Академический Документы

Профессиональный Документы

Культура Документы

Preparation and Properties of Polyurethane / Functionalized Multi-Walled Carbon Nanotubes Rigid Foam Nanocomposites

Загружено:

ankita awasthiИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Preparation and Properties of Polyurethane / Functionalized Multi-Walled Carbon Nanotubes Rigid Foam Nanocomposites

Загружено:

ankita awasthiАвторское право:

Доступные форматы

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/280767721

Preparation and properties of polyurethane / functionalized multi-walled

carbon nanotubes rigid foam nanocomposites

Article in Polimery -Warsaw- · November 2014

DOI: 10.14314/polimery.2014.776

CITATIONS READS

11 212

2 authors, including:

Alireza Yaghoubi

University of Zanjan

4 PUBLICATIONS 26 CITATIONS

SEE PROFILE

Some of the authors of this publication are also working on these related projects:

drug delivery based on carbon nanotubes View project

All content following this page was uploaded by Alireza Yaghoubi on 08 February 2017.

The user has requested enhancement of the downloaded file.

Proceedings of the 5th International Conference on Nanostructures (ICNS5)

6-9 March 2014, Kish Island, Iran

Effect of 3- Aminopropyltriethoxysilane Functionalized Multi-Wall Carbon Nanotubes on

the properties of Polyurethane Rigid Foam Nanocomposites

Mir Mohammad Alavi Nikjea*, Alireza Yaghoubia

a

Department of Chemistry, Faculty of Science, IKIU, Qazvin, POBox: 288, Tel/Fax: +982813780040, Iran

*email: drmm.alavi@gmail.com

Abstract: Surface modification of the hydroxylated multi-walled carbon nanotubes (OH-MWCNTs) was carried out

by silanization with 3-aminopropyltriethoxysilane (APTS). Rigid polyurethane foam nanocompositeswere prepared by

silanized- MWCNTs in different weight percents via one shot method and thermal, mechanical and morphological

properties of the nanocomposites investigated in detail. The obtained results from thermogravimetric analysis indicated

that the thermal stability of nanocomposites was increased by increasing of silanized-MWCNTs content.

Morphological studies showed the increasing of cell density parallel by increasing of silanized-MWCNTs contents in

the polyurethane matrix. In the meantime, the results of tensile properties showed that the Young’s moduli as well as

tensile strengths were improved in comparison with pristine foam. Obtained data revealed reverse effects of 3%

functionalized MWCNT on the properties of respected nanocomposites due to agglomeration of MWCNTs.

Keywords: Multi-wall carbon nanotubes; Rigid polyurethane foams; nanocomposities; surface modification; 3-

Aminopropyltriethoxysilane

Introduction The OH-MWCNTs used in this work was purchased from

Currently, carbon nanotubes (CNTs) are one of the main neutrino Co. (Tehran, Iran). The OH- MWCNTs had a

topics of research due to their extraordinary properties diameter range of 10–20 nm and 3.06 wt. % OH groups

such as high mechanical and thermal properties [1]. The according to the manufacturer’s data. DaltoFoam TAR

agglomeration of the CNTs and poor interaction between 14066 polyether polyol containing all of required

the CNTs and matrix are two major problems that occur additives and PMDI (SuprasecR 5005) for rigid PU foam

during the preparation of CNT-reinforced composites. formulation were supplied by Huntsman Co. 3-

Therefore, to overcome these problems, various methods aminopropyltriethoxysilane (APTS), triethylamine

have been devised. Silanization of the CNTs by silane (TEA), ethanol, acetone were supplied from Merck.

coupling agents is one of these methods that can be used

to introducing of reactive functional groups as well as Silanization of OH- MWCNTs with APTS and

improving of the surface properties. Preparation of PUR foam nanocomposites

This method was used by Velasco for the first time [2]. OH-MWCNT (1g) was dispersed in ethanol (250 ml) by

He modified the oxidized MWCNTs with 3- ultra probe for 5 min. Then distilled water (3 ml),

mercaptopropyl trimethoxysilane (MPTS). It was shown dispersed APTS (3 ml) in ethanol (50 ml), and TEA (1

that silanization of CNTs with 3-mercaptopropyl ml), was dropped into the suspension sequentially. The

trimethoxysilane is an effective way that has lead to a mixture was stirred at 900 rpm for 3 h. The final product

better distribution of the CNTs in the polymer matrix. was then filtered, washed with ethanol and acetone and

