Академический Документы

Профессиональный Документы

Культура Документы

MVC daily analysis and product transfer report

Загружено:

nimrovИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

MVC daily analysis and product transfer report

Загружено:

nimrovАвторское право:

Доступные форматы

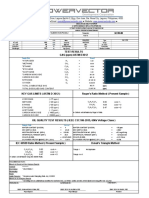

MVC-QF-TECH-008(19) QUALITY CONTROL DAILY ANALYSIS REPORT

Effectivity Date: February 15, 2011 MABUHAY VINYL CORPORATION

Date : 01/25/12 Time : 1135 AM [ ] IEM 1 [ ] IEM 2 [ ] MSG [ ] QC file

IEM 1 IEM 2

50 % CAUSTIC SODA 50 % CAUSTIC SODA Specs

Online Tk – B Online Tk - 9

% NaOH 49.66 49.93 49.26 NA 48-50

32 % CAUSTIC SODA 32 % CAUSTIC SODA

Online Tk- Online Tk - 8

% NaOH 31.32 31.53 30-32

HYDROCHLORIC ACID HYDROCHLORIC ACID

Online Tk- Tk- Online CTB 2 CTA 1

% HCl NA 33.70 33.12 33.06 32-33.5

Color 1 1 1 # 3, max

POLISHED BRINE(After Precoat) POLISHED BRINE(After Precoat)

Ca+Mg, ppm 1.73 + nil = 1.73 1.30 + nil = 1.30 5 ppm, max.

SPB (After Headtank) SPB (After Headtank)

Ca+Mg, ppb nil + nil = nil 8 + 2 = 10 20 ppb, max.

NaCl, gpl 290 327 290 gpl,min.

Na2SO4,gpl NA NA 7 gpl, max.

NaClO3,gpl 6.42 14.20 20 gpl,max.

DEPLETED BRINE DEPLETED BRINE

NaCl, gpl 195 222 200 gpl, min.

Free Cl2 negative positive Negative

NaClO3,gpl 10.99 21.64 27 gpl, max.

SODIUM HYPOCHLORITE PLANT

Tank No. 1 3 4 5

% NaOCl 7.90 7.97 7.99 8.01 7.40, min

% NaOH 0.61 0.70 0.60 0.70 0.40-1.0

Sp. Gr. 1.130 1.130 1.130 1.130 1.108, min

LIQUID CHLORINE PLANT UTILITIES

LIQUID CHLORINE SULFURIC ACID INSTRUMENT AIR @ 11AM

Source % Cl2 Specs Source % H2SO4 Specs Dew Point, °C -3.0 ≤3.8 °C

LCP Tk.# NA 99.5 %,min LCP Comp NA 97 %, min. BOILER WATER

Cl2 Feed 91.0 %,min. SiO2, ppm 129 150 ppm, max

GAS ANALYSIS

IEM 1 IEM 2 FLUE GAS

% Cl2 % H2 O2 + CO2 % Cl2 % H2 O2 + CO2 % CO % CO2 % O2

Line A NA NA NA

Line B

POLLUTION C O N T R O L - EFFLUENTS

pH OIL Hg TDS TSS Color COD

Source 6AM 7PM (+ or -) ppb ppm mg/L Pt-Co Units mg/L

S-2 7.92 8.01 - 0.111 208 5 21 4

S-5 8.44 NA - 0.166 226 6 26 4

Lagoon NA

Sludge Pond NA

Source pH gpl NaOH Source pH SPECIFICATIONS

JBC 7.51 nil S-3 7.61 pH = 6-9 COD = 150 mg/li, max Hg = 2, ppb, max.

Evap Canal 9.61 nil S-4 9.63 Oil = Negative TDS = 1000 ppm, max TSS = 150 mg/li, max

Total Canal 8.27 nil S-7 6.03 Color = 200 Pt-Co units, max.

Remarks: IEM 1 : Depleted brine - NaCl Analyzed by Certified Correct

OFF-SPECS IEM 2 : HCl - online; Depleted brine - Free Cl2

Others : effluents - evaporator canal & S4 NEY/ANB/RGD OVA

MVC-QF-TECH-004 (12)

