Академический Документы

Профессиональный Документы

Культура Документы

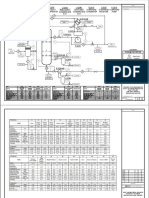

6-18-7 Flow Meters and Pressure Instruments

Загружено:

sudokuАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

6-18-7 Flow Meters and Pressure Instruments

Загружено:

sudokuАвторское право:

Доступные форматы

Revision

Indication

STANDARD SPECIFICATION

UOP Engineering Department

6-18-7 Page 1 of 9

DATE STATUS SPNSR APVD

FLOW METERS AND PRESSURE

INSTRUMENTS 12APR20 Reaffirmed RED MJM

1. GENERAL

1.1 Scope

a. This Standard Specification covers the general requirements for flow meters, differential

CONFIDENTIAL – The information in this document is confidential and must not be used for any purpose, duplicated, or disclosed to others without UOP's written permission.

pressure transmitters, and pressure transmitters.

b. Exceptions or variations shown in the UOP Project Specifications take precedence over

requirements shown herein.

1.2 References

Unless noted below, use the edition and addenda of each referenced document current on the date

of this Standard Specification. When a referenced document incorporates another document, use

the edition of that document required by the referenced document.

a. International Organization for Standardization (ISO) 5167

Measurement of fluid flow by means of pressure differential devices inserted in circular

cross-section conduits running full:

ISO 5167-1, Second Edition (2003), General principles and requirements

ISO 5167-2, First Edition (2003), Orifice plates

ISO 5167-3, First Edition (2003), Nozzles and Venturi nozzles

ISO 5167-4, First Edition (2003), Venturi tubes.

b. American Society of Mechanical Engineers (ASME) MFC-3M-2004, “Measurement of Fluid

Flow in Pipes Using Orifice, Nozzle, and Venturi”, with MFC-3Ma-2007 addenda.

c. ASME MFC-14M-2003, “Measurement of Fluid Flow Using Small Bore Precision Orifice

Meters”.

d. “Flow Measurement Engineering Handbook”, by Richard Miller, 3rd Edition.

e. National Association of Corrosion Engineers (NACE) International Standard MR0103,

“Materials Resistant to Sulfide Stress Corrosion Cracking in Corrosive Petroleum Refining

Environments”.

f. National, state, and local governmental regulations and laws.

1.3 Substitution Criteria

Flow measurement equipment substituted for the equipment specified in the UOP Project

Specifications shall be engineered such that any criteria that may impact process performance (e.g.

accuracy, repeatability, speed of response, update rate, etc.) are equivalent to, or exceed the UOP

specified equipment. It is both the Owner’s and Contractor’s responsibility to ensure equivalency.

Process performance is especially important for metering equipment in control loops and those

associated with unit mass balance streams.

Form QUA-03-7 Qualtrax 9363

Revision

Indication

STANDARD SPECIFICATION

UOP Engineering Department

6-18-7 Page 2 of 9

DATE STATUS SPNSR APVD

FLOW METERS AND PRESSURE

INSTRUMENTS 12APR20 Reaffirmed RED MJM

2. FLOW CALCULATIONS

To determine the actual flow being measured, UOP uses the measured orifice bore diameter/dimensions

and the actual process conditions to calculate the actual meter maximum flow rate. The equations from

ISO 5167-1 through 5167-4 are used to determine the meter maximum flow rate. For those items that

CONFIDENTIAL – The information in this document is confidential and must not be used for any purpose, duplicated, or disclosed to others without UOP's written permission.

fall outside of ISO 5167, the equations from ASME MFC-14M or the Flow Measurement Engineering

Handbook are used. Proprietary flow measuring devices shall use equations and/or information provided

by the vendor of the item.

Primary element (orifice plate or venturi) sizing calculations shall be provided for each primary element,

and the Contractor shall retain one copy of the sizing calculations for review by UOP personnel. For

other types of flow meters, vendor specific calculation information shall be available for review by UOP

personnel.

3. STANDARD FLOW MEASUREMENT EQUIPMENT

The standard flow measurement equipment shall generally be a differential head producing primary

element (orifice plate or a venturi) and an electronic (analog or digital) differential pressure transmitter.

3.1 Orifice Plates

a. Types

(1) Concentric sharp edge orifice plates shall be used for most metering applications. For

orifice bore diameters less than 0.25 inches (6.35 mm), a suitable strainer shall be

installed preceding the meter.

(2) Eccentric type orifice plates shall be used for fluids containing two phases. The

eccentric type orifice plates shall have the bottom of the orifice bore approximately 0.01

times the pipe inside diameter (D) above the bottom inside wall of the pipe. Eccentric

orifice plates shall be installed in horizontal meter runs only.

(3) Quadrant edge orifice plates shall generally be provided for liquid flow measurement

where low Reynolds numbers (less than 20000) are calculated for the normal process

flow rate.

