Академический Документы

Профессиональный Документы

Культура Документы

Lesson Plan - Biofuels Production and Use

Загружено:

Luis LopezОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Lesson Plan - Biofuels Production and Use

Загружено:

Luis LopezАвторское право:

Доступные форматы

1

Lesson Plan – Biofuels Production and Use

Goal

To understand the magnitude of transportation energy use, the process and implications

of biofuel production, and the energy displacement potential of biofuels.

Key Concepts

1. Biofuels are fuels made from recently grown plant material.

2. Carbon in the biomass was recently captured from the atmosphere through

photosynthesis.

3. Combustion of biofuels emits “biogenic” CO2. Since this carbon is essentially

recycled from the atmosphere, it is not considered to be as bad as the release of

fossil carbon from the combustion of fossil fuels. That carbon had previously been

sequestered underground.

4. Biofuels can often be made from “waste” materials. In particular, biodiesel can be

made from waste vegetable oil (e.g., fryer fat)

5. A diesel engine is capable of running on raw vegetable oil, but it must be pre-heated

to lower the viscosity. Biodiesel has a lower viscosity than pure vegetable oil.

6. If crops are grown for the purpose of creating biofuels, there may be significant

environmental impacts associated with feedstock production.

7. Biofuel production requires feedstock production, feedstock processing, fuel

production, and fuel use. It is important to consider environmental implications of all

these “lifecycle” stages.

8. The increased use of biofuels is currently mandated by the U.S. federal government

under the Energy Independence and Security Act of 2007. The goal is to produce

and consume 36 billion gallons of biofuels per year by 2022. That includes 15 BGY

of corn ethanol by 2015.

9. Currently, large-scale biofuel production relies on large-scale agricultural production

of feedstock biomass. The feedstock production phase, especially in the case of

corn ethanol relies on significant fossil fuel use and contributes to various

environmental impacts.

10. The production of 5-6 billion gallons of ethanol in 2007 displaced only a small

percentage (~2%) of our transportation energy use. An increase to 15 BGY by 2015

will put a significant burden on agriculture, food prices, ad fossil fuel use, while still

displacing only a small fraction of our transportation energy.

11. Fuels have different heating (calorific) values and different viscosities. These

differences affect engine performance

Copyright © 2009 Clarkson University, Office of Educational Partnerships revised 08/09

www.clarkson.edu/k12

2

Background

Biofuels are fuels made from recently grown plant or animal matter. Fossil fuels were

also originally plant or animal matter, but that material has spent millions of years

underground in extreme conditions and so it has changed significantly and its energy

value was concentrated. As fossil fuel supplies diminish, renewable energy resources

that can be replenished faster than we use them must be found in order for society to

continue functioning as we are accustomed. Some folks believe that biofuels, like corn

ethanol and biodiesel, could supply this renewable supply of fuel.

There are other negative environmental impacts related to fossil fuel use, in addition to

the depletion of a limited resource. Many toxic chemicals contained in fossil fuels are

released into the atmosphere upon burning of oil and coal. Biofuels are less toxic than

fossil fuels - biodiesel is less toxic than table salt, for example. In addition, carbon

released from the sequestered underground reservoirs of fossil fuels goes into the

atmosphere as carbon dioxide. Most scientists agree that the human-caused increase

in atmospheric carbon dioxide and other greenhouse gases are at least partially

influencing global temperature. Thus, fossil fuel use influences global climate

destabilization.

Biofuels are touted as a potential solution (at least partially) to the problem of

greenhouse gases from fossil fuels. The biofuels still release carbon dioxide into the

atmosphere, but since the fuel comes from recently grown plants, it was extracted from

the atmosphere through photosynthesis, and will be reused by future crops. By limiting

the amount of carbon moving from the underground to the atmosphere, the idea is to

reduce the intensity of global warming.

Ethanol and biodiesel are now commonly mixed with petroleum-based fuels for sale as

transportation fuels. Ethanol from corn is the most commonly used biofuel made in the

U.S. In 2008, over 9 billion gallons of corn ethanol were produced. New technologies

are available to make ethanol from cellulosic materials, including wood chips, switch

grass, and corn stover, which is the stalk and leaf residue remaining after the corn grain

is harvested. Biodiesel is made from soy beans or canola seeds, both of which have

high oil contents. Approximately 0.7 BGY of biodiesel was produced in 2008.

U.S. legislation has shaped much of the national history of ethanol production.

Bioethanol was first seriously considered

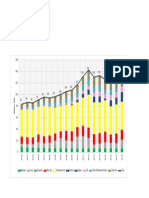

Biofuel Production (billion gallons per year)

40

as a transportation fuel in the 1970s due to 35

other advanced biofuels

the Arab Oil embargo. In 1990, a cellulosic biofuels

30

$0.54/gal subsidy for the sale of gasoline corn ethanol

blends that contain at least 10% ethanol 25

(E10) helped to increase the number of 20

ethanol production facilities. The U.S.

15

Energy Independence and Security Act

(EISA) of 2007 mandates that fuel 10

producers use at least 36 billion gallons of 5

biofuel by 2022. This includes 15 BGY of 0

corn ethanol by 2015 and 21 BGY must be

2006

2007

2008

2009

2010

2011

2012

2013

2014

2015

2016

2017

2018

2019

2020

2021

2022

cellulosic biofuels. The legislation also

Copyright © 2009 Clarkson University, Office of Educational Partnerships revised 08/09

www.clarkson.edu/k12

3

calls for a 20% reduction in oil use by 2010 through improved vehicle fuel economy and

a national fuel economy standard of 35 miles per gallon by 2020. The 2022 EISA

requirements would replace 15 % of the 2006 U.S. gasoline consumption on an energy

basis.

Ethanol

Ethanol is made by the biological fermenting of sugars in the feedstock. If the feedstock

does not contain sugars initially, pretreatment steps must precede the fermentation to

transform the complex starches (corn) or cellulose into simpler sugar molecules. After

the fermentation step, distillation is required to separate the ethanol from water.

In the United States, the main feedstock for the production of ethanol is currently corn.

Approximately 2.8 gallons of ethanol (10 liters) are produced from one bushel of

corn (35 liters). While much of the corn turns into ethanol, some of the corn also yields

by-products such as DDGS (distillers dried grains with solubles) that can be used to

fulfill a portion of the diet of livestock. A bushel of corn produces about 18 pounds of

DDGS. Both the corn farming and ethanol production steps are very energy intensive.

