Академический Документы

Профессиональный Документы

Культура Документы

Reaction Plan of Paint Shop

Загружено:

sunita choudharyАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Reaction Plan of Paint Shop

Загружено:

sunita choudharyАвторское право:

Доступные форматы

DEFECTS RE - ACTION PLAN OF PAINT SHOP kamal

Stage Problem Cause Remedies

Adhesion test Fail Low free alkalinity Bring free Alkanity in range (18 to 22 point) by adding 4357A and 4357 B (for increase by

1 point

Temp addShould

of bath 4357A - 2.3

bring kg and

in spec.( 55 4357

deg to B

65-deg

1.8C).

kgCheck air supply in air operating valve of hot water line

Low Bath Temp supply.check temp setting at temperature meter.

Less Phosphate coating Nozzles Chouk Clean nozzles.

High oil content Run Oil Separation unit contineously.

KOD High oil content Run Oil Separation unit contineously.

White Patch Mark Temp of bath Should bring in spec.( 55 deg to 65 deg C). Check air supply in air operating valve of hot water line

High Bath Temperature

supply.check temp setting at temperature meter.

Water Breakage High Bath Temperature Temp of bath Should bring in spec.( 55 deg to 65 deg C). Check air supply in air operating valve of hot water line

supply.check temp setting at temperature meter.

Less Surfactant in bath solution Add Nipaklin 4357 B - 15 kg in tank

Adhesion test Fail or Less

Phosphate coating

Low freee alkalinity Bring free Alkanity in range (18 to 22 point) by adding 4357A and 4357 B (for increase by

1 point add 4357A - 8.5 kg and 4357 B - 6.5 kg

Low Bath Temp Temp of bath Should bring in spec.( 55 deg to 65 deg C). Check air supply in air operating valve of hot water line

supply.check temp setting at temperature meter.

Circulation pressure is low Circulation pressure Should bring in spec.(0.8 to 1.5 kg/cm2)

DEGREASE

High oil content Run Oil Separation unit contineously.

White Patch Mark High oil content Run Oil Separation unit contineously.

Temp of bath Should bring in spec.( 55 deg to 65 deg C). Check air supply in air operating valve of hot water line

High Bath Temperature

supply.check temp setting at temperature meter.

Temp of bath Should bring in spec.( 55 deg to 65 deg C). Check air supply in air operating valve of hot water line

Water Breakage High Bath Temperature

supply.check temp setting at temperature meter.

Less Surfactant in bath solution Add Nipaklin 4357 B - 30 kg in tank

High Total Alkanity of Bath Start Water Cascading or add fresh soft water

White Patchy Appearance or Circulation or spray pressure is low Clean nozzles

WATER RINSE I & II

Paint Roughness NO water Cascading Circulation pressure Should bring in spec. by adjusting Delivery valve

Nozzles Chauk Maintain

Drain Tank Total

,Clean Acid

& makeofRefresh

bath in spec, ( 7 to 15 point ) by adding GN ZS ( for increase by 1

Non uniform phosphate Total Acid of bath is low point add GN ZS 1 kg)

Surface Activation coating or phosphate crystal pH of bath is low

structure is uneven Bath Circulation pressure is low Circulation pressure Should bring in spec.( 0.8 to 1.5 kg/cm2 ) by adjusting delivery valve

Phosphate coating uneven or

crystal structure uneven

Total Acid of Bath is out of specification Total acid of bath should bring in specification ( 18 to 22 point )by adding Nipaphos 3020

AR 2 (for increase by 1 point add Nipaphos 3020 AR2 - 12 kg)

Yellowish coating Free Acid of bath is high Maintain Free Acid in given space.(0.7 to1.1) by adding Neutriliser 4055 (for decrease by

0.1 point add Neutriliser 4055 - 700 gm)

Phosphate Blue coating,thin caoting Acclerator of bath is high Maintain acc in spec. (2.0 to 3.5) by adding Nipaphos 4707 (for increase by 1 point add

Nipaphos 4707 - 1 kg)

Low total acid Total acid of bath should bring in specification ( 18 to 22 point )by adding Nipaphos 3020

less coating wt. AR 2 (for increase by 1 point add Nipaphos 3020 AR2 - 12 kg)

Low Accelerator Maintain acc in spec. (2.0 to 3.5) by adding Nipaphos 4707 (for increase by 1 point add

Nipaphos 4707 - 1 kg)

