Академический Документы

Профессиональный Документы

Культура Документы

Esbelt Snaren 2018

Загружено:

Koen BidlotИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Esbelt Snaren 2018

Загружено:

Koen BidlotАвторское право:

Доступные форматы

Cleats (flights)

for conveyor Inclined conveyors occasionally require belts with profiles or cleats (flights) on the carrying surface.

belting These prevent slippage of the conveyed material and increases the belt capacity.

The type and height of the most suitable cleat (flight) is determined according to the characteristics

of the conyeved material and the inclination of the conveyor. Optimum conveying capacity can be

achieved up to angles of 70º by this means.

Notched PVC and PU trapezoidal tracking guides can be supplied; this increases belt flexibility and

when fitted to the underside of the belt can reduce the minimum pulley diameter by 10%.

esbelt cleats (flights) are oil and fat resistant.

Examples of possible cleat (flight) arrangements are as follows:

Single transverse cleat Double transverse cleat Herringbone “V” pattern

Inner tracking guide Retaining sidewalls Single transverse cleat with retaining

sidewalls.

Arrangement of Dimensions mm

C F D E

cleats in open A 400 500 600 650 800 1000 1200

“V” pattern B 300 400 450 480 600 800 900

(herringbone)

C 50 50 75 85 100 100 150

A B

D 180 205 210 225 286 348 390

E 20 20 20 20 20 20 20

G

F 18 18 24 30 50 60 60

C G 250 300 325 350 450 550 600

Recommendations Profile attachment is best carried out on 2 or more ply belts.

for profile

Minimum covers thickness for profile type are given below.

attachment

To obtain good results with a tracking gui- Minimum cover

Material and type of profile

thickness

de, the grooves in the pulleys, rollers and

slider beds must be larger than the tracking short fingers 0,3 mm

guide which is welded to the belt. height 20 and 30 mm 0,5 mm

reinforced profiles 0,8 mm

PVC height 40, 50, 60 mm and 0,8 mm

2 mm 2 mm types NE.012 and NE.C14

height 70, 80 mm and types 1 mm

NE.K16, NE.015 and fingers

PU

all types 0,3 mm

TPE

2 mm

PO all types 0,5 mm

Cleats (flights)

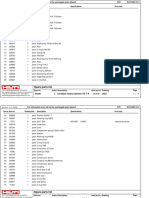

Section Type Dimensions Material Weight Transverse Longitudinal Possible

(1) g/m positioning

minimum ø mm (2) (3)

