Академический Документы

Профессиональный Документы

Культура Документы

Materials Handling and Hoisting

Загружено:

NARGISАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Materials Handling and Hoisting

Загружено:

NARGISАвторское право:

Доступные форматы

Materials handling and hoisting

01- Two 5 tonne shuttle cars operate at an average speed of 1.1 m/s during the

development phase of a panel. The loading machine has a rate of 2.5 tonnes/min.

loader/ change out distance is 30m. If each shuttle car incurs a wait at the change out

point of 0.5 min and the shuttle car discharge time is 1.2 min what is the haul distance

from the change out point to the dumping point?

02-Estimate the cycle time and production of a 72 tonne GVW off highway truck with 41

tonnes on its rear wheels when loaded to its rated capacity, operating on a level haul

road of 1500m length. The road is a rutted dirt roadway with no maintenance and no

stabilisation, tyre penetration is 4cm. The following can be assumed;

a) Loading time 1.4 min

b) Manoeuvre and dump time 0.8 min

c) Truck hauls 40 tonnes of ore each trip

d) Job efficiency of 0.8

03- A Caterpillar D30D articulated dump truck has the rim pull curve in figure 1. (Gross

weight 21.9 t empty, 49.117 t loaded). If the truck ascends an 8% grade with a rolling

resistance of 40 kg/t, find the following:

a) Total resistance (kg)

b) The required rim pull (kg) when loaded

c) The maximum speed of the truck when loaded (km/h)

A Caterpillar 631 E tractor scraper has the following characteristics:

Maximum heaped volume = 19.6 Bm3

Maximum payload = 34,000 kg

The material hauled is earth with a density of 1825 kg/Bm 3

Rolling resistance is 60 kg/t and operating conditions are average with a job efficiency of

50 min/hour.

The haul route comprises of the following sections:

Section 1 (100m) level-loading zone

Section 2 (900m) 5% down grade

Section 3 (100m) level dumping zone

Section 4 (900m) 5% up grade

Section 5 (80m) level turnaround area.

Estimate the machines production under these conditions.

Q4-Q8 (this question weighs five questions)

a) For the following winding conditions determine if a rope with a minimum breaking

force of 10 MN gives a satisfactory factor of safety for the winding of ore?

Depth of wind = 775m

Mass of skip and attachments = 10 tonne

Mass of ore wound per wind = 20 tonne

Height of sheaves above skip top when skip unloading at shaft top = 20m

Mass of rope/100m = 750 kg/100m

Note for ore hoisting using a drum winder minimum factor of safety = 7.0

b) If the maximum winding speed for the wind described in part (b) is 18 m/s and

acceleration = deceleration = 0.6 m/s2 (assume linear change of speed during

acceleration and deceleration) determine:

• Accelerating period

• Decelerating period

• Distance travelled by skip in accelerating period

• Distance travelled by skip during decelerating period

• Time travelling at maximum speed

• Distance travelled at maximum speed.

• Total cycle time assuming a 10 s rest period between winds

• Number of cycles per hour

• Capacity of the system per hour

Plot a speed-time graph for this situation.

c) The system described in parts (a) and (b) are for an unbalanced hoisting system

employing a drum winding system. Determine variation of the tractive force at the

circumference of the drum and the total torque required at the drum to drive the system.

Rope diameter is 50mm, minimum drum diameter = 100 x rope diameter, diameter of

sheaves = 5 m. Skip hoisting system, so k = 1.15. Friction resistance between skip and

guides, air resistance, bending resistance etc. = k x mass of loaded skip.

d) Determine the variation of the power at the drive shaft for this system assuming a

constant radius of coiling of the rope on the drum (hint do this for each element within

the cycle and plot on a torque/power time graph)

e) Determine the rms torque and power for this system.

(B) ORE RESERVE ESTIMATION

PROJECT WORK

Вам также может понравиться

- Structural Health MonitoringОт EverandStructural Health MonitoringDaniel BalageasОценок пока нет

- Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsОт EverandCoupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsОценок пока нет

- Fenner Wedge Belt Drive Selection 299 - Friction - WedgebeltdrivesДокумент22 страницыFenner Wedge Belt Drive Selection 299 - Friction - WedgebeltdrivesSubramanian ChidambaramОценок пока нет

- Automatic Samplers: Proven & DependableДокумент6 страницAutomatic Samplers: Proven & DependableHarish KumarОценок пока нет

