Академический Документы

Профессиональный Документы

Культура Документы

Klueberlub Be 71 501 Special Lubricating Grease Datasheet PDF

Загружено:

phucdc095041Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Klueberlub Be 71 501 Special Lubricating Grease Datasheet PDF

Загружено:

phucdc095041Авторское право:

Доступные форматы

Product information

Klüberlub BE 71-501

Special lubricating grease for rolling and plain bearings

Benefits for your application

– Versatile lubricant for highly loaded rolling and plain bearings

– Reduced operating and maintenance costs due to low consumption

– Good wear protection when exposed to high loads

– Long grease life due to low operating temperatures and friction

– Low waste water disposal costs and long service life of components due to good water resistance

Description grease in commercial central lubrication systems. Klüberlub BE

71-501 is also suitable for high-temperature applications,

Klüberlub BE 71-501 is a light-coloured lubricating grease especially in the steel industry (e.g. ring-roller mills) and wood-

which offers good compatibility with nonferrous metals like working industry (e.g. rolling bearings in pelleting presses).

those used for example as plain bearing material. Due to its

special formulation and solid lubricants, wear is low when

exposed to rotating and oscillating motion and high impact Application notes

loads. Klüberlub BE 71-501 is resistant to water and has a good

sealing effect. The additives contained in this product enhance Klüberlub BE 71-501 can be applied by means of central

its ageing resistance. lubrication systems or by brush, spatula, grease gun and

automatic metering devices. When switching to Klüberlub BE

71-501, the lubricant consumption should be reduced step by

Application step in order to ensure that used lubricant, wear particles and

impurities are completely removed from the bearing.

Klüberlub BE 71-501 can contribute to extending the service life

of plain bearings where low-wear and low-friction operation is

required under mixed friction conditions. This special grease Material safety data sheets

meets the requirements in terms of reduced lubricant

consumption and extended lubrication intervals in forging Material safety data sheets can be requested via our website

presses while maintaining a constant temperature level in the www.klueber.com. You may also obtain them through your

plain bearing. Klüberlub BE 71-501 can also be used for plain contact person at Klüber Lubrication.

bearings subject to high loads in the plastics processing

industry and building machines (e.g. ring-roll mills) and in

construction machines. Owing to the good results achieved on

the rolling bearing test rigs and the good pumpability of the

Pack sizes

Product data Klüberlub BE 71-501

Article number 020160

Chemical composition solid lubricant

Chemical composition, thickener polyurea

Chemical composition, type of oil mineral oil

Colour space yellow

Lower service temperature -20 °C / -4 °F

Service temperature, upper limiting value for continuous lubrication 160 °C

Service temperature, rolling bearings, acc. to DIN 51825 140 °C

Klüberlub BE 71-501,Prod. 020160,en

Edition 20.12.2019 [replaces edition 30.08.2018]

Klüberlub BE 71-501

Special lubricating grease for rolling and plain bearings

Product data Klüberlub BE 71-501

Worked penetration, DIN ISO 2137, 25 °C, lower limit value 310 x 0.1 mm

Worked penetration, DIN ISO 2137, 25 °C, upper limit value 340 x 0.1 mm

Kinematic viscosity of the base oil, DIN 51562 pt. 01/ASTM D-445/ASTM D 7042, 40 °C approx. 490 mm²/s

Kinematic viscosity of the base oil, DIN 51562 pt. 01/ASTM D-445/ASTM D 7042, 100 °C approx. 32 mm²/s

Lubricating greases -K, DIN 51825 in connection with DIN 51502 KPF1N-20*; *Emcor max. 2

Speed factor (n x dm) approx. 300 000 mm/min

Corrosion inhibiting properties of lubricating greases, DIN 51802, (SKF-EMCOR), test duration: <= 2 corrosion degree

1 week, distilled water

Copper corrosion, DIN 51811, (lubricating grease), 24h/100°C 1 - 100 corrosion degree

Drop point, DIN ISO 2176, IP 396 >= 200 °C

Flow pressure of lubricating greases, DIN 51805, test temperature: -20 °C <= 1 400 mbar

Four-ball tester, welding load, DIN 51350 pt. 04 >= 4 000 N

Four-ball EP tester,wear value,DIN 51350 part 5, procedure E,60s/1000N, wear scar diameter <= 1 mm

Load-carrying capacity acc. to Brugger B, based on DIN 51347-1 and -2 >= 30 N/mm²

Water resistance, DIN 51807 pt. 01, 3 h/90 °C, rating <= 1 - 90

Minimum shelf life from the date of manufacture - in a dry, frost-free place and in the unopened 24 months

original container, approx.

