Академический Документы

Профессиональный Документы

Культура Документы

GRINNELL Figure 780 Grooved Snap Couplings 1-1/4 Thru 8 Inch (DN32 Thru DN200) General Description

Загружено:

Сергей КолесниковОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

GRINNELL Figure 780 Grooved Snap Couplings 1-1/4 Thru 8 Inch (DN32 Thru DN200) General Description

Загружено:

Сергей КолесниковАвторское право:

Доступные форматы

Worldwide

www.grinnell.com

Contacts

GRINNELL Figure 780

Grooved Snap Couplings

1-1/4 thru 8 Inch (DN32 thru DN200)

General Snap couplings are factory assembled

to tight safety tolerances. Therefore,

Description some people may have difficultly open-

ing and closing the couplings by hand.

The GRINNELL Figure 780 Grooved Using a leverage pipe can help open or

Snap Couplings are designed for close couplings more easily. A leverage

quickly connecting and disconnecting pipe can be fabricated from an appro-

cut or rolled grooved piping systems. priate length of 1/2 or 3/4 inch Schedule

By utilizing a hinged lever mechanism, 40 pipe.

grooved piping segments are joined This coupling provides a unique two-

quickly and securely without nuts and step closing feature that partially locks

bolts. Coupling housing segments are then closes the coupling, helping to

locked in place by securing the lever minimize the opportunity for personal

handle with a split pin. Coupling sizes 5 injury. Pushing the lever handle initially

thru 8 inch (DN125 thru DN200) feature snaps the housing segments together.

a cross-ribbed housing design for extra Continuing to push the lever handle

strength. then smoothly locks the coupling into

position.

NOTICE

Never remove any piping component

nor correct or modify any piping defi-

Technical

ciencies without first de-pressurizing

and draining the system. Failure to do

Data

so may result in serious personal injury, Sizes

property damage, and/or impaired de- 1-1/4 thru 8 inch (DN32 thru DN200)

vice performance. Maximum Pressure

It is the designer’s responsibility to se- 300 psi (20,7 bar) Gasket Materials

lect products suitable for the intended • Grade “E” EPDM,

Housing and Lever Handle

service and to ensure that pressure Green color code,

Ductile Iron conforming to ASTM

ratings and performance data are not -30°F (-34°C) to +230°F (+110°C)

A536, Grade 65-45-12

exceeded. Material and gasket selec- • Grade “T” Nitrile,

tion should be verified for compatibil- Finish

Orange color code,

ity with the specific application. Always • Black, electro-deposition coated

-20°F (-29°C) to +180°F (+82°C)

read and understand the installation (Standard)

instructions. Refer to Technical Data Sheet G610 for

• Hot-dipped Galvanized

more gasket information.

The products described herein must be (Optional)

installed and maintained in compliance

with this document, as well as with the

applicable standards of the Approval

Toggle Links

Plated Carbon Steel conforming to Ordering

agency, in addition to the standards of

any other authorities having jurisdiction.

ANSI C1010 or C1020

Hinge Pin

Procedure

Failure to do so may result in serious Case-hardened Carbon Steel con- GRINNELL Mechanical Products are

personal injury or impair the perfor- forming to ANSI C1212 available globally through a network of

mance of these devices. distribution centers. Visit www.grinnell.

Rivet com for the nearest distributor.

The owner is responsible for maintain- Carbon Steel conforming to ANSI

ing their mechanical system and devices C1010 When placing an order, indicate the

in proper operating condition. Contact full product name. Specify Figure 780,

Split Pin quantity, size (ANSI inch size or pipe

the installing contractor or product

Carbon Steel Wire Rod conforming to O.D.), finish, and gasket materials.

manufacturer with any questions.

ASTM A421

Snap couplings are not recommended

for services where excessive shock-

loads are present.

Page 1 of 2 SEPTEMBER 2014 G145

G145

Page 2 of 2

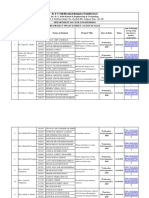

B C

Split Pin

Nominal Pipe Size Nominal Dimensions Deflection

Max. Max. Max. Approx.

