Академический Документы

Профессиональный Документы

Культура Документы

Learner Guide: Front-End Loader/Backhoe

Загружено:

Owen PerrinОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Learner Guide: Front-End Loader/Backhoe

Загружено:

Owen PerrinАвторское право:

Доступные форматы

LEARNER

GUIDE

Front-End

Loader/Backhoe

National Guidelines for

PO Box 2026

Occupational Health & Safety

Mountain Gate VIC 3156 Competency Standards for the

p: 03 9763 5449 Operation of Loadshifting &

Equipment & Other Types of

ABN: 37 106 951 900

Specified Equipment

RTO: 21396

Assessor Guidelines – Specific (Performance Assessment)

ASSESSMENT INSTRUMENT – SPECIATIONS

The performance assessment covers the following Loadshift elements:

1.1, 1.2, 1.3, 2.1, 3.1 & 3.2

1. This assessment requires the 2. Prior learning & experience

operator to check the 2.1 An applicant who holds a

equipment, plan the work and front-end loader,

to safely and competently excavator, dragline or

operate the front-end dozer certificate do not

loader/backhoe. require assessment in

sections 2, 3, 4, 7, 8 and 9.

The Assessment is performed in 2.2 Applicant who produces

ten sections: satisfactory documentary

evidence (such as a log

1.1 Conduct routine pre-

book) which establishes 50

operational check front-

days experience in front-

end loader/backhoe,

end loader/backhoe

equipment and the security

operations specifically

of attachments.

covering competencies

1.2 Inspect the site, plan work

tested in sections 2, 3, 4, 7, 8

and select and fit

and 9 does not require

appropriate attachments.

assessment in these

1.3 Conduct pre-operational

sections.

and post start up checks.

1.4 Drive to the work area.

3. The performance assessment

1.5 Set up machine and

can be conducted at any

excavate a trench.

location which has:

1.6 Use the front-end

Sufficient clear space to

loader/backhoe as a crane

operate the machine

1.7 Backfill the trench and load

Ground suitable for

or simulate lading a truck.

excavating

1.8 Consolidate and level a

surface.

1.9 Pick up and shift material in

the bucket.

1.10 Shut down equipment and

secure site.

Front-End Loader/Backhoe Learner Guide June

1995

4. Equipment and Resources 8. Safety of personnel:

Required: When an applicant is working

Front-End dangerously, recklessly or

loader/backhoe and without the necessary co-

equipment. ordination, the assessor must

A write rope sling, chain direct the applicant to cease

sling, shackle and a work and terminate those parts

fibre rope tag line. of the assessment immediately.

Suitable loads to sling

(such as a bundle of 9. The items in the shaded boxes

timber and a concrete are critical importance. Failing

pipe). to get any of these correct

Suitable site on which to means that the competency

use the front-end has not been achieved.

loader/backhoe and

equipment to excavate 10. Where an applicant is assessed

and backfill a trench, as ‘Not Yet Competent’ he/she

use the front-end must be informed of the

loader/backhoe in the reason(s) in order to gain

crane mode and to further appropriate training.

load or simulate loading

of a truck. 11. The full performance

5. Unless other arrangements are assessment can take up to 1

agreed to by the assessor, it will hour and 30 minutes.

be responsibility of the

applicant, applicants employer 12. The general assessment

or trainer to provide the requirements are set out in the

required equipment and Assessor’s guidelines – general.

resources.

13. The applicant’s competence in

6. To be assessed, an applicant each unit is to be summarised

must wear: for both performance and

Safety helmet (where knowledge on the summary

required) sheet. Competence is

Appropriate footwear achieved for a unit when the

Other protective required number of boxes for

clothing and that unit have been ticked or

equipment as marked as ‘NA’.

appropriate

Overall competence is

7. The performance of each achieved when competence

applicant is to be recorded to in all units has been assessed.

the assessors checklist.

Front-End Loader/Backhoe Learner Guide June

1995

Front-End Loader/Backhoe Learner Guide June

1995

Front-End Loader/Backhoe Learner Guide June

1995

Front-End Loader/Backhoe Learner Guide June

1995

Conduct Routine Checks:

Performance Criteria 1.1.1 and Checks other equipment for

1.1.2 defects:

1. Conducts routine checks on Wire slings

vehicle equipment:

Chain slings

Tyre condition & Shackles

inflation

Other Gear

Checks liquid levels: Checks attachments for

security

Fuel

Hydraulic Oil Performance Criteria 1.2.1, 1.2.3

and 1.2.5

Engine Oil 2. Inspects site and plans work:

Battery Identifies Hazards:

