Академический Документы

Профессиональный Документы

Культура Документы

Property of "Oil & Gas Inspection Services"

Загружено:

Mahmoud AlwasifОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Property of "Oil & Gas Inspection Services"

Загружено:

Mahmoud AlwasifАвторское право:

Доступные форматы

ASNT LEVEL-II / ULTRASONIC TESTING / PROCEUDRE / OIL & GAS INSPECTION SERVICES

6.1.1 Ultrasonic examination equipment shall be of the pulse echo type utilizing “A” scan

presentation, capable of generating and receiving frequencies between 1 and 5 MHz as a minimum

and shall be capable of recording UT data including the scanning positions

6.1.2 The flaw detector shall be calibrated in accordance with the relevant calibration procedure. A

certificate of conformance shall accompany each flaw detector

6.1.3 The ultrasonic instrument shall provide linear vertical presentation within ± 5% of the full

screen height (FSH) for 20% to 80% FSH and to be recorded in Screen Height Linearity Record Form

No. TNE-UT-Doc-02 Rev ‘0.’ The procedure for evaluating screen height linearity is carried out as per

ASME section V, article 4, appendix I (and or AWS D1.1-6.30)

6.1.4 The ultrasonic instrument shall utilize an amplitude control accurate over its useful range to

20% of the nominal amplitude ratio, to allow measurement of indications beyond the linear range of

the vertical display on the screen. The procedure for evaluating amplitude control linearity shall be

performed as per ASME section V, Article 4, appendix II

6.1.5 The requirements of 6.1.3 and 6.1.4 above; shall be met at intervals not to exceed three

months for analogue type instruments and one year for digital type instrument, or prior to first use

thereafter

6.1.6 When any part of the examination system is changed, a calibration check shall be made on the

basic calibration block to verify that distance range points and sensitivity setting (s) satisfy the

requirements of ASME section V, T-466.3

6.1.7 A calibration check on at least one of the reflectors in the basic calibration block shall be

performed at the completion of each examination or series of similar examinations, and when

examination personnel are changed. The distance range and sensitivity values recorded shall satisfy

the requirements of ASME section V, T-466.3

6.1.8 If during any check, it is determined that the examination equipment is not functioning

properly, all the product that has been examined since the last valid equipment calibration shall be

re-examined

6.2 Materials:

6.2.1 Search units shall be electrically matched to the flaw detector

6.2.2 Search units shall be in the frequency range 1 MHz to 5 MHz and be free of noise and internal

reflections. Twin or single transducer elements may be used dependent upon the configuration of

weld under examination

6.2.2.1 In case of AWS D1.1

• Straight-beam Search unit transducers shall have an active area of not less than

1/2in² nor shall more than 1 in². The transducer must be a round shape or square

shape

• Angle-Beam Search Units shall consist of a transducer and an angle wedge. The

unit may be comprised of the two separate elements or may be an integral unit.

Search Units shall be square or rectangular and may vary from 5/8in to 1in in width

and from 5/8in to13/16in in height. The search unit shall produce a sound beam in

the material being tested within±2 o̊ f one of the following proper angles:70 ,̊ 60 ,̊ or

45 .̊ The transducer frequency shall be between 2 and 2.5 MHz

6.2.3 Search units with contoured contact wedges may be used to aid the ultrasonic coupling.

Calibration shall be done with the contact wedges used during the examination

Property of “Oil & Gas Inspection Services”

Вам также может понравиться

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentОт EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentРейтинг: 4.5 из 5 звезд4.5/5 (3)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisОт EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisРейтинг: 4 из 5 звезд4/5 (2)

- Scope:: Property of "Oil & Gas Inspection Services"Документ6 страницScope:: Property of "Oil & Gas Inspection Services"Asem AbdelazizОценок пока нет

- UT ProcedureДокумент6 страницUT ProcedureMurali YОценок пока нет

- SC Ut Sop - Upto 70 DiaДокумент11 страницSC Ut Sop - Upto 70 DiaSrinu GrandhalayamОценок пока нет

- Procedure Pa-DraftДокумент20 страницProcedure Pa-Draftmahmoud naviddoustОценок пока нет

- 05 Ultrasonic Test Procedure 500405Документ11 страниц05 Ultrasonic Test Procedure 500405Sefa KasapogluОценок пока нет

