Академический Документы

Профессиональный Документы

Культура Документы

Chapter 2 Assignment

Загружено:

LuisFernandoMirandaИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Chapter 2 Assignment

Загружено:

LuisFernandoMirandaАвторское право:

Доступные форматы

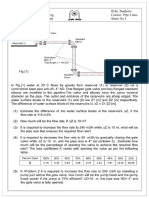

UNIVERSITI MALAYSIA PERLIS

Pusat Pengajian Kejuruteraan Bioproses

ERT 210/4 Process Dynamics and Control

Assignment 2: Theoretical Models of Chemical Processes

2.3 Two tanks are connected together in the level reaches a nominal value of 1.75 m

following unusual way in Fig. E2.3. using constant flow rates: w1 = 120

kg/min, w2 = 100 kg/min, and w3 = 200

kg/min. At that point, inlet flow rate w1 is

adjusted so that the level remains constant.

However, on this particular day, corrosion

of the tank has opened up a hole in the

wall at height of 1 m, producing a leak

whose volumetric flow rate q4 (m3/min)

can be approximated by

Figure E2.3

q 4 0.025 h 1

(a) Develop a model for this system that

can be used to find h1, h2, and w3 as where h is height in meters.

functions of time for any given (a) If the tank was initially empty, how

variations in inputs. long did it take for the liquid level to

(b) Perform a degrees of freedom analysis. reach the corrosion point?

Identify all input and output variables. (b) If mass flow rates w1, w2, and w3 are

kept constant indefinitely, will the tank

Notes: eventually overflow? Justify your

The density of the incoming liquid, , is answer.

constant.

The cross-sectional areas of the tanks are A1

and A2.

w2 is positive for flow from Tank 1 to Tank 2.

The two valves are linear with resistances R2

and R3.

2.13 The liquid storage tank shown in Fig.

E2.13 has two exit streams with mass flow

rates w1 and w2 and an exit stream with

flow rate w3. The cylindrical tank is 2.5 m Figure E2.13

tall and 2 m in diameter. The liquid has a

density of 800 kg/m3. Normal operating

procedure is to fill the tank until the liquid

Вам также может понравиться

- Chapter 2 AssignmentДокумент1 страницаChapter 2 Assignmentteguh100% (1)

- Homework Chapter-2 PDFДокумент7 страницHomework Chapter-2 PDFHuy Nguyễn HoàngОценок пока нет

- Controll Exercises PDFДокумент5 страницControll Exercises PDFTaban Shahab0% (1)

- Feedback Chap 2 HWДокумент13 страницFeedback Chap 2 HWAudreyWalangareDimalibotОценок пока нет

- Continuity and Bernoulli EqnДокумент20 страницContinuity and Bernoulli EqnNeybilОценок пока нет

- Fluid ProblemsДокумент6 страницFluid ProblemsAlaa ShammaaОценок пока нет

- ME 363 - Fluid MechanicsДокумент5 страницME 363 - Fluid MechanicsCristobal MendozaОценок пока нет

- Trolo LolДокумент7 страницTrolo LolAnonymous P1iMibОценок пока нет

- Tutorial 2: KKEK 3152 First Semester 2011/2012 SessionДокумент2 страницыTutorial 2: KKEK 3152 First Semester 2011/2012 SessionLam How EnnОценок пока нет

- Assignment 2012 2nd Year Mechanical EngineeringДокумент17 страницAssignment 2012 2nd Year Mechanical EngineeringFiseha Bogale KibОценок пока нет

- Basic Equations in Fluid Mechanics: Zarina Md. Ali, DR Roslinda Seswoya& DR Tan Lai WaiДокумент34 страницыBasic Equations in Fluid Mechanics: Zarina Md. Ali, DR Roslinda Seswoya& DR Tan Lai WaiHaiqal RafiqОценок пока нет

- Tutorial 1: KKEK 3152 First Semester 2011/2012 SessionДокумент1 страницаTutorial 1: KKEK 3152 First Semester 2011/2012 SessionLam How EnnОценок пока нет