Working

ANSI O.D. End Load(2), End Gap, A B C Degrees Inches/ Weight,

Pressure(1)(2),

Inches Inches Lbs. Inches Inches Inches Inches per Foot Lbs.

psi

DN mm kN mm mm mm mm Coupling mm/m kg

bar

1-1/4 1.660 300 650 0.06 3.28 5.14 1.75 0.65 1.6

3°6'

32 42,4 20,7 2,9 1,6 83,2 130,5 44,5 54,3 0,7

1-1/2 1.900 300 851 0.06 2.95 4.65 1.85 0.80 2.2

3°48'

40 48,3 20,7 3,8 1,6 75,0 118,0 47,0 66,4 1,0

2 2.375 300 1,329 0.06 3.39 4.76 1.89 0.74 2.4

3°31'

50 60,3 20,7 5,9 1,6 86,0 121,0 48,0 61,5 1,1

2-1/2 2.875 300 1,947 0.06 3.62 5.91 1.89 0.52 3.1

2°30'

65 73,0 20,7 8,7 1,6 92,0 150,0 48,0 43,7 1,4

– 3.000 300 2,121 0.06 3.62 5.91 1.89 0.50 3.1

65 76,1 20,7 9,4 1,6 92,0 150,0 48,0 2°24' 41,9 1,4

3 3.500 300 2,886 0.06 4.69 6.42 1.89 0.50 4.0

2°24'

80 88,9 20,7 12,8 1,6 119,0 163,0 48,0 41,9 1,8

4 4.500 300 4,771 0.13 6.50 8.07 2.05 0.67 5.9

3°12'

100 114,3 20,7 21,2 3,2 165,0 205,0 52,0 55,9 2,7

– 5.500 300 7,127 0.13 7.44 9.96 2.05 0.55 10.8

2°37'

125 139,7 20,7 31,7 3,2 189,0 253,0 52,0 45,7 4,9

5 5.565 300 7,289 0.13 7.44 9.96 2.05 0.54 10.8

2°36'

125 141,3 20,7 32,4 3,2 189,0 253,0 52,0 45,4 4,9

– 6.500 300 9,955 0.13 8.39 10.94 2.05 0.47 12.8

2°14'

150 165,1 20,7 44,3 3,2 213,0 278,0 52,0 39,0 5,8

6 6.625 300 10,341 0.13 8.50 11.06 2.05 0.45 12.8

2°10'

150 168,3 20,7 46,0 3,2 216,0 281,0 52,0 37,8 5,8

8 8.625 300 17,528 0.13 10.95 14.02 2.44 0.35 20.5

1°40'

200 219,1 20,7 78,0 3,2 278,0 356,0 62,0 29,1 9,3

Notes:

1. Pressure ratings listed are cold water pressure or maximum working pressure within the service temperature range of the gasket used in the coupling.

2. Maximum working pressures and end loads listed are total of internal and external pressures and loads based on Schedule 40 steel pipe grooved in accordance with

Standard Cut Groove or Roll Groove Specifications.

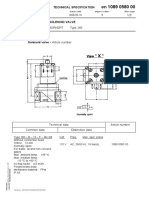

FIGURE 1

FIGURE 780 GROOVED SNAP COUPLINGS

NOMINAL DIMENSIONS

GLOBAL HEADQUARTERS | 1400 Pennbrook Parkway, Lansdale, PA 19446 | Telephone +1-215-362-0700

Copyright © 2014 Tyco Fire Products, LP. All rights reserved.

Вам также может понравиться

- GRINNELL Figure 772 Grooved Rigid Coupling 1-1/4 - 24 Inch (DN32 - DN600) Sizes 1/2 Inch (M12) Bolt For 2 - 4 Inch (DN50 - DN100) Sizes General Description Technical DataДокумент4 страницыGRINNELL Figure 772 Grooved Rigid Coupling 1-1/4 - 24 Inch (DN32 - DN600) Sizes 1/2 Inch (M12) Bolt For 2 - 4 Inch (DN50 - DN100) Sizes General Description Technical DataСергей КолесниковОценок пока нет

- Tyco Grinnell Grooved CouplingДокумент4 страницыTyco Grinnell Grooved Couplingprvns0074377Оценок пока нет

- GRINNEL Fig 577Документ4 страницыGRINNEL Fig 577rutyОценок пока нет

- GRINNELL Figure 716 Flexible Reducing Coupling Technical Data General DescriptionДокумент2 страницыGRINNELL Figure 716 Flexible Reducing Coupling Technical Data General DescriptionСергей КолесниковОценок пока нет

- GRINNEL Figure 577 Acoplamiento Rig RanДокумент4 страницыGRINNEL Figure 577 Acoplamiento Rig RanFIRE RL SYSTEMSОценок пока нет

