Академический Документы

Профессиональный Документы

Культура Документы

MME 2010 Contents and Introduction PDF

Загружено:

AmaraaZoyaОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

MME 2010 Contents and Introduction PDF

Загружено:

AmaraaZoyaАвторское право:

Доступные форматы

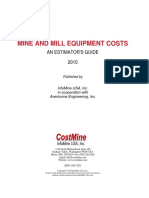

MINE AND MILL EQUIPMENT COSTS

AN ESTIMATOR'S GUIDE

2010

Published by

InfoMine USA, Inc.

in cooperation with

Aventurine Engineering, Inc.

1120 North Mullan Road, Suite 100

Spokane Valley, Washington 99206 USA

Phone (509) 328-8023 • Fax (509) 328-2028

Email: info@costmine.com

Website: www.costmine.com

ISSN 1536-7282

Copyright © 2010 InfoMine USA, Inc.

No part of this book may be reproduced in any form or by any process

without written permission from InfoMine USA, Inc.

CONTENTS

Page Surface Mining Equipment (continued)

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v Transporters, Wheeled . . . . . . . . . . . . . . . . . . SU 34

Trucks, Bottom Dump,

Surface Mining Equipment Coal Haulers, Mechanical . . . . . . . . . . . . . SU 34

Backhoes, Hydraulic . . . . . . . . . . . . . . . . . . . . SU 2 Trucks, Bottom Dump, Mechanical . . . . . . . . SU 34

Blocks, Dragline/Dredge . . . . . . . . . . . . . . . . . SU 4 Trucks, Flatbed . . . . . . . . . . . . . . . . . . . . . . . SU 34

Bucketwheel Excavators . . . . . . . . . . . . . . . . . SU 4 Trucks, 4 Wheel Drive . . . . . . . . . . . . . . . . . . SU 36

Cars, Railroad . . . . . . . . . . . . . . . . . . . . . . . . . . SU 6 Trucks, Rear Dump, Articulated,

Cars, Railroad, Covers . . . . . . . . . . . . . . . . . . . SU 6 Mechanical Drive . . . . . . . . . . . . . . . . . . . SU 36

Compactors . . . . . . . . . . . . . . . . . . . . . . . . . . . SU 6 Trucks, Rear Dump, Rigid Frame . . . . . . . . . SU 38

Compactors, Self-Propelled, Roller . . . . . . . . . SU 6 Trucks, Rear Dump, Highway . . . . . . . . . . . . SU 40

Compactors, Self-Propelled Sheepsfoot . . . . . . SU 6 Trucks, Service . . . . . . . . . . . . . . . . . . . . . . . . SU 40

Compressors, Portable . . . . . . . . . . . . . . . . . . . SU 8 Trucks, Shot Loader . . . . . . . . . . . . . . . . . . . . SU 42

Continuous Miners, Boom-Type (Roadheader) . SU 8 Trucks, Water . . . . . . . . . . . . . . . . . . . . . . . . . SU 42

Continuous Miners, Surface Drum-Type . . . . . SU 8

Cranes, Hydraulic . . . . . . . . . . . . . . . . . . . . . . . SU 8 Appendix A -

Dozers (see Tractors, Crawler) Surface Mining Equipment

Draglines, Crawler . . . . . . . . . . . . . . . . . . . . . SU 10 Additional Information

Draglines, Walking . . . . . . . . . . . . . . . . . . . . SU 10

Dredges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . SU 10 Underground Mining Equipment

Dredges, Cutterhead . . . . . . . . . . . . . . . . . . . . SU 12 Battery Chargers, Cap Lamp . . . . . . . . . . . . . UG 2

Drills, Percussion Crawler . . . . . . . . . . . . . . . SU 12 Battery Chargers, Locomotive . . . . . . . . . . . . UG 2

Drills, Reverse Circulation . . . . . . . . . . . . . . . SU 12 Cars, Rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . UG 2

Drills, Rotary Crawler . . . . . . . . . . . . . . . . . . SU 14 Chargers, Bulk Explosive . . . . . . . . . . . . . . . UG 4

Drills, Rotary, Truck Mounted Blasthole . . . . SU 14 Clarification Systems . . . . . . . . . . . . . . . . . . . UG 4

Excavators, Wheeled . . . . . . . . . . . . . . . . . . . SU 16 Communication System, Underground,

Graders (with ripper/scarifier) . . . . . . . . . . . . SU 16 Voice and Data . . . . . . . . . . . . . . . . . . . . . . UG 4

Haulage Dispatch System, Computerized . . . SU 18 Compressors, Low Profile . . . . . . . . . . . . . . . UG 4

Highwall Miner . . . . . . . . . . . . . . . . . . . . . . . SU 18 Concrete Pumps . . . . . . . . . . . . . . . . . . . . . . . UG 6

Hydraulic Mining Systems . . . . . . . . . . . . . . . SU 20 Continuous Haulage, Belt Conveyor Systems:

Impact Hammer, Mobile . . . . . . . . . . . . . . . . SU 20 Belt Storage Units . . . . . . . . . . . . . . . . . . . . UG 6

Loaders, Crawler . . . . . . . . . . . . . . . . . . . . . . SU 20 Bridge Conveyors . . . . . . . . . . . . . . . . . . . . UG 6

Loaders, Skid Steer . . . . . . . . . . . . . . . . . . . . SU 22 Chain-Type Transfer Conveyors . . . . . . . . . UG 6

Loaders, Wheel . . . . . . . . . . . . . . . . . . . . . . . SU 22 Crawler-Mounted Belt Tailpiece . . . . . . . . . UG 6

Locomotives . . . . . . . . . . . . . . . . . . . . . . . . . . SU 22 Mobile Bridge Carrier . . . . . . . . . . . . . . . . . UG 6

Scrapers, Coal . . . . . . . . . . . . . . . . . . . . . . . . SU 24 Complete Eight Unit Continuous Haulage

Scrapers, Elevating . . . . . . . . . . . . . . . . . . . . SU 24 System with Feeder Breaker . . . . . . . . . UG 6

Scrapers, Standard . . . . . . . . . . . . . . . . . . . . . SU 24 Continuous Miners . . . . . . . . . . . . . . . . . . . . . . UG 8

Scrapers, Tandem, Push-Pull . . . . . . . . . . . . . SU 24 Continuous Miners, Dintheader-Type . . . . . . . UG 8

Scrapers, Towed . . . . . . . . . . . . . . . . . . . . . . . SU 24 Continuous Miners, Boom-type (Roadheaders) UG 10

Shovels, Cable . . . . . . . . . . . . . . . . . . . . . . . . SU 26 Conveyor Feeder-Breakers . . . . . . . . . . . . . . UG 10

Shovels, Hydraulic . . . . . . . . . . . . . . . . . . . . . SU 28 Drilling Equipment:

Tractors, Crawler (with ripper) . . . . . . . . . . . SU 30 Light Rock Drills

Tractors, Off-Highway Hauler . . . . . . . . . . . . SU 30 Airleg Drills . . . . . . . . . . . . . . . . . . . . . . UG 12

Tractors, Wheel . . . . . . . . . . . . . . . . . . . . . . . SU 30 Sinker Drills . . . . . . . . . . . . . . . . . . . . . . UG 12

Trailers, Rear-Dump Haulers . . . . . . . . . . . . . SU 30 Stoper Drills . . . . . . . . . . . . . . . . . . . . . . UG 12

Trailers, Rear-Dump Highway Haulers . . . . . SU 30 Airlegs (for above drills) . . . . . . . . . . . . UG 12

Trailers, Side Tilt . . . . . . . . . . . . . . . . . . . . . . SU 32 Drifters, Pneumatic . . . . . . . . . . . . . . . . . . UG 12

Trailers, Utility Tilt-Deck . . . . . . . . . . . . . . . SU 32 Drifters, Hydraulic . . . . . . . . . . . . . . . . . . . UG 14

Transporters Crawler . . . . . . . . . . . . . . . . . . . SU 32

Page

i Copyright © 2010 InfoMine USA, Inc.