(4) Prefabricated meter runs, consisting of upstream and downstream honed tubes, metering

flanges, and orifice plate (honed flow meter runs), shall be provided for small flow

metering applications where the pipe size is smaller than the 2 inch minimum of the

conventional square edge orifice plate/meter run. In conjunction with this type of flow

metering device, a suitable strainer shall be installed preceding the meter for orifice bore

diameters less than 0.25 inches (6.35 mm).

(5) Prefabricated meter runs with integral orifice meters (in-line type orifice assembly

integrally mounted to a differential pressure transmitter) may be used for extremely

small flow rates when specified on the UOP Project Specification. In conjunction with

this type of device, a suitable strainer shall be installed preceding the meter.

Due to the fabrication with only two bolts at the orifice assembly body, these meters

shall only be used with inert fluids (air, water, nitrogen, etc.).

Form QUA-03-7 Qualtrax 9363

Revision

Indication

STANDARD SPECIFICATION

UOP Engineering Department

6-18-7 Page 3 of 9

DATE STATUS SPNSR APVD

FLOW METERS AND PRESSURE

INSTRUMENTS 12APR20 Reaffirmed RED MJM

b. Fabrication

(1) The vendor's standard equations may be used to calculate the orifice bore diameter (d).

(2) The Beta ratio (d/D) shall be within the following limits:

CONFIDENTIAL – The information in this document is confidential and must not be used for any purpose, duplicated, or disclosed to others without UOP's written permission.

(a) 0.10 and 0.70 inclusive for pipe sizes 2 inches and larger

(b) 0.15 and 0.70 inclusive for honed flow prefabricated meter runs with flange

taps

(c) 0.10 and 0.80 inclusive for honed flow prefabricated meter runs with corner

taps

(d) Vendor’s recommendation for integral orifice prefabricated meter runs

Where required, the pipe size shall be expanded in diameter to avoid d/D ratios

exceeding the upper limits.

(3) For horizontal meter run installations, drain or weep holes may be provided for orifice

plates that have a bore diameter of 1 inch (25 mm) and larger. The drain or weep hole

may be excluded from the orifice bore calculation.

(4) Each orifice plate shall be provided with a tab that projects beyond the flange. The tab

shall be stamped to indicate the orifice plate material, measured bore diameter, nominal

pipe size, flange class, and identifying tag number. The tab shall also be in line with the

drain or weep hole and shall clearly indicate the direction of flow. The information on

the tab shall be visible when the orifice plate is installed in the flanges.

c. Installation

(1) The minimum pipe size for field fabricated orifice meter runs shall be 2 inches. For pipe

sizes less than 2 inches, a prefabricated meter run (either honed flow or integral orifice

meter) shall be used. The minimum pipe size for a prefabricated meter run is 1/2 inch.

(2) Flow conditioning equipment, such as straightening vanes, is not recommended as an

acceptable alternate for required upstream pipe lengths.

(3) Orifice plates in 2 inch pipe sizes and larger shall be installed in tapped orifice flanges

(flange taps). The pipe runs upstream and downstream of the orifice flanges shall be in

accordance with UOP Standard Drawing 6-112.

(4) Orifice plates for honed flow meters in 1/2 through 1-1/2 inch pipe sizes shall be

installed in tapped orifice flanges (flange taps), or corner taps. The pipe runs upstream

and downstream of the orifice flanges shall be in accordance with ASME MFC-14M.

Form QUA-03-7 Qualtrax 9363

Revision

Indication

STANDARD SPECIFICATION

UOP Engineering Department

6-18-7 Page 4 of 9

DATE STATUS SPNSR APVD

FLOW METERS AND PRESSURE

INSTRUMENTS 12APR20 Reaffirmed RED MJM

(5) Orifice plates for integral orifice meters in 1/2 through 1-1/2 inch pipe sizes shall be

installed per the vendor’s recommendations. The pipe runs upstream and downstream of

the orifice flanges shall also be in accordance with the vendor’s recommendations.

(6) Orifice meter run smoothness, out of round, etc., shall conform to the requirements of

CONFIDENTIAL – The information in this document is confidential and must not be used for any purpose, duplicated, or disclosed to others without UOP's written permission.

ISO 5167, or ASME MFC-14M, as applicable.

(7) Thermowells shall not be located upstream of the orifice plate. Thermowells shall be

located a minimum of 5 nominal pipe diameters downstream of the orifice plate.

(8) The layout of the meter run and meter installation shall provide accessibility from a

platform, portable stairs, or temporary ladder for servicing without increasing impulse

line length.

3.2 Venturi

a. The venturi shall be a “Classical” venturi tube as defined in ISO 5167, or an ASME venturi

tube as defined in ASME MFC-3M.

b. The Beta ratio (d/D) shall be within the limits as defined in either ISO 5167, or ASME

MFC-3M, as applicable.

c. The divergent section of the venturi shall have an included angle of 7° to 8° in order to

minimize the permanent pressure loss.

d. Flow conditioning equipment, such as straightening vanes, is not recommended as an

acceptable alternate for required upstream pipe lengths.

e. The pipe runs upstream and downstream of the venturi shall be in accordance with UOP

Standard Drawing 6-134.

f. Venturi meter run smoothness, out of round, etc., shall conform to the requirements of

ISO 5167.

g. The layout of the meter run and meter installation shall be selected to provide accessibility

from a platform, portable stairs, or temporary ladder for servicing without increasing impulse

line length.