- Figure 740 GRINNELL Rapid Installation Pivot-Bolt (GRIP) Rigid CouplingДокумент4 страницыFigure 740 GRINNELL Rapid Installation Pivot-Bolt (GRIP) Rigid CouplingСергей КолесниковОценок пока нет

- Grinnel Fig 577Документ4 страницыGrinnel Fig 577FIRE RL SYSTEMSОценок пока нет

- G135 07 2012 PDFДокумент4 страницыG135 07 2012 PDFСергей КолесниковОценок пока нет

- GRINNELL 577 Replacem. VICTAULIC STYLE 75Документ4 страницыGRINNELL 577 Replacem. VICTAULIC STYLE 75Сергей КолесниковОценок пока нет

- VITAULICДокумент8 страницVITAULICJoko SchumacherОценок пока нет

- Grinnel Fig 522 - Salida StrapДокумент6 страницGrinnel Fig 522 - Salida StraprutyОценок пока нет

- Coupling Grinnell G110!08!2018Документ4 страницыCoupling Grinnell G110!08!2018Claudia YanesОценок пока нет

- Mechanical-T Bolted Branch Outlets: Carbon Steel Pipe - Hole Cut ProductsДокумент8 страницMechanical-T Bolted Branch Outlets: Carbon Steel Pipe - Hole Cut ProductsAritz BilbaoОценок пока нет

- TFP1865 03 2013Документ4 страницыTFP1865 03 2013Srikanth ShanmugamОценок пока нет

- Tee Mecanica RanuradaДокумент8 страницTee Mecanica Ranuradajhoger2012Оценок пока нет

- Rosemount 1195 Integral Orifice Primary Element: Product Data SheetДокумент18 страницRosemount 1195 Integral Orifice Primary Element: Product Data Sheetابزار دقیقОценок пока нет

- Catalogue Seal Oil CoolerДокумент28 страницCatalogue Seal Oil CoolerSharad KokateОценок пока нет

- Conexiones TycoДокумент27 страницConexiones TycoAdriana Agundiz RomeroОценок пока нет

- Quickvic Flexible Coupling For Steel: Carbon Steel Pipe - Grooved CouplingsДокумент4 страницыQuickvic Flexible Coupling For Steel: Carbon Steel Pipe - Grooved CouplingsMina MagdyОценок пока нет

- 7200 Series Rochester GaugesДокумент2 страницы7200 Series Rochester GaugesShafqat IqbalОценок пока нет

- Differential Pressure Recorder Data SheetДокумент8 страницDifferential Pressure Recorder Data SheetEdmund LimОценок пока нет

- 05 Tyco TJRДокумент6 страниц05 Tyco TJRsamОценок пока нет

- Fuji Finepix s5200 s5600Документ121 страницаFuji Finepix s5200 s5600zilikonОценок пока нет

- 2020 21 Hoseflex X Klaw CatalogueДокумент13 страниц2020 21 Hoseflex X Klaw CataloguemassabdelОценок пока нет

- ncsmq92 SolderДокумент2 страницыncsmq92 SolderSergio MoyaОценок пока нет

- Style 28 Coupling: Applied Vic-Ring SystemДокумент4 страницыStyle 28 Coupling: Applied Vic-Ring SystemMina MagdyОценок пока нет

- Product Data Sheet: The Shand & Jurs Model 92021 Automatic Tank Level GaugeДокумент13 страницProduct Data Sheet: The Shand & Jurs Model 92021 Automatic Tank Level GaugeLuciano Nazareno Torres GallardoОценок пока нет

- Flow Meter PDFДокумент20 страницFlow Meter PDFJoe Mari CapaОценок пока нет

- NC-SMQ81: Solder PasteДокумент2 страницыNC-SMQ81: Solder Pastealireza221369Оценок пока нет

- AGS Flexible Coupling: WarningДокумент4 страницыAGS Flexible Coupling: WarningtylerlhsmithОценок пока нет

- THE Tri-Con SeriesДокумент6 страницTHE Tri-Con Seriespablopasqualini18Оценок пока нет

- EagleBurgmann - Cartex ANSI Dual Seals - ENДокумент4 страницыEagleBurgmann - Cartex ANSI Dual Seals - ENJavier PerezОценок пока нет

- Pipe Fit Split Repair SleeveДокумент3 страницыPipe Fit Split Repair Sleeveichal_zaidanОценок пока нет

- Corro-Coat EP TDSДокумент3 страницыCorro-Coat EP TDSShahroze IlyasОценок пока нет

