Академический Документы

Профессиональный Документы

Культура Документы

LTERRU - ANTENNASWAP of COL523 - 201007100817

Загружено:

dumindu1Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

LTERRU - ANTENNASWAP of COL523 - 201007100817

Загружено:

dumindu1Авторское право:

Доступные форматы

Our Ref :200914190240

Date :07-Oct-2020

PAT DETAILS

SiteID/Name COL523 / HydePark

Tower Type/Height RT_2_WM/6 m

PAT Category BTSPAT

Performed By Mobitel

Project Name LTERRU_ANTENNASWAP

General Info

No Task Status

1.1 BTS Type BTS3900

1.2 BTS Configuration 111

1.3 Frequency Band 1800

LTE

1.4 RFU/RRU Type RRU5904w x 3

1.5 Battery Capacity N/A

1.6 PAT Type Expansion

1.7 PAT Status Pass

Earthing

No Task Status

2.1 Feeder cable earth connected to ECB at 90 bend, within 1m N/A

(Vertical rise) - Major

2.2 Feeder cable earth within 1m from bottom feeder connector N/A

- Major

2.3 If vertical feeder length Greater than30m additional feeder N/A

cable earth connected to ECB at every 30m level - Major

2.4 Feeder cable earth within 1m from top feeder connector - N/A

Major

2.5 If horizontal feeder length Greater than20m additional N/A

feeder cable earth connected to ECB at every 20m distance

- Major

2.6 TMA Earthing through proper clamping on tower - Major N/A

Generated through InfraMS Page 1/18

2.7 Feeder earth kit sealing with self-bonding tape - Major N/A

2.8 All GI pipes are earthed from one side (With nut & bolt). N/A

Usually it should be from SPD end to the bus bar (35mm2

cable and lug for power cable GI pipe grounding, 25mm2

cable and lug for E1/FE cable GI pipe grounding) - Major

2.9 BTS cabinet is earthed using 35mm2 cable, lug and N/A

washers. It must be to the bus bar at the side of the cabinet

plinth - Major

2.10 AC power cable shield should be earthed using 35mm2 N/A

cable lug to ECB at the meter cubical - Major

2.11 Patch panel and power distribution box (ACPDB) at the BTS N/A

end are earthed to the main ECB using 35mm2 cable and

lug - Major

2.12 SPD should be installed at the meter cubical end wherever N/A

possible and earthing to the nearest bus bar using 35mm2

cable and lug - Major

2.13 SPD pole (If mounted to the plinth) should be earthed by N/A

35mm2 Cu cable - Major

2.14 SPD pole (If separate) should be earthed by Cu tape - Major N/A

2.15 Steel plinths are earthed by Cu tape with nut & bolt - Major N/A

2.16 Horizontal outdoor cable ladder should be earthed using N/A

35mm2 cable and lug - Major

2.17 Outdoor cable ladder support should be earthed using Cu N/A

tape. Support pole needs to be connected by nut & bolt -

Major

2.18 Tower ECBs are earthed using 35mm2 earth cable - Major N/A

2.19 RRU DC power cable shield should be earthed at the BTS OK

end - Major

2.20 RRU should be earthed using 16mm2 earth cable to ECB - OK

Major

Hardware Installation

No Task Status

3.1 Cabinet(s) bolted to plinth correctly with washers.Use 04 N/A

bolts & it must be GI - Major

3.2 No obstruction at BTS fan & door filters cleaning - Major N/A

3.3 Cabinet door can be opened and closed easily - Major N/A

3.4 Cabinet door can be locked and unlocked easily - Minor N/A

3.5 Power supply system is secured properly to the floor or N/A

plinth - Major

Generated through InfraMS Page 2/18

3.6 Battery terminal tightening is done during the PAT using a N/A

torque wrench (Shoto: 9~11Nm, Leoch: 3.9~5.4Nm) - Major

3.7 Battery breather lines are installed properly - Major N/A

3.8 Battery system is installed properly. 35mm2 DC cables from N/A

battery cabinet are secured with GI coated flexible PVC if

less than 5m and GI pipe if more than or equal 5m - Major

3.9 No. of batteries installed N/A

3.10 Battery type & capacity N/A

3.11 Battery parameter settings are done correctly - Major N/A

3.12 No external damages in cabinets - Major N/A

3.13 Proper fastening of units inside the cabinet (BBU,sensors OK

etc.) - Major

3.14 Cable inlets and outlets are sealed properly in order to be OK

protected from water, humidity, dust, rodents and insects -

Major

3.15 Cabinet keys are handed over to region - Major N/A

Cabling

No Task Status

4.1 Power and signalling cables are separated - Minor N/A

4.2 Connections of RF cable to RFU are secured properly - N/A

Major

4.3 DC power cable from the BTS cabinet to the rectifier (+) bus N/A

bar and (-) bus bar are installed correctly - Major

4.4 Feeder cable routing (Jumper cable is less than 3m with drip N/A

loop. In case of more than 3m prior approval shall be

obtained in TSSR/Readymade jumper cable must be used) -

Major

4.5 AC power cable from the meter cubical to the SPD and from N/A

the SPD to the ACPDB are installed properly. It should be

4x16mm2 armored cable secured with GI pipe and at the

SPD fixing end secured with GI coated flexible PVC - Major

4.6 AC power cable from rectifier to the ACPDB is installed N/A

properly. It should be 4x10mm2 non-armored secured with

GI coated flexible PVC - Major

4.7 Proper installation of fibre cable from BTS to RRU (Each OK

fibre cable is secured separately using PVC, fibre clamps

are fixed at 2m intervals, top & bottom of PVC ends are

sealed properly, bending and tower top fibre cables are

secured with GI coated flexible PVC) - Major

4.8 Suitable fibre length shall be selected and the extra length OK

shall be secured completely using a rubber harness or PVC

casing and shall be tightened to the cable ladder - Major

Generated through InfraMS Page 3/18

4.9 E1 cable is connected properly at the BBU to the TX N/A

devices (For NodeB, 8E1 cable must be laid and connected

to the BBU) - Major

4.10 Alarm cables for sensors and alarm panel are installed N/A

properly - Major

4.11 All cables are routed and labelled properly - Major N/A

4.12 Electrical wiring neatness (Proper securing with buried GI & N/A

GI coated flexible PVC) - Minor

4.13 Using proper colour code & approved cables for power N/A

connection (Including load cable, indoor & outdoor)