3.3 Pressure Tappings

a. For orifice taps and venturi taps in horizontal lines, the following shall apply:

(1) For liquid, steam, or condensable vapor lines the taps shall be in the horizontal. Tap

locations other than in the horizontal, such as 45° taps, are not acceptable.

Form QUA-03-7 Qualtrax 9363

Revision

Indication

STANDARD SPECIFICATION

UOP Engineering Department

6-18-7 Page 5 of 9

DATE STATUS SPNSR APVD

FLOW METERS AND PRESSURE

INSTRUMENTS 12APR20 Reaffirmed RED MJM

(2) For gas lines, the taps shall be in the vertical on the top or not more than 45° from the

vertical on the top.

b. Other aspects of the pressure tappings shall be in accordance with ISO 5167.

CONFIDENTIAL – The information in this document is confidential and must not be used for any purpose, duplicated, or disclosed to others without UOP's written permission.

4. ABSOLUTE / GAUGE PRESSURE AND DIFFERENTIAL PRESSURE TRANSMITTER

REQUIREMENTS

4.1 Construction

a. For differential pressure transmitters, the transmitter body shall have a static pressure rating

of 1500 psig (105 kg/cm2(g)) or 150% of the operating pressure at the operating temperature

shown on the UOP Project Specification, whichever is greater.

b. For absolute and gauge pressure transmitters, the transmitter body shall have a static pressure

rating of 1500 psig (105 kg/cm2(g)) or 150% of the sensor upper range limit (URL) at the

operating temperature shown on the UOP Project Specification, whichever is greater.

c. Transmitter internals in contact with the process (wetted parts) shall be type 316 stainless

steel. In services that are corrosive to available transmitter internals, where plugging may

occur, or high viscosity fluids are encountered, diaphragm seals compatible with the process

fluid shall be used to isolate the transmitter internals from the process fluid.

d. For differential pressure transmitters, measuring elements shall be capable of withstanding

pressure up to that of the static pressure rating on either side of the measuring element

without damage to the element. Any resultant zero shifts shall be limited to less than 1% of

the calibrated span of the transmitter.

e. For absolute and gauge pressure transmitters, measuring elements shall be capable of

withstanding pressure up to that of the static pressure rating without damage to the element.

Any resultant zero shifts shall be limited to less than 1% of the calibrated span of the

transmitter.

f. Transmitters in wet H2S (sour) service shall comply with NACE standard MR0103.

4.2 Performance

a. Response Time and Update Rate

(1) For transmitters used in process control loops, response time and update rate shall be

used in determining transmitter performance and both criteria shall be considered in the

selection of the equipment. Response time is defined as the time it takes for the

transmitter output to reach 63.2% of the actual step change in pressure. The response

time includes any dead time associated with the initial step change in input signal and

the transmitter output actually changing. Update rate is defined as the time interval

between updates of the transmitted process measurement value.

Form QUA-03-7 Qualtrax 9363

Revision

Indication

STANDARD SPECIFICATION

UOP Engineering Department

6-18-7 Page 6 of 9

DATE STATUS SPNSR APVD

FLOW METERS AND PRESSURE

INSTRUMENTS 12APR20 Reaffirmed RED MJM

(2) As a minimum, pressure and differential pressure digital transmitters used in process

control loops shall meet the following requirements:

(a) Transmitters with an upper range limit of 30 inches (760 mm) H2O or less, shall

have a response time of 600 milliseconds or less. Other transmitters shall have a

CONFIDENTIAL – The information in this document is confidential and must not be used for any purpose, duplicated, or disclosed to others without UOP's written permission.

response time of 500 milliseconds or less.

(b) Transmitters shall have an update rate at least as fast as the table below.

Controller Type Output Signal Update Rate *

Flow (ΔP), Pressure, Differential Pressure 125 milliseconds

Level (ΔP) 500 milliseconds

* Faster update rate/response time transmitters may be required for certain

applications such as compressor antisurge control systems. Slow update

rate/response time transmitters may degrade control performance.

b. Process Measurement Communication Protocol

The transmitter output signal for the specified range may be 4 - 20 mA, 4 - 20 mA with a

digital communication protocol superimposed, or fully digital communication. The

communication protocol shall not prevent the instrument from measuring and transmitting the

process pressure or differential pressure, except when the instrument is being configured.

c. Failure Mode

The transmitter electronics shall be capable of monitoring its performance during normal

operation. The diagnostics shall be able to detect both an input sensor failure and transmitter

electronics failure. The sensor or electronics failure shall be transmitted to the host system

(e.g., DCS, PLC) using a low milliamp signal (e.g. <3.75 mA) or by using a fieldbus signal,

depending on the capabilities of the host system.

d. Electronic Damping

The transmitter shall be capable of setting the electronic damping of the output to zero.