CONTENTS

Page Page

Underground Mining Equipment (continued) Underground Mining Equipment (continued)

Drilling Equipment: (continued) Utility Vehicles, Underground: (continued)

Drifter Feeds . . . . . . . . . . . . . . . . . . . . . . UG 14 Lube Truck . . . . . . . . . . . . . . . . . . . . . . . . UG 50

Drifter Feeds, Telescoping . . . . . . . . . . . . . UG 14 Scissors Lift Truck . . . . . . . . . . . . . . . . . . UG 50

Jumbos, Rubber-Tired Drifting ANFO Loader Truck . . . . . . . . . . . . . . . . . UG 50

and Tunneling Rigs . . . . . . . . . . . . . . . . UG 14 Personnel Carrier . . . . . . . . . . . . . . . . . . . . UG 50

Complete Blasthole Drilling Systems . . . . UG 14 Crane Truck . . . . . . . . . . . . . . . . . . . . . . . . UG 50

Large Blasthole Drilling Components Low Profile, Articulated,

Down-the-hole Drill Rigs . . . . . . . . . . . UG 16 Multipurpose Diesel Engine . . . . . . . . . . UG 50

Down-the-hole Drill Hammers . . . . . . . UG 16 Ventilation Equipment, Axial Fans . . . . . . . . UG 52

Booster Compressors . . . . . . . . . . . . . . . UG 16 Ventilation Equipment Auxiliary Fans . . . . . UG 54

Coal Face Drills . . . . . . . . . . . . . . . . . . . . . UG 16

Grout Plants . . . . . . . . . . . . . . . . . . . . . . . . . . UG 16 Appendix B -

Load-Haul-Dump and Coal Underground Mining Equipment - U.S. Standard

Scoop Tractors . . . . . . . . . . . . . . . . . . . . . UG 18 Underground Mining Equipment - Metric

Loaders, Continuous . . . . . . . . . . . . . . . . . . . UG 20 Additional Information

Loaders, Overhead Shovel . . . . . . . . . . . . . . . UG 20

Loaders, Overhead Shovel Autoloader . . . . . UG 20 Milling Equipment

Locomotives, Coal, Diesel . . . . . . . . . . . . . . . UG 20 Air Separators . . . . . . . . . . . . . . . . . . . . . . . . Mill 2

Locomotives, Diesel . . . . . . . . . . . . . . . . . . . . UG 22 Alluvial Mineral Treatment Plants . . . . . . . . . Mill 4

Locomotives, Noncoal, Battery . . . . . . . . . . UG 22 Bag Packing Machines . . . . . . . . . . . . . . . . . . Mill 4

Locomotives, Noncoal, Trolley . . . . . . . . . . . UG 24 Bag Palletizing Machines . . . . . . . . . . . . . . . . Mill 4

Longwall Mining Systems: Bag Placing Machines . . . . . . . . . . . . . . . . . . Mill 4

Longwall Shearers . . . . . . . . . . . . . . . . . . . UG 26 Blowers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Mill 6

Face Shields . . . . . . . . . . . . . . . . . . . . . . . . UG 26 Briquetting Machines . . . . . . . . . . . . . . . . . . . Mill 6

Shield Transporter . . . . . . . . . . . . . . . . . . . UG 26 Carbon Stripping Systems . . . . . . . . . . . . . . . Mill 6

Armored Face Conveyor . . . . . . . . . . . . . . . UG 26 Centrifuges . . . . . . . . . . . . . . . . . . . . . . . . . . . Mill 8

Mobile Roof Supports . . . . . . . . . . . . . . . . . UG 26 Classifiers, Screw . . . . . . . . . . . . . . . . . . . . . . Mill 8

Longwall Shield Retrievers . . . . . . . . . . . . . . UG 28 Coal Breaker . . . . . . . . . . . . . . . . . . . . . . . . Mill 10

Mine Hoists . . . . . . . . . . . . . . . . . . . . . . . . . . UG 28 Compactor, Drum . . . . . . . . . . . . . . . . . . . . . Mill 10

Mine Hoists, Rack and Pinion . . . . . . . . . . . . UG 32 Conveyors, Screw . . . . . . . . . . . . . . . . . . . . Mill 10

Raise Boring Machines . . . . . . . . . . . . . . . . . UG 32 Crushers, Double Roll . . . . . . . . . . . . . . . . . Mill 12

Raise Climber . . . . . . . . . . . . . . . . . . . . . . . . . UG 40 Crushers, Gyratory . . . . . . . . . . . . . . . . . . . . Mill 12

Rock Dusters . . . . . . . . . . . . . . . . . . . . . . . . . UG 40 Crushers, Standard Hammermill . . . . . . . . . Mill 12

Roof Bolters . . . . . . . . . . . . . . . . . . . . . . . . . . UG 40 Crushers, Coal, Reversible Hammermill . . . Mill 14

Scaler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . UG 42 Crushers, Coal, Roll . . . . . . . . . . . . . . . . . . . Mill 14

Scraper Hoists, Electric . . . . . . . . . . . . . . . . . UG 42 Crushers, Reversible Hammermill . . . . . . . . Mill 14

Shaft Cutting Machines . . . . . . . . . . . . . . . . . UG 42 Crushers, Non-clogging Hammermill . . . . . Mill 16

Shotcreting Systems . . . . . . . . . . . . . . . . . . . . UG 44 Crushers, Jaw, Double Toggle . . . . . . . . . . . Mill 16

Shuttle Cars . . . . . . . . . . . . . . . . . . . . . . . . . . UG 44 Crushers, Jaw, Single Toggle . . . . . . . . . . . . Mill 18

Slusher Blocks . . . . . . . . . . . . . . . . . . . . . . . . UG 44 Crushers, Shorthead Cone . . . . . . . . . . . . . . Mill 18

Slusher Buckets . . . . . . . . . . . . . . . . . . . . . . . UG 46 Crushers, Shorthead Cone, Heavy Duty . . . Mill 18

Transmixers . . . . . . . . . . . . . . . . . . . . . . . . . . UG 46 Crushers, Single Rotor Impact . . . . . . . . . . . Mill 20

Trucks, Underground Ore Crushers, Standard Cone . . . . . . . . . . . . . . . Mill 20

and Coal Haulers . . . . . . . . . . . . . . . . . . . . UG 46 Crushers, Standard Cone, Heavy Duty . . . . Mill 20

Tuggers, Air Powered Winches . . . . . . . . . . . UG 48 Crushing/Screening Plants, Portable . . . . . . Mill 22

Tunnel Boring Machines . . . . . . . . . . . . . . . . UG 48 Cyanide Analyzer . . . . . . . . . . . . . . . . . . . . . Mill 22

Utility Vehicles, Underground: Cyclones, Wet, Coal . . . . . . . . . . . . . . . . . . . Mill 24

Service Truck . . . . . . . . . . . . . . . . . . . . . . UG 50 Cyclones, Wet, Mineral . . . . . . . . . . . . . . . . Mill 24

ii Copyright © 2010 InfoMine USA, Inc.

