

- Practical Search Techniques in Path Planning For Autonomous DrivingДокумент6 страницPractical Search Techniques in Path Planning For Autonomous DrivingGergely HornyakОценок пока нет

- Bach Polonaise G Min BWV 119 A4Документ1 страницаBach Polonaise G Min BWV 119 A4vincenzovaiaОценок пока нет