Damping values shall be set to zero unless specified otherwise.

e. Accuracy

Better than +/- 0.15% of Span.

f. Combined pressure and temperature effects (Total Performance)

Better than +/- 1% of Span for a 50°F (28°C) temperature change, up to 1000 psig

(70 kg/cm2(g)).

Form QUA-03-7 Qualtrax 9363

Revision

Indication

STANDARD SPECIFICATION

UOP Engineering Department

6-18-7 Page 7 of 9

DATE STATUS SPNSR APVD

FLOW METERS AND PRESSURE

INSTRUMENTS 12APR20 Reaffirmed RED MJM

g. Stability

Better than +/- 0.5% of upper range limit for 1 year.

h. Calibration

CONFIDENTIAL – The information in this document is confidential and must not be used for any purpose, duplicated, or disclosed to others without UOP's written permission.

The instrument calibration shall be completed by the vendor prior to shipment of the

instrument. Where applicable, calibration via a smart communicator is sufficient.

4.3 Transmitter Installation

a. For differential pressure transmitters, impulse lines shall not be longer than indicated on the

UOP Standard Drawings. Longer impulse lines will increase measurement error due to any

specific gravity differences in the high and low impulse lines.

b. Transmitter output signal indicators shall be readable from the associated control valve

assembly (or other valve(s) as denoted on the UOP Piping and Instrument Diagram). An

integrally mounted indicator is acceptable. If the piping layout is such that an integrally

mounted indicator is not readable from the associated valve(s), then a separate indicator

suitable for remote mounting shall be supplied.

5. MISCELLANEOUS FLOW MEASUREMENT EQUIPMENT

5.1 Averaging Pitot Element

a. Averaging Pitot tube elements shall be permanently marked to indicate proper installation

position and flow direction, unless they are bi-directional.

b. As a minimum, the vendor’s recommended straight run pipe length requirements shall be

used; however, longer lengths are preferred.

c. Blowout prevention is required for removable elements.

d. In large pipe diameters, or where high flow velocity may cause the element to deflect or

vibrate, extra heavy flow elements and/or double ended support shall be used.

5.2 Turbine Type Flow Meters

a. The accuracy of the meter shall be +/- 0.5% of the flow rate or better, and the repeatability

shall be +/- 0.1% or better.

b. Turbine meters shall be designed with hydraulic balance to keep the rotor in place and shall

have journal bearing construction. Designs using thrust bearing are not permitted.

c. Material of construction for the journal bearing and rotor shaft shall be tungsten carbide. The

materials of construction for the body and other wetted parts shall be suitable for hydrocarbon

service as defined on the UOP Project Specification.

Form QUA-03-7 Qualtrax 9363

Revision

Indication

STANDARD SPECIFICATION

UOP Engineering Department

6-18-7 Page 8 of 9

DATE STATUS SPNSR APVD

FLOW METERS AND PRESSURE

INSTRUMENTS 12APR20 Reaffirmed RED MJM

d. The pickup coil shall be hermetically sealed or potted. The pickup coil wiring shall terminate

at a terminal strip located on a remote mounted pulse amplifier. The wiring shall be suitable

for the operating conditions shown on the UOP Project Specification. The length of wiring

between the pickup coil and pulse amplifier shall be sufficient to permit the amplifier to be

located as close to the meter as possible but not on the meter. The output signal of the

CONFIDENTIAL – The information in this document is confidential and must not be used for any purpose, duplicated, or disclosed to others without UOP's written permission.

amplifier shall be compatible with the associated remotely located equipment.

e. Turbine meters shall be designed for operation at a minimum of 130% of the flow range

specified, with no damage to the meter.

f. Each turbine meter shall have a nameplate indicating the average pulses per unit volume over

the meter range specified.

g. Each turbine meter shall be calibrated for either vertical upflow or horizontal installation as

specified on the UOP Project Specification. One copy of the calibration curve shall be

provided with each meter.

h. Strainers with the mesh size, material, and rating as noted on the UOP Project Specification

shall be installed preceding each meter. Where the mesh size is not listed, the turbine meter

vendor’s recommendation shall be followed.

i. Turbine meters shall be marked to indicate the direction of flow.

j. Tools required for removal of the pickup coil shall be provided with the meter.

k. For each meter, one spare rotor and one spare pickup coil shall be provided.

5.3 Positive Displacement Meters

a. The meter body configuration shall be constructed to minimize the pressure drop through the

meter.

b. Counters, where specified, shall be of the non-reset type with calibration adjustments.

Counters shall be weatherproof.

c. Straight through strainers with mesh size, material, and rating as noted on the UOP Project

Specification shall be installed preceding each meter.

d. The accuracy of the measuring device shall be +/- 0.2% of full scale or better.

e. Connections shall be clearly marked to indicate the direction of flow.

5.4 Rotameters

a. Meter bodies shall be equipped with inlet and outlet float stops and, where feasible, cleanout

plugs, which may be utilized as connection taps.