- Sop UtДокумент6 страницSop UtEddy Dwi CahyonoОценок пока нет

- Ultrasonic Test ProcedureДокумент8 страницUltrasonic Test ProcedureShailendra GhaisasОценок пока нет

- Ultrasonic Testing Procedure: 1. ScopeДокумент10 страницUltrasonic Testing Procedure: 1. ScopePrashant PuriОценок пока нет

- Draft PAUT Specification 16.11.18Документ14 страницDraft PAUT Specification 16.11.18teopan PanОценок пока нет

- Appendix F Phased Array Ultrasonic Testing: 1.0 PurposeДокумент17 страницAppendix F Phased Array Ultrasonic Testing: 1.0 PurposeThananon Chomcherd100% (2)

- ScopeДокумент9 страницScoperaghbirОценок пока нет

- PAUT AWS d1 1Документ17 страницPAUT AWS d1 1Jeganeswaran100% (8)

- UT Equipment Calibration ProcedureДокумент14 страницUT Equipment Calibration ProcedureSantanu Saha100% (4)

- Krishna Engineering: 1. ScopeДокумент8 страницKrishna Engineering: 1. Scopegaurav shrimaliОценок пока нет

- Ut Procedure Selon AsmeДокумент9 страницUt Procedure Selon AsmeMajdi JerbiОценок пока нет

- Specification For Ultrasonic Inspection of Al-Alloy Plate For Pressure VesselsДокумент6 страницSpecification For Ultrasonic Inspection of Al-Alloy Plate For Pressure Vesselsmarkieboy36Оценок пока нет

- Ultrasonic Inspection Procedure For Complete Joint Penetration (CJP) Welds in A T-JointДокумент9 страницUltrasonic Inspection Procedure For Complete Joint Penetration (CJP) Welds in A T-JointPierpaolo AparoОценок пока нет

- PAUT Model Procedure PDFДокумент12 страницPAUT Model Procedure PDFநந்த குமார் சம்பத் நாகராஜன்81% (16)

- QUSE PA Crack Sizing Test Procedure API UT 11 May 2017Документ12 страницQUSE PA Crack Sizing Test Procedure API UT 11 May 2017solrac4371100% (2)

- Ultrasonic Examination ProcedureДокумент10 страницUltrasonic Examination ProcedureJake SparrowОценок пока нет

- Ultrasonic Test Procedure1Документ8 страницUltrasonic Test Procedure1MHDОценок пока нет

- Hy Wi Ut 53Документ15 страницHy Wi Ut 53Zulaiha Abdul Rahman100% (1)

- UT MIS AWS Rev 00 TKYДокумент27 страницUT MIS AWS Rev 00 TKYSantanu Saha100% (2)

- 11 Ut ProcedureДокумент11 страниц11 Ut ProcedureSajeesh KrishnanОценок пока нет

- Manual Ultrasonic Testing - WeldДокумент5 страницManual Ultrasonic Testing - Weldkiki270977Оценок пока нет

- Ut Procedure OnsДокумент10 страницUt Procedure OnsPARTHОценок пока нет

- Ultrasonic TestДокумент11 страницUltrasonic TestHarry DobleОценок пока нет

- Procedure For UT TestingДокумент13 страницProcedure For UT TestingKarrar TalibОценок пока нет

- Ultrasonic Angle-Beam Examination of Steel Plates: Standard Specification ForДокумент3 страницыUltrasonic Angle-Beam Examination of Steel Plates: Standard Specification ForSama UmateОценок пока нет

- Ultrasonic Testing Procedure1Документ18 страницUltrasonic Testing Procedure1King Jordan Peralta100% (1)

- Summary of ISO 2954Документ2 страницыSummary of ISO 2954Aamir ayubОценок пока нет

- Standard Practice For Ultrasonic Examination of Heavy Steel ForgingsДокумент6 страницStandard Practice For Ultrasonic Examination of Heavy Steel ForgingsSTRUCPIPE CALIDAD100% (1)

- Ut Written InstructionДокумент6 страницUt Written Instructionmm100% (1)

- Prosedur UTG Asu AnjingДокумент15 страницProsedur UTG Asu Anjingyusuf akbarОценок пока нет

- RFT ProcedureДокумент9 страницRFT ProcedurevikramОценок пока нет

- Ansaldo NDT Specifications 22GRKW v1 0Документ117 страницAnsaldo NDT Specifications 22GRKW v1 0pvssrh9929Оценок пока нет