CONTENTS

Page Page

Milling Equipment (continued) Milling Equipment (continued)

Density Separator . . . . . . . . . . . . . . . . . . . . . Mill 26 Mixers, Small

Drives (See Mill Drives, Reducers) Closed Tank . . . . . . . . . . . . . . . . . . . . . . . Mill 64

Drum Fillers . . . . . . . . . . . . . . . . . . . . . . . . . Mill 28 Open Tank . . . . . . . . . . . . . . . . . . . . . . . . Mill 64

Dryers, Rotary Gas-Fired . . . . . . . . . . . . . . . Mill 28 Pelletizers, Disk . . . . . . . . . . . . . . . . . . . . . . Mill 66

Electrostatic Separators . . . . . . . . . . . . . . . . Mill 28 Pelletizers, Drum . . . . . . . . . . . . . . . . . . . . . Mill 66

Electrowinning Cells . . . . . . . . . . . . . . . . . . Mill 30 Placer Gold Washing Units . . . . . . . . . . . . . Mill 68

Feed Distributors . . . . . . . . . . . . . . . . . . . . . Mill 30 Pug Mill Agglomerators . . . . . . . . . . . . . . . . Mill 68

Feeders, Apron . . . . . . . . . . . . . . . . . . . . . . . Mill 32 Reagent Feeders . . . . . . . . . . . . . . . . . . . . . . Mill 68

Feeders, Belt . . . . . . . . . . . . . . . . . . . . . . . . . Mill 34 Retorts, Mercury . . . . . . . . . . . . . . . . . . . . . Mill 70

Feeders, Vibrating . . . . . . . . . . . . . . . . . . . . Mill 34 Scalpers, Coal . . . . . . . . . . . . . . . . . . . . . . . . Mill 70

Feeders, Wobbler . . . . . . . . . . . . . . . . . . . . . Mill 34 Screens, Dewatering/Desliming . . . . . . . . . . Mill 70

Fillers, Bulk Bag . . . . . . . . . . . . . . . . . . . . . Mill 36 Screens, Trommel . . . . . . . . . . . . . . . . . . . . Mill 70

Filters, Belt Filter Press . . . . . . . . . . . . . . . . Mill 36 Screens, Trommel, Mobile . . . . . . . . . . . . . . Mill 72

Filters, Disk . . . . . . . . . . . . . . . . . . . . . . . . . Mill 36 Screens, Vibrating:

Filters, Plate and Frame Pressure . . . . . . . . . Mill 38 Horizontal Screens . . . . . . . . . . . . . . . . . . Mill 72

Filters, Rotary Drum . . . . . . . . . . . . . . . . . . Mill 38 Inclined Screens, Standard . . . . . . . . . . . Mill 74

Filters, Tube Press Dewatering . . . . . . . . . . Mill 38 Inclined Screens, Scalping . . . . . . . . . . . . Mill 76

Flotation Machines, Column . . . . . . . . . . . . Mill 40 Inclined Screens, Heavy Duty . . . . . . . . . Mill 78

Flotation Machines, Self-Aerating . . . . . . . . Mill 40 Scrubbers, Wet . . . . . . . . . . . . . . . . . . . . . . . Mill 82

Flotation Machines, Standard . . . . . . . . . . . Mill 42 Sieves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Mill 82

Furnaces, Melt . . . . . . . . . . . . . . . . . . . . . . . Mill 42 Sluice Boxes, Magnetic . . . . . . . . . . . . . . . . Mill 82

Gold Concentrator, Centrifugal . . . . . . . . . . Mill 42 Sluice Boxes, Standard . . . . . . . . . . . . . . . . Mill 84

Grinding Mills, Rod and Ball . . . . . . . . . . . . Mill 44 Solution Heaters . . . . . . . . . . . . . . . . . . . . . . Mill 84

Grinding Mills, Roller . . . . . . . . . . . . . . . . . Mill 46 Spiral Concentrators . . . . . . . . . . . . . . . . . . . Mill 86

Grinding Mills, Semi-Autogenous (SAG) . . Mill 46 Stretch Wrapping Systems . . . . . . . . . . . . . . Mill 86

Grinding Mills, Vertically Stirred (Tower) . Mill 48 Tables, Concentrating . . . . . . . . . . . . . . . . . Mill 86

Grinding Mill Liner Cranes . . . . . . . . . . . . . Mill 48 Tanks, Cyanidation, Steel . . . . . . . . . . . . . . Mill 88

Grinding Mill Rod Chargers . . . . . . . . . . . . Mill 48 Thickeners . . . . . . . . . . . . . . . . . . . . . . . . . . Mill 88

Grizzlies, Vibrating . . . . . . . . . . . . . . . . . . . Mill 50 Vacuum Pumps . . . . . . . . . . . . . . . . . . . . . . Mill 88

Heavy Media Vessels . . . . . . . . . . . . . . . . . . Mill 50

Hoppers, Feed . . . . . . . . . . . . . . . . . . . . . . . Mill 50 Appendix C -

Impact Hammers, Pedestal Mounted . . . . . . Mill 52 Milling Equipment - U.S. Standard

Jigs, Baum . . . . . . . . . . . . . . . . . . . . . . . . . . Mill 54 Milling Equipment - Metric

Jigs, Bendelari . . . . . . . . . . . . . . . . . . . . . . . Mill 54 Additional Information

Jigs, Circular (Radial) . . . . . . . . . . . . . . . . . Mill 56

Jigs, Duplex . . . . . . . . . . . . . . . . . . . . . . . . . Mill 56 Miscellaneous Equipment

Jigs, Fine Coal . . . . . . . . . . . . . . . . . . . . . . . Mill 58 Analyzers . . . . . . . . . . . . . . . . . . . . . . . . . . . Misc 2

Jigs, Shot Separator . . . . . . . . . . . . . . . . . . . Mill 58 Bin, Storage . . . . . . . . . . . . . . . . . . . . . . . . . Misc 2

Kilns, Direct-fired Rotary Bucket Elevators . . . . . . . . . . . . . . . . . . . . . Misc 2

Carbon Regeneration . . . . . . . . . . . . . . . . Mill 58 Buildings . . . . . . . . . . . . . . . . . . . . . . . . . . . Misc 2

Kilns, Indirect-fired Rotary Catalytic Diesel Filters . . . . . . . . . . . . . . . . . Misc 4

Carbon Regeneration . . . . . . . . . . . . . . . . Mill 58 Compressors, Booster . . . . . . . . . . . . . . . . . Misc 6

Magnetic Separators . . . . . . . . . . . . . . . . . . . Mill 60 Compressors, Centrifugal, Stationary . . . . . Misc 6

Mill Drivers, Gearless . . . . . . . . . . . . . . . . . Mill 62 Compressors, Shop, Stationary . . . . . . . . . . Misc 6

(Also see Reducers in Miscellaneous Section) Compressors, Rotary Screw, Stationary . . . . Misc 8

Mixers, Large Controller, Variable rpm, Electric Motor . . Misc 8

Closed Tank . . . . . . . . . . . . . . . . . . . . . . . Mill 64 Conveyor Magnet . . . . . . . . . . . . . . . . . . . . Misc 10

Open Tank . . . . . . . . . . . . . . . . . . . . . . . . Mill 64 Conveyors, In-Pit . . . . . . . . . . . . . . . . . . . . Misc 12

iii Copyright © 2010 InfoMine USA, Inc.

CONTENTS

Page Page

Miscellaneous Equipment (continued) Miscellaneous Equipment (continued)

Conveyors, Overland . . . . . . . . . . . . . . . . . Misc 16 Pumps, Centrifugal Trash . . . . . . . . . . . . . Misc 78

Conveyor, Portable Jump . . . . . . . . . . . . . . Misc 20 Pumps, Fuel . . . . . . . . . . . . . . . . . . . . . . . . Misc 78

Conveyors, Process Plant . . . . . . . . . . . . . . Misc 22 Pumps, Metering . . . . . . . . . . . . . . . . . . . . Misc 80

Conveyor, Scales . . . . . . . . . . . . . . . . . . . . Misc 26 Pumps, Process, Heavy Duty . . . . . . . . . . . Misc 80

Cranes, Overhead Traveling Bridge . . . . . . Misc 26 Pumps, Process, Medium Duty . . . . . . . . . Misc 82

Diamond Drill Equipment: Pumps, Slurry, Heavy Duty . . . . . . . . . . . . Misc 84

Diamond Drills . . . . . . . . . . . . . . . . . . . Misc 28 Pumps, Slurry, Medium Duty . . . . . . . . . . Misc 86

Drill Pumps . . . . . . . . . . . . . . . . . . . . . . Misc 28 Pumps, Submersible Permissible . . . . . . . . Misc 88

Core Barrels . . . . . . . . . . . . . . . . . . . . . . Misc 28 Pumps, Submersible . . . . . . . . . . . . . . . . . . Misc 88

