Академический Документы

Профессиональный Документы

Культура Документы

Sizing, Valve, Valve, Temperature, Control, KV, KVS, Pressure, Drop

Загружено:

Saif MhannaОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Sizing, Valve, Valve, Temperature, Control, KV, KVS, Pressure, Drop

Загружено:

Saif MhannaАвторское право:

Доступные форматы

Sizing, valve, valve, temperature, control, Kv, Kvs, pressure, drop

Coéfficient Kv, Kvs, Kvo, taux de fuite. Autorité de la vanne sur circuit hydraulique. Caractéristiques sur les vannes (linéaire,

quadratique, logarithmique, calorifique linéaire).

French site | Home | Thematic | Tables | Programs | Library | Download | Links | Contact | Forum |

_You are in the heading Wed Jan 27 09:49:43 UTC 2010

--

Control system temperature

Thematic

Quotation Determination of Kv

Euro

Margin

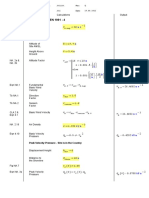

The value of Kv can be calculated according to the values given, such as: flow, Pressure drop and data of the

Hydraulic

operating conditions of the installation.

Linear pressure

loss

Local pressure ● Q = Flow rate (m3/h)

loss Liquids ● DP = Pressure drop (bar)

P2>PS

Compressible (water, etc.) ● r = Density (kg/dm3)

fluids

No circular duct

● G = Mass flow rate (kg/h)

Thermal P2>P2/2 ● DP = Pressure drop (bar)

Thermal fluid Saturated

● P2 = Pressure downstream of the valve (absolute bar)

flow steam

● P1= Pressure upstream of the valve (absolute bar)

Pipe sizing P2<P1/2

steam

Control valves ● G = Mass flow rate (kg/h)

Orifice plate P2>P2/2 ● DP =Pressure drop (bar)

Pumps ● P1= Pressure upstream of the valve (absolute bar)

Ventilators Superheated ● P2 = Pressure downstream of the valve (absolute bar)

Gas

steam ● v2 = Specific volume (m3/kg), under P2 and T1

Fuel gas

● v = Specific volume (m3/kg), under P1/2 et T1

P2<P1/2 ● T1 = Température en amont (K)

● Qn = Mass flow rate at 0°C and 1013 mbar (kg/h)

P2>P2/2 ● rn = Density of gas at 0°C and 1013 mbar (kg/Nm3)

● DP =Pressure drop (bar)

Gas ● P2 = Pressure downstream of the valve (absolute bar)

● P1= Pressure upstream of the valve (absolute bar)

P2<P1/2 ● T1 = Upstream temperature (K)

Le Kvs of the valve:

To characterize the standard valves, one gives a Kvs coefficient, which corresponds at the coefficient Kv for a

nominal displacement of H 100 of the valve

For each type of standard valve, one gives a nominal displacement of H100 for which the valve can be regarded as

completion open.

Le Kvo of the valve:

It is the leakage rate which crosses the valve if it presents a pressure loss of 1 bar (DPv =1 bar) when it is

completely closed. Kvo is expressed in m³/h.

Leakage rate

The leakage rate of a valve is the ratio Kvo / Kvs

For a new valve, this leakage rate must be lower than 0.05 %.

http://www.thermexcel.com/english/ressourc/valves.htm (1 of 4)1/27/2010 10:07:59 AM

Sizing, valve, valve, temperature, control, Kv, Kvs, pressure, drop

Coefficient of flow Kv for a valve

It is the flow of water Q in m3/h measured at 4°C (Density = 1000kg/m3) which for a pressure loss of 1 bar, passes

through the valve considered as entirely open.

A valve under dimensioned can generate a fall of pressure raised through of the device and can consequently

damage the seat of the valve by erosion.

Conversely a oversize control valve can involve an unstable operation of the installation.

For each type of valve, the manufacturer indicates a limit differential pressure acceptable which depends on its

diameter, of the method of construction, the power of the servo-motor, the temperature of the fluid, the leakage rate

and of the maximum flow which crosses it.

With:

● Q = Actual flow rate in m3/h at the temperature x

● r = Density of the water in kg/dm3 (depends on the temperature)

● DP = Pressure drop through the valve in bar

Pressure drop

It is the difference in pressure between the inlet and the outlet of the valve. It is thus its pressure loss.

The value of Kv in the same way is used to calculate the pressure drop in a valve according to the flow which

crosses it.