minimum minimum

b h a pitch ø (2) bottom top

mm mm mm mm mm side side

NE.008 8 8 75 28 60 110

PVC 100 T-G-L-V

h NE.012 12 12 175 32 80 120

PE.008 8 8 56 28

b PO 100 T-V

PE.012 12 12 133 32

h

NE.015 20 15 PVC 330 200 250 G-L

b

NA.X04-62 6 4 4,0 PVC 23 25 30 G-L

NE.Y05-62 8 5 4,4 40 28 50 50 60

NE.Z06-62 10 6 5,6 60 30 70 70 80

NE.A08-62 13 8 7,2 PVC 100 33 90 90 100

NE.B11-62 17 11 9,0 180 37 100 100 120 T-G-L-V

NE.C14-62 22 14 11,8 300 42 150 150 180

a NE.K16-70 30 16 18,4 470 50 250 250 250

UE.Y05 8 5 4,4 40 28 50 50 60

h UE.Z06 10 6 5,6 PU 59 30 70 70 80

T-G-L-V

UE.A08 13 8 7,2 98 33 90 90 100

b

UE.B11 17 11 9,0 170 37 100 100 120

PE.Z06 10 6 5,6 46 30 100

PE.A08 13 8 7,2 PO 75 33 110 T-V

PE.B11 17 11 9,0 130 37 120

EE.Z06 10 6 5,6 56 30 80 80

EE.A08 13 8 7,2 TPE 95 33 90 100 T-G-L-V

EE.B11 17 11 9,0 167 37 100 120

DA.X04-62 6 3,5 4,25 PVC 18 15 G-L

DE.Y05-62 8 4,5 4,7 30 35

DE.Z06-70 10 5,5 6,0 45 50

DE.A08-62 13 7,5 7,5 75 70 G-L

DE.B11-62 17 10,5 10,3 PVC 140 80

DE.C14-62 22 13,5 12,2 245 125

DE.K16-70 30 15,5 18,4 370 170

DUE.Z06 10 5,5 6,0 45 50

DUE.A08 13 7,5 7,5 PU 74 70 G-L

DUE.B11 17 10,5 9,0 130 80

NV.020-70 25 20 285 120

NV.030-70 25 30 370 120

h NV.040-70 25 40 PVC 450 45 120 T

NV.050-70 25 50 600 120

b NV.060-70 25 60 700 150

NL.030-70 25 30 430 50 120

(2) The minimum recom-

mended diameters given NL.040-70 25 40 550 50 120

are for normal working NL.050-70 25 50 PVC 700 50 120

h T

conditions, at 20ºC. Lower NL.060-70 25 60 780 50 150

temperatures require grea- b

NL.070-70 40 70 1240 130 170

ter diameters. NL.080-70 40 80 1400 130 170

(3) Profile positioning: UV.020 10 20 140 40

T - Transversal, G - Inner UV.030 10 30 PU 180 30 45 T

tracking guide, L - Lateral UV.050 10 50 300 50

retaining wall, V - V-shaped. PV.020 10 20 95

h PV.030 10 30 PO 135 30 100 T

PV.050 10 50 235

Unwelded profile angle: b EV.020 10 20 130

EV.030 10 30 TPE 170 30 80 T

α= 65º ± 3º EV.050 10 50 300

α UL.030 10 30

PU

215 40 45 T

UL.050 10 50 320 50

PL.030 10 30 155 T

Once welded, the variation PO 40 100

PL.050 10 50 225

in the angle is minimal.

EL.030 10 30 210

b TPE 40 80 T

EL.050 10 50 310

h NEM.040-62 45 40 soft 640 120 T

NEM.060-62 55 60 PVC 1050 150

b

NEQ.040-62 42 40 635 120

h soft T

NEQ.060-62 60 60 1150 150

PVC

b

NEQ.070-62 60 70 1400 170

(1) Material Color Special characteristics Hardness Temperature ºC

PVC PVC Green 00 - White - Blue 06 FDA, EU, antistatic, oil resistant 70º ShA -10 +80

soft

PVC Green 00 - White - Blue 06 FDA, EU, antistatic, oil resistant 62º ShA -15 +80

PVC

PU Polyurethane Green 09 - White - Blue 06 FDA, EU, oil resistant 85º ShA -10 +100

PO Polyolefin Transparent FDA, EU, oil resistant 90º ShA -10 +50

TPE Polyester Natural FDA, EU, oil resistant 40º ShD -20 +105

Special profiles Fingers

Fingers and Short Fingers

m h

0 itc

m

10 n. p

i

M

As an alternative of cleats, esbelt provides “Finger” profiles. Specially indicated for

conveying fruit on inclined sections (preventing sharp knocks that might damage the

appereance) and frozen food products (the cylindrical structure prevents the frozen pro-

duct from sticking to the belt).

Esbelt offers “Short Fingers” used mainly in harvesters of thin-skinned (apples, necta-

rines, peaches, pears, etc.) and the conveyance and selection of asparagus.

Short

fingers

Profile Height Hardness Color ø minimum

mm ºShA mm

Min. pitch 51 mm

Fingers 92 80 100

White - Green

Short fingers 25 67 60 51 mm

Reinforced profile

Esbelt offers reinforced PVC profiles in 4 different heights, specially designed for applications involving difficult conditions; in general

all applications in which the profiles undergo impact on receiving or conveying material. Excellent resistance to ripping and cutting.