Rigid polyurethane foams are member of the family of dried in a vacuum desiccator at 80 ºC for 24 h.

polymer foams that have a variety of applications in

For the preparation of nanocomposites; in first, different

everyday life which is due to their unique properties [3].

amounts of silanized-MWNT, 1.5, 2 and 3 wt. %, were

Pure PU due to its poor mechanical and thermal

added to the polyol matrix and sonicated in an

properties is not suitable for many applications.

ultrasonicator for 10 min . Then the mixture was

Therefore, Many researchers have attempted to solve this

transferred into a paper cup with a volume of 300 cc. In

problem [4]. In the present study, the OH-MWCNTs

the next step, PMDI was added to the polyol blend and

were functionalized by silanization processes by using 3-

hand mixed. After foaming, the test samples were cured

aminopropyltriethoxysilane (APTS) and the effect of

at room temperature for 24 h. The weight ratio of polyol

chemical functionalization of MWCNTs evaluated on the

to diisocyanate for all nanocomposites was 10 to 12.

mechanical, thermal and morphological properties of Si-

MWCNTs nanocomposites.

Characterization

Fourier transform infrared spectrometer (FT-IR, Brucker

Materials and method Tensor 27) was used to confirm the functionalization of

Materials OH-MWCNTs. Thermal stability of the nanocomposites

was measured by a Thermogravimetry Analyzer (TGA,

Proceedings of the 5th International Conference on Nanostructures (ICNS5)

6-9 March 2014, Kish Island, Iran

DuPont TGA951).The morphology of the samples, were

examined under a (S4160 Hitachi, Japan) Field Emission

Scanning Electron Microscope (FE-SEM). Tensile tests

were done using a Hegewald & Peschke measuring

instrument according to ASTM D412.

Results and Discussion

FT-IR Spectroscopy

The FT-IR spectra are shown in Fig. 1. In OH-MWCNT

spectrum, the bands at 3428, 1382 and 1056 cm-1, are

attributed to O-H stretching, bending in alcoholic groups Fig.2: SEM images of pure and Si-MWCNT-filled PUR foams:

(a) neat, (b) 1.5wt. % Si-MWCNTand (c) 3wt. % Si-MWCNT.

(C-OH) and C-O stretching, respectively. After the

silanization, the peak corresponding to C-OH bending

almost disappeared as well as was reduced the peak

intensity of O-H stretching, which are indications of

successful silanation. The peak at around 1052 - 1095

cm-1 related to Si-O stretching, but it is not clearly seen

due to overlap with other groups [2, 5, 6].

Fig. 3: SEM images of PURfoam nanocomposites: (a) 1.5 wt.%

Si-MWCNT, (b) is magnified image of (a), (c) 3 wt.% Si-

MWCNT And (d) is magnified image of (c).

TGA analysis

Figure 4 shows the TGA curves for OH-MWCNT and Si-

MWCNT. The thermogram of the OH-MWCNT Shows a

weight loss of about 3% (in agreement with company)

Fig.1: FT-IR spectra of OH-MWCNT and Si-MWCNT which is attributed to the amount of OH groups on the

surface of the MWCNTs. After silanization of OH-

Analysis of morphology MWCNTs using APTS, The thermal degradation occur

The cell density for both nanophased and neat PUR are between 40.9 and 383 ºC with a weight loss amount of

shown in Table 1. Cell density ( ) is calculated using about 5.06% which is proportional to the amount of

the following equation [7]: coupling agent what coated the MWCNTs.

105

Weight Loss(%)

where n is the number of cells, A the area of the

micrograph in cm2, and M is the magnification factor. 95

SEM images of the samples are shown in Fig. 2 with a

magnification factor of 60. With increasing of MWCNT

particles, the cell density increased, and as a result, the 85 OH-MWCNT

cell size decreased. This increase is due to nucleation and

Si-MWCNT

growth phenomena during the foaming process. It can be

observed from figures 3b and d that the PUR containing 3 75

wt. % Si-MWCNT was severely agglomerated. However, 25 225 425 625 825

high surface energy between nanoparticles leads to Temperature(ºC)

agglomerate.

Fig.4: TGA thermograms of OH-MWCNT and Si-MWCNT

Table 1. cell density of PUR foam nanocomposites.