Form QUA-03-7 Qualtrax 9363

Revision

Indication

STANDARD SPECIFICATION

UOP Engineering Department

6-18-7 Page 9 of 9

DATE STATUS SPNSR APVD

FLOW METERS AND PRESSURE

INSTRUMENTS 12APR20 Reaffirmed RED MJM

b. Indicating scales shall have full length safety glass (or plastic) shielding, gasketed on both

sides. Indicating scales shall be approximately 5 inches (125 mm) in length for extension

meters used for transmitting service or for armored meters and 10 inches (250 mm) in length

for local indicators not of the armored type. A 2-1/2 inch (65 mm) scale length for purge rate

rotameters is acceptable.

CONFIDENTIAL – The information in this document is confidential and must not be used for any purpose, duplicated, or disclosed to others without UOP's written permission.

c. Gland assemblies shall be of "O" ring construction unless process conditions noted on the

UOP Project Specification require otherwise.

d. Tube construction shall be beaded, ribbed, or flat except for the plain tapered tubes used for

armored type. Plain tapered tubes shall have internal guiding.

e. Floats shall be self-cleaning and shall be designed for dimensional stability and maximum

immunity to viscosity variations.

f. Rotameters shall be completely assembled with all accessories before shipping.

g. Accuracy shall be +/- 2% of full scale or better. For purge rate rotameters accuracy of

+/- 10% of full scale is acceptable.

5.5 Magnetic Flow Meters

a. The accuracy of the meter shall be +/- 0.5% of rate or better.

b. The velocity through the tube shall determine the meter size based upon the selected vendors

recommended velocities.

c. The process conditions indicated on the UOP Project Specification shall be considered in the

selection of the lining, electrodes and grounding requirements.

d. The meter installation shall assure that the meter body remains full of liquid. Vertical upflow

installations are preferred.

5.6 Other Flow meters

Other flow meter types, such as vortex, coriolis, thermal mass, etc., shall be in accordance with the

applicable UOP Project Specification, notes and drawings.

6. NAMEPLATE

A non-corroding nameplate shall be permanently attached to the instrument and shall contain as a

minimum the following information.

a. Equipment tag number

b. Manufacturer name

c. Model

d. Serial number

Form QUA-03-7 Qualtrax 9363

Вам также может понравиться

- Chemical Process Retrofitting and Revamping: Techniques and ApplicationsОт EverandChemical Process Retrofitting and Revamping: Techniques and ApplicationsGade Pandu RangaiahОценок пока нет

- 1-14-3 Steam Heat TracingДокумент5 страниц1-14-3 Steam Heat TracingDavide CongiuОценок пока нет

- UOP 3-28-6 - Storage Tanks Low PressureДокумент3 страницыUOP 3-28-6 - Storage Tanks Low Pressurejev_vdОценок пока нет

- G3ir 1000 25 SP 9001 - R1Документ72 страницыG3ir 1000 25 SP 9001 - R1Ramu NallathambiОценок пока нет

- Inert Gas Generators: Design Practices Fired Heaters Subsection L Exxon EngineeringДокумент5 страницInert Gas Generators: Design Practices Fired Heaters Subsection L Exxon EngineeringFRANKLIN REVILLAОценок пока нет

- Incinerators: SectionДокумент18 страницIncinerators: SectionFRANKLIN REVILLAОценок пока нет

- FRS-DU-5056-E.1 Sizing & Selection of PSVДокумент25 страницFRS-DU-5056-E.1 Sizing & Selection of PSVShivani DubeyОценок пока нет

- 943025-806 Strainers Rev01Документ3 страницы943025-806 Strainers Rev01studyendlessОценок пока нет

- Standard Specification: UOP LLC - 25 East Algonquin Road - Des Plaines, Illinois 60017-5017 - USAДокумент9 страницStandard Specification: UOP LLC - 25 East Algonquin Road - Des Plaines, Illinois 60017-5017 - USAhlagos123Оценок пока нет

- Standard Specification 4-12-4 Tubular Exchangers Hair Pin TypeДокумент5 страницStandard Specification 4-12-4 Tubular Exchangers Hair Pin Typethod3rОценок пока нет

- Final Project Report: Uop, LLCДокумент165 страницFinal Project Report: Uop, LLCSiddharth KishanОценок пока нет

- 8-1200-31 Pipe Class IndexДокумент11 страниц8-1200-31 Pipe Class IndexWilson ramirez zuniniОценок пока нет

- Guide Document GE P312 4.1.2 I General ConsiderationsДокумент31 страницаGuide Document GE P312 4.1.2 I General ConsiderationsDiarista Thoma SaputraОценок пока нет

- Trays and Packing Random and Structured: Standard SpecificationДокумент9 страницTrays and Packing Random and Structured: Standard SpecificationSenthil KumarОценок пока нет

- Line Sizing CriteriaДокумент2 страницыLine Sizing CriteriaPaul OhiorОценок пока нет

- PDE-EQS-3120-EC-00005 - 00 Technical Specification of Ammonia Flash VesselДокумент9 страницPDE-EQS-3120-EC-00005 - 00 Technical Specification of Ammonia Flash Vesselhgag selimОценок пока нет