Diesel fuel and a lot of nitrogen fertilizer are used on the farm. Making the fertilizer

requires a lot of energy and natural gas. The ethanol production step requires a lot of

heat to keep the fermentation tanks warm and to distill the ethanol. On-site steam

production from coal is often used in large-scale ethanol production facilities. Overall,

even though the carbon in the fuel is “free” through the photosynthesis reaction, a lot of

fossil fuels were also consumed to prepare ethanol for use as a transportation fuel.

Biodiesel

The diesel engine was originally designed to run on peanut oil. Modern diesel engines

are designed to run on petroleum (fossil fuel) diesel, but can still run on vegetable oil if

the oil’s viscosity is low. Warming the oil is required to lower the viscosity, so some

alterations must be made to the fuel supply to the engine. The main reason for the use

of petroleum diesel is its low cost and slightly higher energy value. Some people are

promoting a return to vegetable oil for reasons of renewability and low pollution. By

converting the oil to biodiesel, the energy value is increased and viscosity is lowered.

This fuel can then be mixed with petroleum diesel (up to 20% mix (B20) can be used

safely in any diesel engine) or can be used pure in many vehicles.

Biodiesel can be manufactured safely at a local community scale, while petroleum

diesel requires a large refining infrastructure for safety and economy. In terms of

energy independence and security for individuals, communities, states and countries,

fuels such as biodiesel show promise when compared with the large scale operations of

fossil fuel suppliers.

Biodiesel is created by reacting “natural” oils, or triglycerides, with an alcohol (usually

methanol) in the presence of a catalyst. There are different methods for carrying out the

reaction, but one of the simplest and most common is a base-catalyzed batch reaction

of oil with methanol. This reaction is called transesterification. Any type of triglyceride,

which includes plant or animal based oils, can be used as the feedstock. The base

catalyst, typically lye (sodium hydroxide or potassium hydroxide), is mixed with the

alcohol before the reaction is started. The alcohol/catalyst mixture is then added to the

Copyright © 2009 Clarkson University, Office of Educational Partnerships revised 08/09

www.clarkson.edu/k12

4

oil and the whole mixture is stirred vigorously. The overall reaction can be thought of as

a big “E” in which the three fingers are cut off. The “fingers” and the molecules that

comprise biodiesel, and the truncated remaining “E” is the

glycerine.

+ methanol +

Triglyceride Glycerine Biodiesel

(methyl esters)

Simplified conceptualization of transesterification reaction

O

||

CH2 – O – C – R CH2—OH

│ O O │

│ || || │

CH2 – O – C – R + 3 CH3OH Æ 3 CH2 – O – C – R + CH—OH

│ O │

│ || │

CH2 – O – C – R CH2—OH

Triglyceride Methanol+Catalyst Methyl Esters Glycerin

(vegetable oil) (biodiesel)

Transesterification of Triglyceride with Alcohol

After the reaction occurs, there will be two products, which separate into phases (like oil

and water). The lower density phase (on top) is the biodiesel, and the higher density

phase is glycerin. Glycerin can be used in other processes such as making soap or

dynamite. In a high-end biodiesel production facility, the biodiesel must be cleaned

before it can be sold as fuel.

Properties of Biofuels

The heating (calorific) value is an important physical property of all fuels. The calorific

value of diesel is 46 MJ/Kg, kerosene is 47 MJ/Kg, biodiesel is 33–40 MJ/Kg, and

canola oil is 36.9 MJ/Kg. i In the experiment performed during this lesson, students will

use a simple calorimeter to calculate the calorific values of these four fuels.

Copyright © 2009 Clarkson University, Office of Educational Partnerships revised 08/09

www.clarkson.edu/k12

5

The viscosity of a fluid can be expressed as a "dynamic viscosity" and a "kinematic

viscosity". Dynamic viscosity is measured in "centipoise" while kinematic viscosity takes

into account the fluid density and is measured in "centistokes". It is important to note the

temperature of the measurements because the viscosity of a liquid will be reduced as

the temperature rises. For example, the range of viscosity seen for canolabiodiesel is

4.43 to 6.7 centistokes at 40°C; this drops to around 2.4 centistokes at 100°C.

Lard/grease Biodiesel

Soy Biodiesel

Canola Biodiesel

Biodiesel (ASTM D6751)

Petroleum Diesel Fuel

0 1 2 3 4 5 6 7

Kinematic Viscosity at 40 deg.C (centistokes)

The maximum viscosity is limited by the design of engine fuel injection systems. The

maximum allowable viscosity for No. 2 diesel is 4.1 centistokes at 40°C although most

engines are designed to operate on fuels of higher viscosity. ASTM D6751 allows for

slightly higher viscosity for biodiesel. Mixing biodiesel with petroleum diesel lowers the

overall viscosity.

B100 freezes at higher temperatures than most conventional diesel fuel and this must

be taken into account if handling or using B100. Most B100 starts to cloud at between

35°F and 60°F, so heated fuel lines and tanks may be needed even in moderate

climates. As B100 begins to gel, the viscosity also begins to rise, and it rises to levels

much higher than most diesel fuel, which can cause increased stress on fuel pumps and

fuel injection systems. Cold weather properties are the biggest reason many people use

biodiesel blends.

Key Terms

z Biofuel – fuel made from recently grown plant or animal matter.

z Biodiesel – a type of fuel made by a transesterifcation reaction from natural oils

that can be used in a diesel engine with minimal or no alterations.

Copyright © 2009 Clarkson University, Office of Educational Partnerships revised 08/09

www.clarkson.edu/k12

6

z Viscosity – the property of a fluid that resists the force tending to cause the fluid

to flow.

z Glycerin – a co-product of biodiesel manufacture.

z Heating value – the heat energy released through the exothermic oxidation

(combustion) reaction when a fuel is combusted.

Student Learning Objectives NYS Standardsii

Learn to ask "why" questions to seek greater

understanding concerning objects and events they Science Standard 1.

have observed and heard about

Energy exists in many forms, and when these forms

Science Standard 4.

change energy is conserved.

(more needed)

Lesson Plan

This is a multi-day lesson that includes an introduction to biofuels, how they are made

and their pros and cons.