Coolant

Power lines

Checks structure for defects: Phone Lines

Service drains

Damaged or broken

parts Obstructions

Loose nuts, bolts and Access and path of movement

couplings is indicated:

To work area

Checks attachment for defects:

For loads

Damage Fits appropriate equipment:

Bucket for missing, work

or loose teeth Suitable tools used

Hoses, fittings, hydraulic Secures catches

rams for oil leaks

Correct procedure

Connections for missing adopted

pins or keepers

Works safely

Grease holes and

grease pins

Front-End Loader/Backhoe Learner Guide June

1995

Performance Criteria 1.3.1

Secures and mounts

3. Conducts pre-operations and

backhoe seat

post start-up checks in

accordance with Check controls

manufacturers Lowers stabilisers (lowest

specifications/operating side first)

manual

Back wheels of ground

Mounts correctly Smoothly operates

Adjusts seat controls

In neutral Tackles task in logical

sequence

Warning device

Engine start Uses sufficient revs for

work

Gauges Uses correct bucket

Warm-up allowed angle

Attachment movement Crowds sufficiently to fill

Clear for travel bucket

Foot brake Deposits full buckets of

Holding brake soil

Deposits soil away from

Steering trench

SHIFT LOAD: Keeps persons out of

Performance Criteria 2.1.1 & 2.1.3 operating radius

4. Drives to the work area: Cuts trench to

Raises attachments specifications

smoothly Demonstrates digging

Secures backhoe around a pipe

bucket

Ensures travel direction Performance Criteria 2.1.2

clear 6. Operates front-end

loader/backhoe as a crane:

Selects appropriate

route Checks sling

Travels at safe speed attachment point

Establishes weight of

5. Sets up backhoe and load

excavates:

Position backhoe

Load not more than

SWL for the operation

competently

Applies brake

Selects appropriate

slings and gear

Lowers bucket

Raises bucket to

connect load

Front-End Loader/Backhoe Learner Guide June

1995

Supervises correct 8. Consolidates and levels

slinging of the load surface:

Ensures tag line Consolidates fill with

connected (if required) loader

Trial lifts load Levels surface with

Moves load to hand bucket blade

signals Leaves excess fill for

Moves load safely natural compaction

Lowers load to Maintains level surface

designated location to work from

7. Backfills trench and loads 9. Picks up and shifts material in

truck: the bucket:

Bucket at correct level Picks up material

and angle

Shifts material in bucket

Uses sufficient revs and

speed Performance criteria 2.1.1, 2.1.4,

Avoids excessive wheel 2.1.5 and 2.1.6

spin General performance sections of 4,

5, 6, 7, 8 and

Crowds bucket to fill 9

Ensures direction of

travel clear 10. Operates front-end

Travels with bucket low loader/backhoe as a crane:

Acceptable and safe Equipment suitable for

speed the work

Minimises spillage and Machine suitable for

ground damage ground conditions

Uses appropriate path Competently shifts

of travel material

Approaches trench or Equipment operated at

truck correctly a safe speed

Smoothly raises and Signals are interpreted

dumps load and observed

Repositions bucket Loads placed to ensure

ready for reload stability

Maintains stockpile and Loads placed to avoid

working surface causing hazard

Front-End Loader/Backhoe Learner Guide June

1995

SHUT DOWN EQUIPMENT AND

SECURE SITE

Performance Criteria 3.1.1, 3.1.2

and 3.2.1

11. Shuts down equipment and

secures site:

Parks equipment:

Machine parked in

suitable area

Attachments lowered

to ground

Cutting edge of bucket

on ground

Shuts down equipment:

Neutralises controls

Applies holding break

Idles to stop, locks

ignition

Moves controls to

release pressure

Applies safety lock

(where applicable)

Avoid hazards:

Parks away from

danger areas

Removes keys

Locks cabin (if

applicable)

Front-End Loader/Backhoe Learner Guide June

1995

Assessor Guidelines – Specific (Knowledge Assessment)

ASSESSMENT INSTRUMENT – SPECIATIONS

The performance assessment covers the following Load shift elements:

1.1, 1.2, 1.3, 2.1, 3.1 & 3.2

1. Knowledge assessment for Front-end

Unit 2.0

Loader/Backhoe is divided into three

units and seventeen sections 2.1 Shift load

(performance criteria 1.1.1, 1.1.2 etc).

