Академический Документы

Профессиональный Документы

Культура Документы

5.0 Fabrication-20 PDF

Загружено:

Rohit KambleОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

5.0 Fabrication-20 PDF

Загружено:

Rohit KambleАвторское право:

Доступные форматы

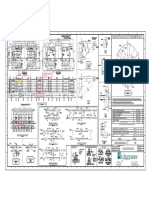

CLAUSE 5. FABRICATION AWS D1.1/D1.

1M:2015

a Radius shall provide smooth notch-free transition; R ≥ 3/8 in [10 mm] (Typical 1/2 in [12 mm]).

b Access hole made after welding web to flange.

c Access hole made before welding web to flange. The web to flange weld shall not be returned through hole.

dh

min = 3/4 in [20 mm] or tw (web thickness), whichever is greater, hmin need not exceed 2 in [50 mm].

e These are typical details for joints welded from one side against steel backing. Alternative joint designs should be considered.

Note: For rolled shapes with flange thickness greater than 2 in [50 mm] and built-up shapes with web material thickness greater than

1-1/2 in [40 mm], preheat to 150°F [65°C] prior to thermal cutting, grind and inspect thermally cut edges of access hole using MT or PT

methods prior to making web and flange splice groove welds.

Figure 5.2—Weld Access Hole Geometry (see 5.16.1.2)

184

Вам также может понравиться

- Thermal CuttingДокумент32 страницыThermal CuttingoviemeОценок пока нет

- 5.0 Fabrication-8 PDFДокумент1 страница5.0 Fabrication-8 PDFRohit KambleОценок пока нет

- Marth 1800 PrestressingДокумент17 страницMarth 1800 PrestressingRamesh100% (4)

- Pipe Fabrication RequirementsДокумент6 страницPipe Fabrication RequirementsHansel FrancisОценок пока нет

- NTT-COOLING TOWER - Structural Priced BOQ R3-09-03-2021Документ18 страницNTT-COOLING TOWER - Structural Priced BOQ R3-09-03-2021Corrosion Factory100% (1)

- Acceptance Criteria of Weld Defects As Per Different CodesДокумент17 страницAcceptance Criteria of Weld Defects As Per Different CodesTanveer Rajput EngrОценок пока нет

- TDS PH GabionZinc+PVC May2014Документ2 страницыTDS PH GabionZinc+PVC May2014SunderОценок пока нет

- Acceptance Criteria of Weld Defects As Per Different CodesДокумент17 страницAcceptance Criteria of Weld Defects As Per Different CodesNavanitheeshwaran Sivasubramaniyam100% (3)

- Design - Part 3 - TWIДокумент9 страницDesign - Part 3 - TWIFreddie KooОценок пока нет

- Spec - ACOДокумент5 страницSpec - ACOReza MohebbiОценок пока нет

- Design Procedure Joint ConfigurationДокумент18 страницDesign Procedure Joint ConfigurationaydaОценок пока нет

- Acceptance Criteria of Weld Defects As Per Different CodesДокумент17 страницAcceptance Criteria of Weld Defects As Per Different CodesShubham ShuklaОценок пока нет

- ST 21Документ9 страницST 21amarnath_jbbОценок пока нет

- Building TolerencesДокумент9 страницBuilding TolerencesmasteriragaОценок пока нет

- Acceptance Criteria of Weld Defects As Per Different CodesДокумент17 страницAcceptance Criteria of Weld Defects As Per Different CodesShankar Pl GowdaОценок пока нет

- Acceptance Criteria of Weld DefectsДокумент17 страницAcceptance Criteria of Weld DefectsvikasОценок пока нет

- Acceptance Criteria of Weld Defects As Per Different CodesДокумент17 страницAcceptance Criteria of Weld Defects As Per Different CodesDudy Pindayana FirdausОценок пока нет

- Technical Specifications: Duct Work and Outlets GeneralДокумент16 страницTechnical Specifications: Duct Work and Outlets GeneralNedunuri.Madhav MurthyОценок пока нет

- Acceptance Criteria of Weld Defects As Per Different CodesДокумент17 страницAcceptance Criteria of Weld Defects As Per Different CodesdhasdjОценок пока нет

- AWS ReferenceДокумент2 страницыAWS ReferenceKent TanakОценок пока нет

- S10-Specification For Gabion Reinforced Earth SystemДокумент9 страницS10-Specification For Gabion Reinforced Earth SystemwongtianhuiОценок пока нет

- Aluminum Welding ProceedureДокумент14 страницAluminum Welding ProceedureGregEverett2Оценок пока нет

- D-5) Piping InstallationДокумент8 страницD-5) Piping InstallationfbellimamОценок пока нет

- Bridge Girder Intermediate Diaphragms - 1Документ5 страницBridge Girder Intermediate Diaphragms - 1Anonymous dWa1xtpKmfОценок пока нет

- Module 4 Lecture 8 FinalДокумент17 страницModule 4 Lecture 8 Finaltejap314Оценок пока нет

- Tolerances As Per Aws D1.1: Structural Welding CodeДокумент34 страницыTolerances As Per Aws D1.1: Structural Welding Codeegy pureОценок пока нет

- TDS - Galmac PVC Coated Gabions June 10Документ2 страницыTDS - Galmac PVC Coated Gabions June 10Chana PalominoОценок пока нет

- NDT-Acceptance Various CodesДокумент17 страницNDT-Acceptance Various CodesShanmuga NavaneethanОценок пока нет