Wireline . . . . . . . . . . . . . . . . . . . . . . . . . Misc 30 Pumps, Vertical . . . . . . . . . . . . . . . . . . . . . Misc 90

Drives (See Reducers in Mill Drives) Pumps, Water Well . . . . . . . . . . . . . . . . . . Misc 90

Dust Collectors, Bag Filter . . . . . . . . . . . . . Misc 30 Rail Car Dumpers . . . . . . . . . . . . . . . . . . . . Misc 92

Dust Collectors, Bin . . . . . . . . . . . . . . . . . . Misc 30 Rail Car Movers . . . . . . . . . . . . . . . . . . . . . Misc 92

Dust Collectors, Wet Scrubber . . . . . . . . . . Misc 32 Reducers:

Electrical Equipment . . . . . . . . . . . . . . . . . Misc 34 Concentric Reducer . . . . . . . . . . . . . . . . Misc 92

Electric Motors, AC: Geared Parallel Shaft Reducers . . . . . . . Misc 94

Standard Protected Motors . . . . . . . . . . Misc 38 Screw Conveyor Reducer . . . . . . . . . . . Misc 94

Totally Enclosed Motors . . . . . . . . . . . . Misc 42 Shaft Mounted Reducers . . . . . . . . . . . . Misc 96

Totally Enclosed Explosion-Proof . . . . Misc 46 Worm Gear Reducers . . . . . . . . . . . . . Misc 100

Electric Motors, AC Crusher Duty: Samplers, Automatic Belt . . . . . . . . . . . . Misc 102

Totally Enclosed Fan Cooled Motors . . Misc 50 Samplers, Automatic Slurry . . . . . . . . . . . Misc 102

Electric Motors, DC: Scales, Truck (See Truck Scales)

Drip-proof – Guarded Motors . . . . . . . . Misc 52 Spill Berms . . . . . . . . . . . . . . . . . . . . . . . . Misc 102

Totally Enclosed Motors . . . . . . . . . . . . Misc 56 Stackers, Conveyor . . . . . . . . . . . . . . . . . Misc 104

Totally Enclosed Explosion-Proof . . . . Misc 60 Stacking Tubes . . . . . . . . . . . . . . . . . . . . . Misc 104

Electric Motors, DC Variable Speed . . . . . Misc 62 Stackers, Portable Conveyor . . . . . . . . . . Misc 106

Electric Power Transmission Lines . . . . . . Misc 64 Tanks, Bladder . . . . . . . . . . . . . . . . . . . . . Misc 106

Engines, Diesel . . . . . . . . . . . . . . . . . . . . . . Misc 66 Tanks, Heavy Duty Cylindrical . . . . . . . . Misc 106

Evaporators, Tailings Pond . . . . . . . . . . . . Misc 66 Tanks, Horizontal Pressure . . . . . . . . . . . Misc 108

Explosive Storage Bins . . . . . . . . . . . . . . . Misc 66 Tanks, Polyethylene . . . . . . . . . . . . . . . . . Misc 108

Explosive Storage Magazines . . . . . . . . . . Misc 68 Tanks, Steel . . . . . . . . . . . . . . . . . . . . . . . Misc 110

Generator Sets, Diesel Tanks, Steel, Fuel . . . . . . . . . . . . . . . . . . . Misc 110

and Gasoline Powered . . . . . . . . . . . . . . Misc 70 Tanks, Water / Liquid Storage . . . . . . . . . Misc 112

Generator Sets, Gas Turbine . . . . . . . . . . . Misc 70 Truck Scales . . . . . . . . . . . . . . . . . . . . . . . Misc 116

Grinders, Drill Bit . . . . . . . . . . . . . . . . . . . Misc 72 Vacuum Tank, Clean Up . . . . . . . . . . . . . Misc 116

Heat Exchanger-Shell and Tube Type . . . . Misc 72

Heaters, Portable Diesel . . . . . . . . . . . . . . . Misc 72 Appendix D -

Hoists, Overhead Trolley . . . . . . . . . . . . . . Misc 72 Miscellaneous Equipment - U.S. Standard

Laboratory Equipment . . . . . . . . . . . . . . . . Misc 74 Miscellaneous Equipment - Metric

Lights, Portable Diesel . . . . . . . . . . . . . . . . Misc 76 Advisor Group

Lime Slaking Plant . . . . . . . . . . . . . . . . . . . Misc 76

Log Washers . . . . . . . . . . . . . . . . . . . . . . . Misc 76

Parts Washers, Power . . . . . . . . . . . . . . . . . Misc 78

Pipe Equipment . . . . . . . . . . . . . . . . . . . . . Misc 78

iv Copyright © 2010 InfoMine USA, Inc.

INTRODUCTION

The Mine and Mill Equipment Cost Guide provides estimators with an exhaustive list of the capital and hourly costs

associated with owning and operating equipment typically used in mining and mineral processing operations. Unit

commodity prices and capital costs found in the Guide are determined by annual surveys of equipment

manufacturers and distributors; fuel, energy, tire, and lubricant suppliers; and U.S. mining companies. Most of the

capital costs in the manual are list or budgeting prices for specific standard-equipped models. The models are

identified by specifications only, without mention of manufacturers' names. This approach prevents utilization of

the manual for promotional purposes and also prevents conflicts between buyers and sellers of items listed in the

manual. Our purpose in publishing these values is to provide information for estimating purposes only, not to

establish market values for the items. Prices contained in this edition of the Guide were collected from June 2010

through September 2010.

Hourly costs are determined by established computational procedures suitable for preliminary engineering estimates.

These procedures are described in more detail below. Additional specification and productivity information for

some of the equipment is provided in the appendices following each section.

Equipment operating costs can vary considerable from mine to mine, and should be adjusted for local conditions.

The paragraphs that follow provide some guidance for doing this. If the operating costs are to be used for contract

bid estimates, company overhead and profit must be added to the hourly costs listed in the Guide.

InfoMine maintains a continuing data collection program to increase the statistical basis for the factors used to

estimate the operating costs. Users are encouraged to submit relevant data from their own operating experience or

to submit comments about any part of the manual to InfoMine. A self-mailer form is provided with each copy of

the Guide for this purpose. We also welcome calls (509-328-8023), faxes (509-328-2028) or email messages

(info@costmine.com).

This manual is designed for mine cost estimators. It provides the equipment capital and operating cost information

necessary for a discounted cash flow approach to making investment decisions. Equipment purchase prices are

listed separately so that they can be treated appropriately with respect to the timing of the purchase. Depreciation

and replacement (Capital Recovery) costs are presented on an hourly basis, as are the ownership expenses associated

with insurance, storage, and record keeping.

Equipment purchase prices, if used, should be totaled separately in the year accrued. Evaluators using this approach

should take care not to double account for the equipment capital costs by including the Capital Recovery value. This

value should only be used in analyses where capital expenditures are not listed separately, or where the operation

establishes a sinking fund used to replace spent equipment.

Generally, the Total operating cost value (the far right column) is applied directly to the estimated equipment use

(hours). Individual cost categories are listed so that the total may be adjusted for conditions specific to the operation.

The use requirements to which the hourly operating costs are applied must be determined by the evaluator. Use

requirements should represent the actual time that the machine operates, not the hourly schedule of the proposed

mine or mill. For instance, during an 8-hour shift, an excavator may work for only 6½ hours,

with the remaining time allotted to operator breaks or scheduled maintenance. The hourly use per shift of some

equipment (such as drills and service vehicles) is more difficult to estimate since many other tasks are interspersed

with machine operation. However, stationary equipment operates on a more predictable schedule. Ventilation fans

often operate 24 hours per day, 7 days a week, as do many of the machines used in mineral processing.

In some cases, hourly ownership costs (which are not included in the Total column) can be included in the analysis

if they are not considered elsewhere in the estimate. If, however, equipment purchase costs are included separately,

i.e. as capital cost items in a cash flow analysis, then the Capital Recovery amount should be included only to

account for equipment replacement anticipated at some time in the future and only if purchase costs for these

replacements are not included separately. Similarly, hourly overhead costs should not be included if insurance,

licensing and record keeping costs are included in a separate estimate of administrative costs.

v Copyright © 2010 InfoMine USA, Inc.