2.1.1 (select 1)

2. To satisfy the requirements for

competency the applicant must 2.1.2 (select 3)

correctly answer (either in writing or

2.1.3 (select 1)

orally) the specified number of

questions in each of the following 2.1.5 (select 1)

sections:

2.1.7 (select 2)

Unit 1.0

Unit 3.0

1.1 Conduct routine checks

3.1 Shut down equipment

1.1.1 (select 4)

3.1.1 (select 1)

1.1.2 (select 1)

3.1.3 (select 1)

1.2 Plan work

3.2 Secure site

1.2.1 (select 2)

3.2.1 (select 1)

1.2.2 (select 3)

3. Prior learning and experience:

1.2.3 (select 1)

An applicant who holds a front-end

1.2.4 (select 1) loader, excavator, dragline or dozer

certificate who answers questions for

1.2.5 (select 1)

performance criteria 1.1.1, 2.1.2 and 2.1.5

1.3 Check controls and equipment satisfactorily is not required to complete

the rest of the assessment.

1.3.1 (select 1)

4. The full knowledge assessment of

1.3.2 (select 1) twenty six questions can take up to

thirty minutes.

5. The items in the shaded boxes are of

critical importance. Failing to get any

Front-End Loader/Backhoe Learner Guide June 1995

of these correct means that 6. What safety precautions should be

competency has not been achieved. taken to inflate split rim wheels?

6. The applicant's competence in each Do not stand in front of the wheel

unit is to be summarised for both

performance and knowledge on the and inflate tyre in a cage if

summary sheet. Competence is available.

achieved for a unit when the required

7. Is it permissible to join a chain sling

number of boxes for that unit have

with a bolt?

been ticked or marked `N/A'.

No.

Overall competence is achieved

when competence in all units has 8. What % of broken wires within a lay or

been assessed. in eight diameters of a wire rope sing

would cause it to be discarded?

CONDUCT ROUTINE CHECKS:

Performance criteria 1.1.1 (select 4 10% of the wires.

including 1 with a shaded box)

1. What precaution must be taken when Performance criteria 1.1.2 (select 1)

inspecting under a raised

attachment? 9. What must be done to a lowered

backhoe bucket before travelling?

Provision provided to prevent

attachment descending. Raise the bucket and secure it.

2. Name three defects to look for in the 10. What shall be provided on a front-

hydraulic system. end loader/backhoe before it is used

as a crane?

Oil leaks, loose connections, splits,

fractures or bulges in hoses. Special provision to attach the

slings to and the SWL marked on

3. When should slings be inspected? the equipment.

Prior to their use. (AS1666)

4. What % wear in a shackle would PLAN WORK:

cause it to be discarded? Performance criteria 1.2.1 (select 2)

10% wear.

11. In built-up areas what checks should

5. Briefly describe how you would be made before excavating?

check the air pressure of water filled

tyres. Check for power, telephone, gas or

Check with the valve at the top of drainage lines.

the wheel.

12. What would you refer to in order to

establish the location of underground

services?

Supply authority or council maps.

Front-End Loader/Backhoe Learner Guide June 1995

13. Name two methods that you would 20. What is the minimum type of

use to prevent a cave in of a trench footwear that an operator should

or excavation? wear to operate loadshifting

equipment?

Shoring, battering or benching.

Non-slip footwear that encloses the

14. If you accidentally damaged an foot.

underground electrical cable who

would you immediately contact to

render the power supply safe?

Performance criteria 1.2.3 (select 1)

The electrical supply authority.

21. Which is the preferred route of travel,

diagonally across or directly down

sloping surface?

Performance criteria 1.2.2 (select 3

including 1 with a shaded box) Directly down the sloping surface.

15. What shall be provided to prevent a 22. What gear should be selected to

person falling into a trench? travel down a steep sloping surface?

Barricades or guardrails or fencing. A low gear. The gear required to

climb the sloping surface.

16. When should ear protection be worn?

Performance criteria 1.2.4 (select 1)

Where the noise could contribute

to the loss of hearing. 23. What would you be required to

obtain from the Relevant Authority to

operate a machine in a hazardous

working area?

17. What is the danger of loading a truck

across a sloping surface? The required permits.

The loader could overturn. 24. What Government licence do you

require to drive a front-end

18. When should an operator wear a

loader/backhoe over 4.5 tonnes on a

safety helmet?

public road?

Where the person could be struck

The appropriate heavy vehicle

on the head.

licences.

19. In doubtful soil, what depth trench is

required to be shored before it is

entered?

Trenches over 1.5m deep.

Front-End Loader/Backhoe Learner Guide June 1995

Performance criteria 1.2.5 (select 1) SHIFT LOAD:

Performance criteria 2.1.1 (select 1)

25. What attachment would you use to

break up reinforced concrete?

30. Is it permissible to hoist persons with

Hydraulic hammer attachment. the bucket of a front-end

loader/backhoe?