Klüberlub BE 71-501,Prod. 020160,en

Edition 20.12.2019 [replaces edition 30.08.2018]

Klüberlub BE 71-501,Prod. 020160,en

Edition 20.12.2019 [replaces edition 30.08.2018]

Product information

Klüberlub BE 71-501

Special lubricating grease for rolling and plain bearings

Klüber Lubrication München SE & Co. KG /

Geisenhausenerstraße 7 / 81379 München / Germany /

Klüber Lubrication – your global specialist phone +49 89 7876-0 / fax +49 89 7876-333.

Innovative tribological solutions are our passion. Through The data in this document is based on our general experience and knowledge at

the time of publication and is intended to give information of possible applications

personal contact and consultation, we help our customers to be to a reader with technical experience. It constitutes neither an assurance of

successful worldwide, in all industries and markets. With our product properties nor does it release the user from the obligation of performing

ambitious technical concepts and experienced, competent staff preliminary field tests with the product selected for a specific application. All data

are guide values which depend on the lubricant's composition, the intended use

we have been fulfilling increasingly demanding requirements by and the application method. The technical values of lubricants change depending

manufacturing efficient high-performance lubricants for more on the mechanical, dynamical, chemical and thermal loads, time and pressure.

than 80 years. These changes may affect the function of a component. We recommend

contacting us to discuss your specific application. If possible we will be pleased to

provide a sample for testing on request. Klüber products are continually improved.

Therefore, Klüber Lubrication reserves the right to change all the technical data in

this document at any time without notice.

Publisher and Copyright: Klüber Lubrication München SE & Co. KG. Reprints,

total or in part, are permitted only prior consultation with Klüber Lubrication

München SE & Co. KG and if source is indicated and voucher copy is forwarded.

Вам также может понравиться

- Berutox FB 22: Technical Product InformationДокумент1 страницаBerutox FB 22: Technical Product InformationMauricio SánchezОценок пока нет

- Molykote® P-37 Datasheet Eng PDFДокумент2 страницыMolykote® P-37 Datasheet Eng PDFBib GmzОценок пока нет

- Shell Turbo T46 PDFДокумент2 страницыShell Turbo T46 PDFdionisio emilio reyes jimenezОценок пока нет

- D6185-11 Standard Practice For Evaluating Compatibility of Binary Mixtures of Lubricating GreasesДокумент9 страницD6185-11 Standard Practice For Evaluating Compatibility of Binary Mixtures of Lubricating GreasesSalvatore LombardoОценок пока нет

- Rolamentos e Retentores - Falk-Type-YB,-YBTДокумент5 страницRolamentos e Retentores - Falk-Type-YB,-YBTVendedorОценок пока нет

- 01.03.01 Coolant TR0199991209109 - enДокумент18 страниц01.03.01 Coolant TR0199991209109 - enEbied Yousif AlyОценок пока нет

- Ss Mobilith SHCДокумент2 страницыSs Mobilith SHCFarrukh JamalОценок пока нет

- PDS Lubrizol-6950pДокумент4 страницыPDS Lubrizol-6950pBurcu Taşçı100% (1)

- 951 130 407 enДокумент26 страниц951 130 407 enli geneОценок пока нет

- TD SCHM f11 Renolit LST 00 en PDFДокумент1 страницаTD SCHM f11 Renolit LST 00 en PDFQuoc HungОценок пока нет

- Ama Machine ManualДокумент97 страницAma Machine ManualmersiumОценок пока нет

- Moly GreaseДокумент2 страницыMoly GreaseDivyanshu SharmaОценок пока нет

- SS-150 Servo System Oil Details PDFДокумент1 страницаSS-150 Servo System Oil Details PDFJagadeesh SharanОценок пока нет

- Petro Canada Duron HP - 15w-40 PDFДокумент10 страницPetro Canada Duron HP - 15w-40 PDFPubcrawl100% (1)

- Velvex Industrial Oil - Nandan Petrochem LTDДокумент27 страницVelvex Industrial Oil - Nandan Petrochem LTDNandan Petrochem Ltd0% (1)