Introduction to Biofuels (1-2 days)

1. Review general concept – why we need alternative fuels

a. Depletion of fossil fuels (which have been great for past century – cheap,

abundant fuel supply, but that won’t last forever)

b. Climate change – combustion of fossil fuels for transportation are a major

source of greenhouse gases

c. Other toxic air pollutants

d. Energy independence – need less dependence on foreign oil

e. Review project – what we will be doing, how biofuels fit

2. Brainstorm – What do we already know about biofuels? (on board - build table

of information about biofuels as the discussion progresses)

a. What are biofuels?

b. What are some examples of biofuels? What are they made of

i. Show samples (in sealed glass vials)– see if students can guess

what the fuels are (gasoline, diesel, ethanol, biodiesel from pure

vegetable oil, biodiesel from fryer fat). Observe similarities and

differences (viscosity, color)

Copyright © 2009 Clarkson University, Office of Educational Partnerships revised 08/09

www.clarkson.edu/k12

7

Fuel Type Feedstocks Process Use

Ethanol Corn, sugar cane, Fermentation, Replacement for

corn stover, cellulosic gasoline

switchgrass technology

Biogas Manure, compostable Bacterial Replaces natural

waste degradation gas – cooking,

heating, electricity

Green Diesel Gas or low MW Fischer-Tropsch Replacement for

hydrocarbons chemical reaction, diesel

Pyrolysis

Biodiesel Any naturally Base-catalyzed Replacement for

occurring oils, fresh transesterification diesel

or recycled

Biobutanol fermentation Replacement for

gasoline

c. Other issues/questions

i. Oil and coal came from biomass, are they biofuels too?

ii. Where did the carbon come from that comprises biomass? Fossil

fuels? Is this carbon the same in terms of climate change

concerns?

d. Emphasize a generic approach to understanding biofuels – build generic

process flow diagram, starting with the “use” of fuel.

i. What kind of transportation vehicles can run on biofuels?

ii. How are they made (in general) and used? (draw general process

flow diagram)

1. Fuel must be made from a feedstock that is grown,

harvested and transported (the “grown” aspect of this not

applicable to waste oil which must be collected and

transported only)

2. The feedstock must be chemically or biologically converted

into a fuel in a manufacturing industry.

iii. What other inputs are required to make this process happen?

Consumer fuel

transportation

transportation

transportation

Feedstock

Biofuel

Fuel

Feedstock

Production Use in

Production Blending

(chemical processing vehicle

(farming)

industry) Petroleum

Fuel

Initial generic process flow diagram

Copyright © 2009 Clarkson University, Office of Educational Partnerships revised 08/09

www.clarkson.edu/k12

8

Air emissions

• CO, CO2 Air emissions Air emissions

• Particulates Fuel spills

• NOx, SOx

Water pollutants

Erosion

Consumer fuel

transportation

transportation

transportation

Feedstock

Biofuel

Fuel

Feedstock

Production Use in

Production Blending

(chemical processing vehicle

(farming)

industry) Petroleum

Fuel

Energy Energy

Fertilizer Process

Water chemicals

Land Water

Process flow diagram with greater detail

e. What benefits and concerns have you heard about biofuels

i. reduced GHG emissions

ii. renewable fuel

iii. food vs. fuel concerns (price, availability (especially in poor

countries))

iv. Land and water use

3. How much biofuels are required?

a. Identify EISA goals for biofuel production

i. 15 BGY bioethanol by 2015

ii. 36 BGY total biofuels by 2022

b. Use visual aids to help students understand the quantities involved

i. Show 2 ¾ gallons of “ethanol” (jugs of water) = ethanol from 1

bushel of corn

ii. Show 1 bushel basket

iii. 145 bushels of corn come from an acre

iv. 1 acre is about the size of a football field or 43,000 square feet

v. Do math – (emphasize units)

1. ethanol from one football field

Copyright © 2009 Clarkson University, Office of Educational Partnerships revised 08/09

www.clarkson.edu/k12

9

gal. etoh bu corn acre gal. etoh

2.75 × 145 × 1 = ~ 400

bu corn acre football field football field

2. number of football fields to generate 15 BGY corn ethanol

gal. etoh

15,000,000,000

y

= ~ 38 million football fields

gal. etoh

400

football field

c. Can compare this to how many classrooms of water that would take to

make ethanol

i. Pull aside one of the gallons of fake “ethanol” then bring out four

more gallons of water to show that each gallon of ethanol requires

four gallons of water to make.

ii. That is only in the fermentation stage - hundreds of gallons of water

are required (exact number depends on geography) to grow the

corn for a gallon of ethanol.

d. Define energy density:

i. the amount of energy or heating value contained in a volume of

fuel.

ii. Remember hydrogen has a very low energy density by volume, but

high energy density by mass.

iii. Ethanol is less energy dense than gasoline, by volume

iv. So if your car could run on pure ethanol, you could fill up your tank

with it, but you would not get as far as you would on a tank of gas

v. It takes about a gallon and a half of ethanol to get the same energy

as one gallon of gasoline.

4. Optional - Hand out ethanol calculation homework to continue with these

types of calculations

a. Project Ethanol worksheet and explain

b. Go through data section on left, explain units and magnitudes

c. Quickly go through questions on right, demonstrate calculations on first

question or two

d. If time allows, have students go to computer lab to go through all

questions on their own and calculate results

e. If not enough time, go through the worksheet as a class or send home as

homework.

f. Discussion questions on EtOH worksheet

i. What percentage of our transportation energy use would the

proposed 15 BGY ethanol displace?

ii. Is that displacement significant? Do you think it is worth it?

iii. Is it important to consider water use in producing biofuels? How

about land area? Why?

Copyright © 2009 Clarkson University, Office of Educational Partnerships revised 08/09

www.clarkson.edu/k12

10

5. Wrap up

a. Limits to continued use of fossil fuels for transportation

b. Biofuels mandated by Congress, will contribute to our future transportation

fuels

c. There are both benefits and concerns about the extended use of biofuels

i. What is it about biofuels that makes them so popular?

ii. Feedstock production has to be considered for expanding biofuel

use.

iii. More detail on this topic when we cover life-cycles of fuels.