- WWW Mechanicalengineeringblog Com 2Документ6 страницWWW Mechanicalengineeringblog Com 2Mashudi FikriОценок пока нет

- Inclined Belt Conveyors For Underground Mass Mining OperationsДокумент6 страницInclined Belt Conveyors For Underground Mass Mining OperationsIsmaelОценок пока нет

- Dura FlexДокумент16 страницDura FlexJohn ChivОценок пока нет

- Papers - Some Design Aspects For Selection of Heavy Duty Apron FeedersДокумент5 страницPapers - Some Design Aspects For Selection of Heavy Duty Apron FeedersarsanioseОценок пока нет

- Hydrochloric Acid Regeneration - Wikipedia, The Free EncyclopediaДокумент5 страницHydrochloric Acid Regeneration - Wikipedia, The Free EncyclopediazamburittiОценок пока нет

- Chain Drives: Back To Contents PagesДокумент104 страницыChain Drives: Back To Contents PagesArul KumarОценок пока нет

- Design and Development of Automated Conveyor System For Material HandlingДокумент5 страницDesign and Development of Automated Conveyor System For Material HandlingNurKholisОценок пока нет

- Gate Mining 2007-2019 PapersДокумент220 страницGate Mining 2007-2019 PapersAarya raj singh RanawatОценок пока нет

- High Angle Conveyor Offers Mine Haulage SavingsДокумент20 страницHigh Angle Conveyor Offers Mine Haulage SavingsZiggy Gregory100% (1)

- Beam Deflection CalculationДокумент2 страницыBeam Deflection CalculationAriful IslamОценок пока нет

- Brochure - Slide Gate Valve - Pubc-0502-SvДокумент2 страницыBrochure - Slide Gate Valve - Pubc-0502-SvedgarspalaciosОценок пока нет

- Iso 3684 1990Документ8 страницIso 3684 1990joaquin fuentealba moralesОценок пока нет

- BOF Plant Write UpДокумент20 страницBOF Plant Write UpKalyan HalderОценок пока нет

- Belt Tear Detector.20160126Документ4 страницыBelt Tear Detector.20160126MikiОценок пока нет

- KC-MD3 User Manual Rev 4.0 - 201710 - ENДокумент74 страницыKC-MD3 User Manual Rev 4.0 - 201710 - ENJulio BarreraОценок пока нет

- Application of Conveyors For UG HaulageДокумент11 страницApplication of Conveyors For UG Haulageminerito2211Оценок пока нет

- Slat ConveyorДокумент8 страницSlat ConveyorpkjddjsydОценок пока нет

- Feeder Loads and Power RequirementsДокумент5 страницFeeder Loads and Power RequirementsarsanioseОценок пока нет

- Datasheet - Vertical Lifter Conveyor For Multi Story Conveyor System DesignДокумент10 страницDatasheet - Vertical Lifter Conveyor For Multi Story Conveyor System DesignImpel IntralogisticsОценок пока нет

- Marg Conveyor Bag Handling PresentationДокумент8 страницMarg Conveyor Bag Handling PresentationMarg ConveyorsОценок пока нет

- Mechanical Grain ConveyingДокумент64 страницыMechanical Grain ConveyingDaniel CookОценок пока нет

- 1.1 Design Features of Bucket Elevator: Package M10: Auxiliary Equipment - Maintenance and RepairДокумент56 страниц1.1 Design Features of Bucket Elevator: Package M10: Auxiliary Equipment - Maintenance and RepairDilnesa EjiguОценок пока нет

- Brochure ConveyorChainДокумент80 страницBrochure ConveyorChainAmrie SarsidaОценок пока нет

- Pipe Conveyor Belts: With Steel Cord and Fabric ReinforcementДокумент5 страницPipe Conveyor Belts: With Steel Cord and Fabric ReinforcementEugenepaccelli Kolandai SamyОценок пока нет

- Makron Fibretec 1000-2000 EngДокумент10 страницMakron Fibretec 1000-2000 EngMAKRONОценок пока нет

- 15ME3112 Design of Machine ElementsДокумент29 страниц15ME3112 Design of Machine Elementslikhith saiОценок пока нет

- Belt ConveyorsДокумент10 страницBelt ConveyorsRaja PalasaОценок пока нет

- Reference Notation Description: 1.bottom Plate ThicknessДокумент6 страницReference Notation Description: 1.bottom Plate ThicknessSakib RafeeОценок пока нет

- Size ReductionДокумент12 страницSize ReductionPCarolina50% (2)