- Toothed Coupling Installation and Maintenance Guide PDFДокумент18 страницToothed Coupling Installation and Maintenance Guide PDFrazvanОценок пока нет

- Lubrizol 1038 - Auto Gear Oil - TdsДокумент3 страницыLubrizol 1038 - Auto Gear Oil - TdsPranit More Arabian Petroleum LimitedОценок пока нет

- Hygold 5000Bs: Base Oil Marketing SpecificationДокумент1 страницаHygold 5000Bs: Base Oil Marketing Specificationsamsoon80100% (1)

- PH 474A-K - Synthetic Gear Oil - Extreme Pressure (EP)Документ4 страницыPH 474A-K - Synthetic Gear Oil - Extreme Pressure (EP)dfbdfbfdbfbОценок пока нет

- Flender Gearbox Lubricant 7300 (En)Документ28 страницFlender Gearbox Lubricant 7300 (En)samer salamehОценок пока нет

- Nox-Rust 311 HMДокумент1 страницаNox-Rust 311 HMNavin JoshiОценок пока нет

- EZO Bearings Catalog Technical ContentsДокумент24 страницыEZO Bearings Catalog Technical ContentsConrad Hendrik De KockОценок пока нет

- ASTM D6158-16 Standard Specification For Mineral Hydraulic OilsДокумент14 страницASTM D6158-16 Standard Specification For Mineral Hydraulic OilsROMAY MERECIASОценок пока нет

- Technology Forum - Indoneusa - Gas Engines (Oct.2014) V2Документ42 страницыTechnology Forum - Indoneusa - Gas Engines (Oct.2014) V2Frana HadiОценок пока нет

- EHD211000 Standard Program Documentation ENG K216 2016Документ69 страницEHD211000 Standard Program Documentation ENG K216 2016gonzalo.lartec2369Оценок пока нет

- Grease Testing InformationДокумент27 страницGrease Testing InformationDanielОценок пока нет

- Shell Albida EMS2Документ1 страницаShell Albida EMS2Muhammad Haris BaigОценок пока нет

- Grease Selection ChartДокумент4 страницыGrease Selection Chartmirali74Оценок пока нет

- Astm D4057 22Документ13 страницAstm D4057 22JOSEОценок пока нет

- High Temperature Grease: DescriptionДокумент2 страницыHigh Temperature Grease: Descriptionvicky kОценок пока нет

- Bechem AL20Документ1 страницаBechem AL20Anil NegiОценок пока нет

- Petro Canada Lubricants Handbook 2012 English PDFДокумент212 страницPetro Canada Lubricants Handbook 2012 English PDFsoumya ghoshОценок пока нет

- Mil PRF 87100a PDFДокумент12 страницMil PRF 87100a PDFNadia SalemОценок пока нет

- Common Position Paper 2012 Signed B7 PDFДокумент5 страницCommon Position Paper 2012 Signed B7 PDFcarbasemyОценок пока нет

- NEA - MaterialsДокумент71 страницаNEA - MaterialsromuloacОценок пока нет

- Mav 2005 InstalationДокумент1 страницаMav 2005 InstalationCamilo Andrés Nope FajardoОценок пока нет

- Additive Market in IndiaДокумент9 страницAdditive Market in IndiaNasr MegahedОценок пока нет

- ASTM D4290 Grease LeakageДокумент8 страницASTM D4290 Grease LeakagesrcattozziОценок пока нет

- RS Clare Oil & Gas BrochureДокумент12 страницRS Clare Oil & Gas BrochureVALENTIN PATRASОценок пока нет

- Shell - Rimula - R4 X 15W40 - Construction ColombiaДокумент1 страницаShell - Rimula - R4 X 15W40 - Construction ColombiaJorge Arrieta Torres100% (1)

- Flender Gear Units: Double-Screw-Extruder Gear UnitДокумент110 страницFlender Gear Units: Double-Screw-Extruder Gear UnitAmirmasoudОценок пока нет

- VTK Varnish Potential Test Kits PDFДокумент1 страницаVTK Varnish Potential Test Kits PDFEduardo CramerОценок пока нет

- O&m RnaaДокумент20 страницO&m RnaaГеннадий ПарфентьевОценок пока нет

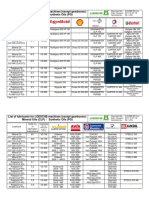

- List of Lubricants For LOESCHE-machines (Except Gearboxes) : Mineral Oils (CLP) / Synthetic Oils (PG)Документ8 страницList of Lubricants For LOESCHE-machines (Except Gearboxes) : Mineral Oils (CLP) / Synthetic Oils (PG)MossaabSelaimiaОценок пока нет