Effectivity Date: May 20, 2010

MABUHAY VINYL CORPORATION PRODUCT TRANSFER CLEARANCE

Assumption Heights, Iligan City

Date : 01/25/12 [ ] IEM 1 [ ] IEM 2 [ ] Mktg [ ] QC file

IEM 1

HYDROCHLORIC ACID LIQUID CAUSTIC SODA SODIUM HYPOCHLORITE

Tk # % HCl SG @ 30”C Color Tk # 50% 32%. Tk # % NaOCl % NaOH SG @ 30”C

1 NA A NA NA 1 7.91 0.61 1.130

2 NA B 49.93 NA 2 NA

3 NA 3 7.97 0.70 1.130

4 NA 4 7.99 0.60 1.130

5 NA 5 8.01 0.70 1.130

IEM 2 SPECIFICATIONS

HYDROCHLORIC ACID LIQUID CAUSTIC SODA HYDROCHLORIC ACID

Tk # % HCl SG @ 30”C Color Tk # 50% 32%. % HCl 32.0 - 33.5

CTA 1 33.06 1.160 1 9 NA - SG @ 30”C, min 1.152

CTA 2 NA 8 - NA Color, max #3

CTA 3 NA LIQUID CAUSTIC SODA

CTB 1 NA 50% 32%

CTB 2 33.12 1.160 1 % NaOH 48 - 50 30 - 32

Remarks: % NaCl 0.10 0.10

WITHIN SPECS, OK for transfer ppm Fe, max 10 10

SODIUM HYPOCHLORITE

Analyzed by Certified Correct % NaOCl, min 7.40

% excess NaOH 0.40 - 1.00

RGD OVA SG @ 30”C, min 1.109

Вам также может понравиться

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationДокумент2 страницыQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovОценок пока нет

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationДокумент2 страницыQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovОценок пока нет

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationДокумент2 страницыQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovОценок пока нет

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationДокумент2 страницыQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovОценок пока нет

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationДокумент2 страницыQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovОценок пока нет

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationДокумент2 страницыQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovОценок пока нет

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationДокумент2 страницыQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovОценок пока нет

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationДокумент2 страницыQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovОценок пока нет

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationДокумент2 страницыQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovОценок пока нет

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationДокумент2 страницыQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovОценок пока нет

- QC 011712Документ2 страницыQC 011712nimrovОценок пока нет

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationДокумент2 страницыQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovОценок пока нет

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationДокумент2 страницыQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovОценок пока нет

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationДокумент2 страницыQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovОценок пока нет

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationДокумент2 страницыQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovОценок пока нет

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationДокумент2 страницыQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovОценок пока нет

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationДокумент2 страницыQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovОценок пока нет

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationДокумент2 страницыQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovОценок пока нет

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationДокумент2 страницыQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovОценок пока нет

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationДокумент2 страницыQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovОценок пока нет

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationДокумент2 страницыQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovОценок пока нет

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationДокумент2 страницыQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovОценок пока нет

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationДокумент2 страницыQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovОценок пока нет

- QC DAILY REPORTДокумент2 страницыQC DAILY REPORTnimrovОценок пока нет

- MVC daily analysis and product transfer reportДокумент2 страницыMVC daily analysis and product transfer reportnimrovОценок пока нет

- QC DAILY REPORTДокумент2 страницыQC DAILY REPORTOliver V. ArominОценок пока нет

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationДокумент2 страницыQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationOliver V. ArominОценок пока нет

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationДокумент2 страницыQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationOliver V. ArominОценок пока нет

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationДокумент2 страницыQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovОценок пока нет

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationДокумент2 страницыQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationOliver V. ArominОценок пока нет

- April 2017 Daily Analysis ReportДокумент253 страницыApril 2017 Daily Analysis ReportnimrovОценок пока нет

- October 1 Daily Analysis ReportДокумент253 страницыOctober 1 Daily Analysis ReportnimrovОценок пока нет

- Solids Evaluation in Mud TSДокумент3 страницыSolids Evaluation in Mud TSNovri IsrarОценок пока нет

- 20HDP Template SuCyProcess v0Документ18 страниц20HDP Template SuCyProcess v0Mario Cancino SerranoОценок пока нет

- The SuCy Process SulfatosДокумент18 страницThe SuCy Process SulfatoslauramanjarresОценок пока нет

- Chlor Alkali Process: Membrane ElectrolysisДокумент18 страницChlor Alkali Process: Membrane ElectrolysisLuqmanОценок пока нет

- Es1c02165 Si 001Документ18 страницEs1c02165 Si 001Ronei de AlmeidaОценок пока нет

- Template Design BasisДокумент5 страницTemplate Design BasisMuhammad UthmanОценок пока нет

- Calculation For Lime ConsumptionДокумент4 страницыCalculation For Lime Consumptionhemendra499Оценок пока нет

- 32 TR 13Документ1 страница32 TR 13John Aaron ComiaОценок пока нет

- Example Report - Batam Line Gas MonitoringДокумент1 страницаExample Report - Batam Line Gas MonitoringSindu WidodoОценок пока нет