No soft water cascading Start soft water cascading or overflow in tank

Bath contaminate Clean tank and make refresh

Sludge on processed part or Clean nozzle

Watar Rinse III & IV Total Acid is out of spec

Paint Dust

tank nozzle not working Circulation pressure Should bring in spec.by operating valve

Circulation pressure is low

Pinholes on painted part or High Conductivity of bath water (more than 20 Maintan conductivity & ph of water within spect limit.by adding DM Water

DM RINSE I

Paint Blister micron)

start overflow low conductivity DM water in bath at rate 5 LPM

Low NV %

set NV% in space.( 12 -16 %) by adding F1 and F 2 (for increase by 1% add F1 -65kg and

F2 - 227 kg in bath)

Low film thickness less voltage supply Incrase voltage from DC Rectifire

pH is low Manitain ph in specification (5.6- 6.2) by adding Additive EDD in bath (for increase by 0.1

add Additive EDD - 3 to 4 kg )

voltage supply is high decrease voltage from DC Rectifire

DFT High / Orange Peel Manitain ph in specification (5.6- 6.2) by adding Additive M in bath (for decrease by 0.1

Paint pH is high

add Additive M - 2 to 3 kg )

Paint pH is high

Manitain ph in specification (5.6- 6.2) by adding Additive M in bath (for decrease by 0.1

add Additive M - 2 to 3 kg )

paint Cogulation Manitain Temperature in specification (28 to 30 Deg C) check chiller unit compressor performance, it should not

CED BATH Bath Temp is High triped and Check air supply in air operating three way valve of chilled water line, Check PHE input and out put

pressure and temperature ,chec

low pH of ED bath Manitain ph in specification (5.6- 6.2) by adding Additive EDD in bath (for increase by 0.1

add Additive EDD - 3 to 4 kg )

conductivity of anolyte tank is high Manitain Conductivity in specification (500-1000 microS) by adding DM water and also

Pin hole and paint wash

check colour of anolyte solution . If colour of solution is blackish than check anodes inlet

and outlet one by one and then find faulty anode and water connection of that

conductivity of bath high Manitain Conductivity in specification (1000-1600 microS) by adding DM water ( for

decrease 50 microS conductivity of bath add aproxi. 50 ltr of DM water.)

bath contaminate start permmeate cascading

UF1 UF2 & DM ED drops

NV%age of bath is more than 1% Tank clean and make refresh if bath contaminate

Less gloss Oven temp is high Adjust setting of Oven Temp. within spec (190 to 210 deg C ) from display

Bend test fail Avoid to hold parts in oven more than 42 minute.

Impect tesh fail

BAKE OVEN

High gloss Oven temp is low Adjust setting of Oven Temp. within spec (190 to 210 deg C ) from display

MIBK (Solvent) fail

paint dust Due to oven dust clean oven

Вам также может понравиться

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGОт EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGОценок пока нет

- w8 ManualДокумент4 страницыw8 ManualPong VongОценок пока нет

- Fundamentals of Liquid Measurement IДокумент6 страницFundamentals of Liquid Measurement Imanuel_medcoОценок пока нет

- 11 M Bester The Application of Regenerative Feed Water Heating To Power CyclesДокумент19 страниц11 M Bester The Application of Regenerative Feed Water Heating To Power CyclesAbraham.CastilloОценок пока нет

- BAC Tab OpenCoolingTowers ENv00Документ2 страницыBAC Tab OpenCoolingTowers ENv00Miguel MancillaОценок пока нет

- Mukherjee Et Al. (2005) - Hydroprocessing Revamp ConfigurationsДокумент7 страницMukherjee Et Al. (2005) - Hydroprocessing Revamp Configurationsvazzoleralex6884Оценок пока нет

- Simple Steam DistillationДокумент4 страницыSimple Steam DistillationZerlyn JoebeОценок пока нет

- OCA AccessoriesДокумент5 страницOCA AccessoriesPedro Javier Medina CornejoОценок пока нет

- Data Sheet: Dupont™ Fm-200® or Hfc-227Ea Agent Storage ContainersДокумент2 страницыData Sheet: Dupont™ Fm-200® or Hfc-227Ea Agent Storage Containersfazil yoosufОценок пока нет

- Exp 11 Grp8 20110153Документ12 страницExp 11 Grp8 20110153Rahul KumarОценок пока нет

- Cause & Effect AnalysisДокумент4 страницыCause & Effect Analysisगुंजन सिन्हाОценок пока нет

- Oil Cooler Bypass Valve Test Results QuestionsДокумент2 страницыOil Cooler Bypass Valve Test Results QuestionsCarlos GaldamezОценок пока нет