- FSEL Linear Potentiometer Calibration Procedure Rev 00Документ7 страницFSEL Linear Potentiometer Calibration Procedure Rev 00SelvamОценок пока нет

- Standard Specification For Straight-Beam Ultrasonic Examination of Steel PlatesДокумент2 страницыStandard Specification For Straight-Beam Ultrasonic Examination of Steel PlatesHarshkulОценок пока нет

- RFT ProcedureДокумент9 страницRFT ProcedureKuppan SrinivasanОценок пока нет

- ASTM A 939-1996 (R2006) - Standard Test Method For Ultrasonic Examination From Bored Surfaces of CyДокумент2 страницыASTM A 939-1996 (R2006) - Standard Test Method For Ultrasonic Examination From Bored Surfaces of CyKhemaraj PathmalingamОценок пока нет

- Asme2a Sa 388Документ8 страницAsme2a Sa 388Dipankar ChakrabortyОценок пока нет

- Section II A SA-435 - SA-435MДокумент3 страницыSection II A SA-435 - SA-435MSocrates MoralesОценок пока нет

- Paut Total ProcedureДокумент25 страницPaut Total ProcedureMassimo Fumarola100% (1)

- 7.4 Eddy Current Testing - 2015R1 - SNS NEWДокумент4 страницы7.4 Eddy Current Testing - 2015R1 - SNS NEWsaenal rapi100% (1)

- Ultrasonic Examination From Bored Surfaces of Cylindrical ForgingsДокумент2 страницыUltrasonic Examination From Bored Surfaces of Cylindrical ForgingsDarwin DarmawanОценок пока нет

- Astm A745Документ5 страницAstm A745Cristian Otivo100% (1)

- ASTM A435 Examen Ultrasonido PlanchasДокумент3 страницыASTM A435 Examen Ultrasonido PlanchasAnonymous wKvJXBJ2iОценок пока нет

- Ultrasonic Inspection of Welds: Section 3.02 ("Non-Destructive Testing Requirements")Документ5 страницUltrasonic Inspection of Welds: Section 3.02 ("Non-Destructive Testing Requirements")carlosОценок пока нет

- B Sa-435Документ2 страницыB Sa-435Antonio GutierrezОценок пока нет

- Property of "Oil & Gas Inspection Services"Документ1 страницаProperty of "Oil & Gas Inspection Services"Mahmoud AlwasifОценок пока нет

- Ultrasonic Angle-Beam Examination of Steel Plates: Standard Specification ForДокумент3 страницыUltrasonic Angle-Beam Examination of Steel Plates: Standard Specification ForJACKELINEОценок пока нет

- A418 99 PDFДокумент7 страницA418 99 PDFJohano AraújoОценок пока нет

- Product Type and Name: AAR Axle Process Document: AAR Axle Ultrasonic Detection Procedure Process Document No. GY (11) TY-024Документ13 страницProduct Type and Name: AAR Axle Process Document: AAR Axle Ultrasonic Detection Procedure Process Document No. GY (11) TY-024gueridiОценок пока нет

- R091952 PDFДокумент5 страницR091952 PDFLC ChongОценок пока нет

- UT ProcedureДокумент14 страницUT Procedureshifa0% (1)

- Implementation of a Remote and Automated Quality Control Programme for Radiography and Mammography EquipmentОт EverandImplementation of a Remote and Automated Quality Control Programme for Radiography and Mammography EquipmentОценок пока нет

- Amateur Radio Quick Study Guide: Amateur Extra Class, July 1, 2016 - June 30, 2020От EverandAmateur Radio Quick Study Guide: Amateur Extra Class, July 1, 2016 - June 30, 2020Рейтинг: 5 из 5 звезд5/5 (1)

- Basics in Minerals Processing 5Документ10 страницBasics in Minerals Processing 5Mahmoud AlwasifОценок пока нет

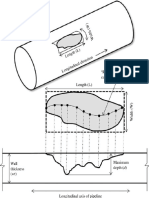

- Dimensions of A Typical Corrosion Defect On PipelineДокумент1 страницаDimensions of A Typical Corrosion Defect On PipelineMahmoud AlwasifОценок пока нет

- Basics in Minerals Processing 3Документ10 страницBasics in Minerals Processing 3Mahmoud AlwasifОценок пока нет

- Basics in Minerals Processing 4Документ10 страницBasics in Minerals Processing 4Mahmoud AlwasifОценок пока нет