- Human Factors in Plant Design: ScopeДокумент28 страницHuman Factors in Plant Design: ScopeRajuОценок пока нет

- PFD Unit 2000 - ReferenceДокумент2 страницыPFD Unit 2000 - ReferenceAgravante JakeОценок пока нет

- Exxon IP 10-10-2 General Purpose Gear UnitsДокумент3 страницыExxon IP 10-10-2 General Purpose Gear UnitsGilvan SilvaОценок пока нет

- Conventional Type Pressure Relief Valve NumbersДокумент18 страницConventional Type Pressure Relief Valve NumbersswatkoolОценок пока нет

- PDE-EQS-3120-EC-00006 - 00 Technical Specification of Ammonia SeparatorДокумент8 страницPDE-EQS-3120-EC-00006 - 00 Technical Specification of Ammonia Separatorhgag selimОценок пока нет

- E PR 810Документ41 страницаE PR 810anju2718Оценок пока нет

- PP Aaa PP1 122Документ19 страницPP Aaa PP1 122Rabah AmidiОценок пока нет

- 03 Crude Unit DesignДокумент88 страниц03 Crude Unit DesignVĂN ĐOÀN HUYОценок пока нет

- Exh 50Документ8 страницExh 50RogerОценок пока нет

- 50a99 ReadingДокумент15 страниц50a99 Readingishu vohraОценок пока нет

- (C Pi LST 0001 Rev.0) C Pi LST 0001 - 0 (Line List)Документ207 страниц(C Pi LST 0001 Rev.0) C Pi LST 0001 - 0 (Line List)Harender SinghОценок пока нет

- Drum SizingДокумент48 страницDrum SizingVikram Sharma100% (1)

- Birkett PSV CatalogДокумент104 страницыBirkett PSV CatalogChetanОценок пока нет

- IPS-M-PM-160-Positive Displacement, Oil Sealed-Rotary Vacuum PumpsДокумент22 страницыIPS-M-PM-160-Positive Displacement, Oil Sealed-Rotary Vacuum PumpsAbdi RahimianОценок пока нет

- Hot Oil SystemДокумент1 страницаHot Oil SystemAli SakhiОценок пока нет

- UOP-Proposed Layout Critical Piping Rev 00Документ6 страницUOP-Proposed Layout Critical Piping Rev 00ermusatОценок пока нет

- Heat and Material BalanceДокумент35 страницHeat and Material BalancesohaibОценок пока нет

- Combustion Design Data: Design Practices Fired Heaters Subsection M Exxon EngineeringДокумент29 страницCombustion Design Data: Design Practices Fired Heaters Subsection M Exxon EngineeringFRANKLIN REVILLAОценок пока нет

- IPS-MBD21907-In-511A-Data Sheet of Level Gauge (Side Mounted) - AДокумент3 страницыIPS-MBD21907-In-511A-Data Sheet of Level Gauge (Side Mounted) - ANikhil KarkeraОценок пока нет

- AIGA 089 - 14 Reciprocating - Cryogenic - Pumps & Pump - Installations - Final PDFДокумент19 страницAIGA 089 - 14 Reciprocating - Cryogenic - Pumps & Pump - Installations - Final PDFmeisamОценок пока нет

- New - Lecture 2 Introduction To S&TДокумент31 страницаNew - Lecture 2 Introduction To S&TWael ElArinyОценок пока нет

- Prico Process PDFДокумент13 страницPrico Process PDFcorkynhoОценок пока нет

- UOP Course DescriptionДокумент2 страницыUOP Course DescriptionVictor Esteban CondorОценок пока нет

- Combustion Source Evaluation: Student ManualДокумент318 страницCombustion Source Evaluation: Student ManualEmmanuel Ortiz ReinaОценок пока нет

- Workshop 1Документ429 страницWorkshop 1Vijay Rajaindran100% (1)

- Pi Ups 1004Документ39 страницPi Ups 1004JOEL ARNAO CORTEGANAОценок пока нет

- Design Practices Product Loading Systems Exxon EngineeringДокумент16 страницDesign Practices Product Loading Systems Exxon EngineeringFRANKLIN REVILLAОценок пока нет

- Balanced Bellows Type Pressure Relief Valve NumbersДокумент17 страницBalanced Bellows Type Pressure Relief Valve NumbersswatkoolОценок пока нет

- Controlling Reboilers Heated by Condensing Steam or VaporДокумент12 страницControlling Reboilers Heated by Condensing Steam or VaporForcus onОценок пока нет

- 1000444Документ5 страниц1000444Semih ÖzsağıroğluОценок пока нет

- DP08 TocДокумент1 страницаDP08 TocFRANKLIN REVILLAОценок пока нет

- Pi Ups 1006Документ27 страницPi Ups 1006JOEL ARNAO CORTEGANAОценок пока нет

- Gas Dehydration (ENGINEERING DESIGN GUIDELINE)Документ23 страницыGas Dehydration (ENGINEERING DESIGN GUIDELINE)Tu Dang TrongОценок пока нет