- GMAW Welding Process Training For High Neck FlangeДокумент5 страницGMAW Welding Process Training For High Neck FlangeHoàng ĐứcОценок пока нет

- BoQ 33 - 11 KV SUBSTATION - 01Документ13 страницBoQ 33 - 11 KV SUBSTATION - 01Ricky ChangОценок пока нет

- Section 2 CTs PTs CVTsДокумент35 страницSection 2 CTs PTs CVTsthumula.rameshОценок пока нет

- Teromatec Eo 8355: Description Procedure of UseДокумент1 страницаTeromatec Eo 8355: Description Procedure of UseAravind rajОценок пока нет

- Stellgrid HR 30Документ2 страницыStellgrid HR 30Mario CordovaОценок пока нет

- CraneДокумент19 страницCranedeua2004Оценок пока нет

- Specification of 11KV MUДокумент16 страницSpecification of 11KV MUPaatala Raagamlo Jeevitha SaagaramОценок пока нет

- X4o0Z5CxUpSv - BOQ FOR LITENДокумент19 страницX4o0Z5CxUpSv - BOQ FOR LITENsunjeyОценок пока нет

- Connection Design - Its Role in Steel DetailingДокумент9 страницConnection Design - Its Role in Steel DetailingEduardo De Castro Cruz Jr.Оценок пока нет

- Design For Hot Dip GalvanisingДокумент9 страницDesign For Hot Dip GalvanisingSreedhar Patnaik.MОценок пока нет

- Introduction-Design-Guide 2Документ16 страницIntroduction-Design-Guide 2Sutha100% (1)

- 2a. Specs For Valves - IAДокумент4 страницы2a. Specs For Valves - IAPraveen KasrottaranОценок пока нет

- Pages From Specification For Structural Steel Building AISC 2005Документ2 страницыPages From Specification For Structural Steel Building AISC 2005SamsuОценок пока нет

- 5.22.1.1 Faying Surface. (AWS D1.1 2000)Документ3 страницы5.22.1.1 Faying Surface. (AWS D1.1 2000)david_baena8586Оценок пока нет

- 2-Sheet Metal Structures TextДокумент29 страниц2-Sheet Metal Structures Textaerogem618Оценок пока нет

- RC Detailing To EuroCode 2Документ39 страницRC Detailing To EuroCode 2ahmadОценок пока нет

- 24 Loomis Welding Procedures 9.10.14Документ22 страницы24 Loomis Welding Procedures 9.10.14viswamanojОценок пока нет

- Gabiões Zinc CoatedДокумент2 страницыGabiões Zinc CoatedAntonio BrasilОценок пока нет

- Closed Drop Forging Die DesignДокумент39 страницClosed Drop Forging Die DesignMohit WaniОценок пока нет

- International Standard For High Frequency Welded Fins DownloadДокумент3 страницыInternational Standard For High Frequency Welded Fins DownloadPrasad Dhume50% (2)

- Weld Like a Pro: Beginning to Advanced TechniquesОт EverandWeld Like a Pro: Beginning to Advanced TechniquesРейтинг: 4.5 из 5 звезд4.5/5 (6)

- Linotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeОт EverandLinotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeОценок пока нет

- How to prepare Welding Procedures for Oil & Gas PipelinesОт EverandHow to prepare Welding Procedures for Oil & Gas PipelinesРейтинг: 5 из 5 звезд5/5 (1)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsОт Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsРейтинг: 4 из 5 звезд4/5 (1)

- 91symp11 2Документ1 страница91symp11 2Rohit KambleОценок пока нет

- 91symp11 3Документ1 страница91symp11 3Rohit KambleОценок пока нет

- 91symp11 1Документ1 страница91symp11 1Rohit KambleОценок пока нет

- OffshoreДокумент225 страницOffshoreRohit KambleОценок пока нет

- Penguard Primer: Technical DataДокумент4 страницыPenguard Primer: Technical DataRohit KambleОценок пока нет

- Aws D1.1 D1.1M-2010 - Structural Welding Code-Steel-1Документ1 страницаAws D1.1 D1.1M-2010 - Structural Welding Code-Steel-1Rohit Kamble0% (1)

- Return Trip RedBus Ticket - TQ3K22800244Документ3 страницыReturn Trip RedBus Ticket - TQ3K22800244Rohit KambleОценок пока нет

- Procedure Qualification Record - Page 1 of 2Документ3 страницыProcedure Qualification Record - Page 1 of 2Rohit KambleОценок пока нет

- 46606-1-Application Format Chartered Engineer CertificateДокумент1 страница46606-1-Application Format Chartered Engineer CertificateRohit KambleОценок пока нет

- 9607 BRO 0005 06 Corporate Brochure SCREEN1Документ12 страниц9607 BRO 0005 06 Corporate Brochure SCREEN1Rohit KambleОценок пока нет

- Work Breakdown StructureДокумент6 страницWork Breakdown StructureRohit KambleОценок пока нет

- TYP TYP: Sideshell Angles Marked in Red 200 100 16Документ1 страницаTYP TYP: Sideshell Angles Marked in Red 200 100 16Rohit KambleОценок пока нет

- Onshore Weighing Procedure: Project Name: Tapti Decommissioning ProjectДокумент32 страницыOnshore Weighing Procedure: Project Name: Tapti Decommissioning ProjectRohit KambleОценок пока нет

- Status of COVID-19 Vaccines Within WHO EUL/PQ Evaluation ProcessДокумент2 страницыStatus of COVID-19 Vaccines Within WHO EUL/PQ Evaluation ProcessRohit KambleОценок пока нет