- Water ContentДокумент21 страницаWater Contentrivai munthe100% (1)

- Recovery Boiler Chemical PrinciplesДокумент18 страницRecovery Boiler Chemical PrinciplesAA MAXОценок пока нет

- CO2 and Lime Dosage Sea WaterДокумент11 страницCO2 and Lime Dosage Sea WaterNoureddine Merah100% (2)

- 32 TR 12Документ1 страница32 TR 12John Aaron ComiaОценок пока нет

- SOBM Calculation SheetДокумент18 страницSOBM Calculation Sheetongcchemist gd chitraОценок пока нет

- Dissolve Gas Analysis ReportДокумент1 страницаDissolve Gas Analysis ReportJohn Aaron ComiaОценок пока нет

- Calculation For Lime ConsumptionДокумент7 страницCalculation For Lime Consumptionhemendra499Оценок пока нет

- SCHEMATIC WATER TREATMENT PROCESSДокумент5 страницSCHEMATIC WATER TREATMENT PROCESSAgung R. DaulayОценок пока нет

- SOBM Calculation SheetДокумент15 страницSOBM Calculation SheetChintan GohelОценок пока нет

- Dissolve Gas Analysis Report SummaryДокумент1 страницаDissolve Gas Analysis Report SummaryJohn Aaron ComiaОценок пока нет

- Ammonia Plant Description by Sohail Raza-2Документ30 страницAmmonia Plant Description by Sohail Raza-2Kade Kevin100% (1)

- Daily Reoprt 08.11.2021Документ1 страницаDaily Reoprt 08.11.2021Shine AungОценок пока нет

- 32 TR 09Документ1 страница32 TR 09John Aaron ComiaОценок пока нет

- New ZQCCS1Документ22 страницыNew ZQCCS1Faizan FarrukhОценок пока нет

- 32 TR 14Документ1 страница32 TR 14John Aaron ComiaОценок пока нет

- 32 TR 01Документ1 страница32 TR 01John Aaron ComiaОценок пока нет

- c06s02 PDFДокумент6 страницc06s02 PDFDewiRSОценок пока нет

- ADVANCE CONSULT ProcessДокумент6 страницADVANCE CONSULT Processsaramartori.2002Оценок пока нет

- QC 011712Документ2 страницыQC 011712nimrovОценок пока нет

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationДокумент2 страницыQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovОценок пока нет

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationДокумент2 страницыQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovОценок пока нет

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationДокумент2 страницыQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovОценок пока нет

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationДокумент2 страницыQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovОценок пока нет

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationДокумент2 страницыQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovОценок пока нет

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationДокумент2 страницыQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovОценок пока нет

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationДокумент2 страницыQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovОценок пока нет

- MVC daily analysis and product transfer reportДокумент2 страницыMVC daily analysis and product transfer reportnimrovОценок пока нет

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationДокумент2 страницыQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovОценок пока нет

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationДокумент2 страницыQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovОценок пока нет

- QC DAILY REPORTДокумент2 страницыQC DAILY REPORTnimrovОценок пока нет

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationДокумент2 страницыQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovОценок пока нет

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationДокумент2 страницыQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovОценок пока нет

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationДокумент2 страницыQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovОценок пока нет

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationДокумент2 страницыQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovОценок пока нет

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationДокумент2 страницыQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovОценок пока нет

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationДокумент2 страницыQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovОценок пока нет

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationДокумент2 страницыQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovОценок пока нет

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationДокумент2 страницыQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovОценок пока нет

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationДокумент2 страницыQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovОценок пока нет

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationДокумент2 страницыQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovОценок пока нет

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationДокумент2 страницыQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovОценок пока нет

- Quality Control Daily Analysis Report: Mabuhay Vinyl CorporationДокумент2 страницыQuality Control Daily Analysis Report: Mabuhay Vinyl CorporationnimrovОценок пока нет

- Uhv Question Bank Unit - IДокумент12 страницUhv Question Bank Unit - IShivaji ParasharОценок пока нет

- Penetrometros para Suelos Analogos 08180 Agratronix Manual InglesДокумент8 страницPenetrometros para Suelos Analogos 08180 Agratronix Manual InglesdanielОценок пока нет

- Form 5.1.3.A JSA Specific Hazards Checklist EnglishДокумент1 страницаForm 5.1.3.A JSA Specific Hazards Checklist EnglishArchana SoorajОценок пока нет

- Multiple-Resources Targeting Using Water-Energy Nexus Cascade Analysis and Mathematical ModellingДокумент35 страницMultiple-Resources Targeting Using Water-Energy Nexus Cascade Analysis and Mathematical Modellingcarlosalfredo35Оценок пока нет