Next time: Make biodiesel

Biodiesel Production and Testing (2 days)

1. Explain that we will be learning about and making biodiesel, how it is useful in

relation to regular diesel.

a. Diesel engine was originally designed to run on peanut oil

b. Petroleum diesel has a slightly higher energy value and is cheaper than

plant oils, but more polluting

c. Could still run diesel engine on vegetable oil, but there are problems with

viscosity so special heaters need to be installed

d. Any type of naturally occurring oil can be used to make biodiesel

e. Biodiesel has energy more readily available than vegetable oil, and a

lower viscosity so it is much easier to use in a diesel engine.

f. Up to 20% biodiesel in petroleum diesel can be used safely in any diesel

engine

2. Background about requirements for biodiesel

i. Process – explain in simple terms

i. Oil is mixed with methanol (alcohol) and catalyst (lye-sodium

hydroxide)

ii. Must be mixed because there are two liquid phases

iii. Heated to speed up reaction

iv. Settling, separation, washing

ii. Feedstocks

i. Options

a. fresh veg oil - soy, Jatropha, rapeseed

b. used veg oil - fryer oil

Copyright © 2009 Clarkson University, Office of Educational Partnerships revised 08/09

www.clarkson.edu/k12

11

c. Animal fats - bacon grease, alligator fats, processing

‘byproducts’

ii. Consider implications of feedstock requirements

a. If specific crops are grown for making biodiesel, other emissions

occur upstream, parallel to the H2 car scenario

b. Can waste oil supply feedstocks? - parallel to using renewable

energy for H2 production

c. Making biodiesel activity

i. Feedstocks: Fresh soybean oil; Used vegetable oil; Bacon Grease?

ii. Recipe

a. 250 mL Oil

b. Put in 500mL flask on heater/stir plate

c. Heat to 55 °C

d. Add Methoxide – turn heat down or off (Previously prepared 50

mL Methanol mixed with 0.875 g NaOH)

e. Stir vigorously for up to 30 min

f. product will have to stay overnight to settle

d. Discuss chemistry of biodiesel (done while reaction running)

i. triglyceride molecular structure (get to know this well, so you can

explain easily)

ii. transesterification

iii. ratios of reactants (hint at this, its a discussion question)

a. Molar 1 oil:3 MeOH

b. Volume/mass ~5 oil:1 MeOH

iv. emulsions (also hint at this, another discussion question) –

a. reaction surface

b. stability/separation

e. Wrap up

i. Making biodiesel – simple, can be done at home –

a. can do at small scale (directions for making biodiesel:

http://journeytoforever.org/biodiesel_make.html

b. Local production more secure/sustainable

ii. Next time – Calorimeter lab, energy of fuels

Copyright © 2009 Clarkson University, Office of Educational Partnerships revised 08/09

www.clarkson.edu/k12

12

3. Testing Biodiesel (day 2 of biodiesel activities)

a. Introduce the concept of the heating value of a fuel (see text in activity

sheet). Specifically point out

i. that the exothermic chemical reaction required to create heat

energy that is converted in an internal combustion (or diesel)

engine) to mechanical energy to move a vehicle.

ii. That the heating value of petroleum fuels is very high, that helps to

make them a very valuable resource. The heating value of biofuels

is less than their petroleum counterparts.

b. Introduce the concept of the lab experiment.

i. Use a candle to show that the mass of the fuel is lost as

combustion proceeds, we can use that mass loss and some

measure of heat released to quantify the heat value of a fuel.

ii. In a calorimeter, the heat released from fuel combustion is used to

heat water. We can estimate the change in the heat energy in the

water from the change in the temperature and the specific heat of

water.

iii. It is assumed that heat released from combustion = heat gained by

water. However, the calorimeter is not 100% efficient. This

introduces experimental errors.

iv. Review the equations and measurements required

v. Model the assembly of the calorimeter

c. The lab should take most of the period.

Roll cotton gauze Push top half into

Soda can into a wick and bottom half to

insert through hole create calorimeter

Cut in half*

+ =

~20 mL fuel into

* caution, edges sharp bottom half

d. While the fuels are combusting, show students demo of “fuels on ice” to

illustrate some of the down sides of biodiesel

i. Set up water and ice baths at different temperatures.

ii. Submerge into the water/ice baths vials of diesel fuel, soy oil and

biodiesel that the students made.

iii. Observe the vials for cloudiness and viscosity, discuss implications.

Copyright © 2009 Clarkson University, Office of Educational Partnerships revised 08/09

www.clarkson.edu/k12

13

e. Wrap up – reaffirm the overall concept, discuss experimental errors, make

sue the students understand lab report assignment.

Assessment

• Ethanol calculation homework (optional)

• Biodiesel production activity sheet

• Calorimeter laboratory report

Resource Files

• Ethanol Calculation homework

• Activity – Making Biodiesel

• Activity – Calorimeter

i

“Calorific values of solid, liquid and gaseous fuels.” http://www.kayelaby.npl.co.uk/chemistry/3_11/3_11_4.html.

Website accessed 28 Nov. 2007.

ii

University of the State of New York State Education Department (NYSED).

http://www.emsc.nysed.gov/ciai/mst.html. Website accessed 28 Nov. 2007

Copyright © 2009 Clarkson University, Office of Educational Partnerships revised 08/09

www.clarkson.edu/k12

1

Activity – Making Biodiesel

Purpose

In this activity we will be making biodiesel, a fuel that functions in diesel engine with

little or no alterations. The main advantages of biodiesel are that it is easy and

relatively safe to make, has a low toxicity and high biodegradability, and is near “carbon

neutral”.

Supplies

Safety glasses

Gloves

Heating stir plate with stir-bar

500 mL erlenmeyer flask

250 mL of oil (feedstock)

50 mL of Methoxide (methanol with catalytic amount of NaOH - 0.875g)

Thermometer

Safety Considerations

Methanol and sodium hydroxide are dangerous substances and should be handled with

caution! Methanol is poisonous to skin and by ingestion, and its fumes are highly

flammable. NaOH is a strong skin irritant and can cause blindness! Always wear gloves

and goggles when working with these chemicals, and keep any sparks or flames away

from methanol containers

Instructions

1. Put on safety glasses. Be aware that methoxide is flammable, poisonous, and

caustic; and that we will be working with heat.

2. Put the stir bar into your 500mL flask, place the flask on the heated stir plate and

turn the heat onto high. This will be your reaction vessel.

3. Pour your oil sample into the reaction vessel. Make and record observations of

the raw oil feedstock (color, viscosity, clarity, etc.)

4. In order for the reaction to proceed at a reasonable pace, the oil must be

warmed before adding the methoxide. Make sure the heat is on under your

reaction vessel, and turn on the stirrer to speed up the heating process. Use

your thermometer to keep track of the oil temperature.

5. When the temperature reaches 55 degrees C, the oil is ready.

6. Turn off the heat plate, the residual heat in the oil will be enough to help the

reaction along.

7. Turn off the stirrer.

8. Carefully, and slowly ad the 50mL of methoxide to the reaction vessel.

9. Make and record observations about the mixture. Are the reactants

homogeneous, or are their layers? If there are layers, which reactant is on top

and which is on the bottom?

Copyright © 2009 Clarkson University, Office of Educational Partnerships revised 08/09

www.clarkson.edu/k12

2

10. Now turn up the stirrer to full power. Mixing speeds up the reaction by

emulsifying the two phases and allowing the reactants to come together more

easily.