The thermal degradation of neat PUR and Si-MWCNT

Wt. % of Si-MWCNTs

0 1.5 3 nanocomposites has taken place in two stages which are

corresponded to the soft and hard segments, respectively

cell density )×10-4 [4]. The T50 for neat PUR matrix is observed around 447

1.10 4.45 4.90

ºC that was improved to approximately 464 and 463 ºC,

Proceedings of the 5th International Conference on Nanostructures (ICNS5)

6-9 March 2014, Kish Island, Iran

at 1.5 and 2 wt. % Si–MWNT filled PUR increases with increase MWCNT content because

nanocomposites, respectively. This displays that the heterogeneous nucleation of MWCNT in PUR matrix. In

thermal stability of the PUR foam nanocomposites is addition, the Young’s modulus of the PUR foam

improved by the addition of the Si-MWCNT to the nanocompositests increased by about 20.2 and 41.5%

polymer matrix and interfacial interactions between with 1.5 and 2 wt. % silanized-MWCNT loading,

MWCNT and the PUR matrix [8]. respectively resulted from tensile tests. Finally, compared

to neat PUR foam, thermogravimetric analysis revealed

that the degradation temperature (at a 50% weight loss) of

Tensile characteristics

the PUR foam nanocomposites was increased by about

The typical stress–strain curves for the pure PUR and its 16.8 ºC and 15.5 ºC with the incorporation of 1.5 and 2

nanocomposites are shown in Fig.5. The modulus and wt.% silanized- MWCNT loading , respectively.

tensile strength of the 2 wt. % Si- MWNT

nanocomposites are enhanced by about 41.5% and 32.5%,

respectively as compared to the neat PUR. The Acknowledgments

mechanical properties of the nanocomposites are shown The authors thank Imam Khomeini International

in Table 2. Enhancement of the mechanical properties of University (IKIU) for the financial supporting of Dr.

the composites is attributed to the uniform distribution of Alavi Nikje.

MWCNTs in the polyurethane matrix, and the strong

interfacial interaction between the MWCNTs and the

References

polyurethane matrix [9].

[1] S. Iijima, “Carbon nanotubes: past, present, and

future”, Physica B: Condensed Matter, 323 (2002)1-5.

0.6 [2] C. Velasco-Santos, A. L. Martinez-Hernandez, M.

0.5 Lozada-Cassou, A. Alvarez-Castillo, V. M. Castano,

Stress(MPa)

“Chemical, functionalization of carbon nanotubes through

0.4 an organosilane”, nanotechnology, 13 (2002) 495-498.

0.3 [3] D. Klempner, K. C. Frisch, “Handbook of Polymeric

Neat PUR foam Foams and Foam Technology”, (1991), Hanser Gardner

0.2 1.5wt.% Si-MWCNT

2 wt.% Si-MWCNT Publications.

0.1 3 wt.% Si-MWCNT [4]. M. C. Saha, M. E. Kabir, S. Jeelani, “Enhancement in

0 thermal and mechanical properties of polyurethane foam

0 10 20 30 infused with nanoparticles”, Materials Science and

Engineering: A, 479(2008) 213-222.

Strain(%)

[5] C. Velasco-Santos, A. L. Martínez-Hernández, V. M.

Fig.5: Stress–strain curves of neat PUR and its nanocomposites. Castaño, “Silanization of carbon nanotubes: surface

modification and polymer nanocomposites Carbon

Table2: the mechanical properties of neat PUR and its nanotubes-polymer nanocomposites”, (2011), Intech,

nanocomposites. Rijeka, 251–280.

Wt. % of Si- Young’s Tensile Elongation at

[6] F. Avilés, C. A. Sierra-Chi, A. Nistal, A. May-Pat, F.

MWCNTs Modulus strength break (%) Rubio, J. Rubio, “Influence of silane concentration on the

(MPa) (MPa) silanization of multiwall carbon nanotubes”, Carbon, 57

0 3.71 0.40 17.25 (2013) 520-529.

1.5 4.46 0.43 15.93

2 5.25 0.53 15.20 [7] X. Han, C. Zeng, L. J. Lee, K. W. Koelling, D. L.

3 3.82 0.38 16.50 Tomasko, “Extrusion of polystyrene nanocomposite

foams with supercritical CO2”, Polymer Engineering &

Science, 43 (2003) 1261-1275.