COST ESTIMATING METHODOLOGY - How to Use This Book

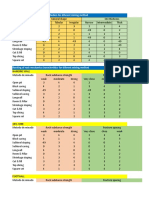

DATA ITEM DESCRIPTIONS

Column Headings

Repair Labor $31.42 per hour Natural Gas $5.860 per MCF ($5.555 per gigajoule)

Diesel Fuel $2.250 per gallon ($0.594 per liter) Electric Power $0.070 per KWH 1

Gasoline $2.870 per gallon ($0.758 per liter) Lube Oil $7.850 per gallon ($2.074 per liter)

SPECIFICATION

Description Weight Motor Capital

(lbs./kilograms) Type/Incl. HP Cost

2 3 4 5 6

HOURLY OPERATING COSTS

CAPITAL OVERHAUL MAINTENANCE FUEL/ WEAR

RECOVERY OVERHEAD PARTS LABOR PARTS LABOR POWER LUBE TIRES PARTS TOTAL

7 8 9 10 11 12 13 14 15 16 17

1 Unit Prices

Some of the hourly operating costs are based on these unit prices. Tire prices are listed separately in the

appendices for the Surface Mine Equipment and Underground Mine Equipment sections. The repair labor rate

is the average wage for mechanics working at U.S. coal, metal, and industrial mineral mines, as determined

by the latest Mining Cost Service survey. Appropriate burden factors are included in the wage rates. The

gasoline and diesel fuel prices are the average prices for sales to end-users in U.S. Petroleum Administration

for Defense District No. IV, which includes the states of Colorado, Idaho, Montana, Utah, and Wyoming.

Motor fuel taxes, which normally apply for on-road use only, are not included in these prices. The natural gas

rate and electric power rates are average for the western U.S. The electric power and natural gas rates include

appropriate demand and service charges as well as energy charges. The lube oil price represents a typical

charge for bulk crankcase oil for off-road diesel equipment. (See "Adjustment of Operating Costs" to learn

how to adjust costs for other unit prices).

2 Description

Most of the item descriptions represent actual equipment models. Sufficient capacity and specification

information is provided to help guide the estimator in selecting the appropriate unit for his or her proposed

equipment fleet. Further specification and productivity information for many of the items is listed in the

appendix following each section.

3 Weight

The weights listed here are provided by the manufacturers of the described items. They may represent either

a working weight or a shipping weight, but are intended for use in estimating the cost of shipping the item to

the project site.

vi Copyright © 2010 InfoMine USA, Inc.

COST ESTIMATING METHODOLOGY - How to Use This Book

4 Motor

An entry in the "Motor Type" column indicates that a motor or engine is required by this unit. The type of

motor or engine is indicated by: d = diesel, e = electric, or g = gasoline. A "y" in the "Motor Included" column

indicates that the cost of purchasing and operating the motor is included in the capital and operating cost

amount. An "n" in the "Motor Included" column indicates that a motor is required, but has not been included

in the capital or operating costs. In this case an appropriate motor should be selected from the Miscellaneous

Section of the manual and both its capital and operating costs added to the estimate.

5 HP (Horsepower)

This entry indicates the size of the motors or engines included with the unit or required by the unit. The listed

horsepower value is used in the equations for computing hourly fuel, or electric power costs.

6 Capital Cost

The values listed here are list or budget prices for the described equipment item. They are listed for estimating

purposes only and should not be considered representative of actual market value. Large disparities can exist

between prices listed here and those actually charged to a specific buyer. Disparities can result from

differences in specifications, from options added, from the results of price negotiations, and from changing

market conditions.

Selling prices are commonly discounted to some degree from list prices. The discount offered by a

manufacturer will depend on such factors as the number of units ordered and how well the model is selling

at the moment. A model that is selling poorly will be discounted more than one that is selling well. When

market conditions are generally depressed or when large inventories of competing used equipment are

available, discounts tend to be higher. In specific instances, a manufacturer may offer a high discount to make

the first sale in a particular area, in a particular segment of the industry, or at a particular mine.

Discounts for large mobile equipment, such as trucks, shovels, and loaders, typically range from 5% to 40%.

Discounts for smaller equipment such as motors and pumps may be higher, often as much as 50% to 55%.

Prices throughout the manual are for U.S. sales in U.S. dollars. Unless otherwise stated, sales taxes,

transportation from the distribution center to the minesite, and installation charges are not included, nor are the

costs of optional accessory items not considered to be standard equipment. Information helpful in estimating

sales taxes and transportation costs can be found in Mining Cost Service published by InfoMine USA, Inc.

Installation or set-up costs vary dramatically. Small mobile units are essentially service-ready upon delivery.

Larger mobile units may require some set-up costs. The costs of the labor and materials required for installing

stationary equipment generally average between 38% and 145%, but can be as high as 300%, of the purchase

price, depending primarily on the degree of foundation, electrical, and piping work required in relation to the

purchase price of the machine.

Our own philosophy in using these prices is to assume the actual cost will be less than the price listed because

of discounting, but the discount will be at least partially offset by the cost of added options. The prices listed

in the manual therefore tend to be on the high side, but are sufficiently accurate for a conservative preliminary

estimate.

vii Copyright © 2010 InfoMine USA, Inc.

COST ESTIMATING METHODOLOGY - How to Use This Book

7 Capital Recovery

Capital recovery costs are included to provide an indication of the funds necessary to purchase or replace the

machine. They are determined by the following relationship:

Capital Recovery Cost (CR) = Capital Cost ÷ R

Where: R = estimated replacement life

The anticipated replacement life is, of course, highly variable and is dependent upon operating conditions and

company maintenance and replacement policies. Equipment lives used to determine the Capital Recovery

values are listed below. No overhauls are included in these estimated lives, and no adjustment has been made

for any residual value at the end of the useful life.

Compressors - 12,000 hours

Conveyors - 10, 000 hours

Crushers - 26,000 to 52,000 hours

Draglines - 45,000 to 65,000 hours

Drills - 12,000 to 18,000 hours

Excavators - 10,000 to 14,000 hours

Flotation cells/Thickeners - 26,000 to 52,000 hours

Grinding mills - 52,000 to 104,000 hours

Mechanical shovels - 25,000 hours

Pumps - 12,000 hours

Trucks - 37,500 hours

The capital recovery costs do not include interest, inflation, or escalation.

8 Overhead

The overhead charges listed here are indirect administrative costs associated with machine ownership. They

include insurance, license, and maintenance and record keeping charges. They are determined by the following

relationship:

Overhead = CR × F

Where: CR = capital recovery cost (dollars per hour)

F = experience-based factor

Property and sales taxes, profit, and company and project overhead charges are not included. Taxes are

specific to project location and can be estimated with the aid of information contained in Mining Cost Service.

Charges associated with profit and corporate overhead should be added if appropriate.

OPERATING COSTS

Hourly operating costs are considered variable and are directly related to daily use. They should be applied

to daily use requirements, regardless of ownership period. The operating costs assume the equipment is

working a full operating hour under average operating conditions. Suggestions for adjusting these values for

other conditions or for other price situations are given in the “Adjustment of Operating Cost” paragraphs

below. The cost of operator’s time is not included. It must be added separately.

viii Copyright © 2010 InfoMine USA, Inc.