Ö Recommendation; L1,L2 & L3 colour - Brown, Black, Grey

N colour - Blue - Major

4.14 AC power cables laying over the plinth should be in 1.5 inch N/A

GI coated flexible PVC - Major

4.15 DC power cables laying over the plinth should be in 1 inch N/A

GI coated flexible PVC - Minor

4.16 Use two colour code for DC cable - Minor N/A

4.17 FE cable is connected from the BBU to the TX devices N/A

properly and secured with PVC or GI pipe (PVC is used

when outdoor cable length is less than 5m, GI pipe is used

when outdoor cable length is more than 5m) - Major

4.18 Fibre cable is connected from the BBU to the TX devices N/A

properly and secured with PVC or GI pipe (PVC is used

when outdoor cable length is less than 5m, GI pipe is used

when outdoor cable length is more than 5m) - Major

4.19 E1 cable is connected from the BBU to the TX devices N/A

properly and secured with PVC or GI pipe (PVC is used

when outdoor cable length is less than 5m, GI pipe is used

when outdoor cable length is more than 5m) - Major

4.20 All FE/E1 cables should be connected to relevant surge N/A

protecting boards in the BBU - Major

4.21 Physically check the E1 from TX devices to the BTS - Major N/A

4.22 Use proper DC cable for connecting RF cabinet to TP N/A

cabinet (35mm2 or 2x16mm2 Black & Blue) - Major

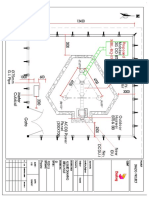

Antenna and Feeders

No Task Status

5.1 Feeder type - Minor N/A

5.2 Feeder length - Minor N/A

5.3 Fibre length - Minor N/A

Generated through InfraMS Page 4/18

5.4 Top jumper fixed - Minor Sector P

Sector Q

Sector R

Sector W

Sector X

Sector Y

5.5 Top jumper type - Minor DIN-4.3

5.6 Top Jumper Remarks - Minor N/A

5.7 Bottom jumper fixed - Minor N/A

5.8 Bottom jumper type - Minor N/A

5.9 Bottom Jumper Remarks - Minor N/A

5.10 Top jumper length - Minor 3

5.11 Bottom jumper length - Minor N/A

5.12 Feeder clamping - Major N/A

5.13 Fibre clamping - Major N/A

5.14 Feeder/Fibre labelling - Major N/A

5.15 Feeder/fibre inlet & other cable openings are sealed N/A

properly using durable UV-resistant products - Major

5.16 GPS antenna installation and cable routing are done N/A

properly (Using clamps when fixing to tower member and

cable ladder) - Major

5.17 Antenna type & model (Manufacture Code No.) - Major Huawei 8 port

5.18 Sector A Antenna down Electrical tilt (Measure through N/A

digital tilt meter) - Major

5.19 Sector B Antenna down Electrical tilt (Measure through N/A

digital tilt meter) - Major

5.20 Sector C Antenna down Electrical tilt (Measure through N/A

digital tilt meter) - Major

5.21 Sector D Antenna down Electrical tilt (Measure through N/A

digital tilt meter) - Major

5.22 Sector P Antenna down Electrical tilt (Measure through 6

digital tilt meter) - Major

5.23 Sector Q Antenna down Electrical tilt (Measure through 6

digital tilt meter) - Major

5.24 Sector R Antenna down Electrical tilt (Measure through 6

digital tilt meter) - Major

Generated through InfraMS Page 5/18

5.25 Sector S Antenna down Electrical tilt (Measure through N/A

digital tilt meter) - Major

5.26 Sector W Antenna down Electrical tilt (Measure through 6

digital tilt meter) - Major

5.27 Sector X Antenna down Electrical tilt (Measure through 6

digital tilt meter) - Major

5.28 Sector Y Antenna down Electrical tilt (Measure through 6

digital tilt meter) - Major

5.29 Sector Z Antenna down Electrical tilt (Measure through N/A

digital tilt meter) - Major

5.30 Sector A Antenna down Mechanical tilt (Measure through N/A

digital tilt meter) - Major

5.31 Sector B Antenna down Mechanical tilt (Measure through N/A

digital tilt meter) - Major

5.32 Sector C Antenna down Mechanical tilt (Measure through N/A

digital tilt meter) - Major

5.33 Sector D Antenna down Mechanical tilt (Measure through N/A

digital tilt meter) - Major

5.34 Sector P Antenna down Mechanical tilt (Measure through 0

digital tilt meter) - Major

5.35 Sector Q Antenna down Mechanical tilt (Measure through 0

digital tilt meter) - Major

5.36 Sector R Antenna down Mechanical tilt (Measure through 0

digital tilt meter) - Major

5.37 Sector S Antenna down Mechanical tilt (Measure through 0

digital tilt meter) - Major

5.38 Sector W Antenna down Mechanical tilt (Measure through 0

digital tilt meter) - Major

5.39 Sector X Antenna down Mechanical tilt (Measure through 0

digital tilt meter) - Major

5.40 Sector Y Antenna down Mechanical tilt (Measure through 0

digital tilt meter) - Major

5.41 Sector Z Antenna down Mechanical tilt (Measure through N/A

digital tilt meter) - Major

5.42 Sector A Antenna at correct tower leg - Major N/A

