Академический Документы

Профессиональный Документы

Культура Документы

Mfg. Process PDF

Загружено:

technopreneurvizag0 оценок0% нашли этот документ полезным (0 голосов)

24 просмотров1 страницаОригинальное название

mfg. process.pdf

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

24 просмотров1 страницаMfg. Process PDF

Загружено:

technopreneurvizagАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 1

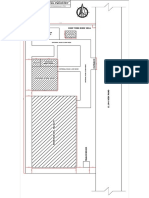

The raw material used for manufacture of bolt is M.S. Rounds.

As some

of the rounds available are rusty and not perfectly round and straight, it

is necessary to make them round. The rounds are pickled in the acid

tanks, washed and drawn in a drawing machine. The cleaned rod is fed

into the cold heading machine. In the machine, one end of the rod is cut

into the desired length with cutting stroke and simultaneously the head

formation takes at another end. For the HT bolts, forging is done on hot

forging press. The pins are then trimmed in the trimming machine. In

quality bolts, the lower side of the head is also faced. Threading is done

in the thread rolling machines.

Вам также может понравиться

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1091)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Technical Feasibility Report-uPVC Windows & DoorsДокумент158 страницTechnical Feasibility Report-uPVC Windows & Doorstechnopreneurvizag100% (1)

- Technical Feasibility Report-uPVC Windows & DoorsДокумент158 страницTechnical Feasibility Report-uPVC Windows & Doorstechnopreneurvizag100% (1)

- Tfr-Upvc Windows and Doors Fab. UnitДокумент31 страницаTfr-Upvc Windows and Doors Fab. UnittechnopreneurvizagОценок пока нет

- Slab Design-ExcelДокумент2 страницыSlab Design-ExceltechnopreneurvizagОценок пока нет

- Dpr-Meghana Roofing Industries-From Page5Документ20 страницDpr-Meghana Roofing Industries-From Page5technopreneurvizagОценок пока нет

- 1.plan-Meghana Aac Blocks Industry-14082020Документ1 страница1.plan-Meghana Aac Blocks Industry-14082020technopreneurvizagОценок пока нет

- Product Portfolio-Disposable SyringesДокумент7 страницProduct Portfolio-Disposable SyringestechnopreneurvizagОценок пока нет

- Plan-Meghana Engineering IndustryДокумент1 страницаPlan-Meghana Engineering IndustrytechnopreneurvizagОценок пока нет

- 3.bom-Civil-Meghana Aac Blocks IndustryДокумент15 страниц3.bom-Civil-Meghana Aac Blocks IndustrytechnopreneurvizagОценок пока нет

- Form No:: Date of Online Filing: 11 Mar 2013Документ6 страницForm No:: Date of Online Filing: 11 Mar 2013technopreneurvizagОценок пока нет

- State Wise Vacancy Information: Vacant Properties Summary For VISAKHAPATNAM Zone Property WiseДокумент2 страницыState Wise Vacancy Information: Vacant Properties Summary For VISAKHAPATNAM Zone Property WisetechnopreneurvizagОценок пока нет

- Details of Vacant Industrial Properties-Visakhapatnam Zone: Health City-ChinagadiliДокумент6 страницDetails of Vacant Industrial Properties-Visakhapatnam Zone: Health City-ChinagadilitechnopreneurvizagОценок пока нет

- Cma-Krishnaveni Upvc Profiles PDFДокумент22 страницыCma-Krishnaveni Upvc Profiles PDFtechnopreneurvizagОценок пока нет

- Dpr-Meghana Roofing Industries-1to4 PagesДокумент4 страницыDpr-Meghana Roofing Industries-1to4 PagestechnopreneurvizagОценок пока нет

- Cma-Meghana SurgicalsДокумент100 страницCma-Meghana SurgicalstechnopreneurvizagОценок пока нет

- Cma Data-414 Lacs-Aac Blocks Mfg. Unit.Документ22 страницыCma Data-414 Lacs-Aac Blocks Mfg. Unit.technopreneurvizagОценок пока нет

- Cross Section of Metal BuildingДокумент1 страницаCross Section of Metal BuildingtechnopreneurvizagОценок пока нет

- Product Portfolio-Aac BlocksДокумент19 страницProduct Portfolio-Aac BlockstechnopreneurvizagОценок пока нет

- Product Portfolio-Aac Blocks ManufactringДокумент15 страницProduct Portfolio-Aac Blocks ManufactringtechnopreneurvizagОценок пока нет