- Lecture6 PDFДокумент9 страницLecture6 PDFsantanuОценок пока нет

- Permeability & In-Situ StressesДокумент23 страницыPermeability & In-Situ StressesDeep ShahОценок пока нет

- Civn7016 Hydraulic Structures: 2. Underflow GatesДокумент11 страницCivn7016 Hydraulic Structures: 2. Underflow GatesAlexander MakaringОценок пока нет

- Homework 2: U KQ Where:u Btu H FT Q FT H K ConstantДокумент6 страницHomework 2: U KQ Where:u Btu H FT Q FT H K ConstantkatelynОценок пока нет

- Lecture 2 (Continuity Equation)Документ1 страницаLecture 2 (Continuity Equation)Joshua TesoroОценок пока нет

- Mass Transfer Fundamentals Ch.E-304: Muhammad Rashed JavedДокумент6 страницMass Transfer Fundamentals Ch.E-304: Muhammad Rashed JavedTalha ImtiazОценок пока нет

- Topic 4 - (III)Документ2 страницыTopic 4 - (III)daabgchiОценок пока нет

- Open Channel Hydraulics 2nd Edition Sturm Solutions ManualДокумент25 страницOpen Channel Hydraulics 2nd Edition Sturm Solutions ManualWilliamDanielsezgj98% (47)

- Homework 2 For 4 GroupДокумент4 страницыHomework 2 For 4 GroupsovannchhoemОценок пока нет

- OCH - Part1-Energy-Critica DepthДокумент33 страницыOCH - Part1-Energy-Critica Depthtewodros getuОценок пока нет

- Fluid Mechanics ProblemsДокумент2 страницыFluid Mechanics Problemsanishg680Оценок пока нет

- Tut 1Документ1 страницаTut 1senwelo gulubaneОценок пока нет

- Dwnload Full Open Channel Hydraulics 2nd Edition Sturm Solutions Manual PDFДокумент35 страницDwnload Full Open Channel Hydraulics 2nd Edition Sturm Solutions Manual PDFwejdianosovf100% (10)

- Assignment No. 2Документ1 страницаAssignment No. 2Charie EralinoОценок пока нет

- Full Download Open Channel Hydraulics 2nd Edition Sturm Solutions ManualДокумент35 страницFull Download Open Channel Hydraulics 2nd Edition Sturm Solutions Manualshandybrady100% (33)

- Fluid DynamicsДокумент70 страницFluid DynamicsH Aries OñaОценок пока нет

- First Semester YearДокумент1 страницаFirst Semester YearlaraОценок пока нет

- 48 - 25795 - ME362 - 2020 - 1 - 2 - 1 - Lecture 7 - Fluid 1 - Flow MeasurementsДокумент19 страниц48 - 25795 - ME362 - 2020 - 1 - 2 - 1 - Lecture 7 - Fluid 1 - Flow Measurementssishu21Оценок пока нет

- July 14 TH Lecture 3Документ19 страницJuly 14 TH Lecture 3Akshay Pratap Singh ShekhawatОценок пока нет

- Review-Module 23 Geo 4Документ3 страницыReview-Module 23 Geo 4Ma Ella Mae LogronioОценок пока нет

- Chapter Two: Energy-Depth RelationsДокумент27 страницChapter Two: Energy-Depth RelationsBIRUK ABATEОценок пока нет

- 3.0 Finite Control Volume Analysis 3.1 Introduction To Fluid FlowДокумент21 страница3.0 Finite Control Volume Analysis 3.1 Introduction To Fluid FlowJack SantosОценок пока нет

- CH202L (Fluid & Particle Mechanics)Документ2 страницыCH202L (Fluid & Particle Mechanics)random noobОценок пока нет