5.43 Sector B Antenna at correct tower leg - Major N/A

5.44 Sector C Antenna at correct tower leg - Major N/A

5.45 Sector D Antenna at correct tower leg - Major N/A

5.46 Sector P Antenna at correct tower leg - Major A

5.47 Sector Q Antenna at correct tower leg - Major B

Generated through InfraMS Page 6/18

5.48 Sector R Antenna at correct tower leg - Major C

5.49 Sector S Antenna at correct tower leg - Major N/A

5.50 Sector W Antenna at correct tower leg - Major A

5.51 Sector X Antenna at correct tower leg - Major B

5.52 Sector Y Antenna at correct tower leg - Major C

5.53 Sector Z Antenna at correct tower leg - Major N/A

5.54 Sector A Antenna at correct tower height - Major N/A

5.55 Sector B Antenna at correct tower height - Major N/A

5.56 Sector C Antenna at correct tower height - Major N/A

5.57 Sector D Antenna at correct tower height - Major N/A

5.58 Sector P Antenna at correct tower height - Major N/A

5.59 Sector Q Antenna at correct tower height - Major N/A

5.60 Sector R Antenna at correct tower height - Major N/A

5.61 Sector S Antenna at correct tower height - Major N/A

5.62 Sector W Antenna at correct tower height - Major N/A

5.63 Sector X Antenna at correct tower height - Major N/A

5.64 Sector Y Antenna at correct tower height - Major N/A

5.65 Sector Z Antenna at correct tower height - Major N/A

5.66 Sector A Antenna directions (According to Mobitel N/A

information, measure through cell alignment tool) - Major

5.67 Sector B Antenna directions (According to Mobitel N/A

information, measure through cell alignment tool) - Major

5.68 Sector C Antenna directions (According to Mobitel N/A

information, measure through cell alignment tool) - Major

5.69 Sector D Antenna directions (According to Mobitel N/A

information, measure through cell alignment tool) - Major

5.70 Sector P Antenna directions (According to Mobitel 50

information, measure through cell alignment tool) - Major

5.71 Sector Q Antenna directions (According to Mobitel 70

information, measure through cell alignment tool) - Major

5.72 Sector R Antenna directions (According to Mobitel 260

information, measure through cell alignment tool) - Major

5.73 Sector S Antenna directions (According to Mobitel N/A

information, measure through cell alignment tool) - Major

Generated through InfraMS Page 7/18

5.74 Sector W Antenna directions (According to Mobitel 50

information, measure through cell alignment tool) - Major

5.75 Sector X Antenna directions (According to Mobitel 70

information, measure through cell alignment tool) - Major

5.76 Sector Y Antenna directions (According to Mobitel 260

information, measure through cell alignment tool) - Major

5.77 Sector Z Antenna directions (According to Mobitel N/A

information, measure through cell alignment tool) - Major

5.78 Feeder/fibre & jumper connectors are sealed properly using OK

durable UV-resistant products - Major

5.79 TX VSWR Test (Less than or equal 1.4) - Major Sector P

Sector Q

Sector R

Sector W

Sector X

Sector Y

5.80 RX VSWR Test (Less than or equal 1.4) - Major Sector P

Sector Q

Sector R

Sector W

Sector X

Sector Y

5.81 TX VSWR Test (Greater than 1.4) - Major N/A

5.82 RX VSWR Test (Greater than 1.4) - Major N/A

5.83 TX DTF Test (Less than or equal 1.05) - Major N/A

5.84 RX DTF Test (Less than or equal 1.05) - Major N/A

5.85 TX DTF Test (Greater than 1.05) - Major N/A

5.86 RX DTF Test (Greater than 1.05) - Major N/A

5.87 Antenna pole is vertical - Major N/A

5.88 Antenna pole is not vertical - Major N/A

5.89 Ability to reach the antennas for O&M works - Major OK

5.90 GPS verification Latitude (Check by LMT) - Major N/A

5.91 GPS verification Longitude (Check by LMT) - Major N/A

Generated through InfraMS Page 8/18

External Alarm Test

No Task Status

6.1 Intruder Alarm (Including battery cabinets) - Major N/A

6.2 Smoke Detector Alarm - Major N/A

6.3 Temperature Alarm (Including battery cabinets) - Major N/A

6.4 Water Leakage Alarm - Major N/A

6.5 Main AC Fault Alarm - Major N/A

6.6 DC Under/Over Voltage Alarm - Major N/A

6.7 Battery Low Voltage Alarm - Major N/A

6.8 Fan Fault Alarm (Including battery cabinets) - Major N/A

6.9 Surge Arrester Alarm - Major N/A

6.10 DC Under Voltage Threshold (Value) - Minor N/A

6.11 AC Under Voltage Threshold (Value) - Minor N/A

6.12 Battery Circuit/Loop Broken Alarm - Major N/A

Call Test

No Task Status

7.1 Mobile to Mobile - Major OK

7.2 Mobile to Other - Major OK

7.3 GPRS Testing - Major OK

RF Cable Diagram for RFU

No Task Status

Miscellaneous

No Task Status

9.1 Black UV-resistant ties are used for outdoor cable fastening OK

- Minor