Strong and long-lasting that increase transverse rigidity of the belt, producing greater stability on the conveyor.

Dimensions Transverse Length

Profile Color Esbelt, also offers

Minimum minimum mm reinforced PVC profiles,

b h pitch ø (2) inclined: NIR070 and

mm mm mm mm NIR100

NRR030 30

h

NRR050 50

Blue 06,

NRR070 70 2000 mm

50 70 120 White and

strips Green 00

NRR100 100

NIR070 68

b

NIR100 97

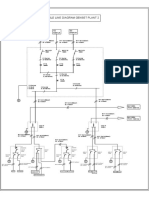

Belt support on the return side

1. Belt with cleats (flights) in “V”, section 5. Belt with sidewalls supported by a

3. Supported on three pulleys.

supported on a cylindrical roller. cylindrical roller which is narrower

than the belt.

6. Belt with sidewalls and transverse

2. Supported on two lateral pulleys. 4. Belt with internal tracking guide

cleat supported by a cylindrical roller.

supported by a cylindrical roller and

driven by a grooved driving pulley.

Вам также может понравиться

- Datasheet TBUT000400 enДокумент2 страницыDatasheet TBUT000400 enpetkoОценок пока нет

- Mitek Cyclone TieДокумент7 страницMitek Cyclone TieTony PedaОценок пока нет

- Technical Data: Model NumberДокумент2 страницыTechnical Data: Model NumberEjaz EjazОценок пока нет

- Mez Standard System 20Документ2 страницыMez Standard System 20Antonio Carlos AtaideОценок пока нет

- Aircraft Structures Iii: Tutorial No 1: Sectional PropertiesДокумент4 страницыAircraft Structures Iii: Tutorial No 1: Sectional PropertiesOmkarОценок пока нет

- Hra Panel SpecДокумент4 страницыHra Panel SpecMuhammad Arslan Khurshid BhattiОценок пока нет

- Brochure Sieve Shakers enДокумент4 страницыBrochure Sieve Shakers enjesusОценок пока нет

- Astm Reference Block For MetalДокумент10 страницAstm Reference Block For MetalrupamОценок пока нет

- NC Specs 3 18 21Документ2 страницыNC Specs 3 18 21ai007.rusmanaОценок пока нет

- Haunched Moment Connection AISC360-10Документ5 страницHaunched Moment Connection AISC360-10osman_sultanОценок пока нет

- 03 2 Seyi SD SDG2 Sde2 eДокумент16 страниц03 2 Seyi SD SDG2 Sde2 eCông Quang Trường PhanОценок пока нет

- Power Press Punching Machine JB23 Series: The Machine of Whole Structure and CharacteristicsДокумент2 страницыPower Press Punching Machine JB23 Series: The Machine of Whole Structure and CharacteristicsRadiadores PlanosОценок пока нет

- Troughed - Design Guidelines and StandardsДокумент6 страницTroughed - Design Guidelines and StandardshaqjmiОценок пока нет

- Cortizo 70 IndustrialДокумент668 страницCortizo 70 IndustrialAndrei Ivanov100% (1)

- Mesh Tech SheetДокумент1 страницаMesh Tech SheetRiana ZammitОценок пока нет

- Mesh Tech Sheet PDFДокумент1 страницаMesh Tech Sheet PDFĐorđe NikolajevićОценок пока нет

- Mesh Tech Sheet PDFДокумент1 страницаMesh Tech Sheet PDFFarooq Al-obaidiОценок пока нет

- Mesh Tech Sheet PDFДокумент1 страницаMesh Tech Sheet PDFluisaОценок пока нет

- Mesh Tech Sheet PDFДокумент1 страницаMesh Tech Sheet PDFKeith Zammit TaboneОценок пока нет

- Mashe Malta PDFДокумент1 страницаMashe Malta PDFluisaОценок пока нет

- Mesh Tech Sheet PDFДокумент1 страницаMesh Tech Sheet PDFRiana ZammitОценок пока нет