Conclusions

The OH-MWCNTs were functionalized via silanization [8] H. Xia, M. Song , “Preparation and characterisation of

process using 3-aminopropyltriethoxysilane (APTS). polyurethane grafted single-walled carbon nanotubes and

Nanocomposites with different amounts of silanized- derived polyurethane nanocomposites” , Journal of

MWCNT (1.5, 2 and 3 wt. %) were prepared to Materials Chemistry, 16 (2006) 1843-1851.

investigate the effects of amine functioned MWCNT on [9] N. G. Sahoo, Y. C. Jung, H. J. Yoo, J. W. Cho,

the properties of PUR foam nanocomposites. The results “Influence of carbon nanotubes and polypyrrole on the

of FT-IR and TGA analysis confirmed the thermal, mechanical and electroactive shape-memory

functionalization of OH-MWCNTs with APTS. Obtained properties of polyurethane nanocomposites”, Composites

data from SEM analysis indicated that the cell density Science and Technology, 67(2007) 1920-1929.

View publication stats

Вам также может понравиться

- Publication 15Документ11 страницPublication 15Vishnu KalyanОценок пока нет

- Effect of Multi-Walled Carbon Nanotube Content On Dynamic Mechanical Properties and Crystallinity of Polypropilene CompositesДокумент0 страницEffect of Multi-Walled Carbon Nanotube Content On Dynamic Mechanical Properties and Crystallinity of Polypropilene CompositesMuhammad FarooqОценок пока нет

- Mechanical Properties and Morphological Characteristics ofДокумент9 страницMechanical Properties and Morphological Characteristics ofAlexander DeckerОценок пока нет

- Huan2020 Article AcrylicAcidGrafted Multi WalleДокумент15 страницHuan2020 Article AcrylicAcidGrafted Multi WalleDivya MahalsekarОценок пока нет

- Aguilar 2010Документ8 страницAguilar 2010Prashanth HadiОценок пока нет

- Concentration Effect of Multi-Walled Carbon Nanotube On Mechanical Properties of Epoxies CompositesДокумент7 страницConcentration Effect of Multi-Walled Carbon Nanotube On Mechanical Properties of Epoxies CompositesInternational Journal of Application or Innovation in Engineering & ManagementОценок пока нет

- MMT PB HTTP WWW - Sciencedirect.codarticleДокумент4 страницыMMT PB HTTP WWW - Sciencedirect.codarticleMarcos GentilОценок пока нет

- Electrical Conductivity and Thermal Properties of Functionalized Carbon Nanotubes Polyurethane CompositesДокумент8 страницElectrical Conductivity and Thermal Properties of Functionalized Carbon Nanotubes Polyurethane CompositesEduardo Alencar MaieronОценок пока нет

- Effect Different Multi-Walled Carbon Nanotubes Mwcnts Type On Mechanical Properties of Epoxy Resin NanocompositesДокумент6 страницEffect Different Multi-Walled Carbon Nanotubes Mwcnts Type On Mechanical Properties of Epoxy Resin NanocompositesInternational Journal of Application or Innovation in Engineering & ManagementОценок пока нет

- Preparation and Characterization of Polyaniline/multi-Walled Carbon Nanotube CompositesДокумент7 страницPreparation and Characterization of Polyaniline/multi-Walled Carbon Nanotube CompositesZeen MajidОценок пока нет

- Functionalized Carbon Nanotube Doping of P3HT:PCBM Photovoltaic Devices For Enhancing Short Circuit Current and e CiencyДокумент11 страницFunctionalized Carbon Nanotube Doping of P3HT:PCBM Photovoltaic Devices For Enhancing Short Circuit Current and e CiencyMartín FigueroaОценок пока нет

- Wang 2010Документ6 страницWang 2010mechatronics NITWОценок пока нет

- Chen 2007Документ7 страницChen 2007OsamaAlshamhaziОценок пока нет

- Polymer NanocompositeДокумент14 страницPolymer NanocompositeRajib BaruaОценок пока нет

- Single-Step in Situ Synthesis of Polymer-Grafted Single-Wall Nanotube CompositesДокумент2 страницыSingle-Step in Situ Synthesis of Polymer-Grafted Single-Wall Nanotube CompositesGaruda Sastha ArunОценок пока нет

- 2013 - J.Документ10 страниц2013 - J.Sara TeixeiraОценок пока нет

- Yao Et Al. - 2013 - Creep Behavior of Polyurethane Nanocomposites With Carbon Nanotubes-AnnotatedДокумент8 страницYao Et Al. - 2013 - Creep Behavior of Polyurethane Nanocomposites With Carbon Nanotubes-AnnotatedMinnu KothakotaОценок пока нет