9.2 Site is clean - Minor OK

9.3 Retain the additional engineering materials for future use N/A

(Bonding tapes, insulation tapes etc.) - Minor

Generated through InfraMS Page 9/18

Site BOQ

No Task Status

Integration Test

No Task Status

11.1 AC power test - Phase to Neutral (V)

11.2 AC power test - Neutral to Earth (V)

11.3 DC power test - BBU (V)

11.4 DC power test - RRU1 (V)

11.5 DC power test - RRU2 (V)

11.6 DC power test - RRU3 (V)

11.7 VSWR test by LMT (If using fibre optical, VSWR is less than

or equal 1.3) S0

11.8 VSWR test by LMT (If using fibre optical, VSWR is less than

or equal 1.3) S1

11.9 VSWR test by LMT (If using fibre optical, VSWR is less than

or equal 1.3) S2

11.10 Transmit output power test by LMT (dBm) S0

11.11 Transmit output power test by LMT (dBm) S1

11.12 Transmit output power test by LMT (dBm) S2

11.13 Remote parameter: At UE connection mode and near the

site (NodeB): CPICH_RSCP is greater than -85 dBm

11.14 Remote parameter: At UE connection mode and near the

site (NodeB): CPICH_Ec/Io is greater than -8 dB

11.15 Remote parameter: At UE connection mode and near the

site (eNodeB): RSRP is greater than -90 dBm

11.16 Remote parameter: At UE connection mode and near the

site (eNodeB): SINR is greater than 19 dB

11.17 UE location update is successful

11.18 Video call is successful

11.19 Data download test result (Mbps)

11.20 Data upload test result (Mbps)

11.21 Primary scrambling code - S0

11.22 Primary scrambling code - S1

Generated through InfraMS Page 10/18

11.23 Primary scrambling code - S2

Inventory S/N

No Task Status

12.1 BTS Cabinet Serial number

12.2 TX Cabinet Serial number

12.3 Battery Cabinet Serial number

12.4 RFU Serial number 1

12.5 RFU Serial number 2

12.6 RFU Serial number 3

12.7 RFU Serial number 4

12.8 RFU Serial number 5

12.9 RFU Serial number 6

12.10 BBU Serial number

12.11 UPEU Serial number 1

12.12 UPEU Serial number 2

12.13 UPEU Serial number 3

12.14 FAN Serial number 1

12.15 FAN Serial number 2

12.16 GTMU Serial number

12.17 WMPT Serial number

12.18 LMPT Serial number

12.19 UMPT Serial number

12.20 WBBP Serial number 1

12.21 WBBP Serial number 2

12.22 WBBP Serial number 3

12.23 UBBP Serial number 1

12.24 UBBP Serial number 2

12.25 UBBP Serial number 3

12.26 LBBP Serial number

Generated through InfraMS Page 11/18

12.27 UTRP Serial number

12.28 UEIU Serial number

12.29 UELP Serial number

12.30 UFLP Serial number

12.31 ULIG Serial number

12.32 SLPU Serial number

12.33 DCPDU Serial number 1

12.34 DCPDU Serial number 2

12.35 RRU Serial number 1 2012312EEM10J9000073

12.36 RRU Serial number 2 2012312EEM10J9000146

12.37 RRU Serial number 3 2012312EEM10J9000062

12.38 RRU Serial number 4

12.39 RRU Serial number 5

12.40 RRU Serial number 6

12.41 RRU Serial number 7

12.42 RRU Serial number 8

12.43 RRU Serial number 9

12.44 RRU Serial number 10

12.45 RRU Serial number 11

12.46 RRU Serial number 12

12.47 PSU Serial number 1

12.48 PSU Serial number 2

12.49 PSU Serial number 3

12.50 PSU Serial number 4

12.51 Monitoring Module (SMU) Serial number

12.52 User Interface Module (UIM) Serial number

12.53 GPS Serial number

12.54 Combiner Serial number 1

12.55 Combiner Serial number 2

12.56 Combiner Serial number 3

Generated through InfraMS Page 12/18

12.57 Combiner Serial number 4

12.58 Band pass filter Serial number 1

12.59 Band pass filter Serial number 2

12.60 Band pass filter Serial number 3

12.61 Antenna Serial number 1 NO1810002899

12.62 Antenna Serial number 2 N01780011571

12.63 Antenna Serial number 3 N017C0010763

12.64 Antenna Serial number 4

12.65 Antenna Serial number 5

12.66 Antenna Serial number 6

12.67 Antenna Serial number 7

12.68 Antenna Serial number 8

12.69 Antenna Serial number 9

12.70 Battery Serial number 1

12.71 Battery Serial number 2

12.72 Battery Serial number 3

12.73 Battery Serial number 4

12.74 Battery Serial number 5

12.75 Battery Serial number 6

12.76 Battery Serial number 7

12.77 Battery Serial number 8

12.78 Battery Serial number 9

12.79 Battery Serial number 10

12.80 Battery Serial number 11

12.81 Battery Serial number 12

12.82 Battery Serial number 13

12.83 Battery Serial number 14

12.84 Battery Serial number 15

12.85 Battery Serial number 16

Inventory Qty

Generated through InfraMS Page 13/18

No Task Status

13.1 SPD Qty 0

13.2 ACPDB Qty 0

13.3 Meter cubical Qty 0

13.4 32A 4P breaker Qty 0

13.5 40A 4P breaker Qty 0

13.6 DC breaker Qty 0

13.7 4x16mm2 AC cable Qty (m) 0

13.8 4x10mm2 AC cable Qty (m) 0

13.9 GI pipe length Qty (m) 0

13.10 Additional cabinet Qty 0