- 1 Project Description: Hospital - DBRДокумент19 страниц1 Project Description: Hospital - DBRkiran raghukiranОценок пока нет

- Energy Storage and Power Management: Sustainable SolutionsДокумент36 страницEnergy Storage and Power Management: Sustainable SolutionsTunji AlabiОценок пока нет

- Evm Techknow PDFДокумент20 страницEvm Techknow PDFPooja PillaiОценок пока нет

- Earth HourДокумент5 страницEarth Hourrocioacosta1598Оценок пока нет

- Cambridge Assessment International Education: Environmental Management 5014/11 May/June 2018Документ14 страницCambridge Assessment International Education: Environmental Management 5014/11 May/June 2018Shadman ChowdhuryОценок пока нет

- Bai Et Al 2009Документ7 страницBai Et Al 2009Swastik RathОценок пока нет

- Prerequisite Programs (PRPS) Provide The Hygienic Foundations For Any Food Operation. The TermsДокумент6 страницPrerequisite Programs (PRPS) Provide The Hygienic Foundations For Any Food Operation. The TermsMawee LastrellaОценок пока нет

- Can Green Infrastructure Promote Urban SustainabilityДокумент12 страницCan Green Infrastructure Promote Urban SustainabilityfaniОценок пока нет

- Stripping, Stockpiling, Site Preparation, and Spreading TopsoilДокумент2 страницыStripping, Stockpiling, Site Preparation, and Spreading TopsoilJeremy NicanorОценок пока нет

- Bill Calculator ARMS Portal For UtilitiesДокумент2 страницыBill Calculator ARMS Portal For UtilitiesJuan David GilОценок пока нет

- LDF-30 Model Medical Waste Incinerator Table 1: Combustion-Support Combustion MachinesДокумент4 страницыLDF-30 Model Medical Waste Incinerator Table 1: Combustion-Support Combustion MachinesDonna YoungОценок пока нет

- Adaptations Help Species Thrive in Extreme EnvironmentsДокумент15 страницAdaptations Help Species Thrive in Extreme EnvironmentsMarina BaltikianОценок пока нет

- Soil Fertility and Management3Документ141 страницаSoil Fertility and Management3Pca ZdnОценок пока нет

- Presented By: Dr. R.K. Khandal: Value Creation of Technologies For Competitive Advantage of Business IndustriesДокумент25 страницPresented By: Dr. R.K. Khandal: Value Creation of Technologies For Competitive Advantage of Business IndustriesMathiyazhagan KОценок пока нет

- ARENDAINSДокумент10 страницARENDAINShiimleoОценок пока нет

- Haramaya University Haramaya Institute of Technology Department of Civil Engineering Building Construction (Ceng 3093)Документ14 страницHaramaya University Haramaya Institute of Technology Department of Civil Engineering Building Construction (Ceng 3093)Muaz HararОценок пока нет

- Technology Breakthrough Research Number 2Документ6 страницTechnology Breakthrough Research Number 2Gabriel ExalaОценок пока нет

- Sci ActДокумент6 страницSci ActB Abella, Justine MaronОценок пока нет

- ESP Reading Comprehension EnvironmentДокумент171 страницаESP Reading Comprehension EnvironmentcarolinaОценок пока нет

- Biosperse 250 Pail 25L UsДокумент16 страницBiosperse 250 Pail 25L UsOmokaro GordonОценок пока нет

- Ethical Issues Related To Genetically Modified OrganisimsДокумент10 страницEthical Issues Related To Genetically Modified Organisimschurail khanОценок пока нет

- (Cô Vũ Mai Phương) Hướng dẫn giải Đề thi tuyển sinh vào lớp 10 năm 2018- 2019 môn Tiếng Anh - Sở GD & ĐT TP. Hồ Chí MinhДокумент13 страниц(Cô Vũ Mai Phương) Hướng dẫn giải Đề thi tuyển sinh vào lớp 10 năm 2018- 2019 môn Tiếng Anh - Sở GD & ĐT TP. Hồ Chí MinhPhung ThuyОценок пока нет

- Cooling Tower Process CalculationДокумент4 страницыCooling Tower Process CalculationDevita AmeliaОценок пока нет

- Article - Understanding The Sustainable LifestyleДокумент3 страницыArticle - Understanding The Sustainable LifestyleU2001033 STUDENTОценок пока нет

- Land and Sea Breezes ExplainedДокумент2 страницыLand and Sea Breezes ExplainedFatima Abacan ReyesОценок пока нет

- Case StudyДокумент4 страницыCase StudyThái Phát TiếnОценок пока нет