COST ESTIMATING METHODOLOGY - How to Use This Book

9 Overhaul Parts

Overhaul parts costs for mobile equipment are those associated with scheduled reconstruction and/or

replacement of major components such as engines and transmissions. For stationary processing equipment,

the costs are for scheduled refurbishing or replacement of major wear components such as drives, support

frames, and vessels. The value is based upon the following relationship:

Hourly Overhaul Parts Cost = (Capital Cost × F) ÷H

Where: F = experience-based factor

H = typical annual operating hours

10 Overhaul Labor

Overhaul labor costs for mobile equipment are those associated with scheduled reconstruction and/or

replacement of major components such as engines and transmissions. For stationary processing equipment,

the costs are for scheduled refurbishing or replacement of major wear components such as drives, support

frames, and vessels. The value is based upon the following relationship:

Hourly Overhaul Labor Cost =Overhaul Parts Cost x F x L

Where: F = experience-based factor

L = overhaul labor hourly wage plus benefits (dollars per hour)

11 Maintenance Parts

This item represents those costs associated with both unscheduled repairs and scheduled servicing of both

minor and major components, excluding overhaul activities. These include all aspects of machine maintenance

exclusive of fueling, lubrication, tire replacement, and maintenance and replacement of those parts used

directly to impart energy (see wear parts). The value is based upon the following relationship:

Hourly Maintenance Parts Cost = (Capital Cost × F) ÷ H

Where: F = experience-based factor

H = typical annual operating hours

12 Maintenance Labor

This item represents a typical charge per hour of operation to cover mechanics' time to perform maintenance

and repair functions, exclusive of overhaul work. The value is estimated by the following relationship:

Hourly Maintenance Labor Cost = Maintenance Parts Cost × F x L

Where: F = experience-based factor

L = repair labor hourly wage plus benefits (dollars per hour)

13 Fuel/Power

This item lists the cost of diesel fuel, gasoline, electric power, or natural gas as appropriate for the equipment

specified. Care should be taken to note whether an “n” or a “y” is listed in the “Motor Included” column. If

an “n” is listed, a motor is required, but the costs to operate it are not included here. In this case an appropriate

(continued next page)

ix Copyright © 2010 InfoMine USA, Inc.

COST ESTIMATING METHODOLOGY - How to Use This Book

13 Fuel/Power (continued)

motor should be selected from the Miscellaneous Section of the manual and both its capital and operating costs

added to the estimate. Costs for each fuel type are determined by the following relationships:

Diesel Fuel

The hourly cost of diesel fuel required to operate the equipment under average conditions is estimated by the

following relationship:

Hourly Diesel Fuel Cost = Engine Horsepower x F x D

Where: F = experience-based factor

D = diesel fuel price (dollars per gallon)

Gasoline

The hourly cost of gasoline required to operate the equipment under average conditions is estimated by the

following relationship:

Hourly Gasoline Cost = Engine Horsepower × F × G

Where: F = experience-based factor

G = gasoline price (dollars per gallon)

Electric Power

The hourly cost of electric power required to operate the equipment under average conditions is estimated by

the following relationship:

Hourly Electric Power Cost = Motor Horsepower × F × 0.746 kW per horsepower × E

Where: F = average electric power draw (%)

E = electric power price (dollars per kWH)

The electric power price (E) includes demand and service charges as well as energy charges.

Natural Gas

The cost of natural gas required to operate the equipment is determined by the following relationship:

Hourly Natural Gas Cost = (E ÷ 1,040,000 btu's/MCF) × N

Where: E = Energy requirement (btu's per hour)

N = natural gas price (dollars per MCF)

14 Lube

The hourly cost of crankcase oil and other lubricants required to operate the equipment is estimated by the

following relationship:

Hourly Lube Cost = (Capital Cost÷F ) + (((Engine HP ÷F ) × L)÷I)

L C

Where: F = experience-based equipment lubrication factor

L

F = experience-based crankcase oil factor

C

L = lube price (dollars per gallon)

I = lube change interval (hours)

x Copyright © 2010 InfoMine USA, Inc.

COST ESTIMATING METHODOLOGY - How to Use This Book

15 Tires

Tire costs assume that each tire will be retreaded two times before being replaced with a new tire. The cost

of a retread is assumed to be 75% the cost of a new tire, and the life expectancy about nine percent less. The

hourly cost of tires is calculated by the following relationship:

Hourly Tire Cost = ((N tires × T) + (2 retreads × (0.75 × T × N tires)))

÷ (L hours + ((2 retreads × L hours)÷1.1))

Where: N = number of tires required by the vehicle

T = tire price (see appendices for surface mining and underground mining sections

for tire prices)

L = expected tire life

16 Wear Parts

Values listed here typically refer to the costs of parts which directly engage the rock and impart some form of

energy designed to change the condition of that rock. These include items such as drill bits, dozer blades,

excavator teeth, crusher and impactor liners, and grinding media. Hourly wear rates are highly variable

(depending on the nature of the rock) and can be adjusted accordingly. Wear rates assumed here are

considered average for hard-rock mining and mineral processing operations. The relationships used to provide

the Wear Parts values are specific to the machine and take the form:

Wear Part Cost = Pc xHc

Where: Pc = cost of the parts (drill bits, grinding balls, bucket teeth)

Hc = parts consumed per hour

17 Total

The total operating cost comprises the sum of the eight items (9 thru 16) listed. It does not include

depreciation, overhead, insurance, or cost of facilities capital. Nor does it include the cost of operators.

ADJUSTMENT OF OPERATING COSTS

The hourly operating costs can be adjusted for variations in working conditions, unit prices, or wages. For some

of the equipment types, sophisticated methods are available for estimating the cost of operating under various

conditions. These methods are described in a variety of technical references. For preliminary estimating purposes,

the hourly operating costs may be adjusted by multiplying them by an appropriate factor. Operating costs can be

expected to vary from between 30% below the listed cost for extremely favorable conditions to 35% above for

adverse conditions.

With the exception of parts, adjustment of the costs for variations in unit commodity prices is simply a matter of

multiplying the cost by a factor determined by dividing the desired unit price by the unit price listed at the top of

the operating cost page:

(continued next page)

xi Copyright © 2010 InfoMine USA, Inc.

COST ESTIMATING METHODOLOGY - How to Use This Book

ADJUSTMENT OF OPERATING COSTS (continued)

Cost B = Cost A × Unit Price B/Unit Price A

Where: Cost B = adjusted cost

Cost A = cost listed in the estimator's guide

Unit Price B = desired unit commodity price

Unit Price A = unit commodity price from the top of the operating cost page

Part costs are not derived from a unit commodity price, but rather from the equipment capital cost. To adjust for

an atypical cost situation, simply increase or decrease the hourly repair part cost by the percentage that you expect

your repair part prices to be higher or lower than average.

Other Products for Your Cost Estimating Needs

from InfoMine USA, Inc.

EQUIPMENT COST CALCULATOR

The industry’s most comprehensive tool for mine and mill cost estimating. Provides access to the CostMine

database containing reliable capital and operating cost data for over 3,000 equipment items commonly found at

mines around the world. As a Mine & Mill Equipment Cost Guide 2010 version purchaser or a Mining Cost

Service Subscriber you are entitled to substantial savings on this valuable information.

MINING COST SERVICE

The industry's most comprehensive data source for mine cost estimating. Features sections on mine transportation,

utilities, equipment, supplies, taxes, wages and benefits, smelting, mine development, cost models, cost indexes, and

more.

COAL COST GUIDE

This product is our North American coal cost estimating guide and includes all of the materials, equipment and costs

that you need to do a pre-feasibility study on a coal property. It includes subjects such as equipment capital costs,

supplies, transportation, coal cost indices and historical coal prices, and North American based coal mine and prep

plant labor, electric power and natural gas costs. The Coal Cost Models section includes models for surface mines,

longwall and continuous miners underground operations, and prep plant and heavy media plant models.

WAGE AND SALARY MINING SURVEYS

Comprehensive surveys of wages, salaries, and benefits at operating coal, metal, aggregate, and industrial mineral

mines in U.S. and Canada plus exploration offices worldwide.

Please contact InfoMine USA, Inc. for more information.

Phone: (509) 328-8023 Fax: (509) 328-2028

E-Mail: info@costmine.com

Website: www.costmine.com

xii Copyright © 2010 InfoMine USA, Inc.