With:

● Q = Actual water Flow in m3/h at temperature x

● r = Density of the water in kg/dm3 (depends on the temperature)

● DP = Pressure drop through the valve in bar

Authority of the valve

The principal function of a control valve is to ensure the progressiveness of a flow. It is the authority of the valve

which will determine the stability of the control system.

This progressiveness will be quantified by the authority of the valve.

● DPv = Pressure loss of the entirely open valve for the nominal capacity l

● DPL = Pressure loss of the variable flow circuit.

http://www.thermexcel.com/english/ressourc/valves.htm (2 of 4)1/27/2010 10:07:59 AM

Sizing, valve, valve, temperature, control, Kv, Kvs, pressure, drop

Changeable flow rates Mix flow rate Circuit de répartition

● E = Generator of heat

● V = Emetteur de chaleur - Transmitting of heat

Characteristics of the valves

Valve at linear characteristic

The best progressiveness of the thermal power is obtained when the valve has an authority, has = 1. It

is unthinkable to choose this value; therefore progressiveness will be poor with this type of valve.

To use this type of valve in cpntrol system, it would be necessary to regulate the proportional tape to

a very high value. This valve cannot be used in progressive control.

Valve with square-law characteristic - Vanne à caractéristique quadratique

Best progressiveness would be obtained for an authority, a = 1. But however for A = 0.5, the

authority of the valve not being linear can in spite of very given satisfaction. If the total head of the

pump allows it, there would be interest to give an authority for example from 0.6 to 0.7

Valve with characteristic logarithmic curve

http://www.thermexcel.com/english/ressourc/valves.htm (3 of 4)1/27/2010 10:07:59 AM

Sizing, valve, valve, temperature, control, Kv, Kvs, pressure, drop

In this type of valve, the displacement of the valve produces a variation of flow proportional to the

preceding total flow the change. The best progressiveness of power is obtained for 0.6 to 0.7.

Valve at linear calorific power

In this type of valve the manufacturer designed the valve in order to obtain a calorific power

proportional to the lifting of the valve, for an authority has = 0.5. A too large authority would have

the same harmful effect as a too small authority.

Last update: 01/27/2010 09:49:43

Copyright © 2003-2004 - ThermExcel - All Rights Reserved

http://www.thermexcel.com/english/ressourc/valves.htm (4 of 4)1/27/2010 10:07:59 AM

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Control Valve Sizing eДокумент4 страницыControl Valve Sizing eAndres Jr QuiambaoОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- A Bms Client and Gateway Using Bacnet Protocol: Abstract. A Building Management System (BMS) Is A Computer-Based ControlДокумент2 страницыA Bms Client and Gateway Using Bacnet Protocol: Abstract. A Building Management System (BMS) Is A Computer-Based ControlMuhammad Hammad RashidОценок пока нет

- Rs 485 SpecДокумент3 страницыRs 485 SpecSaif MhannaОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- RS845, RS232 PDFДокумент5 страницRS845, RS232 PDFsteam100deg1658Оценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Bacnet™ and Lonworks: A White Paper: David Fisher, Polarsoft Inc. July 1996Документ13 страницBacnet™ and Lonworks: A White Paper: David Fisher, Polarsoft Inc. July 1996Saif MhannaОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- E 49 G 7 ContentДокумент34 страницыE 49 G 7 ContentrajimuruganОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- BACnet, LonMark and Modbus - How and Why They WorkДокумент5 страницBACnet, LonMark and Modbus - How and Why They WorkSaif MhannaОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Bom 4 98 PDFДокумент2 страницыBom 4 98 PDFSaif MhannaОценок пока нет

- Smart Buildings - BACnet vs. LonWorksДокумент3 страницыSmart Buildings - BACnet vs. LonWorksSaif MhannaОценок пока нет

- HVAC ManualДокумент107 страницHVAC ManualWissam JarmakОценок пока нет

- Viewpoint:: Bacnet Versus LonworksДокумент3 страницыViewpoint:: Bacnet Versus LonworksSaif MhannaОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- What Is Bacnet?: The Development of BacnetДокумент4 страницыWhat Is Bacnet?: The Development of BacnetSaif MhannaОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Degrees of FreedomДокумент9 страницDegrees of FreedomReyner LozaОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Formulas and Reference Chart EocДокумент3 страницыFormulas and Reference Chart Eocapi-87739323Оценок пока нет