- Preparation, Characterization and Comparative Temperature Dependent Electrical Properties of Polythiophene & Its Nanocomposites Using Carbon NanotubesДокумент5 страницPreparation, Characterization and Comparative Temperature Dependent Electrical Properties of Polythiophene & Its Nanocomposites Using Carbon NanotubesInternational Organization of Scientific Research (IOSR)Оценок пока нет

- 2013 - Properties Enhancement of TPNR-MWNTs-OMMT HybridДокумент5 страниц2013 - Properties Enhancement of TPNR-MWNTs-OMMT HybridMoayad FlaifelОценок пока нет

- Comptes Rendus Mecanique... MWCNT PCДокумент26 страницComptes Rendus Mecanique... MWCNT PCsumit_sharma17723055Оценок пока нет

- Download Structure Of The In Situ Produced Polyethylene Based Composites Modified With Multi Walled Carbon Nanotubes In Situ Synchrotron X Ray Diffraction And Differential Scanning Calorimetry Study Coll full chapter pdf scribdДокумент30 страницDownload Structure Of The In Situ Produced Polyethylene Based Composites Modified With Multi Walled Carbon Nanotubes In Situ Synchrotron X Ray Diffraction And Differential Scanning Calorimetry Study Coll full chapter pdf scribdwesley.ruehle633100% (4)

- Preparation of Resin/nano Fillers Mixture For Composites: A Case StudyДокумент11 страницPreparation of Resin/nano Fillers Mixture For Composites: A Case StudyNiranjan HugarОценок пока нет

- Fabrication, Morphology and Cure Behavior of Triethylenetetramine-Grafted Multiwalled Carbon Nanotube/Epoxy NanocompositesДокумент12 страницFabrication, Morphology and Cure Behavior of Triethylenetetramine-Grafted Multiwalled Carbon Nanotube/Epoxy NanocompositesVinod BalakrishnanОценок пока нет

- Pei 2018Документ9 страницPei 2018Sarah RizkiaОценок пока нет

- Mechanical Behavior and Surface Modification of CNTs That Are Functionalized With Polymer CompositesДокумент9 страницMechanical Behavior and Surface Modification of CNTs That Are Functionalized With Polymer CompositesIJRASETPublicationsОценок пока нет

- Kim 2007Документ5 страницKim 2007OsamaAlshamhaziОценок пока нет

- Using TEM and SEM To Unveil The Role of Nanoclays in Polymer BlendsДокумент6 страницUsing TEM and SEM To Unveil The Role of Nanoclays in Polymer BlendsMuhamad Fahri NurzamsiОценок пока нет

- 0021998316669578Документ14 страниц0021998316669578Riston SinagaОценок пока нет

- Chemical Physics LettersДокумент5 страницChemical Physics LettersVansala GanesanОценок пока нет

- Chao-Ching Chang 2010 - Preparation and Characterization of Polyurethane Gold Nanocomposites Prepared UsingДокумент7 страницChao-Ching Chang 2010 - Preparation and Characterization of Polyurethane Gold Nanocomposites Prepared UsingDeyvid PortoОценок пока нет

- Wang 2011Документ7 страницWang 2011JackОценок пока нет

- Tribological Performance of Carbon Nanotubes-Alumina Hybrid/epoxy CompositesДокумент6 страницTribological Performance of Carbon Nanotubes-Alumina Hybrid/epoxy Compositesabdullah 3mar abou reashaОценок пока нет

- Tribological Performance of Carbon Nanotubes-Alumina Hybrid/epoxy CompositesДокумент6 страницTribological Performance of Carbon Nanotubes-Alumina Hybrid/epoxy Compositesabdullah 3mar abou reashaОценок пока нет

- Nanofibrillated Cellulose As Nanoreinforcement in Portland Cement: Thermal, Mechanical and Microstructural PropertiesДокумент13 страницNanofibrillated Cellulose As Nanoreinforcement in Portland Cement: Thermal, Mechanical and Microstructural PropertiesMatheus LacerdaОценок пока нет

- Materials Science and Engineering AДокумент10 страницMaterials Science and Engineering ARushyanth KRОценок пока нет

- Study On Polycarbonate Multi Walled Carbon Nanotubes Composite Produced by Melt ProcessingДокумент5 страницStudy On Polycarbonate Multi Walled Carbon Nanotubes Composite Produced by Melt Processingahm2181984Оценок пока нет