Вам также может понравиться

- Guidelines for Mine Waste Dump and Stockpile DesignОт EverandGuidelines for Mine Waste Dump and Stockpile DesignРейтинг: 3.5 из 5 звезд3.5/5 (3)

- Process Control PhilosophyДокумент91 страницаProcess Control PhilosophyFR75% (4)

- CAPCOSTS: A Guide to Estimating Mining and Mineral Processing Equipment CostsДокумент332 страницыCAPCOSTS: A Guide to Estimating Mining and Mineral Processing Equipment CostsPaulo Ossandon SanchezОценок пока нет

- Can Crusher InstructionsДокумент10 страницCan Crusher Instructionsgary.nolan100% (3)

- Estimating Mining and Mineral Processing Equipment CostsДокумент20 страницEstimating Mining and Mineral Processing Equipment CostsJesús Alexander Flores AbadОценок пока нет

- Long Hole Stoping With Short Interval ControlДокумент30 страницLong Hole Stoping With Short Interval ControlMimi SegoviaОценок пока нет

- Block Valuation at Antamina Mine: Harry Parker & Kim Kirkland Mintec Seminar April 2007Документ28 страницBlock Valuation at Antamina Mine: Harry Parker & Kim Kirkland Mintec Seminar April 2007Harold G. Velasquez SanchezОценок пока нет

- Talpac Tutorial - Metric PDFДокумент52 страницыTalpac Tutorial - Metric PDFIsaac Visual100% (1)

- GPS Guidance Reduces Mining CostsДокумент13 страницGPS Guidance Reduces Mining CostsAmaraaZoyaОценок пока нет

- Rao Minerals PDFДокумент348 страницRao Minerals PDFOppie ChelyОценок пока нет

- PKO BusinessДокумент35 страницPKO BusinessvicaschendeОценок пока нет

- Automation at Northparkes Rio TintoДокумент30 страницAutomation at Northparkes Rio TintoAmilton filhoОценок пока нет

- Preconditioning Implementation On Rock Bulks in Codelco Chile and Its ResultsДокумент16 страницPreconditioning Implementation On Rock Bulks in Codelco Chile and Its ResultsFernando RicardoОценок пока нет

- Northparkes E26 Lift 2 Block Cave - A Case StudyДокумент10 страницNorthparkes E26 Lift 2 Block Cave - A Case StudyEduardo MenaОценок пока нет

- Código JORCДокумент44 страницыCódigo JORCPatricio LeddyОценок пока нет

- Map3D - TutorialДокумент531 страницаMap3D - TutorialVicente VasquezОценок пока нет

- Extending The Mathews Stability Graph For Open Stope DesignsДокумент14 страницExtending The Mathews Stability Graph For Open Stope DesignsRómulo Eduardo Ayala JimenezОценок пока нет

- 2018 March El Peñón PDFДокумент170 страниц2018 March El Peñón PDFPedro PizarroОценок пока нет

- Ranking of Geometry/Grade Distribution For Diferent Mining MethodДокумент8 страницRanking of Geometry/Grade Distribution For Diferent Mining MethodVictor QuispeОценок пока нет

- Incline Caving As A Massive Mining MethodДокумент9 страницIncline Caving As A Massive Mining MethodwalterloliОценок пока нет

- Saw Et Al - AusIMM UOC 2017Документ16 страницSaw Et Al - AusIMM UOC 2017sawhlaayeОценок пока нет

- AI Solution for Dragline PlanningДокумент25 страницAI Solution for Dragline PlanningAditya HimanshuОценок пока нет

- E 31 PDFДокумент58 страницE 31 PDFandestaОценок пока нет

- Full Text 01Документ140 страницFull Text 01Lucas Martin AbascalОценок пока нет

- Design of The Second Block Cave at Northparkes E26 MineДокумент12 страницDesign of The Second Block Cave at Northparkes E26 MineYojan Ccoa CcopaОценок пока нет

- Mineral Resources Ore Reserves Guidelines-Aug2006 - 2 - DraftДокумент31 страницаMineral Resources Ore Reserves Guidelines-Aug2006 - 2 - DraftMiguel MiguelitoОценок пока нет

- BenchFill VillaescusaДокумент10 страницBenchFill VillaescusaFredd_AlvaroОценок пока нет

- Selecting Shaft or DeclineДокумент8 страницSelecting Shaft or DeclineStephen HolleyОценок пока нет

- CourseOutline MINE4260 2014Документ20 страницCourseOutline MINE4260 2014Welsinsin Kevin SinОценок пока нет

- Gate Mining 2007-2019 PapersДокумент220 страницGate Mining 2007-2019 PapersAarya raj singh RanawatОценок пока нет

- Optimum Ramp Design in Open Pit MinesДокумент9 страницOptimum Ramp Design in Open Pit MinesFrancys CcoriОценок пока нет

- Norra-Karr PFS 43-101 PDFДокумент378 страницNorra-Karr PFS 43-101 PDFAsri Mawaddah ChairunnisaОценок пока нет

- 1992 Burden, Spacing and Borehole Diameter at Rock BlastingДокумент10 страниц1992 Burden, Spacing and Borehole Diameter at Rock BlastinghnavastОценок пока нет

- Estimation of Incremental Haulage Costs by Mining Historical Data and Their Influence in The Final Pit DefinitionДокумент6 страницEstimation of Incremental Haulage Costs by Mining Historical Data and Their Influence in The Final Pit DefinitionGaluizu001Оценок пока нет

- Block CavingДокумент19 страницBlock CavingmanikantaОценок пока нет

- Ams Stope Optimiser Ver 2 Reference Manual - 1.0 FinalДокумент146 страницAms Stope Optimiser Ver 2 Reference Manual - 1.0 Finalroldan2011Оценок пока нет

- Thesis - Optimization of Level and Raising Spacing Range in Platinum MineДокумент228 страницThesis - Optimization of Level and Raising Spacing Range in Platinum MineCarlos A. Espinoza MОценок пока нет

- 2011 Cost Models SectionДокумент56 страниц2011 Cost Models Sectionoduk odbayarОценок пока нет

- Introduction To FPCДокумент25 страницIntroduction To FPCBenito Lionel ZoboОценок пока нет

- O-Pitblast - Decks ManiualДокумент30 страницO-Pitblast - Decks ManiualAftherJemigDamanikОценок пока нет

- 6-3 Drilling and Blasting Stopes Tm3Документ7 страниц6-3 Drilling and Blasting Stopes Tm3johnson OlubiОценок пока нет

- Mathematical Modelling of Blasting Decisions Using An Integrated Open Pit Mine To Mill Model (Pérez Errázuriz)Документ51 страницаMathematical Modelling of Blasting Decisions Using An Integrated Open Pit Mine To Mill Model (Pérez Errázuriz)matias79Оценок пока нет

- OP Blast Design - LabДокумент20 страницOP Blast Design - LabRizki PurwinantoОценок пока нет

- How To Build A Gridded Seam ModelДокумент86 страницHow To Build A Gridded Seam ModelBill WatersonОценок пока нет

- MODEL - Lerchs-Grossman OptimizationДокумент41 страницаMODEL - Lerchs-Grossman OptimizationDouglas Yusuf0% (2)

- The Modified Stability Graph Method; More Than 30 Years LaterДокумент7 страницThe Modified Stability Graph Method; More Than 30 Years Lateroscar2302Оценок пока нет

- TFMPelayoLopezGRUO PDFДокумент91 страницаTFMPelayoLopezGRUO PDFshivakumar bairojuОценок пока нет

- Addressing The Challenges and Future of Cave Mining PDFДокумент20 страницAddressing The Challenges and Future of Cave Mining PDFDiego Ignacio VelizОценок пока нет

- Open Cast Blasting Improvements - Gerhard StenzellДокумент82 страницыOpen Cast Blasting Improvements - Gerhard StenzellRudianto SitanggangОценок пока нет

- SURPAC Google Earth Linear and Graphic Functions: (Pty) LTDДокумент26 страницSURPAC Google Earth Linear and Graphic Functions: (Pty) LTDBibhuti Bhusan SahooОценок пока нет

- Ventsim ManualДокумент232 страницыVentsim ManualMendoza Castillo JulioОценок пока нет