- Module 2 Kinematics in One DimensionДокумент9 страницModule 2 Kinematics in One DimensionNina GalesteОценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- 2012 Polymer-Composite Materials For Radiation ProtectionДокумент10 страниц2012 Polymer-Composite Materials For Radiation Protectionduque_stradaОценок пока нет

- A Closed Form Ula For The Riemann Normal Coordinate ExpansionДокумент10 страницA Closed Form Ula For The Riemann Normal Coordinate ExpansionGabriel GomezОценок пока нет

- Universiti Malaysia Perlis: EQT 102 Engineering Mathematics II (Matematik Kejuruteraan II)Документ7 страницUniversiti Malaysia Perlis: EQT 102 Engineering Mathematics II (Matematik Kejuruteraan II)lailarry321Оценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Acoustics of Buildings: Applications in The PentagonДокумент5 страницAcoustics of Buildings: Applications in The PentagonMudrikaОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- DELTA VFD-MS300 ManualДокумент512 страницDELTA VFD-MS300 ManualDavidОценок пока нет

- Friction &belt DrivesДокумент55 страницFriction &belt Drivesshubhaastro2827Оценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Pressure DistributionДокумент3 страницыPressure DistributionMahadevanОценок пока нет

- Lecture Notes: Electrical MachinesДокумент148 страницLecture Notes: Electrical MachinesRayan NezarОценок пока нет

- Technical Service Systems I (GSE366a) Acoustics and IlluminationДокумент23 страницыTechnical Service Systems I (GSE366a) Acoustics and Illuminationahmed madoooОценок пока нет

- Plasma AntennaДокумент9 страницPlasma Antennaleena999Оценок пока нет

- Lecture 4 - Free EnergyДокумент16 страницLecture 4 - Free EnergyyudhiprasetyoОценок пока нет

- Flywheel Moment of InertiaДокумент3 страницыFlywheel Moment of InertiaLuis AfonsoОценок пока нет

- Wind Loads Is en 1991-1-4Документ1 страницаWind Loads Is en 1991-1-4David O'MearaОценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- 107D Iv Feg 05a 00012Документ68 страниц107D Iv Feg 05a 00012vinayak jadhavОценок пока нет

- Q2 Lesson 1Документ43 страницыQ2 Lesson 1Sheena AragoОценок пока нет

- WPH01 01 Rms 20180308 2 PDFДокумент17 страницWPH01 01 Rms 20180308 2 PDFAtik MahmudОценок пока нет

- Laporan Kerja Ptaktik Pabrik Gula BungamayangДокумент81 страницаLaporan Kerja Ptaktik Pabrik Gula BungamayangArdiSaputraОценок пока нет

- T.E. (Electrical) (Semester - II) Power System - IIДокумент4 страницыT.E. (Electrical) (Semester - II) Power System - IIShubham KaklijОценок пока нет

- Calculus of Vector Valued FunctionsДокумент18 страницCalculus of Vector Valued FunctionsDilo Tan100% (1)

- Acceleration vs. Time GraphДокумент16 страницAcceleration vs. Time Graphlea pagusaraОценок пока нет

- CFD Analysis of Liquid-Liquid Extraction Pulsed ColumnДокумент6 страницCFD Analysis of Liquid-Liquid Extraction Pulsed ColumnArunОценок пока нет

- Donor, and A: Group V Valence Electrons N-Type Semiconductor Group III P-Type Semiconductor Group V Group III DiodeДокумент1 страницаDonor, and A: Group V Valence Electrons N-Type Semiconductor Group III P-Type Semiconductor Group V Group III DiodeMuhammad Saad ArshadОценок пока нет

- Dynamic High School: Form Iii Terminal Exam - August 2021 PhysicsДокумент6 страницDynamic High School: Form Iii Terminal Exam - August 2021 PhysicsJoshuaОценок пока нет

- 0102 Physics Paper With Answer EveningДокумент5 страниц0102 Physics Paper With Answer EveningDeepakОценок пока нет

- Tray Dryer PDFДокумент3 страницыTray Dryer PDFAlshreef AljeelanyОценок пока нет

- Solar Energy FundamentalsДокумент25 страницSolar Energy FundamentalsAvinesh ChandОценок пока нет

- Radiation From Apertures: 17.1 Field Equivalence PrincipleДокумент33 страницыRadiation From Apertures: 17.1 Field Equivalence PrincipleMookambiga ParvathyОценок пока нет