- Guangrong Deng, Liang Liang, Zhao Jin, Chenyang LiДокумент39 страницGuangrong Deng, Liang Liang, Zhao Jin, Chenyang LichandrakiranОценок пока нет

- HR Asia, Oct 2011Документ3 страницыHR Asia, Oct 2011emediageОценок пока нет

- IMPORTANT Evaluating The Effects of Multi-Walled Carbon Nanotubes IMPORTANTДокумент7 страницIMPORTANT Evaluating The Effects of Multi-Walled Carbon Nanotubes IMPORTANTMahalingam SОценок пока нет

- Li 2015Документ4 страницыLi 2015jhonburbano5Оценок пока нет

- Yue, 2014Документ11 страницYue, 2014Amanda XavierОценок пока нет

- RSC Advances: PaperДокумент9 страницRSC Advances: PaperBhabani Sankar SwainОценок пока нет

- Montmorillonite Nano Composite 3908420734Документ6 страницMontmorillonite Nano Composite 3908420734nilayОценок пока нет

- Essay 01Документ10 страницEssay 01maedeh.216.froОценок пока нет

- Soumyadip Dutta 19RT60R11 M.Tech (1 Sem) Rubber Technology Centre, IIT KharagpurДокумент21 страницаSoumyadip Dutta 19RT60R11 M.Tech (1 Sem) Rubber Technology Centre, IIT Kharagpurসম্রাট সৌম্যদিপ দত্তОценок пока нет

- Poly (Vinyl Methyl Ether) Poly (Methyl Methacrylate) Blends Using Diblock CopolymerДокумент5 страницPoly (Vinyl Methyl Ether) Poly (Methyl Methacrylate) Blends Using Diblock Copolymerfadhillah ivanОценок пока нет

- Iron/multiwalled Carbon Nanotube (Fe/MWCNT) Hybrid Materials Characterization: Thermogravimetric Analysis As A Powerful Characterization TechniqueДокумент9 страницIron/multiwalled Carbon Nanotube (Fe/MWCNT) Hybrid Materials Characterization: Thermogravimetric Analysis As A Powerful Characterization TechniqueSajid HussainОценок пока нет

- Sonication - Fibre - Fibrilation - Tanpichai2014Документ6 страницSonication - Fibre - Fibrilation - Tanpichai2014suki chandranОценок пока нет

- Research PaperДокумент9 страницResearch PaperVENKANNA GUGULOTHОценок пока нет

- Polymer MaterialsДокумент27 страницPolymer MaterialsjawadullahОценок пока нет

- Journal of Thermoplastic Composite Materials 2013 Nurul 627 39Документ14 страницJournal of Thermoplastic Composite Materials 2013 Nurul 627 39Siti RohmahОценок пока нет

- Accepted Manuscript: Composites: Part AДокумент29 страницAccepted Manuscript: Composites: Part ANguyễn Bá LâmОценок пока нет

- Swath I 2010Документ11 страницSwath I 2010Estudiante2346Оценок пока нет

- Composite Structures: M.M. Rahman, S. Zainuddin, M.V. Hosur, J.E. Malone, M.B.A. Salam, Ashok Kumar, S. JeelaniДокумент10 страницComposite Structures: M.M. Rahman, S. Zainuddin, M.V. Hosur, J.E. Malone, M.B.A. Salam, Ashok Kumar, S. JeelaniDharmalingam RОценок пока нет

- Mechanical and Electrical Properties of A MWNT/epoxy CompositeДокумент7 страницMechanical and Electrical Properties of A MWNT/epoxy CompositeVansala GanesanОценок пока нет

- Compression and Hardness With Ftir Characterization of Uhmwpe Nanocomposites As Acetabular Cup in Hip Joint ReplacementДокумент10 страницCompression and Hardness With Ftir Characterization of Uhmwpe Nanocomposites As Acetabular Cup in Hip Joint ReplacementTJPRC PublicationsОценок пока нет

- Ramadhoni 2018 IOP Conf. Ser. Mater. Sci. Eng. 319 012041Документ9 страницRamadhoni 2018 IOP Conf. Ser. Mater. Sci. Eng. 319 012041Gemblung01Оценок пока нет

- Navidfar 2016Документ10 страницNavidfar 2016nafsiyah xyzОценок пока нет

- Characteristics of Friction Stir Processed UHMW PoДокумент6 страницCharacteristics of Friction Stir Processed UHMW Poimran rominОценок пока нет