- 3DG-B32-00004 Crude & Vacuum UnitsДокумент32 страницы3DG-B32-00004 Crude & Vacuum UnitsCarlos0% (1)

- Engineering Standard: IPS-E-PR-330Документ30 страницEngineering Standard: IPS-E-PR-330Akmal ZuhriОценок пока нет

- Onshore Terminal For KG DWN 98/2 Development Project: B.Sunil PrasadДокумент7 страницOnshore Terminal For KG DWN 98/2 Development Project: B.Sunil Prasadsumit kumar100% (1)

- VesselДокумент113 страницVesselAleem QureshiОценок пока нет

- Engineering Standard: IPS-E-PR-340Документ22 страницыEngineering Standard: IPS-E-PR-340Sadegh AhmadiОценок пока нет

- Instrumentation For Fired Heaters IP 15-1-1: ScopeДокумент14 страницInstrumentation For Fired Heaters IP 15-1-1: ScopeLuis Alonso Aguirre LopezОценок пока нет

- UhdeДокумент9 страницUhdeibkhiОценок пока нет

- 61404U JI N°x - Process Guidlines For PRV Design - Rev0Документ26 страниц61404U JI N°x - Process Guidlines For PRV Design - Rev0CristinaОценок пока нет

- MQ SP I 7003 PDFДокумент92 страницыMQ SP I 7003 PDFJaseelKanhirathinkalОценок пока нет

- Facts at Your Fingers - Positive-Displacement-Pumps PDFДокумент1 страницаFacts at Your Fingers - Positive-Displacement-Pumps PDFjohn VilladaОценок пока нет

- Characteristics of Thermosiphon Reboilers: Stephan Arneth, Johann StichlmairДокумент7 страницCharacteristics of Thermosiphon Reboilers: Stephan Arneth, Johann StichlmairKiril AckovskiОценок пока нет

- Standard Specification: UOP Engineering Department Date Status SPNSR ApvdДокумент5 страницStandard Specification: UOP Engineering Department Date Status SPNSR ApvdsudokuОценок пока нет

- Pressure Vessel Handbook Fourteenth Edition Eugene R MegyesyДокумент1 014 страницPressure Vessel Handbook Fourteenth Edition Eugene R Megyesyluis sepulveda80% (10)

- Technical-specs-Heat ExchangersДокумент96 страницTechnical-specs-Heat ExchangerssudokuОценок пока нет

- 3-11-10 Pressure Vessels Carbon SteelДокумент34 страницы3-11-10 Pressure Vessels Carbon Steelsudoku100% (2)

- ASME Code Case 2901Документ2 страницыASME Code Case 2901sudokuОценок пока нет

- 6-14-9 Control ValvesДокумент14 страниц6-14-9 Control ValvessudokuОценок пока нет

- 15250-194-EN04-SP-005-Rev 0 (Specification For Atmospheric Storage Tank)Документ22 страницы15250-194-EN04-SP-005-Rev 0 (Specification For Atmospheric Storage Tank)sudokuОценок пока нет

- 350 - Tray Installation Manual - EngДокумент36 страниц350 - Tray Installation Manual - EngRashid MadathilОценок пока нет

- Tema 9Документ300 страницTema 9sudokuОценок пока нет

- Astm A578 - 07 PDFДокумент5 страницAstm A578 - 07 PDFMuhammad Maulana100% (1)

- Specification For Hot Insulation PDFДокумент55 страницSpecification For Hot Insulation PDFapply19842371Оценок пока нет

- E010 - Hydrotest Gland RingДокумент5 страницE010 - Hydrotest Gland RingsudokuОценок пока нет

- Structural Analysis and Design of Process EquipmentДокумент360 страницStructural Analysis and Design of Process EquipmentSurya Tej88% (8)

- ASTM A388 Standard Practice For Ultrasonic Examination of Heavy Steel ForgingsДокумент8 страницASTM A388 Standard Practice For Ultrasonic Examination of Heavy Steel ForgingsGonzalo TelleríaОценок пока нет

- E-001 - Hydrotest Device (Loose Ring) - OutДокумент13 страницE-001 - Hydrotest Device (Loose Ring) - OutsudokuОценок пока нет

- Basics 2016Документ81 страницаBasics 2016andy131078Оценок пока нет

- KettleДокумент185 страницKettlesudokuОценок пока нет

- 2917 HXGN LIVE 2917 DelaforceДокумент58 страниц2917 HXGN LIVE 2917 DelaforceVitor OlivettiОценок пока нет

- PipeДокумент44 страницыPipesudokuОценок пока нет

- Standard Stud Heavy Hex Nut Specs Peste 4 InchДокумент1 страницаStandard Stud Heavy Hex Nut Specs Peste 4 InchsudokuОценок пока нет

- NI-0253 - J Pressure Vessel DesignДокумент45 страницNI-0253 - J Pressure Vessel DesignsudokuОценок пока нет

- Training Manual For PVelite Basic LevelДокумент41 страницаTraining Manual For PVelite Basic LevelsudokuОценок пока нет

- Handbook of Mechanical Engineering TermsДокумент366 страницHandbook of Mechanical Engineering Termsjakejohns95% (44)