- Tugas 1 Perancangan Alat ProsesДокумент6 страницTugas 1 Perancangan Alat ProsesAldo HoseaОценок пока нет

- Suntec Heat Pump Water HeaterДокумент18 страницSuntec Heat Pump Water Heaterajeet ranaОценок пока нет

- Control of An Isomerization Column/Reactor Process: William L. LuybenДокумент8 страницControl of An Isomerization Column/Reactor Process: William L. LuybenMirko SusichОценок пока нет

- 1998 - Thesis - Kappa Number Prediction Based On Cooking Liquor MeasurementsДокумент33 страницы1998 - Thesis - Kappa Number Prediction Based On Cooking Liquor MeasurementsPedro MarquesОценок пока нет

- Fyrquel EHC Product BulletinДокумент3 страницыFyrquel EHC Product BulletinEDBОценок пока нет

- Econtrol Web 4 PDFДокумент10 страницEcontrol Web 4 PDFJeyaraj KLОценок пока нет

- Dow Corning® 210H Fluid: Product InformationДокумент5 страницDow Corning® 210H Fluid: Product InformationEcosuministros ColombiaОценок пока нет

- Autoclave - Kaizen ImperialДокумент3 страницыAutoclave - Kaizen ImperialAnaThomasОценок пока нет

- Tugas 1 Pengendalian ProsesДокумент9 страницTugas 1 Pengendalian ProsesAldo HoseaОценок пока нет

- Nomenclature For Gpsa Engineering Data Book, 12 Ed - Section 9, Heat ExchangersДокумент8 страницNomenclature For Gpsa Engineering Data Book, 12 Ed - Section 9, Heat ExchangerstizeskiОценок пока нет

- ISO 7253 2001 Method Statement PDFДокумент4 страницыISO 7253 2001 Method Statement PDFFadi MagdyОценок пока нет

- Dia of Pipe Calc 2003Документ71 страницаDia of Pipe Calc 2003PrasadОценок пока нет

- Water Treatment - EngineerTraining2021fffДокумент49 страницWater Treatment - EngineerTraining2021fffRakeshKrishnanОценок пока нет

- Improve Control of Liquid Level LoopsДокумент8 страницImprove Control of Liquid Level LoopsSyed Samir AlamОценок пока нет

- Seta KV-6 Viscosity BathДокумент2 страницыSeta KV-6 Viscosity BathAzimul Hasnat ChowdhuryОценок пока нет

- Mini Service ManualДокумент2 страницыMini Service Manualkyubok chongОценок пока нет

- OAK RESTORER-HW (Hot Water Formula)Документ3 страницыOAK RESTORER-HW (Hot Water Formula)Iris BetancourtОценок пока нет

- KIA Carnival 04-Emission Control SystemДокумент10 страницKIA Carnival 04-Emission Control SystemHenryHutabarat100% (1)

- Artikel Es DДокумент14 страницArtikel Es Dberkah fajarОценок пока нет

- Thermodynamic Properties of SteamДокумент10 страницThermodynamic Properties of SteamMohammed AlSalehОценок пока нет

- RMC Thermal Balancing ValvesДокумент2 страницыRMC Thermal Balancing ValveskuraimundОценок пока нет

- Refining HB 2000 For CD RomДокумент10 страницRefining HB 2000 For CD RomCarlos Alberto Ubillas AlcaldeОценок пока нет

- 3) Pertemuan 3 (Distilasi)Документ15 страниц3) Pertemuan 3 (Distilasi)ILHAM KIKI SHAHILAОценок пока нет

- OhcuДокумент11 страницOhcuDheeraj ShuklaОценок пока нет

- Introduction To CalibrationsДокумент26 страницIntroduction To Calibrationsjaboerboy100% (1)

- Cavagna CatalogueДокумент95 страницCavagna CatalogueALONSOОценок пока нет

- Total Feed Water Through BFW PumpsДокумент7 страницTotal Feed Water Through BFW PumpslightsonsОценок пока нет

- ABO Procedure DBOLДокумент4 страницыABO Procedure DBOLprof.ankurtrivediОценок пока нет

- Aqua Blend AB1 PDFДокумент4 страницыAqua Blend AB1 PDFusaid saifullahОценок пока нет

- Triple Effect EvaporatorДокумент8 страницTriple Effect Evaporatormfruge7Оценок пока нет