- Types of Gear BoxДокумент5 страницTypes of Gear Boxankita awasthiОценок пока нет

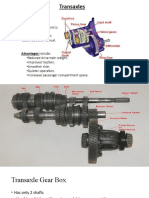

- Transaxle Part Unit-2Документ18 страницTransaxle Part Unit-2ankita awasthiОценок пока нет

- Ii Year Automobile Engineering at 6402 - Automotive Chassis - Question Bank Unit I - Layout, Frame, Front Axle and Steering System Part AДокумент6 страницIi Year Automobile Engineering at 6402 - Automotive Chassis - Question Bank Unit I - Layout, Frame, Front Axle and Steering System Part Aankita awasthiОценок пока нет

- Fixed Orifice Tube Cycling Clutch System Theory SupportДокумент15 страницFixed Orifice Tube Cycling Clutch System Theory Supportankita awasthiОценок пока нет

- Vehicle Body Testing: Application Note 1270-5Документ2 страницыVehicle Body Testing: Application Note 1270-5ankita awasthiОценок пока нет

- Biodiesel Production From Algal Blooms:: A Step Towards Renewable Energy Generation and MeasurementДокумент12 страницBiodiesel Production From Algal Blooms:: A Step Towards Renewable Energy Generation and Measurementankita awasthiОценок пока нет

- A Review of Thermoelectric Cooling: Materials, Modeling and ApplicationsДокумент11 страницA Review of Thermoelectric Cooling: Materials, Modeling and Applicationsankita awasthiОценок пока нет

- Electric Arc WeldingДокумент36 страницElectric Arc Weldingankita awasthiОценок пока нет

- Pelvic Floor DisordersДокумент1 164 страницыPelvic Floor Disordersankita awasthiОценок пока нет

- To Enhance The Heat Transfer Rate in Thermoelectric Cooler: A ReviewДокумент6 страницTo Enhance The Heat Transfer Rate in Thermoelectric Cooler: A Reviewankita awasthiОценок пока нет

- A Review On Modelling Techniques For Formability Prediction of Sheet Metal FormingДокумент11 страницA Review On Modelling Techniques For Formability Prediction of Sheet Metal Formingankita awasthiОценок пока нет

- Experimental Investigation of Thermoelectric Refrigeration System Running On Solar Energy and Development of Mathematical ModelДокумент7 страницExperimental Investigation of Thermoelectric Refrigeration System Running On Solar Energy and Development of Mathematical Modelankita awasthiОценок пока нет

- Thermoelectric Materials by Design, Computational Theory and StructureДокумент25 страницThermoelectric Materials by Design, Computational Theory and Structureankita awasthiОценок пока нет

- On-Chip Cooling by Superlattice-Based Thin-Film ThermoelectricsДокумент4 страницыOn-Chip Cooling by Superlattice-Based Thin-Film Thermoelectricsankita awasthiОценок пока нет

- Thermoelectric Devices: Cooling and Power GenerationДокумент5 страницThermoelectric Devices: Cooling and Power Generationankita awasthiОценок пока нет

- A Review On Flexible Forming of Sheet Metal Parts: December 2019Документ6 страницA Review On Flexible Forming of Sheet Metal Parts: December 2019ankita awasthiОценок пока нет

- Numerical Simulation of Sheet Metal Forming: A Review: Original ArticleДокумент16 страницNumerical Simulation of Sheet Metal Forming: A Review: Original Articleankita awasthiОценок пока нет

- Preview PDFДокумент91 страницаPreview PDFankita awasthiОценок пока нет

- 10.1007@978 3 030 35346 9 PDFДокумент405 страниц10.1007@978 3 030 35346 9 PDFankita awasthi100% (2)

- Design and Analysis of Wheel Rim With Spoke Patterns Using Different MaterialsДокумент4 страницыDesign and Analysis of Wheel Rim With Spoke Patterns Using Different Materialsankita awasthiОценок пока нет

- Ecde 09 00309Документ8 страницEcde 09 00309ankita awasthiОценок пока нет

- Materials Today: Proceedings: Prashant Saxena, Varun Jain, Sharad K. PradhanДокумент5 страницMaterials Today: Proceedings: Prashant Saxena, Varun Jain, Sharad K. Pradhanankita awasthiОценок пока нет

- VA RESUME HelloracheДокумент1 страницаVA RESUME HelloracheJessa AbadianoОценок пока нет