- Declaration g4 g7Документ1 страницаDeclaration g4 g7sudokuОценок пока нет

- Buckling Stress Check For A Vertical VesselДокумент11 страницBuckling Stress Check For A Vertical Vesselmechengg01Оценок пока нет

- Allowable Stress PDFДокумент6 страницAllowable Stress PDFsudokuОценок пока нет

- B564Документ11 страницB564razvandanutОценок пока нет

- Rayleigh Method Versus Eigenvalue MethodДокумент6 страницRayleigh Method Versus Eigenvalue MethodCY Lee0% (1)

- Astm A194m 15 PDFДокумент13 страницAstm A194m 15 PDFsudokuОценок пока нет

- Acceptable Use Policy 08 19 13 Tia HadleyДокумент2 страницыAcceptable Use Policy 08 19 13 Tia Hadleyapi-238178689Оценок пока нет

- Asus x453Документ5 страницAsus x453Rhiry Ntuh AthryОценок пока нет

- Optical Transport Network SwitchingДокумент16 страницOptical Transport Network SwitchingNdambuki DicksonОценок пока нет

- Dynamic Study of Parabolic Cylindrical Shell A Parametric StudyДокумент4 страницыDynamic Study of Parabolic Cylindrical Shell A Parametric StudyEditor IJTSRDОценок пока нет

- Blackbook 2Документ94 страницыBlackbook 2yogesh kumbharОценок пока нет

- Lecture 19 Code Standards and ReviewДокумент27 страницLecture 19 Code Standards and ReviewAdhil Ashik vОценок пока нет

- SPFL Monitoring ToolДокумент3 страницыSPFL Monitoring ToolAnalyn EnriquezОценок пока нет

- 2022 AMR Dashboard Funding Opportunity Announcement 11.18.2022Документ16 страниц2022 AMR Dashboard Funding Opportunity Announcement 11.18.2022Tuhin DeyОценок пока нет

- Celula de CargaДокумент2 страницыCelula de CargaDavid PaezОценок пока нет

- Fortnite Task Courier Pack 1500 V Bucks - BuscarДокумент1 страницаFortnite Task Courier Pack 1500 V Bucks - Buscariancard321Оценок пока нет

- Pen Pal Lesson Plan 3Документ3 страницыPen Pal Lesson Plan 3api-664582820Оценок пока нет

- DBM Uv W ChartДокумент2 страницыDBM Uv W ChartEddie FastОценок пока нет

- Transactions List: Marilena Constantin RO75BRDE445SV93146784450 RON Marilena ConstantinДокумент12 страницTransactions List: Marilena Constantin RO75BRDE445SV93146784450 RON Marilena ConstantinConstantin MarilenaОценок пока нет

- Ships Near A Rocky Coast With Awaiting Landing PartyДокумент2 страницыShips Near A Rocky Coast With Awaiting Landing PartyFouaAj1 FouaAj1Оценок пока нет

- ABHA Coil ProportionsДокумент5 страницABHA Coil ProportionsOctav OctavianОценок пока нет

- Chapter1 Intro To Basic FinanceДокумент28 страницChapter1 Intro To Basic FinanceRazel GopezОценок пока нет

- Vendor Registration FormДокумент4 страницыVendor Registration FormhiringОценок пока нет

- FluteДокумент13 страницFlutefisher3910% (1)

- 8 X 56 M.-SCH.: Country of Origin: ATДокумент1 страница8 X 56 M.-SCH.: Country of Origin: ATMohammed SirelkhatimОценок пока нет

- Ticket: Fare DetailДокумент1 страницаTicket: Fare DetailSajal NahaОценок пока нет

- QAU TTS Form Annual AssessmentДокумент6 страницQAU TTS Form Annual AssessmentsohaibtarikОценок пока нет

- Present Tenses ExercisesДокумент4 страницыPresent Tenses Exercisesmonkeynotes100% (1)

- Managing Errors and ExceptionДокумент12 страницManaging Errors and ExceptionShanmuka Sreenivas100% (1)

- 02 CT311 Site WorksДокумент26 страниц02 CT311 Site Worksshaweeeng 101Оценок пока нет

- Febrile Neutropenia GuidelineДокумент8 страницFebrile Neutropenia GuidelineAslesa Wangpathi PagehgiriОценок пока нет

- Localization On ECG: Myocardial Ischemia / Injury / InfarctionДокумент56 страницLocalization On ECG: Myocardial Ischemia / Injury / InfarctionduratulfahliaОценок пока нет

- Dependent ClauseДокумент28 страницDependent ClauseAndi Febryan RamadhaniОценок пока нет

- Caroline Coady: EducationДокумент3 страницыCaroline Coady: Educationapi-491896852Оценок пока нет

- Bill of Quantities 16FI0009Документ1 страницаBill of Quantities 16FI0009AJothamChristianОценок пока нет

- UG ENGLISH Honours PDFДокумент59 страницUG ENGLISH Honours PDFMR.Shantanu SharmaОценок пока нет