26. When a front-end loader/backhoe

is used in a demolition process what No.

shall be provided to the machine to

protect the operator? 31. Is it permissible to attach slings to the

teeth of the bucket?

An overhead protective structure.

(AS 2601) No.

CHECK CONTROLS AND EQUIPMENT: Performance criteria 2.1.2 (select 3)

Performance Criteria 1.3.1 (select 1)

32. What effect would sloping ground

have on the load that you would

27. What action would you take if you hoist and carry with the front-end

noticed a bulge form in a hydraulic loader/backhoe?

hose?

It would reduce the load that

Replace the hose before the could be safely carried.

machine is used.

33. What is the approximate weight of

28. When should tests, checks and cubic metre of concrete?

inspections be made by the

operator on the front-end 2.4 tonnes.

loader/backhoe that is to be

34. What is the approximate SWL of a

operated?

12mm diameter wire rope?

Daily before use.

12 x 12 x 8 = 1152kg.

35. Of topsoil or clay which is more

Performance criteria 1.3.2 (select 1) cohesive and harder to excavate,

push and spread?

29. What action would you take with

damage and defects found on the Clay.

machine?

36. What effect does a choker hitch

Report the damage and defects to around a square load have on the

authorised person and ensure SWL for the sling?

safety is not jeopardised.

Reduces the SWL by 50%.

37. State the rule of thumb formula to

calculate the SWL of wire rope.

Diameter in mm squared x 8 = SWL

in kgs.

Front-End Loader/Backhoe Learner Guide June 1995

Performance criteria 2.1.3 (select 1) 44. If the machine contacted a live

power line which could not be

38. Before reversing the machine what released or the power turned off, how

precaution should be taken? would you dismount the machine?

Ensure the direction of travel is Jump clear ensuring contact with

the ground and machine is not at

clear.

the same time.

39. What is the added danger when a

45. If the slings shifted on a load being

trench is under cut?

hoisted, what action would you take?

The trench is more likely to cave in.

Stop the crane, warn people in the

area, then carefully lower the load

and have the slings re-positioned

Performance criteria 2.1.5 (select 1) and secured.

40. Applicant to state the meaning of the SHUT DOWN EQUIPMENT:

hand signal for "hoisting lower" Performance criteria 3.1.1 (select 1)

demonstrated by the assessor.

Hoisting lower. 46. Name three areas where you would

not park the front-end

41. Applicant to state the meaning of the loader/backhoe.

hand signal for "hoisting raise"

demonstrated by the assessor. Access ways, near overhangs,

refuelling sites, tidal or flood areas,

Hoisting raise. adjacent to an excavation.

42. Applicant to state the meaning of the 47. When leaving the loadshifting

hand signal of "stop" demonstrated equipment what should be done with

by the assessor. all hydraulically raised attachments?

Stop. Attachments lowered and pressure

removed from hydraulic lines.

Performance criteria 2.1.7 (select 2)

Performance criteria 3.1.3 (select 1)

43. What action would you take if a

hydraulic hose sprung a leak while 48. What post-operational checks should

the bucket was raised? be carried out by the operator on the

front-end loader/backhoe to prepare

Lower bucket and have repairs

it ready to be reoperated?

carried out.

Check the structure and equipment

for defects and wear and the oil,

fuel and water levels.

Front-End Loader/Backhoe Learner Guide June 1995

SECURE SITE:

Performance criteria 3.2.1 (select 1)

49. What shall be provided when a front-

end loader/backhoe has to be

parked on or protrudes onto an

access way?

Barricades, lights and signs.

50. For what reason should the key be

removed from the ignition of the

machine?

To prevent unauthorised

movement.

51. Before leaving the site what must be

provided to restrict access to the site?

Barricades or fences.

Front-End Loader/Backhoe Learner Guide June 1995

Unit Form of Total Number of Number of Were all Assessment

assessment number of boxes boxes critical standard

boxes in given or required to boxes given requirement

the NA meet or NA? s achieved *

assessme standard

nt

Performance 40 36 Yes No Yes No

Knowledge 15 10 Yes No Yes No

Assessment completed within time allowed Yes No NA

Performance 59 54 Yes No Yes No

Knowledge 8 5 Yes No Yes No

Assessment completed within time allowed Yes No NA

Performance 11 9 Yes No Yes No

Knowledge 3 2 Yes No Yes No

Assessment completed within time allowed Yes No NA

*Performance standard = Number of items required to meet standard

(including all critical boxes)

Knowledge standard = Number of questions required to meet standard

(including all critical boxes)

Summary

Candidate is:

COMPETENT Date:_____________________________________________

NOT YET COMPETENT

Name of Assessor:__________________________________ Signature: ____________________________

Name of Candidate_______________________________ Signature: ____________________________

Comments/feedback:

_________________________________________________________________________________________________________

Front-End Loader/Backhoe Learner Guide June

_________________________________________________________________________________________________________

1995

_________________________________________________________________________________________________________

Вам также может понравиться

- Top loading safety procedureДокумент10 страницTop loading safety procedureVictor BallesterosОценок пока нет

- Liebherr L556 454 Wheel Loader Operators Operating ManualДокумент48 страницLiebherr L556 454 Wheel Loader Operators Operating ManualNik ShaginОценок пока нет

- Forklift TrainingДокумент39 страницForklift Trainingagus sofyan100% (1)

- Excavator Training Hard Hat PDFДокумент25 страницExcavator Training Hard Hat PDFRajesh Kumar Singh100% (1)

- Efficient and Safe Machine OperationДокумент9 страницEfficient and Safe Machine OperationYeny CatzinОценок пока нет

- Fifth Wheel Coupling and Uncoupling ProceduresДокумент3 страницыFifth Wheel Coupling and Uncoupling ProceduresAbrar HussainОценок пока нет

- Cranes Hoists Truck CranesДокумент26 страницCranes Hoists Truck Cranesrajesh_jeev100% (1)

- Load Chart ErwinДокумент6 страницLoad Chart Erwinerwin piliangОценок пока нет

- Daily Mobile Crane Inspection Checklist Section A: InspectionДокумент2 страницыDaily Mobile Crane Inspection Checklist Section A: InspectionFraz AhmadОценок пока нет

- Sample Vehicle Fleet Safety & Usage PolicyДокумент6 страницSample Vehicle Fleet Safety & Usage PolicycoennovationsОценок пока нет

- Earthmoving Equipment Used As A CraneДокумент3 страницыEarthmoving Equipment Used As A CraneImran Alam100% (1)

- Digger Derrick Operator - Candidate Handbook - 091517c PDFДокумент42 страницыDigger Derrick Operator - Candidate Handbook - 091517c PDFyousuf79Оценок пока нет

- 3 Tonne Electric: Forklift TruckДокумент2 страницы3 Tonne Electric: Forklift TruckGokulprasad GopalanОценок пока нет

- Haul Truck Operation PDFДокумент57 страницHaul Truck Operation PDFRalph Castillo100% (1)

- Rim Clamp Tire Changer Maintenance TipsДокумент7 страницRim Clamp Tire Changer Maintenance Tipsdionisio emilio reyes jimenezОценок пока нет

- Traffic management strategies for mines and quarriesДокумент24 страницыTraffic management strategies for mines and quarriesSuriya Prakash.mОценок пока нет

- Electric Pallet Jack SafetyДокумент2 страницыElectric Pallet Jack Safetyurip supriyatnaОценок пока нет

- Front-End Loader Safety ProceduresДокумент15 страницFront-End Loader Safety Proceduresreda mesbahОценок пока нет

- 1638 MowerДокумент56 страниц1638 MowerMandy MaddockОценок пока нет

- Genie Train The Trainer CatalogДокумент9 страницGenie Train The Trainer CatalogClaudio FreitasОценок пока нет

- MTD 24A46E729 Chipper-Shredder Owner's ManualДокумент20 страницMTD 24A46E729 Chipper-Shredder Owner's ManualcpprioliОценок пока нет

- Aerial-Scissor-Lift-Safety-Program SAMPLEДокумент19 страницAerial-Scissor-Lift-Safety-Program SAMPLEluis Veloz100% (1)

- Frequent Inspection ChecklistДокумент2 страницыFrequent Inspection Checklistzae nurdinОценок пока нет

- Manitowoc 8500 1Документ24 страницыManitowoc 8500 1Mohd FadliОценок пока нет

- 5 Truck Drivers GuideДокумент25 страниц5 Truck Drivers Guidedsn_sarmaОценок пока нет

- Inspection Plan For Crane PDFДокумент3 страницыInspection Plan For Crane PDFalinor_tnОценок пока нет

- TMW 041 Exam PDFДокумент8 страницTMW 041 Exam PDFMarco Guachun0% (1)

- LF Forklift Training Manual 04.4Документ89 страницLF Forklift Training Manual 04.4indikumaОценок пока нет

- Marines Heavy Construction Equipment - ScraperДокумент37 страницMarines Heavy Construction Equipment - ScraperSpace_Hulker100% (2)