13.11 SPD pole Qty (for rooftop site) 0

13.12 SPD pole Qty (for greenfield site) 0

13.13 Feeder earth kit Qty 0

13.14 Feeder length Qty (m) 0

13.15 Feeder connector Qty 0

13.16 Fibre length - per fibre (m) 0

13.17 Feeder clamp Qty 0

13.18 Fibre clamp Qty 0

13.19 No. of RRU DC power cable Qty 0

13.20 RRU DC power cable length (m) 0

13.21 TMA Qty 0

13.22 GSM antenna bracket Qty 0

13.23 GI plinth Qty 0

13.24 Conversion plate Qty 0

13.25 Rooftop concrete plinth Qty 0

13.26 Cable ladder Qty (m) 0

13.27 Cable extension bar Qty 0

13.28 35mm2 earth cable Qty (m) 0

13.29 25mm2 earth cable Qty (m) 0

Generated through InfraMS Page 14/18

13.30 16mm2 earth cable Qty (m) 0

13.31 35mm2 DC cable Qty (m) 0

13.32 25mm2 DC cable Qty (m) 0

13.33 16mm2 DC cable Qty (m) 0

13.34 Bus bar (Inside cabinet) Qty 0

13.35 Cu tape Qty (m) 0

13.36 ECB Qty 0

13.37 GI coated flexible PVC Qty (m) 0

13.38 PVC pipe length Qty (m) 0

13.39 IF cable Qty (m) 0

13.40 Jumper cable (3m) Qty 18

13.41 Jumper cable (5m) Qty 0

13.42 Ethernet cable Qty (m) 0

13.43 Cad weld Qty 0

13.44 Optical fibre cable (Multi-mode) Qty 0

13.45 SFP module (Multi-mode) Qty 0

13.46 Optical fibre cable (Single-mode) Qty 0

13.47 SFP module (Single-mode) Qty 0

13.48 RRU power earth kit Qty 0

13.49 For TX: Ethernet cable Qty (m) 0

13.50 For TX: No. of fibre cable Qty 0

13.51 For TX: Fibre cable length (m) 0

13.52 For TX: Single-mode SFP Qty 0

13.53 For TX: GI pipe Qty (m) 0

13.54 For TX: GI flexible Qty (m) 0

13.55 Ladder support pole 1m Qty 0

13.56 Ladder support pole 2m Qty 0

13.57 Ladder support pole 3m Qty 0

13.58 GPS arrester Qty 0

13.59 GPS cable (m) 0

Generated through InfraMS Page 15/18

13.60 4X4 PVC casing Qty (m) 0

13.61 Combiner bracket Qty 0

13.62 Extended RRU bracket Qty 0

13.63 (Combiner + RRU) bracket Qty (with steel tie) 0

13.64 Installation materials package Qty (including bonding tape, 0

insulation tape, cable tie etc.)

13.65 Battery installation materials package Qty (including lug, 0

terminal, breather line and loop-broken alarm cable for 4-8

batteries)

13.66 Battery installation materials package Qty (including lug, 0

terminal, breather line and loop-broken alarm cable for

12-16 batteries)

PAC Eligibility

No Task Status

14.1 PAC Eligibility - Earthing N/A

14.2 PAC Eligibility - Hardware Installation OK

14.3 PAC Eligibility - Cabling OK

14.4 PAC Eligibility - Antenna and Feeders OK

14.5 PAC Eligibility - Alarm N/A

Punch List

No Task Status

15.1 Punch List item1

15.2 Punch List item2

15.3 Punch List item3

15.4 Punch List item4

15.5 Punch List item5

15.6 Punch List item6

15.7 Punch List item7

15.8 Punch List item8

15.9 Punch List item9

15.10 Punch List item10

Generated through InfraMS Page 16/18

General Remarks

No Task Status

16.1 PAT Remarks

Team Info

No Task Status

17.1 PAT performed Huawei site engineer

17.2 PAT performed sub contract company

17.3 PAT performed sub contract officer

Site Images

No Task Status

Image Proof

RFU cable diagram BOQ Plinth Image

Meter Cubical Image ACDB Images SPD Images

Special Notes

Huawei shall inform any inventory mismatches within 2 weeks from the PAT approved date in the system.

If there are no changes within this period, approved inventory will be considered for issuing PAC.

Approver's Remarks

Name Comments Date Org

Rakitha Thalawatta pass 2020-10-07 10:08:08 Mobitel

Process Infomation

PAT Performed By PAT Pass By

Chathuranga Ukwatta Rakitha Thalawatta

Generated through InfraMS Page 17/18

Mobitel Mobitel

2020-10-07 10:08:08

Generated through InfraMS Page 18/18

Powered by TCPDF (www.tcpdf.org)

Вам также может понравиться

- BTSPAT of ZHOM53Документ18 страницBTSPAT of ZHOM53dumindu1Оценок пока нет

- UMTS RNS I 08 20090530-Antenna Feeder Grounding Antilightning Principle 31Документ31 страницаUMTS RNS I 08 20090530-Antenna Feeder Grounding Antilightning Principle 31oucht79Оценок пока нет

- VRF Electrical DiagramsДокумент3 страницыVRF Electrical Diagramscalvin.bloodaxe447867% (3)

- MW Installation ChecklistДокумент26 страницMW Installation Checklistjoey wheelerОценок пока нет

- Zain E-Band Project Quality of Implementation V1.0Документ20 страницZain E-Band Project Quality of Implementation V1.0Saeed Ashraf KhanОценок пока нет

- Antenna Line Installation Quide - v02Документ22 страницыAntenna Line Installation Quide - v02belzebootОценок пока нет

- BQ - Elec - JinjangДокумент27 страницBQ - Elec - JinjangAdzwan AhmadiОценок пока нет

- Checklist & Functional Test - JAW-JT-KBM-0704Документ22 страницыChecklist & Functional Test - JAW-JT-KBM-0704Yudha BloomsОценок пока нет