- HHM HandoutДокумент16 страницHHM HandoutArun ChaitanyaОценок пока нет

- Week 10: Non-Uniform Flow: University of Nueva Caceres College of Engineering and ArchitectureДокумент5 страницWeek 10: Non-Uniform Flow: University of Nueva Caceres College of Engineering and ArchitectureAngelica LosaresОценок пока нет

- FM QBДокумент5 страницFM QBChinki Rockzz.. ..Оценок пока нет

- Thermo EXAMPLE-CHAPTER 5 PDFДокумент30 страницThermo EXAMPLE-CHAPTER 5 PDFFattihiEkhmalОценок пока нет

- Chapter 05 Part 1Документ25 страницChapter 05 Part 1Abdulmajeed AlqОценок пока нет

- Week5 6 Chapter4Документ60 страницWeek5 6 Chapter4NadiaОценок пока нет

- CHAPTER 3 - Non - Uniform Flow in Open Channel (Part 2)Документ21 страницаCHAPTER 3 - Non - Uniform Flow in Open Channel (Part 2)Honin Alshaer0% (1)

- Assignment On Ch. 3 KinematicsДокумент1 страницаAssignment On Ch. 3 KinematicsAbelОценок пока нет

- CE 141 Hydraulic EngineeringДокумент7 страницCE 141 Hydraulic EngineeringAngelo Mathew ReyesОценок пока нет

- L, Immersed in A Stream Flowing NormalДокумент1 страницаL, Immersed in A Stream Flowing NormalJacobo NaderОценок пока нет

- Mohd Adib Mohd Razi PDFДокумент10 страницMohd Adib Mohd Razi PDFLukman HakimОценок пока нет

- Lucrare 8 2006Документ7 страницLucrare 8 2006Rares HalbacОценок пока нет

- Hydraulics Chapter Two AssignmentДокумент3 страницыHydraulics Chapter Two AssignmentAbelОценок пока нет

- Chnical Engineering Refresher PDF Version 1Документ4 страницыChnical Engineering Refresher PDF Version 1ELMERОценок пока нет

- Topic 4 Control Volume Approach and Continuity EquationДокумент15 страницTopic 4 Control Volume Approach and Continuity EquationJovanie MatratarОценок пока нет

- Assignment No3 1Документ3 страницыAssignment No3 1Terefe DeribeОценок пока нет

- Bernoulli Equation in A Flume Lab ReportДокумент3 страницыBernoulli Equation in A Flume Lab ReportMan100% (1)

- Topic 4 - (IV)Документ2 страницыTopic 4 - (IV)daabgchiОценок пока нет

- Old Exam 4307Документ6 страницOld Exam 4307rizwan ghafoorОценок пока нет

- Lab Manual 3.2 - LEVEL 1 - Determination of Hydraulic Parameters in Uniform Flow For Open Channels.Документ4 страницыLab Manual 3.2 - LEVEL 1 - Determination of Hydraulic Parameters in Uniform Flow For Open Channels.Muhamad IzzanОценок пока нет

- Tutorial 1Документ2 страницыTutorial 1Netra PujarОценок пока нет

- Sheet-1 PipelinesДокумент1 страницаSheet-1 PipelinesKhairy ElsayedОценок пока нет

- DC DC BoostДокумент21 страницаDC DC BoosttrshaaaОценок пока нет

- Nut & Bolt ScienceДокумент3 страницыNut & Bolt SciencetanujaayerОценок пока нет

- Coding 3 D ShapesДокумент10 страницCoding 3 D ShapesgmconОценок пока нет

- Simulation of Congestion Control Algorithm AimДокумент4 страницыSimulation of Congestion Control Algorithm AimHaru HarshuОценок пока нет

- HP Proliant DL380 G6 Server - Step by StepДокумент9 страницHP Proliant DL380 G6 Server - Step by StepBoss100% (1)

- Battery SubsystemДокумент7 страницBattery SubsystemahmaborashedОценок пока нет

- Valve & Amplifier Design, Valve EquivalentsДокумент51 страницаValve & Amplifier Design, Valve EquivalentsValve Data80% (5)