- 009 - 6060 - RH340B - Hydraulic Oil Cooling - CATДокумент17 страниц009 - 6060 - RH340B - Hydraulic Oil Cooling - CAThectorОценок пока нет

- Idoc - Pub Astm TablesДокумент253 страницыIdoc - Pub Astm TablesShekhar SumanОценок пока нет

- Experiment No 11Документ5 страницExperiment No 11Muhammad Zohaib ShahidОценок пока нет

- Stepan Formulation 625Документ2 страницыStepan Formulation 625mohamed AdelОценок пока нет

- SOP 21 Standard Operating Procedure For Calibration of LPG ProversДокумент19 страницSOP 21 Standard Operating Procedure For Calibration of LPG ProversLakshman KaretiОценок пока нет

- 2 Ats 07Документ12 страниц2 Ats 07carlos maradiagaОценок пока нет

- Supercritical Boiler Basics CombinedДокумент50 страницSupercritical Boiler Basics Combinedsameer betalОценок пока нет

- Superglo Bright Nickel Process: Technical Data SheetДокумент6 страницSuperglo Bright Nickel Process: Technical Data SheetLuuThiThuyDuong100% (1)

- EXP 2B-Packed Column Distillation-Jan 2015Документ5 страницEXP 2B-Packed Column Distillation-Jan 2015Siti KhalidaОценок пока нет

- NP-PM-50 Silicone Bath Fluid PDFДокумент1 страницаNP-PM-50 Silicone Bath Fluid PDFBan ZanganaОценок пока нет

- UL 969 Rev 5 30 2017 ED 7 10 2019Документ2 страницыUL 969 Rev 5 30 2017 ED 7 10 2019studentmgmОценок пока нет

- Establishment of A Secondary Temperature Calibration LaboratoryДокумент2 страницыEstablishment of A Secondary Temperature Calibration LaboratoryRavi RanjanОценок пока нет

- Sanitizing Hand Gel: With Purac Sanilac 80Документ2 страницыSanitizing Hand Gel: With Purac Sanilac 80May Wulan DewiОценок пока нет

- Calibration of Analytical BalanceДокумент4 страницыCalibration of Analytical BalanceSandeepОценок пока нет

- HLV Presentation To Prospects and Customers - 2013Документ9 страницHLV Presentation To Prospects and Customers - 2013atripathi2009Оценок пока нет

- Lecture Note 3-Petroleum Measure Units HC PropertiesДокумент61 страницаLecture Note 3-Petroleum Measure Units HC Propertiesmohamadijambk22Оценок пока нет

- Chapter 1 Azeotrope and Multicomponent DistillationДокумент32 страницыChapter 1 Azeotrope and Multicomponent DistillationMUHAMMAD LUQMAN HAKIMI MOHD ZAMRIОценок пока нет

- QA-REC-122 Attiribute MSAДокумент4 страницыQA-REC-122 Attiribute MSAsunita choudharyОценок пока нет

- Operator 1 Operator 2 Cus-Operator 1 Operator 2 TomerДокумент6 страницOperator 1 Operator 2 Cus-Operator 1 Operator 2 Tomersunita choudharyОценок пока нет

- 13 DAR For Paint Stuck in M14 ThreadsДокумент3 страницы13 DAR For Paint Stuck in M14 Threadssunita choudharyОценок пока нет

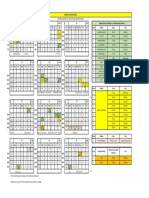

- A1. 2020-21 Holiday Calendar - 6 DaysДокумент1 страницаA1. 2020-21 Holiday Calendar - 6 Dayssunita choudhary25% (4)

- Sample Resignation Letter 1Документ1 страницаSample Resignation Letter 1partha_biswas_uiuОценок пока нет

- PR-1000 - Operations Handover ProcedureДокумент19 страницPR-1000 - Operations Handover ProcedureParmit Choudhury100% (1)

- DY150T 36英文说明书 1Документ115 страницDY150T 36英文说明书 1Astroval AquinoОценок пока нет

- Az (P) Y1 Series: Johnson Controls - Hitachi Air ConditioningДокумент9 страницAz (P) Y1 Series: Johnson Controls - Hitachi Air ConditioningKen M PratamaОценок пока нет

- Bungo Stray Dogs, Vol. 4 55 Minutes by Kafka Asagiri and Sango HarukawaДокумент221 страницаBungo Stray Dogs, Vol. 4 55 Minutes by Kafka Asagiri and Sango HarukawaEla Begüm Çam100% (3)