- Standard Operation Procedure For IAM Swap Project BTS3900AL (DC) +TP48200A Swap Outdoor Macro Site (V3 11-4-2013)Документ18 страницStandard Operation Procedure For IAM Swap Project BTS3900AL (DC) +TP48200A Swap Outdoor Macro Site (V3 11-4-2013)Soufiane LamsaouebОценок пока нет

- Raha Toll Plaza Estimate (Electrical)Документ2 страницыRaha Toll Plaza Estimate (Electrical)Bilal A BarbhuiyaОценок пока нет

- Estimate for Electrical ItemsДокумент4 страницыEstimate for Electrical ItemsBilal A Barbhuiya100% (1)

- 40 M Compact 4 SQuare Antenna - EA5AVL 1Документ8 страниц40 M Compact 4 SQuare Antenna - EA5AVL 1Max SantosОценок пока нет

- Acoplador MotorolaДокумент22 страницыAcoplador Motorolaqwerd134Оценок пока нет

- WCDMA Flexi BTS Site Installation and Configuration ReportДокумент63 страницыWCDMA Flexi BTS Site Installation and Configuration ReportpredragnikОценок пока нет

- Cable List for Gibson Island Fertilizer Plant MachineryДокумент6 страницCable List for Gibson Island Fertilizer Plant MachineryClémentОценок пока нет

- dbs3900 Bts3900a 48v Emua Cable Connection Guide 2009 5 27 PDFДокумент12 страницdbs3900 Bts3900a 48v Emua Cable Connection Guide 2009 5 27 PDFEdwin PortuguezОценок пока нет

- WiMAX InstallationДокумент105 страницWiMAX Installationrebin1988Оценок пока нет

- Matching Chip Antennas for 2.4GHz WirelessДокумент17 страницMatching Chip Antennas for 2.4GHz WirelesstzofОценок пока нет

- Installation of Low Voltage Service Using 3 Core Bunched Wavecon CablesДокумент15 страницInstallation of Low Voltage Service Using 3 Core Bunched Wavecon CablesphilipnartОценок пока нет

- Antenna & Antenna LineДокумент36 страницAntenna & Antenna Linepradeeptanwar11Оценок пока нет

- Active Antenna 1-30 MHZДокумент4 страницыActive Antenna 1-30 MHZrik206Оценок пока нет

- Huawei Site Design GuidelineДокумент7 страницHuawei Site Design GuidelineHeru BudiantoОценок пока нет

- Two Pico Pole Site SOP For MPT1229 (AC Sharing)Документ16 страницTwo Pico Pole Site SOP For MPT1229 (AC Sharing)TheinHtayAungAungОценок пока нет

- SD8B 3 Part5Документ162 страницыSD8B 3 Part5Daniel PrataОценок пока нет

- Roll Up J PoleДокумент3 страницыRoll Up J PolemojoehandОценок пока нет

- FM TheoryДокумент8 страницFM TheoryMainak BandyopadhyayОценок пока нет

- 137MHz LNA Build GuideДокумент3 страницы137MHz LNA Build GuidealimahhassanОценок пока нет

- ECGTДокумент4 страницыECGTExplore the world TodayОценок пока нет

- ZF AuskopplungДокумент31 страницаZF AuskopplungAchmad Zaenal ArifinОценок пока нет

- Antenna Parts Installation Pass: Site Handover DocumentДокумент31 страницаAntenna Parts Installation Pass: Site Handover DocumentChris KitwangeОценок пока нет

- KORRM - Survey - New Site - TSSR - Supermoon New Site Rev DДокумент36 страницKORRM - Survey - New Site - TSSR - Supermoon New Site Rev DZul QaddimОценок пока нет

- Baofeng VarioДокумент6 страницBaofeng VarioDiego García MedinaОценок пока нет

- Installation Considerations for Wireless Receiver SystemsДокумент18 страницInstallation Considerations for Wireless Receiver SystemspahiescorpОценок пока нет

- Short Instruction of Tigron Modbus ConnectionДокумент10 страницShort Instruction of Tigron Modbus ConnectionrannuОценок пока нет

- TW325VSMДокумент88 страницTW325VSMPepe Garcia100% (1)

- Erection Procedures of Earthing Arrangements TNC TNS TNCS and TTДокумент7 страницErection Procedures of Earthing Arrangements TNC TNS TNCS and TTPierre Enrique Carrasco Fuentes0% (1)

- Parabolic Antenna for 10-11 GHz Microwave LinksДокумент5 страницParabolic Antenna for 10-11 GHz Microwave LinksfmorocotoОценок пока нет

- TSM-4485 r05Документ2 страницыTSM-4485 r05Aldo Germán Pavez MoraОценок пока нет

- Site Cabling & Antenna InstallationДокумент49 страницSite Cabling & Antenna Installation0555668118Оценок пока нет

- Site Installation Standard Album (Upgrade Site) V2.1Документ25 страницSite Installation Standard Album (Upgrade Site) V2.1soefmuangmaungchitОценок пока нет

- Papnm-survey-#000435-Reeng Layer l9 2 s111 TSSR Venus Rev A1Документ52 страницыPapnm-survey-#000435-Reeng Layer l9 2 s111 TSSR Venus Rev A1Zul QaddimОценок пока нет

- 20W HF PA Construction V2-1Документ9 страниц20W HF PA Construction V2-1diligore2399Оценок пока нет

- MFJ 989D PDFДокумент20 страницMFJ 989D PDFLucian FaraonОценок пока нет

- Evaluating JFET Transistors for Linear Performance in Active Antenna DesignsДокумент9 страницEvaluating JFET Transistors for Linear Performance in Active Antenna DesignsAlex SanОценок пока нет

- MIC 750-3300TL-X Quick Guide EN202201Документ2 страницыMIC 750-3300TL-X Quick Guide EN202201zatkbgfebnjolcvruvОценок пока нет

