Академический Документы

Профессиональный Документы

Культура Документы

Biology

Загружено:

lolipop_21gurlzzzИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Biology

Загружено:

lolipop_21gurlzzzАвторское право:

Доступные форматы

Benefits

Mass production of food is much cheaper overall than individual production

of meals from raw ingredients. Therefore, a large profit potential exists for

the manufacturers and suppliers of processed food products. Individuals

may see a benefit in convenience, but rarely see any direct financial cost

benefit in using processed food as compared to home preparation. Poor

quality ingredients and sometimes questionable processing and

preservation methods detract greatly from the overall benefit gained by

individual consumers.

More and more people live in the cities far away from where food is grown

and produced. In many families the adults are working away from home

and therefore there is little time for the preparation of food based on fresh

ingredients. The food industry offers products that fulfill many different

needs: From peeled potatoes that only have to be boiled at home to fully

prepared ready meals that can be heated up in the microwave oven within

a few minutes.

Benefits of food processing include toxin removal, preservation, easing

marketing and distribution tasks, and increasing food consistency. In

addition, it increases seasonal availability of many foods, enables

transportation of delicate perishable foods across long distances, and

makes many kinds of foods safe to eat by de-activating spoilage and

pathogenic micro-organisms. Modern supermarkets would not be feasible

without modern food processing techniques, long voyages would not be

possible, and military campaigns would be significantly more difficult and

costly to execute.

Modern food processing also improves the quality of life for people with

allergies, diabetics, and other people who cannot consume some common

food elements. Food processing can also add extra nutrients such

as vitamins.

Processed foods are often less susceptible to early spoilage than fresh

foods, and are better suited for long distance transportation from the

source to theconsumer. Fresh materials, such as fresh produce and raw

meats, are more likely to harbour pathogenic micro-organisms (e.g.

Salmonella) capable of causing serious illnesses.

Performance parameters for food processing

When designing processes for the food industry the following performance

parameters may be taken into account:

Hygiene, e.g. measured by number of micro-organisms per ml of

finished product

Energy consumption, measured e.g. by “ton of steam per ton of

sugar produced”

Minimization of waste, measured e.g. by “percentage of peeling loss

during the peeling of potatoes'

Labour used, measured e.g. by ”number of working hours per ton of

finished product”

Minimization of cleaning stops measured e.g. by “number of hours

between cleaning stops”

Trends in modern food processing

Cost reduction

Profit Incentive drives most of the factors behind any industry; the

food industry not least of all. Health concerns are generally subservient

to profit potential, leading the food processing industry to often ignore

major health concerns raised by the use of industrially-produced

ingredients (partially-hydrogenated vegetable oils, for example, a well-

known and well-researched cause of heart disease, that is still

commonly used in processed food to increase profit margin.) Consumer

pressure has led to a reduction in the use of industrially-produced

ingredients in processed food, but the (often slight) potential for

increased profits has barred widespread acceptance by the industry of

recognized health problems caused by over-consumption of processed

foods.

Often farmers take most of the burden in cost reduction because

they're usually submitted to a monopsony by food processing

industries.

Health

Reduction of fat content in final product e.g. by using baking instead

of deep-frying in the production of potato chips, another processed food

Maintaining the natural taste of the product e.g. by using less

artificial sweetener than they used before.

Hygiene

The rigorous application of industry and government endorsed standards

to minimise possible risk and hazards. In the USA the standard adopted

is HACCP.

Efficiency

Rising energy costs lead to increasing usage of energy-saving

technologies[2], e.g. frequency converters on electrical drives, heat

insulation of factory buildings and heated vessels, energy recovery

systems, keeping a single fish frozen all the way from China to

Switzerland.

Factory automation systems (often Distributed control systems)

reduce personnel costs and may lead to more stable production results.

