Академический Документы

Профессиональный Документы

Культура Документы

13 Larisch Kelly - The Fundamental Principles and Differences Between Drilled Displacement Columns and Piles

Загружено:

myplaxisОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

13 Larisch Kelly - The Fundamental Principles and Differences Between Drilled Displacement Columns and Piles

Загружено:

myplaxisАвторское право:

Доступные форматы

The fundamental principles and

differences between Drilled

Displacement Columns (DDCs) and piles

AGS WA Seminar 2014 ‘Soft ground engineering’

14th November 2014, Perth

M. D. Larisch1,3, R. Kelly2,4

1GeotechnicalEngineering Centre, The University of Queensland, Brisbane, Australia

2CGSE, The University of Newcastle, Newcastle, Australia

3Piling Contractors Pty Ltd, Brisbane, Australia

4Coffey Geotechnics, Sydney, Australia

1. INTRODUCTION

1. INTRODUCTION

Drilled displacement piles & columns became very

popular in the last decades due to:

- High production rates (standardized piling equipment)

- Usually higher pile capacities than CFA / bored piles of similar

diameter due to displacement effect (increased shaft capacity)

- Minimal spoil creation

- Typical diameters 360mm, 450mm (and 540mm)

Drilled displacement piles can be used as:

- Load bearing piles

- Settlement reduction elements (rigid inclusions)

Following major risks can be associated with auger displacement piles:

- Potential damage of adjacent piles / structures due to displacement effect

- Inability to drill through hard layers / obstructions

1. INTRODUCTION

Applications:

- Piled foundations (reinforcement, embedment in stiff layer, etc)

- Mixed foundations (pile raft – combined load transfer by piles and

slab)

- Rigid inclusions (combined load transfer through columns and

soil between columns – use of load transfer platform)

2. PILED FOUNDATIONS

Load transfer:

- From the structure to the pile via a rigid connection (pile cap)

- The soft layer is bridged by the pile and the load is transferred in the ground by:

- Shaft resistance

- Base resistance

2. PILED FOUNDATIONS

Pile capacity:

- Verified by pile load tests (static, dynamic or other testing methods)

- Settlement of the pile determines the settlement of the structure

2. PILED FOUNDATIONS

Summary piled foundations:

- Fixed connection between pile and structure (pile cap);

- Transfer of tension, lateral loads and/or bending might be required (reinforcement cage);

- Substantial penetration into competent layers is required (load transfer);

- ‘High strength’ (> 32 Mpa) reinforced concrete;

- Sensitive to installation tolerances (additional bending moments);

- Verification of shaft integrity is important as load transfer occurs through the pile;

- Ground heave will occur due to displacement effect (typically minor);

- Lateral movements will occur due to displacement effect (typically minor); and

- Soil displacement effects can be taken into consideration in some design methods (e.g.

Bustamante & Gianeselli, 2003)

- Typically required for high/medium structural loads with low settlements

3. RIGID INCLUSIONS / DDCs

Working principles of DDCs:

3. RIGID INCLUSIONS / DDCs

Working principles of DDCs:

- Settlement of soft soil between

DDC heads

- Transfer of load to DDCs by

negative skin friction

- Settlement of DDCs and load

transfer by positive skin friction

at DDC toe / base section

- Equilibrium between negative

and positive forces at neutral

point (inside soft soil) (courtesy of Bachy Menard)

3. RIGID INCLUSIONS / DDCs

Shear mechanism, stresses and displacements of an embankment founded on rigid

inclusions after Simon und Schlosser, 2006.

3. RIGID INCLUSIONS / DDCs

Plomteux und Lacazidieu (2007) define the condition of equilibrium as followed:

Q + Fn = Fp + Qp

where:

Q = vertical load at the head of the rigid inclusion;

Fn = negative skin friction, applied above the equal-settlement lower plane;

Fp = positive skin friction, mobilised below the equal-settlement lower plane; and

Qp = tip resistance in the anchorage layer.

Shaft capacity / skin friction determination is critical!

Knowledge of soil parameters; and

Knowledge of installation method

3. RIGID INCLUSIONS / DDCs

Typical elements of DDC systems:

- Slab or structure;

- Load transfer layer;

- Rigid inclusion / DDC;

- Soft soil; and

- Bearing layer.

The system requires a grid of

columns to behave like rigid

inclusions. The system needs to

develop the load transfer

mechanism, individual columns

will behave like piles.