- Optimization of Mining Method and EquipmentДокумент6 страницOptimization of Mining Method and EquipmentkullieОценок пока нет

- Algoritmo Holmberg Persson VoladurasДокумент33 страницыAlgoritmo Holmberg Persson VoladurasgaguilloОценок пока нет

- Zaldivar MMS PDFДокумент114 страницZaldivar MMS PDFsebastian sougarretОценок пока нет

- Discover3D TutorialsДокумент76 страницDiscover3D TutorialsAlejandroОценок пока нет

- DeswikCAD - SchedulerДокумент103 страницыDeswikCAD - Schedulermusa ballah koroma100% (1)

- LKAB Tests 50m Sublevel Caving at Konsuln MineДокумент13 страницLKAB Tests 50m Sublevel Caving at Konsuln MinekinsaeyaОценок пока нет

- MME 2010 Contents and Introduction PDFДокумент13 страницMME 2010 Contents and Introduction PDFAmaraaZoyaОценок пока нет

- Underground Mining PDFДокумент32 страницыUnderground Mining PDFAmaraaZoyaОценок пока нет

- Dictionary GeodesyДокумент35 страницDictionary GeodesyAmaraaZoyaОценок пока нет

- Dictionary MinesДокумент20 страницDictionary MinesAmaraaZoyaОценок пока нет

- 2017 Geovia Whitepaper PseudoflowДокумент9 страниц2017 Geovia Whitepaper PseudoflowFarouk AzzouhriОценок пока нет

- U.S. Labor Section PDFДокумент113 страницU.S. Labor Section PDFGalaaBoldooОценок пока нет

- Legal Copyright Notice PDFДокумент1 страницаLegal Copyright Notice PDFAmaraaZoyaОценок пока нет

- Advisor Group: Coal Cost GuideДокумент27 страницAdvisor Group: Coal Cost GuideGalaaBoldooОценок пока нет

- Glogex LLC PDFДокумент1 страницаGlogex LLC PDFAmaraaZoyaОценок пока нет

- Electric Power - CanadaДокумент15 страницElectric Power - CanadaGalaaBoldooОценок пока нет

- Advisor Group: Coal Cost GuideДокумент27 страницAdvisor Group: Coal Cost GuideGalaaBoldooОценок пока нет

- Surpac PlanningДокумент2 страницыSurpac PlanningAmaraaZoyaОценок пока нет

- Glogex LLC PDFДокумент1 страницаGlogex LLC PDFAmaraaZoyaОценок пока нет

- Legal Copyright Notice PDFДокумент1 страницаLegal Copyright Notice PDFAmaraaZoyaОценок пока нет

- Smelting and Refining Section 2011Документ42 страницыSmelting and Refining Section 2011GalaaBoldooОценок пока нет

- Canada Labor SectionДокумент47 страницCanada Labor SectionGalaaBoldooОценок пока нет

- SCANNER Introductions PDFДокумент10 страницSCANNER Introductions PDFAmaraaZoyaОценок пока нет

- Often Referred To As: Application of Laser Scanning in Mine SurveyingДокумент10 страницOften Referred To As: Application of Laser Scanning in Mine SurveyingAmaraaZoyaОценок пока нет

- Underground Mine: Surface FacilitiesДокумент30 страницUnderground Mine: Surface FacilitiesAmaraaZoyaОценок пока нет

- Deswik White Paper Pseudoflow ExplainedДокумент10 страницDeswik White Paper Pseudoflow ExplainedKamara100% (1)

- Maptek I-Site Overview PDFДокумент8 страницMaptek I-Site Overview PDFAmaraaZoyaОценок пока нет

- Maptek I-Site 8400 Spec Sheet PDFДокумент1 страницаMaptek I-Site 8400 Spec Sheet PDFAmaraaZoyaОценок пока нет

- LibraryДокумент4 страницыLibraryAmaraaZoyaОценок пока нет

- LibraryДокумент4 страницыLibraryAmaraaZoyaОценок пока нет

- Sample SpeakingДокумент65 страницSample SpeakingAmaraaZoyaОценок пока нет

- Set On The Heart of North Center of MongoliaДокумент1 страницаSet On The Heart of North Center of MongoliaAmaraaZoyaОценок пока нет

- Determine PersonДокумент1 страницаDetermine PersonAmaraaZoyaОценок пока нет

- ZYS High Efficient Cone CrusherДокумент18 страницZYS High Efficient Cone CrusherjoyalcrusherОценок пока нет

- Chapters 1, 2, & 3 - MUOДокумент99 страницChapters 1, 2, & 3 - MUOamanuelОценок пока нет

- Sandvik QH331 Cone Crusher: Technical Specification SheetДокумент2 страницыSandvik QH331 Cone Crusher: Technical Specification SheetFöldes LeventeОценок пока нет

- Shock Monitor Manual PDFДокумент184 страницыShock Monitor Manual PDFHerrydroidОценок пока нет

- Crushing Principles and Equipment: by Evgueni Porokhovoi. 2019Документ53 страницыCrushing Principles and Equipment: by Evgueni Porokhovoi. 2019DubistWhite100% (1)

- CHPP FieldtripДокумент33 страницыCHPP FieldtripsurajkgpОценок пока нет

- Understanding Mining Production Costs and Future Plans for Panel CavingДокумент5 страницUnderstanding Mining Production Costs and Future Plans for Panel CavingDiego Arturo Rojas AlfaroОценок пока нет

- Gundlach Roll Crushers BrochureДокумент2 страницыGundlach Roll Crushers Brochurerajeevup2004Оценок пока нет

- Rendering Fat Screw PressДокумент2 страницыRendering Fat Screw Presssofiane mokhtariОценок пока нет

- Wheeled Jaw Plant089682Документ2 страницыWheeled Jaw Plant089682macross086Оценок пока нет

- Result and ConclusionДокумент7 страницResult and ConclusionTrilok KhanalОценок пока нет

- Overhead Standards As Per Standard Rate Analysis Book (MoRTH)Документ3 страницыOverhead Standards As Per Standard Rate Analysis Book (MoRTH)murugeshuniv90% (10)

- Fine AggregatesДокумент22 страницыFine Aggregatesezer joseph bacoОценок пока нет

- General Spec Sheet Power Crusher PC 1270Документ2 страницыGeneral Spec Sheet Power Crusher PC 1270ion_zloteaОценок пока нет

- Jaw Crushers Machine Suppliers in VadodaraДокумент2 страницыJaw Crushers Machine Suppliers in VadodaraExcel SourceОценок пока нет

- Operating Instruction of PE Series Jaw CrusherДокумент22 страницыOperating Instruction of PE Series Jaw CrusherEnso E Rosales FОценок пока нет

- TCCL Plant SpecificationДокумент273 страницыTCCL Plant SpecificationThaigroup CementОценок пока нет

- Apron Feeder DScrusherДокумент7 страницApron Feeder DScrusherRyan R CunninghamОценок пока нет

- An Overview of Recovery of Metals From SlagsДокумент17 страницAn Overview of Recovery of Metals From SlagsPauloValdiviesoОценок пока нет

- Safe Demolition Method Statement & Risk AssessmentsДокумент27 страницSafe Demolition Method Statement & Risk Assessmentsmohamedamine.zemouriОценок пока нет

- 3022 B4ce78acДокумент12 страниц3022 B4ce78acmmkattaОценок пока нет

- AASTU ProjectДокумент26 страницAASTU ProjectSamuel MergaОценок пока нет

- 91 - PDFsam22 - QH441 Operations Manual 14 04 15 EnglishДокумент30 страниц91 - PDFsam22 - QH441 Operations Manual 14 04 15 Englishisahin0508Оценок пока нет

- FLSMIDTHДокумент36 страницFLSMIDTHJuan CastroОценок пока нет

- Horizontal Shaft Impactor SpecsДокумент2 страницыHorizontal Shaft Impactor SpecsEduardo QuiñonesОценок пока нет

- Methods and EquipmentДокумент5 страницMethods and EquipmentChrissy LayugОценок пока нет