Академический Документы

Профессиональный Документы

Культура Документы

Application: NTMOS Calibration Kit 010272-001

Загружено:

CheloX LОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Application: NTMOS Calibration Kit 010272-001

Загружено:

CheloX LАвторское право:

Доступные форматы

INSTRUCTIONS

NTMOS Calibration Kit

010272-001

APPLICATION

The Model 010272-001 NTMOS Calibration Kit provides

an accurate concentration of the gas/air mixture that is

used for periodically testing and calibrating the NTMOS

H2S gas detector. The kit allows calibration gas to be

delivered to the sensor at a regulated flow rate and at

ambient humidity, thereby ensuring consistent and

accurate calibration of the NTMOS sensor, even under

worst case conditions.

FEATURES

• Ensures accurate calibration of NTMOS H2S sensors.

• Calibration gas delivered to sensor at ambient humidity

via humidification tube.

• Replacement cylinders, regulators, humidification tube

cages, and calibration cups are readily available. Calibration interval—

Typically 30 day intervals, depending on ambient

conditions such as extreme high and low temperatures

and humidity.

DESCRIPTION

DIMENSIONS—

The calibration kit consists of a pressurized cylinder of

19 inches (48 cm) high, 7 inches (18 cm) wide, 3.5 inches

50 ppm calibration gas (H2S in air), a 0.5 LPM pressure

(9 cm) deep.

regulator with indicator, a humidification tube cage, two

hoses, and a calibration cup that is designed to fit directly

SHIPPING WEIGHT (Approximate)—

onto the sensor. The regulator is preset to provide the

7.7 pounds (3.5 kilograms).

proper flow rate to ensure accurate calibration.

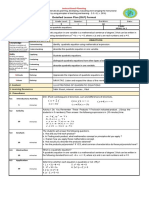

OPERATING THE KIT

SPECIFICATIONS

To prepare the kit for calibration:

FLOW RATE (Regulator)—

0.5 liter per minute. 1. Screw the regulator onto the calibration gas bottle

(only 50 ppm H2S in air may be used).

OPERATING TIME— note

Factors such as calibration tube length/diameter, wind, A 0.5 LPM regulator must be used. Any other flow

gas volume, and flow rate can affect the operating time rate will result in inaccurate calibration.

of the gas cylinder. A full cylinder will last approximately

two hours at 0.5 LPM flow rate. 2. Attach one plastic hose between the regulator and

the humidification tube cage.

TEMPERATURE RANGE— 3. Attach the other plastic hose between the

+14°F to +130°F (–10°C to +55°C). Cylinder could burst if humidification tube cage and the calibration cup.

exposed to temperatures that exceed the upper limit. See Figure 1.

1.1 ©Detector Electronics Corporation 2009 12/09 95-8648

SAFETY PRECAUTIONS

The calibration kit should be operated by qualified

personnel only. Read the entire manual before operating

the kit.

Observe the following safety items:

–– Handle and operate the calibration kit with care.

–– Use a portable detection instrument to be sure that

the hazardous area is safe for entry (no high levels of

either toxic or combustible gas are present).

–– Do not expose the gas cylinder to high

temperatures.

–– Do not operate the calibration kit if any part is

damaged or defective.

–– Remove the regulator from the gas bottle after use.

Figure 1—Calibration Setup for the NTMOS Sensor

DEVICE REPAIR AND RETURN

Prior to returning devices or components, contact the

nearest local Detector Electronics office so that an RMI

To apply the calibration gas to the sensor:

(Return Material Identification) number can be assigned.

1. Attach the calibration cup to the sensor. Ensure that A written statement describing the malfunction must

the O-ring is present on the calibration cup and that the accompany the returned device or component to expedite

calibration cup is properly seated on the sensor. finding the cause of the failure. Return all equipment

2. To apply gas to the sensor, turn the regulator valve transportation prepaid to the factory in Minneapolis.

counterclockwise.

3. To stop the flow of gas to the sensor, turn the regulator

ORDERING INFORMATION

valve clockwise.

For additional information regarding NTMOS sensor When ordering please specify:

calibration, refer to the NTMOS Gas Sensor Instruction

Manual, number 95‑8604. Part Number Description

010272-001 NTMOS Calibration Kit, 50 ppm H2S

Replacement parts

CALIBRATION FAILURE

Part Number Description

The sintered filters on the NTMOS sensor housing 227117-014 Bottle of Calibration Gas,

protect the sensing element from contaminants in the 50 ppm H2S in air

environment. However, an accumulation of dirt on the 010525-001 Humidification Tube Cage

sinters can block the flow of gas to the sensing element 162552-003 Regulator, 0.5 LPM

and adversely affect its response. If the detector cannot 005964-001 Calibration Cup

be calibrated or responds slowly to the calibration gas, 101678-007 Hose (three foot length)

check the condition of the sinters. If the sinters are dirty, 162553-001 Carrying Case

clean them (if possible) using a canister of air. If they

cannot be properly cleaned or if they are damaged, the

entire NTMOS sensor must be replaced.

Specifications subject to change without notice.

ER

ED BY UL

AN

Detector Electronics Corporation

T D

IS

Det-Tronics and the DET-TRONICS logo are registered trademarks or trademarks 6901 West 110th Street • Minneapolis, Minnesota 55438 USA

G

BS

RE

of Detector Electronics Corporation in the United States, other countries, or both. ISO 9001

Other company, product, or service names may be trademarks or service marks Operator: (952) 941-5665 or (800) 765-FIRE

REGIS

REGI

Customer Service: (952) 946-6491 • Fax (952) 829-8750

RM

TER TE

of others.