11. Continue stirring and allow the reaction to proceed for up to 30 minutes. After

this time, most of the reactants have been used up, so the remaining reaction is

insignificant.

12. Allow the flask to cool, or use a hot glove to grasp it, and pour the contents into

an appropriate container, provided by the teacher, to allow for settling. The

biodiesel will separate from its byproduct over the course of about 24 hours.

13. The following day – observe layers, decant biodiesel.

Observations

Raw oil feedstock:

Initial mixture of reactants:

During reaction:

After reaction, before settling:

After reaction, after settling:

Discussion Questions

1. What are the reactants used to make biodiesel in this lab? What are some

options for reactants, or “feedstocks”, that could be used to make biodiesel?

2. Based on the balanced chemical equation for the biodiesel formation reaction,

what ratio of the two reactants is required to allow the reaction to proceed to

completion?

3. What was the ratio of the volumes of the reactants used in this lab? Does this

volumetric ratio match the ratio of the reactants in your answer to Question 2?

Why or why not?

4. The biodiesel reaction occurs between two liquid phases, an aqueous

(hydrophilic) phase and a lipophilic (hydrophobic) phase – the reactants do not

readily mix together, nor do the products. Discuss one advantage and one

disadvantage resulting from the nature of this two-phase liquid reaction that

would have to be considered in designing a process for biodiesel production.

Copyright © 2009 Clarkson University, Office of Educational Partnerships revised 08/09

www.clarkson.edu/k12

1

Activity – Calorimeter Experiment

Overview

Fuels that we use have a wide variety of Heating Values. The heating value defines

how much heat is generated in the exothermic combustion reaction when the fuel is

burned. The heating value can be presented in terms energy released per the number

of the moles, or mass or volume of fuel. Petroleum fuels have very high heating values,

this makes them a very desirable fuel. Biofuels generally have a lower heating value.

Thus, you often need to use more volume of biofuels than volume of a comparable

petroleum fuel.

Gasoline 125,000 Btu/gal Ethanol 76,000 Btu/gal

Diesel fuel 128,450 Btu/gal Biodiesel – Waste vegetable oil 120,000 Btu/gal

A calorimeter is a tool used to measure the heating value of a fuel. This name came

from the standard use of “calories” as a measure of heat energy. A calorie is the

amount of heat required to heat one gram of water one degree Celsius. Heat energy is

also often measured in Joules (J) and British Thermal Units (Btus).

In a calorimeter, the fuel is burned creating a source of heat, which is used to heat

water. The increase in the water temperature is directly proportional to the heat input to

the water. The figure below illustrates the basic concept.

Experimental What happens What we measure

Concept

The temperature of a Mass (or volume) of water

Water is measured mass of Initial temperature of water

heated water in the flask Final temperature of the water

increases

Heat energy

Mass of fuel decreases Initial mass of fuel and can

Fuel is Final mass of fuel and can

as it is combusted

Combusted

The heat that is used to raise the temperature of the water can be calculated based on

the specific heat of water:

Q = m*c*ΔT

Where:

Q is the heat flow (calories)

m is the mass of the water (grams)

c is the specific heat of water (c = 1 calorie/gram)

ΔT is the temperature change (°C)

Copyright © 2009 Clarkson University, Office of Educational Partnerships revised 08/09

www.clarkson.edu/k12

2

It is assumed that the heat energy used to raise the water temperature equals the heat

released by the exothermic combustion reaction.

The quality of the measurements depends on the efficiency of the system in directing all

heat from the flame to the water. Any losses to the ambient air and water/fuel

containers will reduce the calculated heat value of the fuel.

Purpose

The purpose of this experiment is to measure the heating value of a fuel (MJ/kg). The

biodiesel generated in the previous class will be tested alongside other standard fuels.

Safety Aspects

• The combustion of fuels is inherently dangerous. The experiment requires open

flames. Safety goggles must be worn and no loose hair or clothing allowed.

• The fuel and water vessels get very hot; tongs of insulated gloves are required

for disassembly and the final weighing of the fuel.

• Some fuels create a lot of smoke when combusted. A fume hood or room with

great air ventilation should be used.

Materials

♦ Erlenmeyer Flask

♦ Ring Stand

♦ Graduated Cylinder

♦ Thermometer

♦ Soda can calorimeter (see notes below)

♦ Wick made of Cotton Gauze or cheesecloth (2 × 10 cm)

♦ Aluminum Foil Shields

♦ Water (200 mL)

♦ Fuel (~20 mL) (one type per group: biodiesel, canola or soy oil, petroleum diesel)

♦ Safety glasses

♦ Tongs or gloves to hold hot objects

Instructions

♦ Put your safety goggles on and tie back any long hair.

♦ Record your fuel type in the Data Table.

♦ Assemble the calorimeter (see the figure below).

o Use approximately 20mL of your fuel into the bottom half of the soda can

calorimeter. It should be about ½ to 1 inch deep.

o Roll the cotton gauze wick and insert through drinking hole in can top. Drip

a few drops of fuel onto the top of the wick to make sure there is fuel to

burn at the top

o Assemble the calorimeter carefully (edges are sharp)

Copyright © 2009 Clarkson University, Office of Educational Partnerships revised 08/09

www.clarkson.edu/k12

3

o Weigh the entire apparatus and record weight in the data table.

Roll cotton gauze Push top half into

Soda can into a wick and bottom half to

insert through hole create calorimeter

Cut in half*

+ =

~20 mL fuel into

* caution, edges sharp bottom half

♦ Assemble the water heating flask:

o Pour 200 mL of water into the flask (using the graduated cylinder).

o Place the flask on the ring stand (or use a clamp as your teacher directs);

approximately ten centimeters (~ 4 in.) above the base.

o Measure the temperature of the water in your can and record the initial

temperature.

♦ Place the soda can fuel container below the flask of water.

♦ Place your aluminum foil shield around the bottom of the flask like a skirt.

♦ Carefully light the wick and let the fuel burn for about ten minutes, or until you get

about 30-40°C change in temperature. The time required will vary with different

fuels. Use a thermometer in the flask to slowly stir the water.

♦ Extinguish the wick by covering with ceramic crucible.

♦ Record the final temperature of the water. Remove the aluminum foil skirt, and

record the final mass of the soda can (with remaining fuel and wick).