- Forklift TruckДокумент1 страницаForklift TruckShazaley AbdullahОценок пока нет

- Forklift Training Quiz and AnswersДокумент10 страницForklift Training Quiz and AnswersPablo Valenzuela Arredondo100% (2)

- Thunder Tiger ManualДокумент49 страницThunder Tiger ManualOle Kristian FlatøyОценок пока нет

- What ROPS FOPS Certification MeansДокумент8 страницWhat ROPS FOPS Certification MeansJose Morales100% (1)

- DKAKPLDRДокумент36 страницDKAKPLDRCarlos Mezt100% (1)

- Driver Training Strategies: An Educational Webcast Sponsored byДокумент54 страницыDriver Training Strategies: An Educational Webcast Sponsored byJunaid QamerОценок пока нет

- Drive Rider&Pushmower PartsДокумент36 страницDrive Rider&Pushmower Partsfogdart100% (2)

- 1 DX450 SCT Leaflet en W3636Документ4 страницы1 DX450 SCT Leaflet en W3636Jonathan Alexis Quispe HuamaniОценок пока нет

- Fall Protection Work Plan - Roof CladdingДокумент2 страницыFall Protection Work Plan - Roof CladdingGibbs PerОценок пока нет

- Planetary Rigid and Steering Axle Wheel Ends: Cantilever-Mounted Planetary Pinion Shaft DesignДокумент44 страницыPlanetary Rigid and Steering Axle Wheel Ends: Cantilever-Mounted Planetary Pinion Shaft DesignAmal TharakaОценок пока нет

- Warn 2013-2014 Application GuideДокумент75 страницWarn 2013-2014 Application Guideapi-238139220Оценок пока нет

- Harrington Ner Er Hoist Manual Parts ListДокумент143 страницыHarrington Ner Er Hoist Manual Parts ListliftОценок пока нет

- TR - Backhoe LoaderДокумент84 страницыTR - Backhoe LoaderRonald Poldo100% (1)

- Inspection ChecklistДокумент2 страницыInspection ChecklistBerp OnrubiaОценок пока нет

- Catalogue V 7Документ212 страницCatalogue V 7Keris TidarОценок пока нет

- Cub Cadet Zero TurnДокумент1 страницаCub Cadet Zero TurngillerdoitОценок пока нет

- Bradco 625 Trencher ManualДокумент107 страницBradco 625 Trencher ManualAnonymous zSpR5jUdОценок пока нет

- Truck Mounted Cranes: Hazard & Risk Assessment - Plant OperationДокумент3 страницыTruck Mounted Cranes: Hazard & Risk Assessment - Plant OperationsoumyakantОценок пока нет

- Craftsman Tractor ManualДокумент72 страницыCraftsman Tractor Manualbjhoxie106Оценок пока нет

- Skyjack 3219, 3226 & 4632 operating instructionsДокумент16 страницSkyjack 3219, 3226 & 4632 operating instructionsVasske VasovićОценок пока нет

- Forklift PDFДокумент17 страницForklift PDFANKUSHОценок пока нет

- Front-End Loader Performance AssessmentДокумент25 страницFront-End Loader Performance Assessmentsyedthahir6609Оценок пока нет

- Scissors Lifts TrainingДокумент27 страницScissors Lifts TrainingpanjemadjoОценок пока нет

- Lawn Mover ManualДокумент52 страницыLawn Mover ManualJACKОценок пока нет

- Vortex Loading Spout Data PDFДокумент2 страницыVortex Loading Spout Data PDFPat AuffretОценок пока нет

- Belsaw M-14 Owners ManualДокумент16 страницBelsaw M-14 Owners ManualVzslzg100% (1)

- Forklift QuizДокумент2 страницыForklift Quiz7twofourОценок пока нет

- 360 Excavator Training ManualДокумент14 страниц360 Excavator Training ManualBiruk YifruОценок пока нет

- Safe Work Procedure - Dump Truck: Company NameДокумент4 страницыSafe Work Procedure - Dump Truck: Company Nameangkatan 2014Оценок пока нет

- Air Conditioning System Refrigerant Check ProcedureДокумент48 страницAir Conditioning System Refrigerant Check Procedurespeedkar9Оценок пока нет

- Haul Truck 1Документ16 страницHaul Truck 1Mohammed Iddrisu AntwiОценок пока нет

- Karel The Robot Learns Python 11codeДокумент1 страницаKarel The Robot Learns Python 11codeOwen PerrinОценок пока нет

- Eggplant ParmesanДокумент1 страницаEggplant ParmesanDewayne AginОценок пока нет