- TaxationДокумент26 страницTaxationReynamae Garcia AbalesОценок пока нет

- Cornering Fatigue Test and Radial Fatigue Test On A Rim With Steps For A Mono-Tyre E-Vehicle Using Finite Element AnalysisДокумент8 страницCornering Fatigue Test and Radial Fatigue Test On A Rim With Steps For A Mono-Tyre E-Vehicle Using Finite Element AnalysisGowtham KumarОценок пока нет

- Effectives of e Wallets NewДокумент15 страницEffectives of e Wallets NewRicardo SantosОценок пока нет

- 850 Elective English QPДокумент3 страницы850 Elective English QPRudra SahaОценок пока нет

- 2020 LBG q1 Ims Pillar 3 DisclosuresДокумент8 страниц2020 LBG q1 Ims Pillar 3 DisclosuressaxobobОценок пока нет

- Rawson Homes Duplex DesignsДокумент16 страницRawson Homes Duplex DesignsJhondy TibubosОценок пока нет

- The Biography of Hazrat Shah Qamaos Sahib in One PageДокумент3 страницыThe Biography of Hazrat Shah Qamaos Sahib in One PageMohammed Abdul Hafeez, B.Com., Hyderabad, IndiaОценок пока нет

- Police Forces and The Administration of Justice in Tanzania.Документ6 страницPolice Forces and The Administration of Justice in Tanzania.Praygod Manase100% (2)

- Division of Genetics ICAR-Indian Agricultural Research Institute, New Delhi - 110012Документ9 страницDivision of Genetics ICAR-Indian Agricultural Research Institute, New Delhi - 110012Shivam PateriyaОценок пока нет

- Exercise No. 2 (DCC First and Second Summary)Документ3 страницыExercise No. 2 (DCC First and Second Summary)Lalin-Mema LRОценок пока нет

- Es PS 0614Документ6 страницEs PS 0614陳相如Оценок пока нет

- Students List - All SectionsДокумент8 страницStudents List - All SectionsChristian RiveraОценок пока нет

- Report End of Chapter 1Документ4 страницыReport End of Chapter 1Amellia MaizanОценок пока нет

- Qualitative Research Chapter 1-5Документ16 страницQualitative Research Chapter 1-5Mikhaela Centeno100% (1)

- Architecture As Interface - Healing Architecture For Epatients. In: Healing Architecture. Hrsg. Nickl-Weller. 2013Документ6 страницArchitecture As Interface - Healing Architecture For Epatients. In: Healing Architecture. Hrsg. Nickl-Weller. 2013Asmaa AyadОценок пока нет

- Part D - Disclosure and TransparencyДокумент21 страницаPart D - Disclosure and TransparencyMuhammadYudithEddwinaОценок пока нет

- (EN) Google Developer Policy - September 1, 2021Документ56 страниц(EN) Google Developer Policy - September 1, 2021JimmyОценок пока нет

- Gurdan Saini: From Wikipedia, The Free EncyclopediaДокумент6 страницGurdan Saini: From Wikipedia, The Free EncyclopediaRanjeet SinghОценок пока нет

- Police OrgДокумент70 страницPolice OrgSeagal UmarОценок пока нет

- CodeДокумент47 страницCodeNadia KhurshidОценок пока нет

- Final Journal 2Документ60 страницFinal Journal 2Swetha NikaljeОценок пока нет

- My Favorite MovieДокумент2 страницыMy Favorite MovieAnabellyluОценок пока нет

- Digital Dash I/O Adapter Configuration: Connector Pin FunctionsДокумент8 страницDigital Dash I/O Adapter Configuration: Connector Pin FunctionsAfeef Ibn AlbraОценок пока нет

- Din en 10346Документ45 страницDin en 10346Lucero AlemanОценок пока нет

- Kids Cooking Teams: That's FreshДокумент74 страницыKids Cooking Teams: That's FreshNCB School of Herbalism & Holistic HealthОценок пока нет

- Pico Power: A Boon For Rural Electrification: Rajat KapoorДокумент8 страницPico Power: A Boon For Rural Electrification: Rajat KapoorBamОценок пока нет

- Kindergarten ArchitectureДокумент65 страницKindergarten ArchitectureAnushka Khatri83% (6)

- BoSY CRLA Grade 1 MT Administration GuideДокумент13 страницBoSY CRLA Grade 1 MT Administration GuideJOCELYN SANANO100% (1)

- Region XiДокумент2 страницыRegion XiGarcia, Rafael Rico O.Оценок пока нет