Data Table

FUEL TYPE:

Mass of soda can and fuel before burning: grams

Mass of soda can and fuel after burning: grams

Volume of water in flask: mL

Initial water temperature: °C

Final water temperature: °C

Copyright © 2009 Clarkson University, Office of Educational Partnerships revised 08/09

www.clarkson.edu/k12

4

Calorimeter Experiment - Calculations

1. Calculate the mass of fuel combusted (grams).

2. Calculate the change in temperature of the water due to heating by the fuel (°C).

3. The density of water is 1g/mL. Calculate the mass of water you heated (grams).

4. Calculate the heat flow in calories released by combusting your fuel, use the

following formula and check your units:

Q = m*c*ΔT

Where:

Q is the heat flow (calories)

m is the mass of the water (grams)

c is the specific heat of water (c = 1 calorie/gram)

ΔT is the temperature change (°C)

5. The metric unit of energy is the joule (J). Calculate the number of joules released

during your fuel combustion. (1 calorie = 4.186 joules)

6. Divide the number of joules released by the mass of oil combusted. What is the

heating value of your fuel (MJ/kg)?

Calorimeter Activity – Lab Report Instructions

Copyright © 2009 Clarkson University, Office of Educational Partnerships revised 08/09

www.clarkson.edu/k12

5

For this lab you will be required to write a lab report. The lab report must include

the following sections.

1. Introduction – Give some background about the different fuels we combusted,

and why we might be interested in measuring their heating values. [1/2 – 1 page]

2. Objective – One sentence describing the goal of the lab.

3. Procedure – Basically repeat the procedure described in the lab in paragraph

form. But leave out obvious stuff (like “pour water into flask”) and expand a little

on why the main steps (like “record the starting mass of your fuel”) are important.

[1/2 – 1 page]

4. Results – Restate the results you recorded in the data table, the calculations you

did, and the results of the calculations. [1 page]

5. Discussion – Answer the discussion questions, and relate them to the

experiment where appropriate. [1 – 2 pages]

6. Conclusion – Brief overview of the entire lab report, stating the main results, any

problems you had, and suggestions for future labs. [1 page]

Discussion questions:

1. How do your results compare to the reported heating values of diesel (46 MJ/Kg),

biodiesel (33–40 MJ/Kg), or canola oil (36.9 MJ/Kg) 1 ?

2. How does the experiment we performed differ from an ideal, controlled

experiment?

3. Where do you think the biggest errors came from?

4. Why is the heating value of biodiesel reported as a range?

5. Which fuel (diesel, biodiesel, or vegetable oil) is most “efficient” in a vehicle?

Explain your answer?

6. Sample problem: The mass heat of combustion of Fuel B is 1,250 kJ/g. If you

were to burn 15 grams of this compound in a bomb calorimeter (a special device

that allows almost no heat loss) with a reservoir that holds 2.50 L of water, what

would the expected temperature increase be?

1

“Calorific values of solid, liquid and gaseous fuels.” http://www.kayelaby.npl.co.uk/chemistry/3_11/3_11_4.html.

Accessed 28 Nov. 2007.

Copyright © 2009 Clarkson University, Office of Educational Partnerships revised 08/09

www.clarkson.edu/k12

Вам также может понравиться

- Report Myanmar Opium Survey 2020 UNODCДокумент64 страницыReport Myanmar Opium Survey 2020 UNODCAung Thet ThanОценок пока нет

- Cafi Final PaperДокумент11 страницCafi Final Paperapi-437719364Оценок пока нет

- Myanmar Opium Survey 2021Документ58 страницMyanmar Opium Survey 2021saptarshi mukhopadhyayОценок пока нет

- 2.VPP Presentation of Task 2 Part 1 IE enДокумент20 страниц2.VPP Presentation of Task 2 Part 1 IE enTrần Quang MinhОценок пока нет

- FactSet Bank Tracker: 7-AugДокумент11 страницFactSet Bank Tracker: 7-AugBrianОценок пока нет

- PCA Regional Office V Road Map PresentationДокумент37 страницPCA Regional Office V Road Map PresentationAudrei MujarОценок пока нет

- Thailand Sugar Industry Outlook 2018-20Документ9 страницThailand Sugar Industry Outlook 2018-20Pranetr RaksincharoensakОценок пока нет

- 214 Industry Report FinalДокумент7 страниц214 Industry Report Finalapi-661554832Оценок пока нет

- Data Analyisis Part 2Документ4 страницыData Analyisis Part 2mohsin ashiqОценок пока нет

- Session 14Документ41 страницаSession 14ZHANG EmilyОценок пока нет

- Extremism in The Ranks and After - October - 12 - 2021 Final-1-1Документ6 страницExtremism in The Ranks and After - October - 12 - 2021 Final-1-1The Department of Official InformationОценок пока нет

- WindEurope Mid Year Offshore Statistics 2016Документ19 страницWindEurope Mid Year Offshore Statistics 2016anteoprivatoОценок пока нет

- 4-Panorama-2017 VA EtatDesLieuxPerspectivesBiocarburants v3Документ5 страниц4-Panorama-2017 VA EtatDesLieuxPerspectivesBiocarburants v3Steven PeñaОценок пока нет

- Rupee The New Dollar - 230507 - 211659Документ12 страницRupee The New Dollar - 230507 - 211659raj_techieОценок пока нет

- Greenhouse Gas EmissionsДокумент1 страницаGreenhouse Gas EmissionsClock 9Оценок пока нет

- GREED & Fear Pressure Cooker Adjusted - JefferiesДокумент25 страницGREED & Fear Pressure Cooker Adjusted - JefferiesVivek AgОценок пока нет

- WARC Global Ad Trends State of The Industry 2020 21 SAMPLEДокумент31 страницаWARC Global Ad Trends State of The Industry 2020 21 SAMPLEVanessa FonsecaОценок пока нет

- Anticipated Market and Pricing Impacts From New Marine Fuel RegulationsДокумент5 страницAnticipated Market and Pricing Impacts From New Marine Fuel Regulationsingbarragan87100% (1)

- FOXBORO IA - Series - Lifecycle - Product - Phase - ListingДокумент26 страницFOXBORO IA - Series - Lifecycle - Product - Phase - Listingtricucha priyantoОценок пока нет

- Does India Require Environmental Super-Regulator: A Critical Analysis of The Extant and InnovateДокумент7 страницDoes India Require Environmental Super-Regulator: A Critical Analysis of The Extant and InnovateLenin Toribio DiegoОценок пока нет

- Annual Outlook 2023Документ51 страницаAnnual Outlook 2023AbdusОценок пока нет

- 2 - Avendano - Digital Regulation Framework For ASEANДокумент15 страниц2 - Avendano - Digital Regulation Framework For ASEANAom SakornОценок пока нет