ED FIR RED FI

M

S

NO

. 6

A 23 82

05 • NO. 25

©Copyright Detector Electronics Corporation 2009. All rights reserved. http://www.det-tronics.com • E-mail: det-tronics@det-tronics.com

Вам также может понравиться

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Gasgard XL Wall Mount Controller: Operating ManualДокумент90 страницGasgard XL Wall Mount Controller: Operating ManualCheloX LОценок пока нет

- Instructions: Infiniti Gas Transmitter Model U9500Документ50 страницInstructions: Infiniti Gas Transmitter Model U9500CheloX LОценок пока нет

- Instructions 95-8671: Det-Tronics Standard Gas PanelДокумент20 страницInstructions 95-8671: Det-Tronics Standard Gas PanelCheloX LОценок пока нет

- Flexvu Universal Display Model Ud10 Model Ud10 With CGS: Safety ManualДокумент6 страницFlexvu Universal Display Model Ud10 Model Ud10 With CGS: Safety ManualCheloX LОценок пока нет

- Eagle Quantum Premier 8 Channel Analog Input Module (AIM) EQ3710AIMДокумент4 страницыEagle Quantum Premier 8 Channel Analog Input Module (AIM) EQ3710AIMCheloX LОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- R3.105 Final Report UpdatedДокумент77 страницR3.105 Final Report UpdatedSamОценок пока нет

- 253 968 2 SPДокумент16 страниц253 968 2 SPAlvin MRОценок пока нет

- ACC20 Engine Safety UnitДокумент2 страницыACC20 Engine Safety UnitVictor EugenОценок пока нет

- Gas SolubilityДокумент59 страницGas Solubilitysomsubhra100% (1)

- Solow Model Extension-Human CapitalДокумент16 страницSolow Model Extension-Human CapitalQusay Falah Al-dalaienОценок пока нет

- Danyar Et Al., 2020 - FinalДокумент24 страницыDanyar Et Al., 2020 - FinalSardar SaleemОценок пока нет

- DE SHORT METHODS - RevisedДокумент4 страницыDE SHORT METHODS - RevisedWilma NaderaОценок пока нет

- Name: Edwin D. Bagos Jr. Date: Course, Year §ion: BSIT 1-E Rating: Contact Number: 09755276308 Subject: Computer Programming 1-JAVAДокумент5 страницName: Edwin D. Bagos Jr. Date: Course, Year §ion: BSIT 1-E Rating: Contact Number: 09755276308 Subject: Computer Programming 1-JAVAMonalyn Señaris100% (2)

- Current Calculator For Barrel Plating - Chlorize Zinc PlatingДокумент4 страницыCurrent Calculator For Barrel Plating - Chlorize Zinc PlatingARVINDA KUMARОценок пока нет

- The Impact of Credit Risk On The Financial Performance of Chinese BanksДокумент5 страницThe Impact of Credit Risk On The Financial Performance of Chinese Banksvandv printsОценок пока нет

- Chapter Two Second Order Ordinary Differential Equation (SOODE)Документ11 страницChapter Two Second Order Ordinary Differential Equation (SOODE)BennyОценок пока нет

- Tutorial Module 3Документ24 страницыTutorial Module 3erieshaОценок пока нет

- ISODRAFT Reference ManualДокумент248 страницISODRAFT Reference Manualgabi_nanaОценок пока нет

- BS Iso 21573-1-2014Документ32 страницыBS Iso 21573-1-2014Salafi MhmdОценок пока нет

- AN78M20FДокумент10 страницAN78M20FFrantsiskoОценок пока нет

- G. Measurement of Angles and DirectionsДокумент3 страницыG. Measurement of Angles and DirectionsJasleneDimarananОценок пока нет

- CuClad Laminates Data SheetДокумент4 страницыCuClad Laminates Data SheetDenis CarlosОценок пока нет

- DSP Floating Point FormatsДокумент29 страницDSP Floating Point FormatsManjot KaurОценок пока нет

- Detailed Lesson Plan (DLP) Format: Nowledge ObjectivesДокумент2 страницыDetailed Lesson Plan (DLP) Format: Nowledge ObjectivesErwin B. NavarroОценок пока нет

- MK3 Harness PinoutДокумент12 страницMK3 Harness Pinoutluis5107Оценок пока нет

- Week 1Документ3 страницыWeek 1DELMAR REYES100% (1)

- Alpha New Trader GuideДокумент9 страницAlpha New Trader GuideChaitanya ShethОценок пока нет

- Piping Presentation - PpsДокумент61 страницаPiping Presentation - PpsVijayabaraniОценок пока нет

- 6.report Face RecognitionДокумент45 страниц6.report Face RecognitionSuresh MgОценок пока нет

- gp2 Speed IncreaserДокумент2 страницыgp2 Speed Increasermayur22785Оценок пока нет

- IBM PVM Getting Started GuideДокумент104 страницыIBM PVM Getting Started GuideNoureddine OussouОценок пока нет

- Airstage J-IIДокумент6 страницAirstage J-IIBulclimaОценок пока нет

- MD Boiler Asme WTДокумент159 страницMD Boiler Asme WTdodikОценок пока нет

- Linear Partial Differential Equations of High Order With Constant CoefficientsДокумент58 страницLinear Partial Differential Equations of High Order With Constant CoefficientsShahin Kauser ZiaudeenОценок пока нет