- Bts 3900 DetailsДокумент12 страницBts 3900 DetailsEkta Vivek JhinjhaОценок пока нет

- Radio Access Network and Operations 2 Passive PDFДокумент104 страницыRadio Access Network and Operations 2 Passive PDFHoneyPhooОценок пока нет

- Antenna Add On 2 12 18 Pdfmate MergeДокумент946 страницAntenna Add On 2 12 18 Pdfmate MergepowerinfiniteОценок пока нет

- 2008 Bluetooth Antenna DesignДокумент32 страницы2008 Bluetooth Antenna DesignRamОценок пока нет

- Company Directive: Standard Technique: Sd8B/3 (Part 6) Relating To 275kV Underground Cable RatingsДокумент33 страницыCompany Directive: Standard Technique: Sd8B/3 (Part 6) Relating To 275kV Underground Cable RatingsDaniel PrataОценок пока нет

- Connection Guide: of The MOTOTRBO Radio To The Radioserver As A Control StationДокумент6 страницConnection Guide: of The MOTOTRBO Radio To The Radioserver As A Control StationSmartPTTОценок пока нет

- Aviat Quick Start Guide For Indoor Equipment GroundingДокумент20 страницAviat Quick Start Guide For Indoor Equipment GroundingKevin_IОценок пока нет

- Site Survey Report SummaryДокумент62 страницыSite Survey Report SummaryAnildip SinghОценок пока нет

- SSDAC Cable TestingДокумент21 страницаSSDAC Cable Testingecarvind100% (1)

- NDRF-Patna - QuotationДокумент23 страницыNDRF-Patna - QuotationPowersolution KolkataОценок пока нет

- Cable Engineering in Substation and Power PlantДокумент7 страницCable Engineering in Substation and Power PlantVasudev AgrawalОценок пока нет

- The FARA 2 Meter Amplifier ProjectДокумент9 страницThe FARA 2 Meter Amplifier ProjectDhemitz AjaОценок пока нет

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsОт EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsРейтинг: 3 из 5 звезд3/5 (2)

- The Link-Prediction Problem For Social Networks: David Liben-NowellДокумент13 страницThe Link-Prediction Problem For Social Networks: David Liben-Nowelldumindu1Оценок пока нет

- Netsure Control Unit (Ncu) : User Manual, Umm830B Document Code: 11 Ko 7503 JL (Revision B, October 24, 2014)Документ172 страницыNetsure Control Unit (Ncu) : User Manual, Umm830B Document Code: 11 Ko 7503 JL (Revision B, October 24, 2014)Sahand ArasОценок пока нет

- Training: Session ExtractsДокумент11 страницTraining: Session Extractsdumindu1Оценок пока нет

- Mba508 HRM - S1 - SHRM - HoДокумент11 страницMba508 HRM - S1 - SHRM - Hodumindu1Оценок пока нет

- Teece Et Al-1997-Strategic Management JournalДокумент25 страницTeece Et Al-1997-Strategic Management JournalAsna UswatunОценок пока нет

- MBL-RQ-050998 - Pinpara Site Layout - DWG PDFДокумент1 страницаMBL-RQ-050998 - Pinpara Site Layout - DWG PDFdumindu1Оценок пока нет

- NetSure 701 A50 - User ManualДокумент96 страницNetSure 701 A50 - User ManualJune JangОценок пока нет

- Cognition and Hierarchy Rethinking The Microfoundations of Capabilities' DevelopmentДокумент20 страницCognition and Hierarchy Rethinking The Microfoundations of Capabilities' Developmentdumindu1Оценок пока нет

- Business Intelligence and Analytics - Research DirectionsДокумент12 страницBusiness Intelligence and Analytics - Research Directionsdumindu1Оценок пока нет

- NetSure 701 A30 - User ManualДокумент58 страницNetSure 701 A30 - User ManualJames Erwin GupongОценок пока нет

- MBA508 HRM - S2 - Rec and Sel - HOДокумент13 страницMBA508 HRM - S2 - Rec and Sel - HOdumindu1Оценок пока нет

- MBA508 HRM - S3 - Employee Discipline - HO PDFДокумент25 страницMBA508 HRM - S3 - Employee Discipline - HO PDFdumindu1Оценок пока нет

- MBL-RQ-050998 - Pinpara Tower Layout - DWGДокумент1 страницаMBL-RQ-050998 - Pinpara Tower Layout - DWGdumindu1Оценок пока нет

- Pinpara Dialog AP MBL-RQ-050998Документ1 страницаPinpara Dialog AP MBL-RQ-050998dumindu1Оценок пока нет

- Preliminary Acceptance Test (Mobitel) - TXДокумент9 страницPreliminary Acceptance Test (Mobitel) - TXdumindu1Оценок пока нет

- BTSPAT of GMUDA2Документ17 страницBTSPAT of GMUDA2dumindu1Оценок пока нет

- Kaudulla ModelДокумент1 страницаKaudulla Modeldumindu1Оценок пока нет

- PAT Status:: - Pass - Pass With Minor El - Reject ElДокумент16 страницPAT Status:: - Pass - Pass With Minor El - Reject Eldumindu1Оценок пока нет

- PAT Status:: MobitelДокумент20 страницPAT Status:: Mobiteldumindu1Оценок пока нет

- TBC Battery Cabinet AlarmДокумент16 страницTBC Battery Cabinet Alarmdumindu1Оценок пока нет

- Rcl6Nka. Mobitel: Pat StatusДокумент20 страницRcl6Nka. Mobitel: Pat Statusdumindu1Оценок пока нет

- Moratuwa UniversityДокумент23 страницыMoratuwa Universitydumindu1Оценок пока нет