- Macro L6Документ16 страницMacro L6naspgОценок пока нет

- Canadian Dollar Vs Pakistani RupeeДокумент2 страницыCanadian Dollar Vs Pakistani Rupeebehroze khattakОценок пока нет

- TransTech Diseño PlantaДокумент24 страницыTransTech Diseño PlantaAndres PercyОценок пока нет

- CBOAnalysisof BudgetДокумент5 страницCBOAnalysisof BudgetCommittee For a Responsible Federal BudgetОценок пока нет

- Analisis Pengaruh Inflasi, Suku Bunga Kredit, Pendapatan Per Kapita Terhadap Penanaman Modal Dalam Negeri Di IndonesiaДокумент19 страницAnalisis Pengaruh Inflasi, Suku Bunga Kredit, Pendapatan Per Kapita Terhadap Penanaman Modal Dalam Negeri Di IndonesiaEllisyaОценок пока нет

- ecoFORCE Folder ENGДокумент12 страницecoFORCE Folder ENGNitinОценок пока нет

- 1q 22 Ir Roadshow PresentationДокумент68 страниц1q 22 Ir Roadshow PresentationIosu Arrue GanzarainОценок пока нет

- ARF Climate Risk Into Credit Risk ModelsДокумент18 страницARF Climate Risk Into Credit Risk ModelssamiОценок пока нет

- IO Motorcycle 2017 EN PDFДокумент7 страницIO Motorcycle 2017 EN PDFKaren PendumaОценок пока нет

- Practice U3O1 Part 2 # 2Документ9 страницPractice U3O1 Part 2 # 2lachykoumisОценок пока нет

- 5,115 KM 5,400 KM 4,431 KM 5,696 KM: © 2019 Mapbox ©openstreetmapДокумент1 страница5,115 KM 5,400 KM 4,431 KM 5,696 KM: © 2019 Mapbox ©openstreetmapCarlos TrujilloОценок пока нет

- UNCTAD (2019) From Development To Differentiation - Just How Much Has The World ChangedДокумент33 страницыUNCTAD (2019) From Development To Differentiation - Just How Much Has The World ChangedlluvesliОценок пока нет

- FullCV Prof - Mahmoodi March2022Документ19 страницFullCV Prof - Mahmoodi March2022Terem Tebauta JrОценок пока нет

- Africa's Growing Debt Crisis: Who Is The Debt Owed To?Документ24 страницыAfrica's Growing Debt Crisis: Who Is The Debt Owed To?Liu YanОценок пока нет

- Rupsha Power Plant PDFДокумент19 страницRupsha Power Plant PDFHossain Mohammad MahbubОценок пока нет

- MAEcono Pol 3Документ117 страницMAEcono Pol 3Edimarf SatumboОценок пока нет

- Toolkit PDFДокумент36 страницToolkit PDFdomingoscorreiaОценок пока нет

- ECO314 Assignment 3Документ6 страницECO314 Assignment 3adisuaeОценок пока нет

- Artificial Lift For Guest LectureДокумент117 страницArtificial Lift For Guest LectureZenga Harsya Prakarsa100% (1)

- G30 2023 Why Does Latin America Underperform SELECCДокумент20 страницG30 2023 Why Does Latin America Underperform SELECCporota loverОценок пока нет

- Earnings Growth Is The Biggest Driver of Share Prices : Sensex Price Sensex PE (X) Sensex EPSДокумент20 страницEarnings Growth Is The Biggest Driver of Share Prices : Sensex Price Sensex PE (X) Sensex EPSravstuhiОценок пока нет

- Usman Ashraf-85 PresentationДокумент18 страницUsman Ashraf-85 PresentationDopest KhanОценок пока нет

- CV Ana Ventura en 23.05.2023Документ13 страницCV Ana Ventura en 23.05.2023Ana Cristina VenturaОценок пока нет

- 4Документ1 страница4Gissa SevieОценок пока нет

- 2Документ1 страница2Gissa SevieОценок пока нет

- HVS India Hotels Outlook Impact of COVID 19Документ18 страницHVS India Hotels Outlook Impact of COVID 19gaurav englesОценок пока нет

- Environmental Perfomance Indicators-2017 - GHG PDFДокумент2 страницыEnvironmental Perfomance Indicators-2017 - GHG PDFalejandro ramirezОценок пока нет

- Chile Day NY Toronto Jun 2023 - V7Документ48 страницChile Day NY Toronto Jun 2023 - V7Contacto Ex-AnteОценок пока нет

- Sustainability 12 05303Документ14 страницSustainability 12 05303world citizenОценок пока нет

- Macroeconomisc Essay Jimena LizДокумент19 страницMacroeconomisc Essay Jimena LizJimena LizОценок пока нет

- Biofuels Annual Manila Philippines 10-28-2019Документ13 страницBiofuels Annual Manila Philippines 10-28-2019Michael GarciaОценок пока нет

- What Matters For Latam in 2020?: 6th BBVA Latin America ConferenceДокумент26 страницWhat Matters For Latam in 2020?: 6th BBVA Latin America ConferenceCabezaFriaОценок пока нет

- 30745-Article Text-112087-1-10-20220714Документ12 страниц30745-Article Text-112087-1-10-20220714Zun NguyenОценок пока нет

- Apec Oct 2018 Infog - Bogor - 181102 - 1536Документ2 страницыApec Oct 2018 Infog - Bogor - 181102 - 1536Zelfina FahiraОценок пока нет

- Trend of The Agredated GHG Per Capita, Per Square KM and Per GDPДокумент36 страницTrend of The Agredated GHG Per Capita, Per Square KM and Per GDPAnisoaraBotnariОценок пока нет

- Presentation To The Cabinet by Governor - 28 June 2023 (E Final)Документ34 страницыPresentation To The Cabinet by Governor - 28 June 2023 (E Final)Janaka PriyalalОценок пока нет

- Malaysia'S Cocoa Industry: Progress and DevelopmentДокумент29 страницMalaysia'S Cocoa Industry: Progress and DevelopmentaseancocoaclubОценок пока нет

- COVID-19 in Humanitarian Settings and LessonsДокумент2 страницыCOVID-19 in Humanitarian Settings and LessonsLuis LopezОценок пока нет

- Poplar Populus SPP Trees For Biofuel ProductionДокумент12 страницPoplar Populus SPP Trees For Biofuel ProductionLuis LopezОценок пока нет

- Reporte Sustentabilidad 2021 VW InglesДокумент111 страницReporte Sustentabilidad 2021 VW InglesLuis LopezОценок пока нет