- Warning: Recommended Lube Oil Change Intervals Taking An Oil SampleДокумент6 страницWarning: Recommended Lube Oil Change Intervals Taking An Oil SamplegalaxiprinceОценок пока нет

- Data Sheet REMALOX (ENG)Документ1 страницаData Sheet REMALOX (ENG)anggada satriaОценок пока нет

- Caltex Product CatalogueДокумент34 страницыCaltex Product CatalogueAR YelОценок пока нет

- DU Sliding Material SpecificationsДокумент55 страницDU Sliding Material SpecificationsMichał AmborОценок пока нет

- Proceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987От EverandProceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987W. R. TysonОценок пока нет

- Nes M0135-2001Документ22 страницыNes M0135-2001farhad pashaei mehr80% (5)

- F2489Документ13 страницF2489msbarretosОценок пока нет

- Rev 3 - KEL 8 - Tugas 2 Lubricant & BearingДокумент7 страницRev 3 - KEL 8 - Tugas 2 Lubricant & BearingHasan Ahmad Zaky100% (1)

- D7097-Determination of Mederately High Temperature Piston Deposis by Thermooxidation Engine Oil Simulation Test TEOST MHTДокумент14 страницD7097-Determination of Mederately High Temperature Piston Deposis by Thermooxidation Engine Oil Simulation Test TEOST MHTengrsurifОценок пока нет

- Sleeve Bearing Load LimitsДокумент2 страницыSleeve Bearing Load Limitssperthawin2787630Оценок пока нет

- Viscosity ClassificationsДокумент6 страницViscosity ClassificationsDarmawan PutrantoОценок пока нет

- Model For Prediction of Churning LossesДокумент6 страницModel For Prediction of Churning LossesSaipriya BalakumarОценок пока нет

- Single Line Progressive SystemsДокумент70 страницSingle Line Progressive SystemsOverhaul QAОценок пока нет

- Klübersynth HBE 94-401: Synthetic Heavy-Duty Grease For Long-Term LubricationДокумент4 страницыKlübersynth HBE 94-401: Synthetic Heavy-Duty Grease For Long-Term LubricationErico Haryanto LumbanrajaОценок пока нет

- Klüberplex BEM 41-141: Product InformationДокумент2 страницыKlüberplex BEM 41-141: Product InformationPRAKASH BОценок пока нет

- Isoflex Topas NB 5051Документ2 страницыIsoflex Topas NB 5051jcapancho.pertuaОценок пока нет

- Low Viscosity Oils Impact On Heavy Duty Diesel Engine ComponentsДокумент14 страницLow Viscosity Oils Impact On Heavy Duty Diesel Engine Componentsphucdc095041Оценок пока нет

- LNG AUG20 SampleДокумент25 страницLNG AUG20 Samplephucdc095041Оценок пока нет

- 2016 Hyundai h350 101119Документ473 страницы2016 Hyundai h350 101119phucdc095041Оценок пока нет

- Petamo Ghy 133 N: Product InformationДокумент4 страницыPetamo Ghy 133 N: Product Informationphucdc095041Оценок пока нет

- Part EДокумент24 страницыPart Ephucdc095041Оценок пока нет

- Operator'S Manual: Read and Save This ManualДокумент112 страницOperator'S Manual: Read and Save This Manualphucdc095041Оценок пока нет

- Ceran-Xm-220 TDS v171128Документ2 страницыCeran-Xm-220 TDS v171128phucdc095041Оценок пока нет

- Product Information: Valvoline Elgi AirlubeДокумент1 страницаProduct Information: Valvoline Elgi Airlubephucdc095041100% (1)

- Tot Preslia 06-18 TDSДокумент1 страницаTot Preslia 06-18 TDSphucdc095041Оценок пока нет

- Current Product Brand New Product Brand: BP Lubricants USA Inc 150 West Warrenville RD Naperville, IL 60563Документ2 страницыCurrent Product Brand New Product Brand: BP Lubricants USA Inc 150 West Warrenville RD Naperville, IL 60563phucdc095041Оценок пока нет

- Klüber Summit SH 32, 46, 68, 100: Product InformationДокумент4 страницыKlüber Summit SH 32, 46, 68, 100: Product Informationphucdc095041Оценок пока нет