- HobbyДокумент9 страницHobbyOwen PerrinОценок пока нет

- USB Connector Type GuideДокумент9 страницUSB Connector Type GuideOwen PerrinОценок пока нет

- Société Bic: Société Bic S.A., Commonly Referred To Simply As Bic and StylizedДокумент6 страницSociété Bic: Société Bic S.A., Commonly Referred To Simply As Bic and StylizedOwen PerrinОценок пока нет

- Googles Carbon Programming Language Could Be A Worthy Successor To CДокумент3 страницыGoogles Carbon Programming Language Could Be A Worthy Successor To COwen PerrinОценок пока нет

- Synthesis of ChloroformДокумент5 страницSynthesis of ChloroformOwen PerrinОценок пока нет

- Nist Ams 200-12Документ87 страницNist Ams 200-12Owen PerrinОценок пока нет

- Haloform ReactionДокумент2 страницыHaloform ReactionOwen PerrinОценок пока нет

- Australian - Museum Pied ButcherbirdДокумент4 страницыAustralian - Museum Pied ButcherbirdOwen PerrinОценок пока нет

- Getting Started With GitHub Copilot in VS Code (Docs Github Com)Документ5 страницGetting Started With GitHub Copilot in VS Code (Docs Github Com)Owen Perrin100% (1)

- Getting Started With GitHub Copilot in A JetBrains IDE (Docs Github Com)Документ7 страницGetting Started With GitHub Copilot in A JetBrains IDE (Docs Github Com)Owen PerrinОценок пока нет

- Excavator Leraner Guide PDFДокумент32 страницыExcavator Leraner Guide PDFOwen PerrinОценок пока нет

- Timber-Framed Construction For Townhouse Buildings Class 1aДокумент44 страницыTimber-Framed Construction For Townhouse Buildings Class 1aOwen PerrinОценок пока нет

- AIW Tech Drawings For AS4654 2Документ17 страницAIW Tech Drawings For AS4654 2Owen PerrinОценок пока нет

- CPCCPB3010A Manually Sand Plaster WorkДокумент12 страницCPCCPB3010A Manually Sand Plaster WorkOwen PerrinОценок пока нет

- Concrete Testing Price List: GippslandДокумент2 страницыConcrete Testing Price List: GippslandOwen PerrinОценок пока нет

- Askin Understanding Requirements For External Cladding PDFДокумент6 страницAskin Understanding Requirements For External Cladding PDFOwen PerrinОценок пока нет

- CPCCPB3001A Fix Standard Plasterboard Wall Sheets TAP PDFДокумент9 страницCPCCPB3001A Fix Standard Plasterboard Wall Sheets TAP PDFOwen PerrinОценок пока нет

- Excavator Leraner Guide PDFДокумент32 страницыExcavator Leraner Guide PDFOwen PerrinОценок пока нет

- 6-C-RIIMPO301E - Conduct Hydraulic Excavator Operations - Learner Guide - V 1.1 02122019 PDFДокумент31 страница6-C-RIIMPO301E - Conduct Hydraulic Excavator Operations - Learner Guide - V 1.1 02122019 PDFOwen PerrinОценок пока нет

- Askin Understanding Requirements For External Cladding PDFДокумент6 страницAskin Understanding Requirements For External Cladding PDFOwen PerrinОценок пока нет

- 6-C-RIIMPO301E - Conduct Hydraulic Excavator Operations - Learner Guide - V 1.1 02122019 PDFДокумент31 страница6-C-RIIMPO301E - Conduct Hydraulic Excavator Operations - Learner Guide - V 1.1 02122019 PDFOwen PerrinОценок пока нет

- CPCCPB3025A Store Plasterboard and Related ProductsДокумент14 страницCPCCPB3025A Store Plasterboard and Related ProductsOwen PerrinОценок пока нет

- Timber Wall Framing: Understanding NoggingsДокумент1 страницаTimber Wall Framing: Understanding NoggingsOwen PerrinОценок пока нет

- CPCCPB3008A Mix Plastering Compounds TAPДокумент8 страницCPCCPB3008A Mix Plastering Compounds TAPOwen PerrinОценок пока нет

- CPCCPB3002A Fix Standard Plasterboard Ceiling SheetsДокумент8 страницCPCCPB3002A Fix Standard Plasterboard Ceiling SheetsOwen PerrinОценок пока нет

- CPCCPB3009A Finish Plasterboard Joints ManuallyДокумент13 страницCPCCPB3009A Finish Plasterboard Joints ManuallyOwen PerrinОценок пока нет

- Fix battens CPCCPB3003A trainer answer packДокумент11 страницFix battens CPCCPB3003A trainer answer packOwen PerrinОценок пока нет