- Associations Between Blood Type and Covid Infection Intubation and DeathДокумент6 страницAssociations Between Blood Type and Covid Infection Intubation and DeathLuis LopezОценок пока нет

- Green Biodiesel Production A Review On Feedstook Catalyst Monolithic Reactor and Supercritical Fluid TechnologyДокумент17 страницGreen Biodiesel Production A Review On Feedstook Catalyst Monolithic Reactor and Supercritical Fluid TechnologyLuis LopezОценок пока нет

- TBD Devastator Squadron Signal Aircraft in Action 1Документ52 страницыTBD Devastator Squadron Signal Aircraft in Action 1Luis Lopez100% (4)

- Dinosaurs and Dinosaurs Like AnimalsДокумент12 страницDinosaurs and Dinosaurs Like AnimalsLuis LopezОценок пока нет

- Diversity Late Cretaceous Dinosaurs From MexicoДокумент47 страницDiversity Late Cretaceous Dinosaurs From MexicoLuis LopezОценок пока нет

- Superiority Competition Opportunism in Evolutionary Radiation of DinosaursДокумент5 страницSuperiority Competition Opportunism in Evolutionary Radiation of DinosaursLuis LopezОценок пока нет

- Sex Drugs Disasters and The Extinction of DinosaursДокумент5 страницSex Drugs Disasters and The Extinction of DinosaursLuis LopezОценок пока нет

- Maximizing and Collecting Algae Biomass For Fuel ProductionДокумент5 страницMaximizing and Collecting Algae Biomass For Fuel ProductionLuis LopezОценок пока нет

- Microscopy As A Toll Deconstruction of Lignocellulosic BiomassДокумент7 страницMicroscopy As A Toll Deconstruction of Lignocellulosic BiomassLuis LopezОценок пока нет

- Wood Chips To Biofuel in HoursДокумент2 страницыWood Chips To Biofuel in HoursLuis LopezОценок пока нет

- Aphids and Ants, Mutualistic Species, Share A Mariner Element With An Unusual Location On Aphid Chromosomes - PMCДокумент2 страницыAphids and Ants, Mutualistic Species, Share A Mariner Element With An Unusual Location On Aphid Chromosomes - PMC2aliciast7Оценок пока нет

- What Is A Solar Storm?Документ2 страницыWhat Is A Solar Storm?Shawn SriramОценок пока нет

- 2 Avaliação Edros 2023 - 7º Ano - ProvaДокумент32 страницы2 Avaliação Edros 2023 - 7º Ano - Provaleandro costaОценок пока нет

- PDAJChallenge KitДокумент15 страницPDAJChallenge KitElango Minnoor100% (1)

- Training and BreathingДокумент6 страницTraining and BreathingMIIIBОценок пока нет

- Writing The Motherland From The DiasporaДокумент23 страницыWriting The Motherland From The DiasporaIfeoluwa Watson100% (1)

- Sim Medium 2 (English)Документ2 страницыSim Medium 2 (English)TheLobitoОценок пока нет

- Dearcán Ó Donnghaile: ProfileДокумент2 страницыDearcán Ó Donnghaile: Profileapi-602752895Оценок пока нет

- 006R5-WMS-JI-MI-MAU-ACS-II-23 Working Method - Pile CapДокумент20 страниц006R5-WMS-JI-MI-MAU-ACS-II-23 Working Method - Pile CapEko Budi HartantoОценок пока нет

- Theory of Accounts On Business CombinationДокумент2 страницыTheory of Accounts On Business CombinationheyОценок пока нет

- Stepanenko DermatologyДокумент556 страницStepanenko DermatologySanskar DeyОценок пока нет

- Broza Saric Kundalic - Ethnobotanical Study On Medicinal +Документ16 страницBroza Saric Kundalic - Ethnobotanical Study On Medicinal +turdunfloranОценок пока нет

- February 2023 PROGRAM OF THE MPLEДокумент8 страницFebruary 2023 PROGRAM OF THE MPLEDale Iverson LacastreОценок пока нет

- EarthmattersДокумент7 страницEarthmattersfeafvaevsОценок пока нет

- DoDough FriedДокумент7 страницDoDough FriedDana Geli100% (1)

- The Nursing ShortageДокумент6 страницThe Nursing Shortageapi-455495817Оценок пока нет

- 742210V01Документ2 страницы742210V01hakim_zadehОценок пока нет

- O OP PE ER RA Attiin NG G Iin NS STTR RU UC Cttiio ON NS S: UF 755 G UF 455 GДокумент14 страницO OP PE ER RA Attiin NG G Iin NS STTR RU UC Cttiio ON NS S: UF 755 G UF 455 GHomeroPerezОценок пока нет

- Chuyên Anh S Hà N I 2021Документ5 страницChuyên Anh S Hà N I 2021Jennifer WatsonОценок пока нет

- Performance Management and Strategic Planning:: Organization's Strategic PlanДокумент7 страницPerformance Management and Strategic Planning:: Organization's Strategic PlanSara AbidОценок пока нет

- Ronnel Del RioДокумент5 страницRonnel Del Rioamity balweg100% (2)

- Urinary Tract Infection (UTI) - 4 Nursing Diagnosis InterventionsДокумент4 страницыUrinary Tract Infection (UTI) - 4 Nursing Diagnosis InterventionsEricsonMitra0% (2)

- Gulayan Sa Barangay OrdinanceДокумент2 страницыGulayan Sa Barangay OrdinancekonsinoyeОценок пока нет

- Screenshot 2019-10-30 at 12.44.00Документ25 страницScreenshot 2019-10-30 at 12.44.00Miền VũОценок пока нет

- Decision Trees QuestionsДокумент2 страницыDecision Trees QuestionsSaeed Rahaman0% (1)

- Hedayati2014 Article BirdStrikeAnalysisOnATypicalHeДокумент12 страницHedayati2014 Article BirdStrikeAnalysisOnATypicalHeSharan KharthikОценок пока нет

- Naming Alcohols, Aldehydes. EtcДокумент1 страницаNaming Alcohols, Aldehydes. Etcim_mikezОценок пока нет

- Surgical Management in LeprosyДокумент33 страницыSurgical Management in Leprosynsv.epicОценок пока нет

- Case Diagnosis For RomanДокумент4 страницыCase Diagnosis For RomanChris Marie JuntillaОценок пока нет

- Reading Test - 3 Clinical Depression Text AДокумент17 страницReading Test - 3 Clinical Depression Text AJisha JanardhanОценок пока нет