- The Specialists in Industrial Flooring and Handrailing: Tubular StandardsДокумент3 страницыThe Specialists in Industrial Flooring and Handrailing: Tubular StandardsHazim AffendiОценок пока нет

- ZLOE 315 1 A 17279961.html PDFДокумент2 страницыZLOE 315 1 A 17279961.html PDFJhonFerneyBohorquezSaldarriagaОценок пока нет

- Raptor 600 Cone CrushersДокумент4 страницыRaptor 600 Cone CrushersIgnacio León IbarraОценок пока нет

- ACE Manual Feed: New Generation Magnetic Base Drilling Machines Help Meet Productivity and Safety GoalsДокумент2 страницыACE Manual Feed: New Generation Magnetic Base Drilling Machines Help Meet Productivity and Safety GoalsAyien MuhammadОценок пока нет

- Screw Press SL Conveyor Sd2Документ2 страницыScrew Press SL Conveyor Sd2MariusCapraОценок пока нет

- ABESTANO Wall and Column Footing Details LДокумент1 страницаABESTANO Wall and Column Footing Details LAldrin Abestano Jr.Оценок пока нет

- PL 500 Technical LeafletДокумент2 страницыPL 500 Technical LeafletAsad AijazОценок пока нет

- The Ers Var 15 Brake: Electrically Released Brake For Stage & Theater ApplicationsДокумент2 страницыThe Ers Var 15 Brake: Electrically Released Brake For Stage & Theater ApplicationsAli GameelОценок пока нет

- New Brosur Beva Razor & Beva Barb 2020 CompressedДокумент12 страницNew Brosur Beva Razor & Beva Barb 2020 CompressedWilly BaskoroОценок пока нет

- Microsection 7Документ14 страницMicrosection 7MMM-MMMОценок пока нет

- 6.1 BBS Pile Cap P1 - Block BДокумент2 страницы6.1 BBS Pile Cap P1 - Block BSURAJ SINHAОценок пока нет

- An Externally Mounted Flange Facing Machine For All Types of Flange Facings, Seal Groove Machining, Weld Preparation and Counter BoringДокумент3 страницыAn Externally Mounted Flange Facing Machine For All Types of Flange Facings, Seal Groove Machining, Weld Preparation and Counter BoringManish MohananОценок пока нет

- Side Sling Calculation - OGДокумент2 страницыSide Sling Calculation - OGkiencuong3052007Оценок пока нет

- Çavuş Bant KatalogДокумент4 страницыÇavuş Bant KatalogAvazagha HuseynovОценок пока нет

- 150 RacДокумент1 страница150 RacM Umar ChatthaОценок пока нет

- App 2037023000Документ6 страницApp 2037023000danielОценок пока нет

- Drills 7 TappersДокумент10 страницDrills 7 TappersBe HappyОценок пока нет

- GratingДокумент24 страницыGratingsigОценок пока нет

- S-Touch eДокумент10 страницS-Touch eQuang NguyenОценок пока нет

- UNS S41000 (Type SS 410) : SS 304 Bonded To 3mm Non-Conductive Grey EPDM WasherДокумент1 страницаUNS S41000 (Type SS 410) : SS 304 Bonded To 3mm Non-Conductive Grey EPDM WasherrimshadtpОценок пока нет

- Zhengtan Belting Rubber Conveyor BeltДокумент24 страницыZhengtan Belting Rubber Conveyor BeltJohn Renzel Rivera IIIОценок пока нет

- M710B EnglishДокумент2 страницыM710B Englishjdiaz87Оценок пока нет

- Surface Grinders - OKAMOTO - ACC 450 DXДокумент1 страницаSurface Grinders - OKAMOTO - ACC 450 DXMaster WimalaОценок пока нет

- Advanced Thermal Solutions 05232018 ATS-TI1OP-519 - 1368383Документ2 страницыAdvanced Thermal Solutions 05232018 ATS-TI1OP-519 - 1368383David_MacielОценок пока нет