- Selecting A Belt Slide: Technical InformationДокумент3 страницыSelecting A Belt Slide: Technical InformationawemetalОценок пока нет

- Designing of Chain Drive MechanismДокумент1 страницаDesigning of Chain Drive MechanismrasgeetsinghОценок пока нет

- DTS - Belt Conveyor Data SheetДокумент3 страницыDTS - Belt Conveyor Data SheetBRUNA NASCIMENTOОценок пока нет

- Chain ConveyorrabДокумент36 страницChain ConveyorrabPrayogo Hadi SОценок пока нет

- Dorner 3200 Vacuum ConveyorДокумент8 страницDorner 3200 Vacuum ConveyorBobKatОценок пока нет

- Weightometers in IndustryДокумент3 страницыWeightometers in IndustryRamoutar (Ken) SeecharranОценок пока нет

- SAIL BSBK Visit Docx-15.06. R-1rtfДокумент7 страницSAIL BSBK Visit Docx-15.06. R-1rtfsssadangi100% (1)

- Belting FormulasДокумент1 страницаBelting Formulasmanoj-kr-dorai-9476Оценок пока нет

- Belt Conveyor CalculationДокумент8 страницBelt Conveyor CalculationFarrahxviiiОценок пока нет

- Helix Dynamic Sample Conveyor CV202 5500tph ST4500 3x1000kW 500kgm2 Flywheels ISOДокумент39 страницHelix Dynamic Sample Conveyor CV202 5500tph ST4500 3x1000kW 500kgm2 Flywheels ISOthiemxmcpОценок пока нет

- High Performance Bucket Elevator CatalogДокумент12 страницHigh Performance Bucket Elevator CatalogcachorrexОценок пока нет

- Calculation of Working Moment & Power For Vibrating Grizzly FeederДокумент1 страницаCalculation of Working Moment & Power For Vibrating Grizzly FeederzahoorОценок пока нет

- Sprocket SelectionДокумент4 страницыSprocket SelectionallovidОценок пока нет

- Design of Conveyor in Metric UnitsДокумент10 страницDesign of Conveyor in Metric Unitsmuhd.qasimОценок пока нет

- Rexnord Power Transmission FormulasДокумент1 страницаRexnord Power Transmission FormulasDeividi CardosoОценок пока нет

- Design of A Material Handling Equipment ProjectДокумент13 страницDesign of A Material Handling Equipment ProjectEyob AbabuОценок пока нет

- Catalogue R I Tang Đ NG Cơ Rulmeca PDFДокумент8 страницCatalogue R I Tang Đ NG Cơ Rulmeca PDFRulmeca Việt Nam100% (1)

- Incline Haulage TrucksДокумент2 страницыIncline Haulage Trucksgarves007Оценок пока нет

- Hms Drum PlantДокумент2 страницыHms Drum Plantrichard gutierrez100% (1)

- TFMPelayoLopezGRUO PDFДокумент91 страницаTFMPelayoLopezGRUO PDFshivakumar bairojuОценок пока нет

- Foundations For Auto Shredders : - Hammer / / / / / / / / / IДокумент6 страницFoundations For Auto Shredders : - Hammer / / / / / / / / / ISandraОценок пока нет

- CEMA 6 Belt Conveyors Belt AlignmentДокумент2 страницыCEMA 6 Belt Conveyors Belt Alignmentali kajbafОценок пока нет

- Chapter 7Документ44 страницыChapter 7Nebiyou KorraОценок пока нет

- E-Catalog - Operator Less Continues Vertical Conveyor From Impel Intralogistic - IndiaДокумент6 страницE-Catalog - Operator Less Continues Vertical Conveyor From Impel Intralogistic - IndiaImpel IntralogisticsОценок пока нет

- Assignment 5140Документ12 страницAssignment 5140venkatОценок пока нет

- Questions On Mining MachineryДокумент9 страницQuestions On Mining MachineryBishnu SharmaОценок пока нет

- PGPM 33 - NICMAR AssignmentsДокумент18 страницPGPM 33 - NICMAR AssignmentsVinod Vasan100% (2)

- Effect of Waste Polymer Modifier On The Properties of Bituminous Concrete MixesДокумент8 страницEffect of Waste Polymer Modifier On The Properties of Bituminous Concrete MixesluanaheresОценок пока нет

- Mustang Light Bulb Identification Guide PDFДокумент11 страницMustang Light Bulb Identification Guide PDFBob KennedyОценок пока нет