- ST STДокумент1 страницаST STMahmoud AlwasifОценок пока нет

- A Principle of C ScanДокумент1 страницаA Principle of C ScanMahmoud AlwasifОценок пока нет

- Basics in Minerals Processing 2Документ10 страницBasics in Minerals Processing 2Mahmoud AlwasifОценок пока нет

- Basics in Minerals Processing 1Документ10 страницBasics in Minerals Processing 1Mahmoud AlwasifОценок пока нет

- أهم الأفعال الجزء الثالثДокумент3 страницыأهم الأفعال الجزء الثالثMahmoud AlwasifОценок пока нет

- أهم الأفعال الجزء الاولДокумент4 страницыأهم الأفعال الجزء الاولMahmoud AlwasifОценок пока нет

- أهم الأفعال الجزء الثانيДокумент4 страницыأهم الأفعال الجزء الثانيMahmoud AlwasifОценок пока нет

- Cubo de Unidad de Millar-HandmadeДокумент1 страницаCubo de Unidad de Millar-HandmadeJannaОценок пока нет

- MT Crack 2Документ1 страницаMT Crack 2Mahmoud AlwasifОценок пока нет

- أهم الأفعال الجزء الرابعДокумент4 страницыأهم الأفعال الجزء الرابعMahmoud AlwasifОценок пока нет

- What Is HDPE PIPEДокумент7 страницWhat Is HDPE PIPEKarthikeyan MoorthyОценок пока нет

- Heat Treatment of Steel: Assessment Performance CriteriaДокумент6 страницHeat Treatment of Steel: Assessment Performance CriteriaMahmoud AlwasifОценок пока нет

- Heat Treatment Furnace Heat Treatment FurnaceДокумент1 страницаHeat Treatment Furnace Heat Treatment FurnaceMahmoud AlwasifОценок пока нет

- MT Crack 3Документ1 страницаMT Crack 3Mahmoud AlwasifОценок пока нет

- MT CrackДокумент1 страницаMT CrackMahmoud AlwasifОценок пока нет

- Annealing TemperaturesДокумент7 страницAnnealing TemperaturesEmijo.AОценок пока нет

- Stress Relieving, Normalising and Annealing: Datasheet For Non-Heat-TreatersДокумент2 страницыStress Relieving, Normalising and Annealing: Datasheet For Non-Heat-TreatersGani PateelОценок пока нет

- Metal Ki PehchaanДокумент14 страницMetal Ki PehchaanParteek GandhiОценок пока нет

- HardnessДокумент13 страницHardnesshema_avraoОценок пока нет

- 4 - Project Cost ManagementДокумент60 страниц4 - Project Cost ManagementMohamed Arbi Ben YounesОценок пока нет

- PMP Formula Pocket GuideДокумент1 страницаPMP Formula Pocket GuideJamie LeОценок пока нет

- Precious MetalsДокумент18 страницPrecious MetalsRaj BindasОценок пока нет

- Formulas Math For PMPДокумент3 страницыFormulas Math For PMPramorclОценок пока нет

- Economic Selection CriteriaДокумент16 страницEconomic Selection Criteriaamrezzat100% (1)

- Engineering Encyclopedia: Metallic Communications CableДокумент45 страницEngineering Encyclopedia: Metallic Communications CableMahmoud AlwasifОценок пока нет

- Engineering Encyclopedia: Failure Analysis ReportДокумент1 страницаEngineering Encyclopedia: Failure Analysis ReportMahmoud AlwasifОценок пока нет

- Immediate Settlement Analysis Using Finite Element Analysis Models of Fb-MultipierДокумент22 страницыImmediate Settlement Analysis Using Finite Element Analysis Models of Fb-MultipierRaaf RifandiОценок пока нет

- Formula SheetДокумент3 страницыFormula SheetgogogogoОценок пока нет

- (FreeCourseWeb - Com) 1493997599Документ386 страниц(FreeCourseWeb - Com) 1493997599MuruganandamGanesanОценок пока нет

- Ashton and Feldman 2003. BERGMANN'S RULE IN NONAVIAN REPTILES - TURTLES FOLLOW IT, LIZARDS AND SNAKE REVERSE IT PDFДокумент13 страницAshton and Feldman 2003. BERGMANN'S RULE IN NONAVIAN REPTILES - TURTLES FOLLOW IT, LIZARDS AND SNAKE REVERSE IT PDFFred LimaОценок пока нет