3. RIGID INCLUSIONS / DDCs

Summary soil improvement with rigid inclusions / DDCs:

- Settlement reduction (consider the entire system);

- Typically no bending moments or tension loads (from structure);

- Penetration into competent layers only marginal (load transfer);

- ‘Low strength’ (often 5-15 Mpa) plain concrete members;

- NOT sensitive to installation tolerances (soil improvement system);

- Ground heave will occur due to displacement effect (can be significant);

- Lateral movements will occur due to displacement effect (can be significant);

- Verification of shaft integrity is important for construction QA; and

- Soil displacement effects are NOT taken into consideration in the design

- Typically required for low/medium structural loads with medium/high settlements

4. INSTALLATION PROCESS

Typical installation process of drilled displacement columns / piles after Bottiau (1998):

1. Set up auger at position and install

cap to close concrete outlet at auger tip.

2. Install auger by rotating clockwise and

applying vertical pull down force.

3. Drill auger to design depth, the

displacement body of the auger pushes

the soil cut by the auger tip into the

surrounding ground.

4. Pump concrete through hollow auger

stem and extract auger while rotating

clockwise, always maintaining concrete

pressure positive and auger embedded

in fresh concrete.

5. Install reinforcement into fresh concrete,

if required.

1. 2. 3. 4. 5.

4. INSTALLATION PROCESS

Typical installation process of drilled displacement columns / piles after Bottiau (1998):

1. Set up auger at position and install

cap to close concrete outlet at auger tip.

2. Install auger by rotating clockwise and

applying vertical pull down force.

3. Drill auger to design depth, the

displacement body of the auger pushes

the soil cut by the auger tip into the

surrounding ground.

4. Pump concrete through hollow auger

stem and extract auger while rotating

clockwise, always maintaining concrete

pressure positive and auger embedded

in fresh concrete.

5. Install reinforcement into fresh concrete,

if required.

Pictures courtesy of Bauer Maschinen GmbH (Germany)

4. INSTALLATION PROCESS

Different full-displacement augers can be used:

Counter

- Progressive Displacement Auger (left)

screw

- Rapid Displacement Auger (right) section

Displacement

body

Lower screw

section

Auger tip with

end cap

4. INSTALLATION PROCESS - ENERGY INPUT

Installation monitoring records:

- provide information about

energy input and potential

performance of the DDC

or pile

- Insufficient energy input

(left)

- Sufficient energy input

(right)

- Insufficiently powered rigs

can cause underperforming

columns or piles

5. WHAT ELSE…

Potential issues:

- Ground heave during installation:

- Lifting of column heads;

- Potential cracking of columns; and

- Lifting of working platform.

- Lateral soil movement during installation:

- Adopt suitable working sequence.

- Necking:

- Ensure sufficient concrete over-consumption;

- Ensure sufficient concrete pressure; and

- Avoid deep cut-off levels (fresh DDCs/piles).

- Provide adequate working platform;

- Provide suitable load transfer platform; and

- Install monitoring system to verify design.

6. CONCLUSIONS

- The design philosophy between rigid inclusions and piles is different:

- Settlement reduction of existing soil, reinforced with rigid elements (DDC);

- Load transfer via stiff elelents to bridge the soft soil layer (PILES).

- Soil movement will occur during the installation of all soil displacement systems,

depending on the soil type, installation sequence, installation parameters, etc.), soil

movements can be significant in all directions;

- Soil movement and the resulting effects on structures and adjacent piles/columns are not

taken into consideration in current design approaches for both, rigid inclusions (DDC)

and displacement piles;

- Soil improvement effects around the pile shaft are taken into consideration for some

design methods for displacement piles, which leads to increased load capacities;

- The design of the LTP needs to be carried out carefully;

- Installation monitoring is crucial for both systems to control QA on site; and

- Performance monitoring (load tests and settlement monitoring) is crucial to verify the

design parameters.

7. DISCUSSION / Q&A

Thank you

for your attention!