- Design of A Drivetrain For Sae Baja RaciДокумент9 страницDesign of A Drivetrain For Sae Baja Raciragavendra marimuthuОценок пока нет

- Rockfall Management Program: Tdot Materials & Tests Division, Geotechnical Engineering SectionДокумент34 страницыRockfall Management Program: Tdot Materials & Tests Division, Geotechnical Engineering SectionDinny Kus AndianyОценок пока нет

- Life Lines of National Economy PDFДокумент5 страницLife Lines of National Economy PDFAlok Yadav57% (7)

- Ap20105 Acm 34 s3 Iom Final TestДокумент6 страницAp20105 Acm 34 s3 Iom Final TestRajdip SilОценок пока нет

- Audi Takes CVT From 15th Century To 21st Century: Tech BriefsДокумент3 страницыAudi Takes CVT From 15th Century To 21st Century: Tech BriefskarthikozyОценок пока нет

- The Five Cs of Neighborhood PlanningДокумент6 страницThe Five Cs of Neighborhood PlanningFadly Bron IbrahimОценок пока нет

- British MotorcycleДокумент12 страницBritish MotorcycleAditya Khare100% (1)

- Bridge Inspection and MaintenanceДокумент5 страницBridge Inspection and MaintenanceAmjid AfridiОценок пока нет

- Modern Steel Construction - May 2011 (True PDFДокумент76 страницModern Steel Construction - May 2011 (True PDFDanilo MiricОценок пока нет

- Meyer and Miller - Urban Transportation PlanningДокумент10 страницMeyer and Miller - Urban Transportation Planningmukoro ejiroОценок пока нет

- General Guide: FOR Industrial Lift TrucksДокумент16 страницGeneral Guide: FOR Industrial Lift TrucksibrahimОценок пока нет

- Shahjahanabad - Heritage CityДокумент23 страницыShahjahanabad - Heritage CityaanchalОценок пока нет

- Press Release Kochi - NationalДокумент2 страницыPress Release Kochi - NationalD229vОценок пока нет

- Division Department Tender Ref. No. Tender Opening Date Name of WorkДокумент55 страницDivision Department Tender Ref. No. Tender Opening Date Name of WorkkoolmanojsainiОценок пока нет

- Holsetpartnumbers 2008 PDFДокумент1 страницаHolsetpartnumbers 2008 PDFIvan Leong100% (1)

- Metro Construction UpdateДокумент12 страницMetro Construction UpdateMetro Los AngelesОценок пока нет

- Ted Talk Driverless Cars CLT Communicative Language Teaching Resources Conv - 105875Документ9 страницTed Talk Driverless Cars CLT Communicative Language Teaching Resources Conv - 105875SYLVIA RODRIGUEZ GONZALEZОценок пока нет

- Information Technology Implementation Across National Highways and Urban InfrastructureДокумент6 страницInformation Technology Implementation Across National Highways and Urban InfrastructureDhruv SuriОценок пока нет

- Evidence of PIPS November 13-19, 2013Документ11 страницEvidence of PIPS November 13-19, 2013Marc CalderonОценок пока нет

- CE 452 Transportation Engineering Sessional II (Manual) : Department of Civil EngineeringДокумент43 страницыCE 452 Transportation Engineering Sessional II (Manual) : Department of Civil EngineeringjulesОценок пока нет

- Shadowrun Mini Adventure enДокумент33 страницыShadowrun Mini Adventure enfnurket100% (2)

- Driving Licence UKДокумент20 страницDriving Licence UKnabilouche0% (2)

- Utilisation of Waste Plastic in Bituminous Mixes For Road ConstructionДокумент34 страницыUtilisation of Waste Plastic in Bituminous Mixes For Road Constructionshiva5059100% (4)

- Mid Term Exam 2Документ3 страницыMid Term Exam 2Refisa JiruОценок пока нет

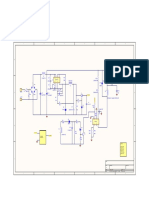

- Schematic For LED Driver IC BP2851Документ1 страницаSchematic For LED Driver IC BP2851ztxОценок пока нет

- Nasehat Bagi Pavement Engineer Vol-1Документ106 страницNasehat Bagi Pavement Engineer Vol-1sonysaza100% (1)

- Bus Inspection Report3-FullДокумент7 страницBus Inspection Report3-FullMc BagualОценок пока нет

- GSM RF Design GuidelinesДокумент20 страницGSM RF Design GuidelinesfitchedОценок пока нет