- Pressure Reducing Valves Technical SpecificationДокумент4 страницыPressure Reducing Valves Technical SpecificationSanket SavlaОценок пока нет

- Gas Sampling Device Comem GSD: Data SheetДокумент4 страницыGas Sampling Device Comem GSD: Data SheethecjavpaОценок пока нет

- Fujifilm Finepix s9000 s9500 SM ET 1Документ147 страницFujifilm Finepix s9000 s9500 SM ET 1newionОценок пока нет

- PVCMC 0501 Us PDFДокумент40 страницPVCMC 0501 Us PDFAshok SureshОценок пока нет

- Style 31 Vic-Ring CouplingДокумент2 страницыStyle 31 Vic-Ring CouplingJohan Vilchez EsquivelОценок пока нет

- INH InstaLock Brochure LRДокумент8 страницINH InstaLock Brochure LRviniciusОценок пока нет

- Victaulic Style W77 16.12Документ6 страницVictaulic Style W77 16.12Mi KeОценок пока нет

- PRESOTATO S4320 TecsisДокумент2 страницыPRESOTATO S4320 TecsisRolando Jara YoungОценок пока нет

- Smart Ideas for the Smart GenerationДокумент48 страницSmart Ideas for the Smart GenerationKavin SengodanОценок пока нет

- RSK eДокумент4 страницыRSK eedark2009Оценок пока нет

- NTTДокумент8 страницNTTIon FloareaОценок пока нет

- Catalogo EV Agua M&MДокумент56 страницCatalogo EV Agua M&Mmemosurf3775Оценок пока нет

- Canadoil Pipe Ltd. manufactures LSAW pipesДокумент20 страницCanadoil Pipe Ltd. manufactures LSAW pipesSharad ShahОценок пока нет

- Airmaster HVAC Ducting BrochureДокумент12 страницAirmaster HVAC Ducting BrochureWaseem NaamoОценок пока нет

- Y Strainer VictaulicДокумент4 страницыY Strainer VictaulicMohammed NiqrisОценок пока нет

- ITT Grinnell Products Standard and Line Pipe Catalog 2008Документ69 страницITT Grinnell Products Standard and Line Pipe Catalog 2008ITT GRINNELLОценок пока нет

- LOT 4 - Technical Specs - 132 KV Transmission Line AccessoriesДокумент13 страницLOT 4 - Technical Specs - 132 KV Transmission Line AccessoriesPeters Clever OkelloОценок пока нет

- Increase Safety and Efficiency with Line Blinding OptionsДокумент22 страницыIncrease Safety and Efficiency with Line Blinding Options최승원Оценок пока нет

- MGH CatalogueДокумент8 страницMGH CataloguemghdarОценок пока нет

- AUIRG7CH80K6B-M: Automotive GradeДокумент3 страницыAUIRG7CH80K6B-M: Automotive GradeMiguel GonzalezОценок пока нет

- APD Cat 26Документ34 страницыAPD Cat 26MAC DIAGОценок пока нет

- Fujifilm Finepix s8000fdДокумент134 страницыFujifilm Finepix s8000fdzilikonОценок пока нет

- Volute Casing Centrifugal Pumps for Heat Transfer Oils up to 350°CДокумент12 страницVolute Casing Centrifugal Pumps for Heat Transfer Oils up to 350°CjambukuningОценок пока нет

- Allweiler NTTДокумент12 страницAllweiler NTTSalsa Amorir50% (2)

- FAMAT Cold Reheat Check Valves 2013 PDFДокумент11 страницFAMAT Cold Reheat Check Valves 2013 PDFAMITОценок пока нет

- WIX Poland ISOTS - 16949 Expires 06-12-2016Документ1 страницаWIX Poland ISOTS - 16949 Expires 06-12-2016Сергей КолесниковОценок пока нет

- Ga30+ AtlascopcoДокумент114 страницGa30+ AtlascopcoDamian DanajОценок пока нет

- Hp-008a Ningbo Yinzhou Maisi MechanicalДокумент1 страницаHp-008a Ningbo Yinzhou Maisi MechanicalСергей КолесниковОценок пока нет

- MAN ISO9001200 - MHDESP - 14.09.2016 - EngДокумент1 страницаMAN ISO9001200 - MHDESP - 14.09.2016 - EngСергей КолесниковОценок пока нет