- 611 Eirc1: - Pass - Reject - Pass With MinorДокумент23 страницы611 Eirc1: - Pass - Reject - Pass With Minordumindu1Оценок пока нет

- Moratuwa UniversityДокумент23 страницыMoratuwa Universitydumindu1Оценок пока нет

- Galle SLT PDFДокумент23 страницыGalle SLT PDFdumindu1Оценок пока нет

- GMALU1Документ21 страницаGMALU1dumindu1Оценок пока нет

- Muddaragama-Existing Site Layout-Model PDFДокумент1 страницаMuddaragama-Existing Site Layout-Model PDFdumindu1Оценок пока нет

- Hapugasthalawa TSSRДокумент19 страницHapugasthalawa TSSRdumindu1Оценок пока нет

- Flowmon Ads Enterprise Userguide enДокумент82 страницыFlowmon Ads Enterprise Userguide ennagasatoОценок пока нет

- Inventory ControlДокумент26 страницInventory ControlhajarawОценок пока нет

- Technical specifications for JR3 multi-axis force-torque sensor modelsДокумент1 страницаTechnical specifications for JR3 multi-axis force-torque sensor modelsSAN JUAN BAUTISTAОценок пока нет

- Paper 4 (A) (I) IGCSE Biology (Time - 30 Mins)Документ12 страницPaper 4 (A) (I) IGCSE Biology (Time - 30 Mins)Hisham AlEnaiziОценок пока нет

- Physics Derived Units and Unit Prefixes Derived UnitДокумент15 страницPhysics Derived Units and Unit Prefixes Derived UnitJohnRenzoMolinarОценок пока нет

- Computer Networks Transmission Media: Dr. Mohammad AdlyДокумент14 страницComputer Networks Transmission Media: Dr. Mohammad AdlyRichthofen Flies Bf109Оценок пока нет

- Staffing Process and Job AnalysisДокумент8 страницStaffing Process and Job AnalysisRuben Rosendal De Asis100% (1)

- Template WFP-Expenditure Form 2024Документ22 страницыTemplate WFP-Expenditure Form 2024Joey Simba Jr.Оценок пока нет

- Real Estate Broker ReviewerREBLEXДокумент124 страницыReal Estate Broker ReviewerREBLEXMar100% (4)

- Technical Manual - C&C08 Digital Switching System Chapter 2 OverviewДокумент19 страницTechnical Manual - C&C08 Digital Switching System Chapter 2 OverviewSamuel100% (2)

- Stroboscopy For Benign Laryngeal Pathology in Evidence Based Health CareДокумент5 страницStroboscopy For Benign Laryngeal Pathology in Evidence Based Health CareDoina RusuОценок пока нет

- Nokia CaseДокумент28 страницNokia CaseErykah Faith PerezОценок пока нет

- Simba s7d Long Hole Drill RigДокумент2 страницыSimba s7d Long Hole Drill RigJaime Asis LopezОценок пока нет

- JM Guide To ATE Flier (c2020)Документ2 страницыJM Guide To ATE Flier (c2020)Maged HegabОценок пока нет

- Process Financial Transactions and Extract Interim Reports - 025735Документ37 страницProcess Financial Transactions and Extract Interim Reports - 025735l2557206Оценок пока нет

- Propoxur PMRAДокумент2 страницыPropoxur PMRAuncleadolphОценок пока нет

- Evil Days of Luckless JohnДокумент5 страницEvil Days of Luckless JohnadikressОценок пока нет

- Tutorial 1 Discussion Document - Batch 03Документ4 страницыTutorial 1 Discussion Document - Batch 03Anindya CostaОценок пока нет

- Developing the cycle of maslahah based performance management system implementationДокумент27 страницDeveloping the cycle of maslahah based performance management system implementationM Audito AlfansyahОценок пока нет

- Equilibruim of Forces and How Three Forces Meet at A PointДокумент32 страницыEquilibruim of Forces and How Three Forces Meet at A PointSherif Yehia Al MaraghyОценок пока нет

- Cableado de TermocuplasДокумент3 страницыCableado de TermocuplasRUBEN DARIO BUCHELLYОценок пока нет

- CS210 Lecture 32 Magical Application Binary Tree IIIДокумент38 страницCS210 Lecture 32 Magical Application Binary Tree IIIOshoОценок пока нет

- Form 709 United States Gift Tax ReturnДокумент5 страницForm 709 United States Gift Tax ReturnBogdan PraščevićОценок пока нет

- Oxgen Sensor Cat WEBДокумент184 страницыOxgen Sensor Cat WEBBuddy Davis100% (2)

- Evaluative Research DesignДокумент17 страницEvaluative Research DesignMary Grace BroquezaОценок пока нет

- The Service Marketing Plan On " Expert Personalized Chef": Presented byДокумент27 страницThe Service Marketing Plan On " Expert Personalized Chef": Presented byA.S. ShuvoОценок пока нет

- Duca Industries March 2023 pay slip for Dipankar MondalДокумент1 страницаDuca Industries March 2023 pay slip for Dipankar MondalPritam GoswamiОценок пока нет

- Physioex 9.0 Exercise 1 Act 1Документ5 страницPhysioex 9.0 Exercise 1 Act 1Adela LhuzОценок пока нет

- October 2009 Centeral Aucland, Royal Forest and Bird Protecton Society NewsletterДокумент8 страницOctober 2009 Centeral Aucland, Royal Forest and Bird Protecton Society NewsletterRoyal Forest and Bird Protecton SocietyОценок пока нет

- MQC Lab Manual 2021-2022-AutonomyДокумент39 страницMQC Lab Manual 2021-2022-AutonomyAniket YadavОценок пока нет