- V-Turn 410-1000Документ1 страницаV-Turn 410-1000Frederik HenderwanzaОценок пока нет

- ByStar Fiber Datasheet Eng Original 14278Документ2 страницыByStar Fiber Datasheet Eng Original 14278Trần Ngọc ThànhОценок пока нет

- Begg Cousland Tower InternalsДокумент4 страницыBegg Cousland Tower InternalsHavocFireОценок пока нет

- SDL J (Pedestal)Документ4 страницыSDL J (Pedestal)SURAJ SINHAОценок пока нет

- Hunsone CNC Machine CatalogueДокумент38 страницHunsone CNC Machine CatalogueLucy MontfortОценок пока нет

- Kristeel CatalogueДокумент52 страницыKristeel CatalogueRam TejaОценок пока нет

- RS 14 Saclp 01Документ1 страницаRS 14 Saclp 01fadialkasrawiОценок пока нет

- Haitian Mars TechДокумент4 страницыHaitian Mars TechRenardОценок пока нет

- Accutom10 100 Tech EnglishДокумент2 страницыAccutom10 100 Tech EnglishDaniel CОценок пока нет

- Toggle-Injection-Moulding-Machines 2Документ16 страницToggle-Injection-Moulding-Machines 2Vimal AathithanОценок пока нет

- Catalogue 0501Документ8 страницCatalogue 0501Neeraj VohraОценок пока нет

- Lam KatalogДокумент8 страницLam KatalogMAbdel EldesouОценок пока нет

- SE50EV AspecsMETRICДокумент1 страницаSE50EV AspecsMETRICJean AlexОценок пока нет

- Ficha Técnica Tornos Convencionales CDS CW - Compressed1 PDFДокумент1 страницаFicha Técnica Tornos Convencionales CDS CW - Compressed1 PDFedisonОценок пока нет

- En SNR Muctbl205Документ2 страницыEn SNR Muctbl205Koen BidlotОценок пока нет

- S-08640 - How To Rename An Enterprise PDM File VaultДокумент12 страницS-08640 - How To Rename An Enterprise PDM File VaultKoen BidlotОценок пока нет

- Barataria SSPДокумент76 страницBarataria SSPKoen BidlotОценок пока нет

- ASTER 12G2F - Data Sheet: StructureДокумент1 страницаASTER 12G2F - Data Sheet: StructureKoen BidlotОценок пока нет

- Habasit Fabrication Tools and Hot Presses: Habasit - Solutions in MotionДокумент24 страницыHabasit Fabrication Tools and Hot Presses: Habasit - Solutions in MotionKoen BidlotОценок пока нет

- 25 Cognitive Biases PDFДокумент28 страниц25 Cognitive Biases PDFKoen BidlotОценок пока нет

- Rexnord Marbett Issue 14-English. Part 1 Componenten PDFДокумент246 страницRexnord Marbett Issue 14-English. Part 1 Componenten PDFKoen Bidlot100% (1)

- Tig Welding W19 12 3 LSiДокумент2 страницыTig Welding W19 12 3 LSiKoen BidlotОценок пока нет

- Driveworks Feature Comparison PDFДокумент2 страницыDriveworks Feature Comparison PDFKoen BidlotОценок пока нет

- 122 - A Resilient Modeling Strategy - Richard Gebhard PDFДокумент36 страниц122 - A Resilient Modeling Strategy - Richard Gebhard PDFKoen BidlotОценок пока нет

- A New Mindset in Product DesignДокумент5 страницA New Mindset in Product DesignKoen BidlotОценок пока нет

- Manual Me ProДокумент414 страницManual Me ProJavier Gaete ObrequeОценок пока нет

- Files Without This Message by Purchasing Novapdf PrinterДокумент1 страницаFiles Without This Message by Purchasing Novapdf PrinterKoen BidlotОценок пока нет