- Парт листДокумент108 страницПарт листUbanAirlanggaОценок пока нет

- Rotex Torsionally Flexible Coupling: Shaft Coupling Design No. 001 - Material SteelДокумент1 страницаRotex Torsionally Flexible Coupling: Shaft Coupling Design No. 001 - Material SteelСергей КолесниковОценок пока нет

- Электромагнитный клапан соленоидный Burkert 6014Документ4 страницыЭлектромагнитный клапан соленоидный Burkert 6014Сергей КолесниковОценок пока нет

- Dichiarazione Di Conformita PED Rev 20-05-02 ENGДокумент1 страницаDichiarazione Di Conformita PED Rev 20-05-02 ENGСергей КолесниковОценок пока нет

- Dichiarazione Ignifuga Separatori EngДокумент1 страницаDichiarazione Ignifuga Separatori EngСергей КолесниковОценок пока нет

- Rotex Flexible Jaw Couplings: Selection of Standard IEC MotorsДокумент1 страницаRotex Flexible Jaw Couplings: Selection of Standard IEC MotorsСергей КолесниковОценок пока нет

- Electrica Rva Versus Ge3arr3 PDFДокумент3 страницыElectrica Rva Versus Ge3arr3 PDFSlavko TitanОценок пока нет

- Atlas Copco: Parts ListДокумент214 страницAtlas Copco: Parts ListСергей КолесниковОценок пока нет

- Electrica Relay DeterminationДокумент1 страницаElectrica Relay DeterminationmayurnadgoudaОценок пока нет

- Aerzen High Vacuum Blower Moves Practically Any GasesДокумент12 страницAerzen High Vacuum Blower Moves Practically Any GasesСергей КолесниковОценок пока нет

- Rotex Torsionally Flexible Coupling: Technical Data of Our Standard SpidersДокумент1 страницаRotex Torsionally Flexible Coupling: Technical Data of Our Standard SpidersСергей КолесниковОценок пока нет

- Quick reference guide to hose fitting measurementsДокумент6 страницQuick reference guide to hose fitting measurementsСергей КолесниковОценок пока нет

- Advanced Sealing Technology in Compact Two-Stage Design: For The Most Reliable Engine ProtectionДокумент13 страницAdvanced Sealing Technology in Compact Two-Stage Design: For The Most Reliable Engine ProtectionСергей КолесниковОценок пока нет

- Solenoid 1089058003 1089058001 1089058000Документ1 страницаSolenoid 1089058003 1089058001 1089058000Сергей КолесниковОценок пока нет

- Donaldson Filter PDFДокумент3 страницыDonaldson Filter PDFСергей КолесниковОценок пока нет

- FPG Air CleanerДокумент14 страницFPG Air CleanergeorgeОценок пока нет

- Asl Ga 15, Ga 18, Ga 22, Ga 26 Desde Cai 782294Документ228 страницAsl Ga 15, Ga 18, Ga 22, Ga 26 Desde Cai 782294Claudio Andres Lagos Guerrero100% (2)

- Atlas Copco: Oil-Injected Rotary Screw Air CompressorsДокумент70 страницAtlas Copco: Oil-Injected Rotary Screw Air CompressorsСергей КолесниковОценок пока нет

- Air Intake AccessoriesДокумент42 страницыAir Intake AccessoriesMark CarterОценок пока нет

- Air Intake Systems Product Guide PDFДокумент312 страницAir Intake Systems Product Guide PDFbendadiОценок пока нет

- 3RT10656AP36 Datasheet enДокумент11 страниц3RT10656AP36 Datasheet enСергей КолесниковОценок пока нет

- QGS 75-100 Parts Manual - July 24 2020Документ202 страницыQGS 75-100 Parts Manual - July 24 2020Сергей КолесниковОценок пока нет

- CRLI industrial soft starters for motors up to 400kWДокумент2 страницыCRLI industrial soft starters for motors up to 400kWСергей КолесниковОценок пока нет

- Stationary compressor specs and dimensions KSV 65Документ3 страницыStationary compressor specs and dimensions KSV 65Сергей КолесниковОценок пока нет

- MPVL MPVLC HAKG HDKG codesДокумент1 страницаMPVL MPVLC HAKG HDKG codesСергей КолесниковОценок пока нет

- Installation: For Air Ends Witch Can Be Pressurized at The Suction DuctДокумент3 страницыInstallation: For Air Ends Witch Can Be Pressurized at The Suction DuctСергей КолесниковОценок пока нет

- Bert SCH RollsДокумент20 страницBert SCH RollszegyeОценок пока нет

- Ilovepdf Merged AllДокумент47 страницIlovepdf Merged AllAkash VakkayilОценок пока нет