- PHP Question AnswerДокумент20 страницPHP Question AnswerManish SharmaОценок пока нет

- Flume User GuideДокумент48 страницFlume User GuideRajulОценок пока нет

- DigfiltДокумент237 страницDigfiltJuhi SinghОценок пока нет

- Kluang (A) S2 STPM 2019Документ9 страницKluang (A) S2 STPM 2019Rex KalОценок пока нет

- Gaggenau DF 291-760Документ1 страницаGaggenau DF 291-760PurcellMurrayОценок пока нет

- Smith Meter Microloadnet Operator Reference Manual-A Voir PDFДокумент96 страницSmith Meter Microloadnet Operator Reference Manual-A Voir PDFmehrezОценок пока нет

- D 880 - 92 R97 Rdg4mc05mli5nw - PDFДокумент4 страницыD 880 - 92 R97 Rdg4mc05mli5nw - PDFomar alvaradoОценок пока нет

- Class Progress Chart Electrical Installation and Maintenance NC Ii (196 HRS)Документ2 страницыClass Progress Chart Electrical Installation and Maintenance NC Ii (196 HRS)Shairrah Claire Bañares BatangueОценок пока нет

- PUMY-P100-140YHM Technical & Service Manual (OC355revB)Документ90 страницPUMY-P100-140YHM Technical & Service Manual (OC355revB)Pavle PerovicОценок пока нет

- Atma Ram Sanatan Dharma College: PresentationДокумент6 страницAtma Ram Sanatan Dharma College: PresentationRishikeshav RaviОценок пока нет

- Bsm2300a SeriesДокумент324 страницыBsm2300a SeriesIBRAHIMОценок пока нет

- Microstructure and Mechanical Properties of Borated Stainless Steel (304B) GTA and SMA WeldsДокумент6 страницMicrostructure and Mechanical Properties of Borated Stainless Steel (304B) GTA and SMA WeldsReza nugrahaОценок пока нет

- Soil Bearing Capacity CalculationДокумент29 страницSoil Bearing Capacity CalculationJohn Jerome TerciñoОценок пока нет

- S3 3 TrigonometryДокумент81 страницаS3 3 TrigonometryEugene ChoongОценок пока нет

- Kahawalage TR 0061123036 Tony Ahfock ThesisДокумент74 страницыKahawalage TR 0061123036 Tony Ahfock ThesisTharindu RukshanОценок пока нет

- 1piece Exam - Week 11 Solution (Geas)Документ14 страниц1piece Exam - Week 11 Solution (Geas)Elguapito DelisciusoОценок пока нет

- Abnormal Labour: Perceptor: Dr. Nurul Islamy, M. Kes., Sp. OGДокумент54 страницыAbnormal Labour: Perceptor: Dr. Nurul Islamy, M. Kes., Sp. OGramadhiena destia100% (1)

- Image Processing Math Prob1Документ13 страницImage Processing Math Prob1MunmunОценок пока нет

- Grade Sheet BlankДокумент50 страницGrade Sheet BlankCarlo Troy AcelottОценок пока нет

- VP5 Datasheet Infusion Pump PDFДокумент2 страницыVP5 Datasheet Infusion Pump PDFsafouen karrayОценок пока нет

- Correlated Optical Convolutional Neural Network With "Quantum Speedup"Документ27 страницCorrelated Optical Convolutional Neural Network With "Quantum Speedup"jaccneeОценок пока нет

- UML Class Diagram Examples of Common Scenarios - EdrawMaxДокумент12 страницUML Class Diagram Examples of Common Scenarios - EdrawMaxelizabeth enggОценок пока нет

- SO100K Installation InstructionДокумент32 страницыSO100K Installation InstructionAlwin Anno SastraОценок пока нет

- From Navier Stokes To Black Scholes - Numerical Methods in Computational FinanceДокумент13 страницFrom Navier Stokes To Black Scholes - Numerical Methods in Computational FinanceTrader CatОценок пока нет

- Quadratic Equation - MATH IS FUNДокумент8 страницQuadratic Equation - MATH IS FUNChanchan LebumfacilОценок пока нет

- EagleBurgmann - API682 4th Facts, Innovations, SolutionsДокумент26 страницEagleBurgmann - API682 4th Facts, Innovations, SolutionsTasawwur Tahir100% (1)