- Workshop Manual: Quality Department After-SalesДокумент83 страницыWorkshop Manual: Quality Department After-Salesphucdc095041Оценок пока нет

- 19-Microendoscopic Lumbar DiscectomyДокумент8 страниц19-Microendoscopic Lumbar DiscectomyNewton IssacОценок пока нет

- ICTSAS601 Student Assessment Tasks 2020Документ30 страницICTSAS601 Student Assessment Tasks 2020Lok SewaОценок пока нет

- Financial Performance Report General Tyres and Rubber Company-FinalДокумент29 страницFinancial Performance Report General Tyres and Rubber Company-FinalKabeer QureshiОценок пока нет

- Tesmec Catalogue TmeДокумент208 страницTesmec Catalogue TmeDidier solanoОценок пока нет

- Chemistry InvestigatoryДокумент16 страницChemistry InvestigatoryVedant LadheОценок пока нет

- Designing HPE Server Solutions: Supporting ResourcesДокумент3 страницыDesigning HPE Server Solutions: Supporting ResourcesKARTHIK KARTHIKОценок пока нет

- Do You Agree or Disagree With The Following StatementДокумент2 страницыDo You Agree or Disagree With The Following StatementVũ Ngọc Minh ThuОценок пока нет

- Qafqaz UniversityДокумент3 страницыQafqaz UniversityQafqazlife QUОценок пока нет

- Quiz 07Документ15 страницQuiz 07Ije Love100% (1)

- MELC5 - First ObservationДокумент4 страницыMELC5 - First ObservationMayca Solomon GatdulaОценок пока нет

- FCAPSДокумент5 страницFCAPSPablo ParreñoОценок пока нет

- Digestive System LabsheetДокумент4 страницыDigestive System LabsheetKATHLEEN MAE HERMOОценок пока нет

- Lifelong Learning: Undergraduate Programs YouДокумент8 страницLifelong Learning: Undergraduate Programs YouJavier Pereira StraubeОценок пока нет

- Green and White Zero Waste Living Education Video PresentationДокумент12 страницGreen and White Zero Waste Living Education Video PresentationNicole SarileОценок пока нет

- ENTRAPRENEURSHIPДокумент29 страницENTRAPRENEURSHIPTanmay Mukherjee100% (1)

- Newspaper OrganisationДокумент20 страницNewspaper OrganisationKcite91100% (5)

- Hanumaan Bajrang Baan by JДокумент104 страницыHanumaan Bajrang Baan by JAnonymous R8qkzgОценок пока нет

- Simplified Electronic Design of The Function : ARMTH Start & Stop SystemДокумент6 страницSimplified Electronic Design of The Function : ARMTH Start & Stop SystembadrОценок пока нет

- Executive SummaryДокумент3 страницыExecutive SummarySofia ArissaОценок пока нет

- Contract of Lease (711) - AguilarДокумент7 страницContract of Lease (711) - AguilarCoy Resurreccion Camarse100% (2)

- CebuanoДокумент1 страницаCebuanoanon_58478535150% (2)

- The Eaglet - Vol. 31, No. 3 - September 2019Документ8 страницThe Eaglet - Vol. 31, No. 3 - September 2019Rebecca LovettОценок пока нет

- Academic Decathlon FlyerДокумент3 страницыAcademic Decathlon FlyerNjeri GachОценок пока нет

- Wastewater Treatment: Sudha Goel, Ph.D. Department of Civil Engineering, IIT KharagpurДокумент33 страницыWastewater Treatment: Sudha Goel, Ph.D. Department of Civil Engineering, IIT KharagpurSubhajit BagОценок пока нет

- AITAS 8th Doctor SourcebookДокумент192 страницыAITAS 8th Doctor SourcebookClaudio Caceres100% (13)

- You Are The Reason PDFДокумент1 страницаYou Are The Reason PDFLachlan CourtОценок пока нет

- 059 Night of The Werewolf PDFДокумент172 страницы059 Night of The Werewolf PDFomar omar100% (1)

- Dragon Ball AbrigedДокумент8 страницDragon Ball AbrigedAlexander SusmanОценок пока нет

- PUERPERAL SEPSIS CoverДокумент9 страницPUERPERAL SEPSIS CoverKerpersky LogОценок пока нет

- Manhole DetailДокумент1 страницаManhole DetailchrisОценок пока нет