- On Vertical Formwork: Concr Ete PressureДокумент7 страницOn Vertical Formwork: Concr Ete PressureatiОценок пока нет

- Pid General Rev.b1-Pid GeneralДокумент1 страницаPid General Rev.b1-Pid GeneralDaniel GomezОценок пока нет

- Accessories For Dosage and Application PDFДокумент7 страницAccessories For Dosage and Application PDFmochkurniawanОценок пока нет

- Mannum Report - WordДокумент26 страницMannum Report - WordajОценок пока нет

- h06962 Chemical Injection SystemДокумент1 страницаh06962 Chemical Injection SystemkirankirkОценок пока нет

- PRovincial Architecture GujratДокумент31 страницаPRovincial Architecture GujratPiyush Mahakalkar67% (3)

- Research Portals for Construction Project ManagementДокумент9 страницResearch Portals for Construction Project ManagementrajnishatpecОценок пока нет

- Welded Connections DesignДокумент35 страницWelded Connections DesignBelkacem AchourОценок пока нет

- " Hysil " Calcium Silicate Insulation Blocks & Pipes-SpecificationsДокумент1 страница" Hysil " Calcium Silicate Insulation Blocks & Pipes-SpecificationsJCSОценок пока нет

- Elevators and Escalators Design PDFДокумент10 страницElevators and Escalators Design PDFdanokrayОценок пока нет

- BCA Green Mark For New Residential Buildings Version RB/4.1Документ13 страницBCA Green Mark For New Residential Buildings Version RB/4.1MinhHyОценок пока нет

- DinДокумент11 страницDinharshadОценок пока нет

- Cracking in Post-Tensioned Slabs KBondyCrackingSlabsДокумент6 страницCracking in Post-Tensioned Slabs KBondyCrackingSlabsMark RamnarineОценок пока нет

- Standard Method of Measurement for Building Works in QatarДокумент158 страницStandard Method of Measurement for Building Works in Qatarizac007Оценок пока нет

- WFDTH Waterflow Detector: Sprinkler Systems MonitoringДокумент2 страницыWFDTH Waterflow Detector: Sprinkler Systems MonitoringArgile-assholeОценок пока нет

- Plaxis: Computational Geotechnics Course (2D Plaxis Course)Документ2 страницыPlaxis: Computational Geotechnics Course (2D Plaxis Course)Fajar Adi NugrohoОценок пока нет

- Bridge Building PDFДокумент4 страницыBridge Building PDFGio PadillaОценок пока нет

- Essential Masonry ToolsДокумент4 страницыEssential Masonry ToolsKamonGwgОценок пока нет

- PTS-1028 Ra FC Operation ManualДокумент32 страницыPTS-1028 Ra FC Operation ManualOrlando PWRОценок пока нет

- Static Vs Dynamic PDFДокумент12 страницStatic Vs Dynamic PDFshivaniОценок пока нет

- Maintenance Checklist Form: SL No Condition Inspection / Check Point MonthlyДокумент1 страницаMaintenance Checklist Form: SL No Condition Inspection / Check Point MonthlyAneesh ConstantineОценок пока нет

- PIP PCECV001 Guidelines For Application of Control ValvesДокумент39 страницPIP PCECV001 Guidelines For Application of Control ValvesAndresОценок пока нет

- Smoke Control System DesignДокумент4 страницыSmoke Control System DesignHermi DavidОценок пока нет

- Dr. D. Y. Patil School of Engineering & Technology Department of Civil Engineering Be Project Phase Ii Sheet (Ay2019-20) Sem IiДокумент3 страницыDr. D. Y. Patil School of Engineering & Technology Department of Civil Engineering Be Project Phase Ii Sheet (Ay2019-20) Sem IiRao SahabОценок пока нет

- Install Refnet branches for Daikin heat pumpsДокумент4 страницыInstall Refnet branches for Daikin heat pumpsIloaie FlorinОценок пока нет

- Optimal Foundation Solution For Storage Terminal in MangaloreДокумент4 страницыOptimal Foundation Solution For Storage Terminal in MangalorelingamkumarОценок пока нет

- Seismic Retrofit of RC Frame Buildings With Masonry Infill Walls: Literature Review and Preliminary Case StudyДокумент83 страницыSeismic Retrofit of RC Frame Buildings With Masonry Infill Walls: Literature Review and Preliminary Case Studybasabi12Оценок пока нет