- Diagnosis and Testing: Four Wheel Drive (4WD) Systems - Electronic ShiftДокумент38 страницDiagnosis and Testing: Four Wheel Drive (4WD) Systems - Electronic ShiftLojan Coronel José Humberto100% (1)

- Band Gaps and Electronics Structure of PerovskitesДокумент12 страницBand Gaps and Electronics Structure of PerovskitesThanh Long TaОценок пока нет

- Basic Electronics (ES-112)Документ49 страницBasic Electronics (ES-112)Bharat LalОценок пока нет

- Design and Implementation of Audio Transceiver Using Infrared Laser For Audio Signal DetectionДокумент4 страницыDesign and Implementation of Audio Transceiver Using Infrared Laser For Audio Signal DetectionGoitom HaileОценок пока нет

- CAT Álogo de Peças de Reposi ÇÃO: Trator 5403Документ364 страницыCAT Álogo de Peças de Reposi ÇÃO: Trator 5403MARCOS DIONIS ALVES LIMAОценок пока нет

- 5 Key Factors To The Correct Cable Selection and ApplicationДокумент7 страниц5 Key Factors To The Correct Cable Selection and ApplicationSugeng SumarnoОценок пока нет

- ACPS CP S1 01 FDA SlidesДокумент78 страницACPS CP S1 01 FDA SlidesBlueSagaОценок пока нет

- Numerical Methods in Rock Mechanics - 2002 - International Journal of Rock Mechanics and Mining SciencesДокумент19 страницNumerical Methods in Rock Mechanics - 2002 - International Journal of Rock Mechanics and Mining SciencesAnderson Lincol Condori PaytanОценок пока нет

- Mac Keyboard ShortcutsДокумент16 страницMac Keyboard ShortcutsSaira FazalОценок пока нет

- Linear Algebra Cheat SheetДокумент2 страницыLinear Algebra Cheat SheetBrian WilliamsonОценок пока нет

- Sri Chaitanya: KEY SheetДокумент13 страницSri Chaitanya: KEY SheetMODALAVALASA SRIHARSHAОценок пока нет

- 3 Chemistry of Milk Constituents PDFДокумент26 страниц3 Chemistry of Milk Constituents PDFFrancisco Rodriguez VazquezОценок пока нет

- Omega PTFE Needle Valve - FVLT100Документ1 страницаOmega PTFE Needle Valve - FVLT100XavierОценок пока нет

- Midterm BUS510Документ8 страницMidterm BUS510Ramesh KomarapuriОценок пока нет

- Performance Evaluation of Existing Sunshine-Based Computing Models For Estimating Global Solar Radiation at Lagos, NigeriaДокумент12 страницPerformance Evaluation of Existing Sunshine-Based Computing Models For Estimating Global Solar Radiation at Lagos, NigeriasamuelОценок пока нет

- Evaluating Capital ProjectsДокумент254 страницыEvaluating Capital Projectsariff_sodriОценок пока нет

- Clase 13-06Документ28 страницClase 13-06Jhurema NihuaОценок пока нет

- FELPRO - Tablas-de-Torque - 035Документ1 страницаFELPRO - Tablas-de-Torque - 035Clodoaldo BiassioОценок пока нет

- Evaluation and Selection of Sustainable Strategy For Green Supply Chain Management ImplementationДокумент28 страницEvaluation and Selection of Sustainable Strategy For Green Supply Chain Management ImplementationMuhammad Dzaky Alfajr DirantonaОценок пока нет

- S ParametersДокумент29 страницS ParameterseloiseОценок пока нет

- Ubd Planning Template With QuestionsДокумент3 страницыUbd Planning Template With Questionsapi-217297849Оценок пока нет

- Application Note 31 Monitoring Quicklime Monitoring PDFДокумент4 страницыApplication Note 31 Monitoring Quicklime Monitoring PDFomar rahmounОценок пока нет

- Hope Therapy PDFДокумент18 страницHope Therapy PDFalexОценок пока нет