- AISI 304 SUS 304 Grade Stainless Steel PDFДокумент4 страницыAISI 304 SUS 304 Grade Stainless Steel PDFVladimirОценок пока нет

- 9701 s10 QP 13 PDFДокумент16 страниц9701 s10 QP 13 PDFtess_15Оценок пока нет

- Alternator Problem - Charging Problem and or Noisy Operation - 3516HДокумент3 страницыAlternator Problem - Charging Problem and or Noisy Operation - 3516Hwagner_guimarães_1Оценок пока нет

- Acti9 Ic40 - A9P42606Документ3 страницыActi9 Ic40 - A9P42606south adventureОценок пока нет

- Spare Parts List: Chain Saws 562 XP/XPGДокумент37 страницSpare Parts List: Chain Saws 562 XP/XPGbbeisslerОценок пока нет

- PCM-Manual 0507Документ32 страницыPCM-Manual 0507PamellaОценок пока нет

- NGSS & Common Core 5E Lesson Plan: Crosscutting Concepts, and Core IdeasДокумент5 страницNGSS & Common Core 5E Lesson Plan: Crosscutting Concepts, and Core Ideasapi-300263583Оценок пока нет

- Electrificación de Grúas Insul 8Документ36 страницElectrificación de Grúas Insul 8cenicercОценок пока нет

- Essar Shipping ProjectДокумент78 страницEssar Shipping ProjectvkkothariОценок пока нет

- Moot Proposition.8th Anand Swaroop Gupta Memorial International Moot Court Competition 24Документ5 страницMoot Proposition.8th Anand Swaroop Gupta Memorial International Moot Court Competition 24pranavdubey2018Оценок пока нет

- Test Bank For Essentials of Biology 3rd Edition Sylvia MaderДокумент24 страницыTest Bank For Essentials of Biology 3rd Edition Sylvia MaderCharlesMorganyfde100% (40)

- Chapter 4 Psychomentry, Humidification and DehumidificationДокумент14 страницChapter 4 Psychomentry, Humidification and DehumidificationNurshaqina SufianОценок пока нет

- Catalogo 17,5kV 2008 PDFДокумент40 страницCatalogo 17,5kV 2008 PDFJuan E Torres MОценок пока нет

- 1.7 Financial ManagementДокумент26 страниц1.7 Financial ManagementEngr Mohammed UsmaniaОценок пока нет

- 2800 Series: 2806C-E16TAG2Документ2 страницы2800 Series: 2806C-E16TAG2Tony LiОценок пока нет

- A Working Guide To Shell-and-Tube Heat ExchangersДокумент642 страницыA Working Guide To Shell-and-Tube Heat ExchangersSiva baalan80% (5)

- 1420-2R1 Lube Oil Logic Enhancement PDFДокумент4 страницы1420-2R1 Lube Oil Logic Enhancement PDFManuel L LombarderoОценок пока нет

- Smart Screen 6Документ11 страницSmart Screen 6leslie94Оценок пока нет

- Hopper Building: Tikaria Expansion Project-ACC Pre-Commissioning ChecklistДокумент2 страницыHopper Building: Tikaria Expansion Project-ACC Pre-Commissioning ChecklistRajuОценок пока нет

- ME460 Exam No. 2: NameДокумент1 страницаME460 Exam No. 2: NameSayyadh Rahamath BabaОценок пока нет

- Viskoziteee PDFДокумент8 страницViskoziteee PDFKamil AytekinОценок пока нет

- 1b: The Seebeck Thermo-Electric EffectДокумент5 страниц1b: The Seebeck Thermo-Electric EffectSalina ShaffieОценок пока нет

- Semester II Shivaji University Kolhapur S. E. Electrical II Power ElectronicsДокумент2 страницыSemester II Shivaji University Kolhapur S. E. Electrical II Power ElectronicsAnonymous q6cOT5XgXAОценок пока нет

- 1997 - Veletsos Et Al - Dynamics of Solid Containing TanksДокумент93 страницы1997 - Veletsos Et Al - Dynamics of Solid Containing TanksmahdiebОценок пока нет

- Resolver Vs EncoderДокумент7 страницResolver Vs EncoderAmirtha swamy.nОценок пока нет

- E 312 06 PDFДокумент8 страницE 312 06 PDFGia Minh Tieu TuОценок пока нет

- Cobar 1540 Ross Garling Hydraulic MiningДокумент26 страницCobar 1540 Ross Garling Hydraulic MiningAbyzhar AlpasyahОценок пока нет