- Box TippingДокумент4 страницыBox TippingKoen BidlotОценок пока нет

- Kendo Leaflet PDFДокумент16 страницKendo Leaflet PDFeka purwanaОценок пока нет

- S&T TM (T14S10) PDFДокумент13 страницS&T TM (T14S10) PDFFrezgi BirhanuОценок пока нет

- Throttle Spring ModДокумент13 страницThrottle Spring Modbibibibibiib123123Оценок пока нет

- Deskripsi Eye WasherДокумент11 страницDeskripsi Eye Washerrsgs gunungsawoОценок пока нет

- Blade Lift Cyl AssemblyДокумент4 страницыBlade Lift Cyl AssemblySHANEОценок пока нет

- NOV Manual Elevators Rev L-20-22Документ3 страницыNOV Manual Elevators Rev L-20-22Standards Procedures100% (1)

- Air Filter PDFДокумент15 страницAir Filter PDFArun KarthikeyanОценок пока нет

- Technical Details For Tools From Our Manufacturing InventoryДокумент15 страницTechnical Details For Tools From Our Manufacturing InventoryRehan AhmedОценок пока нет

- Company ProfileДокумент15 страницCompany ProfileUlla SlaluОценок пока нет

- Hanro Tools Incorporation Delhi IndiaДокумент10 страницHanro Tools Incorporation Delhi IndiaHanro Tools IncorporationОценок пока нет

- Inventor - Despiece - GarruchaДокумент1 страницаInventor - Despiece - GarruchaMiguelОценок пока нет

- HVAC Loren Cook FansДокумент28 страницHVAC Loren Cook FansExcelОценок пока нет

- Ladder Safety General Ladder UseДокумент20 страницLadder Safety General Ladder UseferozОценок пока нет

- Spare Parts List: Cordless Rotary Hammer TE 7-AДокумент9 страницSpare Parts List: Cordless Rotary Hammer TE 7-AGayduk ValeriyОценок пока нет

- CEMA Standard 501.1-2015Документ16 страницCEMA Standard 501.1-2015MОценок пока нет

- Fisher EZ Sliding - Stem Control Valve: The Easy - Et Valve FamilyДокумент20 страницFisher EZ Sliding - Stem Control Valve: The Easy - Et Valve FamilyAlberto GuillenОценок пока нет

- Air Arms TX200Документ8 страницAir Arms TX200kurakОценок пока нет

- Temp Cont Manual For ST380-R0 060316 PDFДокумент20 страницTemp Cont Manual For ST380-R0 060316 PDFManh VuОценок пока нет

- PN427604Документ152 страницыPN427604Cesar MuñozОценок пока нет

- Berendsen Hydraulic Troubleshooting GuideДокумент19 страницBerendsen Hydraulic Troubleshooting GuideBradley Berg100% (1)

- CV FORMAT 2Документ2 страницыCV FORMAT 2useforfreelanceworkОценок пока нет

- Single Line Diagram Genset P2Документ1 страницаSingle Line Diagram Genset P2Dwika YanuariОценок пока нет

- Design of Column (C-1)Документ3 страницыDesign of Column (C-1)Khael Angelo Zheus JaclaОценок пока нет

- Palamoottil InfrastructureДокумент15 страницPalamoottil InfrastructureFajal SayyadОценок пока нет

- Maquina Modelo 1200Документ4 страницыMaquina Modelo 1200Napoleon LedezmaОценок пока нет

- Control ValveДокумент2 страницыControl ValveKashif ZiaОценок пока нет

- Reece 42 SeriesДокумент86 страницReece 42 Seriescarlosrebeca17gmail.comОценок пока нет

- Part ListДокумент9 страницPart ListMuhammad GaneshaОценок пока нет

- TC1 ModДокумент1 страницаTC1 ModAlexander SverdlovОценок пока нет

- Support Panel LVMD False FloorДокумент1 страницаSupport Panel LVMD False FloorSeptiyan WidiantoОценок пока нет