Вам также может понравиться

- Laterally Loaded Rock Socket Design - A Review of The P-Y Curve Design ApproachДокумент9 страницLaterally Loaded Rock Socket Design - A Review of The P-Y Curve Design ApproachmyplaxisОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- Dynamic Analysis of Soil-Steel Railway Bridge Plaxis 2004Документ137 страницDynamic Analysis of Soil-Steel Railway Bridge Plaxis 2004myplaxisОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Optimisation FinalДокумент42 страницыOptimisation FinalmyplaxisОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Simplified Method For Analysis of Piles Undergoing Lateral Spreading in Liquefied Soils 2004Документ15 страницSimplified Method For Analysis of Piles Undergoing Lateral Spreading in Liquefied Soils 2004myplaxisОценок пока нет

- PygmyManual v2 - 31Документ67 страницPygmyManual v2 - 31myplaxisОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Experimental Determination of Frequencies and Tension For Elastic CablesДокумент6 страницExperimental Determination of Frequencies and Tension For Elastic CablesmyplaxisОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Time-Dependent Deformation of Shaly Rocks in Southern Ontario 1978Документ11 страницTime-Dependent Deformation of Shaly Rocks in Southern Ontario 1978myplaxisОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- 02 Websper Tagg - in Situ Ground Investigation Techniques For Soft Soils - New Perth StadiumДокумент20 страниц02 Websper Tagg - in Situ Ground Investigation Techniques For Soft Soils - New Perth StadiummyplaxisОценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- P-Multiplier For Pile Groups Subjected To Eccentric Lateral LoadingДокумент9 страницP-Multiplier For Pile Groups Subjected To Eccentric Lateral LoadingmyplaxisОценок пока нет

- Regional Distribution of in Situ Horizontal Stresses in Rocks of Southern OntarioДокумент11 страницRegional Distribution of in Situ Horizontal Stresses in Rocks of Southern OntariomyplaxisОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- 11 Kelly - The Ballina BypassДокумент28 страниц11 Kelly - The Ballina BypassmyplaxisОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- 14 Stewart - Some Perth Bridges On Soft SoilsДокумент18 страниц14 Stewart - Some Perth Bridges On Soft SoilsmyplaxisОценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- 01 Stewart - Past and Current Construction Projects On Swan River Soft SoilsДокумент79 страниц01 Stewart - Past and Current Construction Projects On Swan River Soft SoilsmyplaxisОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- 03 Palmer Hamidi - Elizabeth Quay Inlet Wall ProjectДокумент7 страниц03 Palmer Hamidi - Elizabeth Quay Inlet Wall ProjectmyplaxisОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Order Form IGEngSoft 2020-201Документ2 страницыOrder Form IGEngSoft 2020-201myplaxisОценок пока нет

- User Manual For PileGroupДокумент120 страницUser Manual For PileGroupmyplaxisОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Duncan Lateral Load Analysis of Groups of Piles and Drilled Shafts 1994Документ17 страницDuncan Lateral Load Analysis of Groups of Piles and Drilled Shafts 1994myplaxis100% (1)

- Statistical To Fuzzy Approach Toward CPTДокумент8 страницStatistical To Fuzzy Approach Toward CPTmyplaxisОценок пока нет

- A USER-CONTROLLED ARC-LENGTH METHOD For Convergence To Predefined Deformation StatesДокумент8 страницA USER-CONTROLLED ARC-LENGTH METHOD For Convergence To Predefined Deformation StatesmyplaxisОценок пока нет

- User Manual For ALLCPTДокумент46 страницUser Manual For ALLCPTmyplaxisОценок пока нет

- STABL6 With Reinforcing Layer Option User Manual Implementation Report 1986Документ46 страницSTABL6 With Reinforcing Layer Option User Manual Implementation Report 1986myplaxisОценок пока нет

- Solution Procedure For Non-Linear Finite Element Equations 2003Документ23 страницыSolution Procedure For Non-Linear Finite Element Equations 2003myplaxis100% (1)

- Dual Outlet Diverter 2Div-Body: Operation & Maintenance ManualДокумент12 страницDual Outlet Diverter 2Div-Body: Operation & Maintenance ManualJorge TamayoОценок пока нет

- Freeboard CalculationДокумент45 страницFreeboard CalculationgksahaОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- 02 - U-064 - ISTANBUL - METRO - PROJECT - Technical Data - EN PDFДокумент5 страниц02 - U-064 - ISTANBUL - METRO - PROJECT - Technical Data - EN PDFBerat DeğirmenciОценок пока нет

- Danfuss PumpДокумент84 страницыDanfuss PumpEslamAldenAbdoОценок пока нет

- Onhand Bulan Juni 2017Документ283 страницыOnhand Bulan Juni 2017Indra SeptiawanОценок пока нет