Industries

Food processing industries and practices include the following:

Cannery

Fish processing

Industrial rendering

Meat packing plant

Slaughterhouse

Sugar industry

Vegetable packing plant

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Financial Audit NotesДокумент11 страницFinancial Audit NotesMamunoor RashidОценок пока нет

- Variant Configuration Step by Step ConfigДокумент18 страницVariant Configuration Step by Step Configraghava_83100% (1)

- 6 Acop v. OmbudsmanДокумент1 страница6 Acop v. OmbudsmanChester Santos SoniegaОценок пока нет

- PTCL History, Services, Subsidiaries & SWOT AnalysisДокумент18 страницPTCL History, Services, Subsidiaries & SWOT AnalysiswaqarrnОценок пока нет

- Power Steering Rack Components and Auto Suppliers Reference GuideДокумент12 страницPower Steering Rack Components and Auto Suppliers Reference GuideJonathan JoelОценок пока нет

- QA InspectionДокумент4 страницыQA Inspectionapi-77180770Оценок пока нет

- Term Paper Mec 208Документ20 страницTerm Paper Mec 208lksingh1987Оценок пока нет

- Chapter FiveДокумент12 страницChapter FiveBetel WondifrawОценок пока нет

- ENY1-03-0203-M UserДокумент101 страницаENY1-03-0203-M UserAnil KumarОценок пока нет

- Ibad Rehman CV NewДокумент4 страницыIbad Rehman CV NewAnonymous ECcVsLОценок пока нет

- Agro Chems MrRGAgarwalДокумент17 страницAgro Chems MrRGAgarwalapi-3833893Оценок пока нет

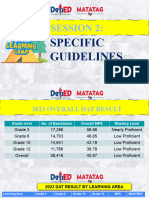

- FINAL Session 3 Specific GuidelinesДокумент54 страницыFINAL Session 3 Specific GuidelinesBovelyn Autida-masingОценок пока нет

- Matching a Vendor's HRSG in THERMOFLEXДокумент30 страницMatching a Vendor's HRSG in THERMOFLEXRafraf EzdineОценок пока нет

- Christmasworld Trend Brochure 2024Документ23 страницыChristmasworld Trend Brochure 2024Ольга ffОценок пока нет

- Balanced Modulator and Demodulator ExperimentДокумент6 страницBalanced Modulator and Demodulator ExperimentShubham SharmaОценок пока нет

- Request For Information (Rfi) : Luxury Villa at Isola Dana-09 Island - Pearl QatarДокумент1 страницаRequest For Information (Rfi) : Luxury Villa at Isola Dana-09 Island - Pearl QatarRahmat KhanОценок пока нет

- Potential Land Suitability For TeaДокумент26 страницPotential Land Suitability For TeaGautam NatrajanОценок пока нет

- Aggregate Demand and Supply: A ReviewДокумент36 страницAggregate Demand and Supply: A ReviewYovan DharmawanОценок пока нет

- Claim Form - Group Health InsuranceДокумент5 страницClaim Form - Group Health Insurancevizag mdindiaОценок пока нет

- Fayol's Principles in McDonald's ManagementДокумент21 страницаFayol's Principles in McDonald's Managementpoo lolОценок пока нет

- FTC470XETДокумент2 страницыFTC470XETDecebal ScorilloОценок пока нет

- Distribution Requirements PlanningДокумент8 страницDistribution Requirements PlanningnishantchopraОценок пока нет

- Portfolio Corporate Communication AuditДокумент8 страницPortfolio Corporate Communication Auditapi-580088958Оценок пока нет

- Caf 8 Aud Spring 2022Документ3 страницыCaf 8 Aud Spring 2022Huma BashirОценок пока нет

- Investigations in Environmental Science: A Case-Based Approach To The Study of Environmental Systems (Cases)Документ16 страницInvestigations in Environmental Science: A Case-Based Approach To The Study of Environmental Systems (Cases)geodeОценок пока нет

- Microprocessor Based Systems: by Nasir Mahmood Nasir - Mahmood@seecs - Edu.pkДокумент15 страницMicroprocessor Based Systems: by Nasir Mahmood Nasir - Mahmood@seecs - Edu.pkMuhammad ZubairОценок пока нет

- BUS 301 Final AssesmentДокумент15 страницBUS 301 Final AssesmentTanzim ShahriarОценок пока нет

- CS221 - Artificial Intelligence - Machine Learning - 3 Linear ClassificationДокумент28 страницCS221 - Artificial Intelligence - Machine Learning - 3 Linear ClassificationArdiansyah Mochamad NugrahaОценок пока нет

- Application Tracking System: Mentor - Yamini Ma'AmДокумент10 страницApplication Tracking System: Mentor - Yamini Ma'AmBHuwanОценок пока нет

- Educ 3 ReviewerДокумент21 страницаEduc 3 ReviewerMa.Lourdes CamporidondoОценок пока нет