- How Airbags Work StoichiometryДокумент2 страницыHow Airbags Work StoichiometryEman FatimaОценок пока нет

- Technical Manual: Specifications - Operation - Maintenance - PartsДокумент3 страницыTechnical Manual: Specifications - Operation - Maintenance - PartsHanyОценок пока нет

- MS 20Документ52 страницыMS 20Guru Nath33% (3)

- 11 and 12Документ2 страницы11 and 12Ronnie Garcia Del RosarioОценок пока нет

- Ticket Frankfurt Berlin 3076810836Документ2 страницыTicket Frankfurt Berlin 3076810836farzad kohestaniОценок пока нет

- Customer Letter MailingДокумент6 страницCustomer Letter MailingalliancerОценок пока нет

- ME (1) The Direct Current Motor Generator REPORT1Документ7 страницME (1) The Direct Current Motor Generator REPORT1Giorgia DalusungОценок пока нет

- 1 Sejarah Strukur&DesainДокумент34 страницы1 Sejarah Strukur&Desaininspektorat babelОценок пока нет

- WPS Bus Alternato Starters 2013Документ12 страницWPS Bus Alternato Starters 2013boussebsi ahmedОценок пока нет

- Vic 2019 CatalogДокумент893 страницыVic 2019 CatalogAnna Mae Marantan100% (1)

- Indian Railways (IR) Is AДокумент10 страницIndian Railways (IR) Is AdsОценок пока нет

- Space Inquiries GIIAS 2023-Supporting-SendДокумент8 страницSpace Inquiries GIIAS 2023-Supporting-Sendpenyimpanan videoОценок пока нет

- FinalДокумент36 страницFinalTinsae SolomonОценок пока нет

- Long Arm Excavator SeriesДокумент4 страницыLong Arm Excavator SeriesBryson PlazosОценок пока нет

- Wheel User ManualДокумент90 страницWheel User ManualWilliam MendezОценок пока нет

- Hino-5 Ton LorryДокумент2 страницыHino-5 Ton LorrythowchinОценок пока нет

- AL JanamДокумент34 страницыAL Janamkalpana patelОценок пока нет

- SATIP-Q-006-02 Rev 8 Conventional & Sulfur Extended Asphalt Paving FinalДокумент3 страницыSATIP-Q-006-02 Rev 8 Conventional & Sulfur Extended Asphalt Paving FinalSehna SerajОценок пока нет

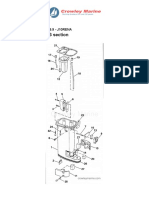

- Exhaust Housing - 1992 Johnson Outboards 9.9 J10renaДокумент7 страницExhaust Housing - 1992 Johnson Outboards 9.9 J10renaCharlie CB PortnerОценок пока нет

- Rural Development Construction.Документ41 страницаRural Development Construction.Anuj SubbaОценок пока нет

- Toyota's Five Forces Analysis (Porter's Model) : Business ManagementДокумент14 страницToyota's Five Forces Analysis (Porter's Model) : Business ManagementOnalenna Tracy MaikanoОценок пока нет

- HBT80C-1818DIII Trailer-Mounted Concrete PumpДокумент2 страницыHBT80C-1818DIII Trailer-Mounted Concrete PumpRentalmix manutenção umОценок пока нет

- Agrolux 50E Tractor - T-676-1182-2009 PDFДокумент10 страницAgrolux 50E Tractor - T-676-1182-2009 PDFPreet SinghОценок пока нет

- Hyosung Comet 650S - 650R Service ManualДокумент49 страницHyosung Comet 650S - 650R Service Manualuros zupancicОценок пока нет

- EPPR-21-17 Humidity and Temperature Correction Factors For NOx From DieselДокумент16 страницEPPR-21-17 Humidity and Temperature Correction Factors For NOx From DieselMagoroku D. YudhoОценок пока нет

- Consumer Satisfaction Towards Maruti SuzukiДокумент97 страницConsumer Satisfaction Towards Maruti SuzukiManjar ImamОценок пока нет

- ST Augustine Map and Tour SitesДокумент3 страницыST Augustine Map and Tour SitesacrerakeОценок пока нет

- Superelevation Calculation (New Standard)Документ16 страницSuperelevation Calculation (New Standard)jkrlos_188441Оценок пока нет

- Opel Insigna Dritat e GjataДокумент4 страницыOpel Insigna Dritat e GjataZamir ShehuОценок пока нет

- P&G - RFQ - Ex. ZirakpurДокумент5 страницP&G - RFQ - Ex. Zirakpurgurpreet.singh1Оценок пока нет