- Fa37g - Sew-EurodriveДокумент8 страницFa37g - Sew-Eurodriveم بОценок пока нет

- Homemade Paintball GunДокумент8 страницHomemade Paintball GunAinis Štelemėkas0% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Portal Frames (Compatibility Mode)Документ35 страницPortal Frames (Compatibility Mode)Asish BarailiОценок пока нет

- Cost StructureДокумент36 страницCost StructureNiken Lestari GОценок пока нет

- Daftar Harga - AHS Equipment by Watertec-Kolam UNPДокумент4 страницыDaftar Harga - AHS Equipment by Watertec-Kolam UNPAsrifhal AlkhadrОценок пока нет

- PH AmoniacoДокумент1 страницаPH AmoniacoLeonardo AndresОценок пока нет

- Epcc For Sewage System Refurbishment: Ubf Maintenance Sdn. Bhd. Petronas Chemicals Polyethylene SDN BHDДокумент1 страницаEpcc For Sewage System Refurbishment: Ubf Maintenance Sdn. Bhd. Petronas Chemicals Polyethylene SDN BHDMc LokiОценок пока нет

- Operating Principles of Narkomed Anaesthesia Systems - DrägerДокумент189 страницOperating Principles of Narkomed Anaesthesia Systems - DrägerSergio MontesОценок пока нет

- Typical Laboratory VFX Submittal REV BДокумент48 страницTypical Laboratory VFX Submittal REV BERIK FLOREZ MALDONADOОценок пока нет

- Schedule of Technical Data For Water Tube BoilerДокумент5 страницSchedule of Technical Data For Water Tube BoilerMurugan MuniandyОценок пока нет

- SHS 07504 Bend 00 00Документ3 страницыSHS 07504 Bend 00 00Luong LeОценок пока нет

- The Factories Act, 1965 - 230918 - 112659Документ124 страницыThe Factories Act, 1965 - 230918 - 112659rahman2011018Оценок пока нет

- Asme B18.15-2015Документ22 страницыAsme B18.15-2015Kamal El Shawadfy50% (2)

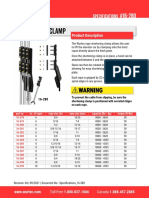

- Product DescriptionДокумент1 страницаProduct DescriptionFabian Alberto Mercado TheranОценок пока нет

- 350 Series Broce Broom Parts Catalog 404001-404561 MANUAL BA-04Документ126 страниц350 Series Broce Broom Parts Catalog 404001-404561 MANUAL BA-04Eduardo SainzОценок пока нет

- Suth03 Spoke LengthsДокумент82 страницыSuth03 Spoke LengthsastrolopitequusОценок пока нет

- PV 3919 enДокумент6 страницPV 3919 enerik0007Оценок пока нет

- EAS1000-1.823 Hot Air Sealer Operations Manual PublishedДокумент26 страницEAS1000-1.823 Hot Air Sealer Operations Manual Publishedjohnstn4544Оценок пока нет

- A Homebrewed Scrape Blade: Our Mini-Tractor's First Implement Will Work With Any Category 0 Tractor Hitch!Документ2 страницыA Homebrewed Scrape Blade: Our Mini-Tractor's First Implement Will Work With Any Category 0 Tractor Hitch!WolfgangОценок пока нет

- 20004O CRTi2 4.5 Specification Summary JULY 2020Документ4 страницы20004O CRTi2 4.5 Specification Summary JULY 2020Muhammad SaiedОценок пока нет

- STEEL RULES - English PDFДокумент6 страницSTEEL RULES - English PDFpinoОценок пока нет

- Original Instructions Manual Core Drilling Machine: Serial NumberДокумент9 страницOriginal Instructions Manual Core Drilling Machine: Serial NumberPungan IonОценок пока нет

- BVA H Series Manual 55 & 100 Ton ModelsДокумент12 страницBVA H Series Manual 55 & 100 Ton ModelsTitanplyОценок пока нет

- User Manual: Centro-Matic Injector SL-11Документ6 страницUser Manual: Centro-Matic Injector SL-11Putro 10Оценок пока нет

- Compatible Puller Stud and Hydraulic Cylinder Capacity Chart (0599, 7000, 7562)Документ5 страницCompatible Puller Stud and Hydraulic Cylinder Capacity Chart (0599, 7000, 7562)Odai AlsaafinОценок пока нет