Академический Документы

Профессиональный Документы

Культура Документы

27x1 TDS

Загружено:

ajaldaco0 оценок0% нашли этот документ полезным (0 голосов)

205 просмотров1 страницаPRESTEC COMPOSITE COATINGS FORMULATING "AIR CURE" HI-GLOSS CLEAR / PIGMENTED POLYESTER SURFACE COATING. 27X1 CLEAR HI GLOSS TOP COAT - EXOTIC WOOD COATING GEL COAT ADDITIVE FOR AIR CURE APPLICATIONS - PRODUCT FEATURES EXCEPTIONAL UV RESISTANT SUPER CLEAR--GLAS

Исходное описание:

Авторское право

© Attribution Non-Commercial (BY-NC)

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документPRESTEC COMPOSITE COATINGS FORMULATING "AIR CURE" HI-GLOSS CLEAR / PIGMENTED POLYESTER SURFACE COATING. 27X1 CLEAR HI GLOSS TOP COAT - EXOTIC WOOD COATING GEL COAT ADDITIVE FOR AIR CURE APPLICATIONS - PRODUCT FEATURES EXCEPTIONAL UV RESISTANT SUPER CLEAR--GLAS

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

205 просмотров1 страница27x1 TDS

Загружено:

ajaldacoPRESTEC COMPOSITE COATINGS FORMULATING "AIR CURE" HI-GLOSS CLEAR / PIGMENTED POLYESTER SURFACE COATING. 27X1 CLEAR HI GLOSS TOP COAT - EXOTIC WOOD COATING GEL COAT ADDITIVE FOR AIR CURE APPLICATIONS - PRODUCT FEATURES EXCEPTIONAL UV RESISTANT SUPER CLEAR--GLAS

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 1

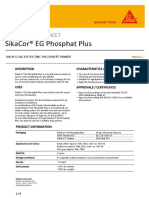

PRESTEC COMPOSITE COATINGS

FORMULATING “AIR CURE” POLYMER COATINGS SINCE 1979

SEALERS ◦ PUTTIES ◦ PRIMERS ◦ HI-GLOSS CLEAR / PIGMENTED

POLYESTER SURFACE COATINGS — 27X1 CLEAR HI GLOSS TOP COAT

-PRODUCT APPLICATIONS-

-PRODUCT SPECIFICATIONS-

EXOTIC WOOD COATING

GEL COAT ADDITIVE FOR AIR CURE APPLICATION CLEAR

MUSICAL INSTRUMENT WOOD COATING

TOP COAT OVER STAINS AND PRIMERS PRODUCT:

27X1 SUPER CLEAR HI-GLOSS

TOP COAT OVER PIGMENTED COLORS FOR CLEAR DEPTH POLYESTER COATING

AUTOMOTIVE INTERIOR COMPOSITE PARTS CLEAR COATING

ARCHITECTURAL WOOD CRAFTS GEL TIME:

16-20 min

-PRODUCT FEATURES-

VISCOSITY:

400 cps

EXCEPTIONAL UV RESISTANT

SUPER CLEAR—GLASS LIKE APPEARANCE CURE TIME:

SCRATCH RESISITANT 2 HOURS

BUFFS TO A SUPER HI-GLOSS FINISH

REFINISHES TO ORIGINAL HI-GLOSS COVERAGE (16-MILS):

PRACTICALLY A WALK-A-WAY GLOSS FINISH 100 sf / gallon

VOC:

250gr / liter

-SURFACE PREPARATION-

THIX INDEX:

PREPARE SURFACE BY SANDING WITH 220g PAPER (ALWAYS NON- 2.0

STEARATED)

CLEAN SURFACE WITH IPA (ACETONE IS NOT SUITABLE) WEIGHT PER GALLON:

8.7 lbs.

FLASH POINT:

-PRODUCT APPLICATION SUGGESTIONS- 98° F

CATALYZE AT 2% W / MEKP INITIATOR (.5-OZ PER QUART) VOCs:

UTILIZATION OF HVLP SPRAY GUN OPTIMIZES FINISH 1.02 lbs. / gal.

AIR PRESSURE 25-40 PSI

MAINTAIN 12-18” DISTANCE BETWEEN GUN AND SURFACE MONOMER CONTENT:

25%

OPTIMUM TEMPERATURE OF 77°F

START WITH FLASH COAT (2mils) WAIT 2 MINUTES THEN START

SHELF LIFE:

BUILD COATS OF (4mils) PER PASS WAITING APPROX. 5 MINUTES 6 months @ 68° F

BETWEEN COATS. DURING COOLER TEMPERATURES WAIT 20 MIN-

UTES BETWEEN COATS. IF YOU EXCEED 90 MINUTES, YOU MUST DUST FREE TIME:

LET CURE, SAND, AND THEN RESUME BUILD COATS. 60 min @ 77° F

OPTIMUM BUILD OF 16 MILS

ALLOW FULL CURE (24 HOURS) PRIOR TO SANDING AND POLISH-

ING

CYRCA COMPOSITE PRODUCTS COMPANY

www.cyrcacpc.com 1-(909) 259-5000

Вам также может понравиться

- Lect2 - 1151 - Grillage AnalysisДокумент31 страницаLect2 - 1151 - Grillage AnalysisCheong100% (1)

- Sanskrit Subhashit CollectionДокумент110 страницSanskrit Subhashit Collectionavinash312590% (72)

- Hempaprime Multi 500 Summer 45950Документ3 страницыHempaprime Multi 500 Summer 45950omar alkarabliehОценок пока нет

- Poly Bondtec Isolator 20x50tsДокумент1 страницаPoly Bondtec Isolator 20x50tsajaldacoОценок пока нет

- Poly Sealer - Filler 28x50Документ1 страницаPoly Sealer - Filler 28x50ajaldacoОценок пока нет

- Nano Ceramic Thermal Insulation CoatingДокумент2 страницыNano Ceramic Thermal Insulation CoatingAli AlghanimОценок пока нет

- 5100 SYSTEM Acrylic Dry Fall Coating: Acrylic Technical Data RO-59Документ2 страницы5100 SYSTEM Acrylic Dry Fall Coating: Acrylic Technical Data RO-59Chereddy RambabuОценок пока нет

- Technical Information Sheet 949Документ2 страницыTechnical Information Sheet 949SUBHOMOYОценок пока нет

- Spc-38 Glow in The Dark Max TdsДокумент2 страницыSpc-38 Glow in The Dark Max TdsnophiaОценок пока нет

- Intergard 400+eng+A4+Y+20141215Документ2 страницыIntergard 400+eng+A4+Y+20141215salman GtrОценок пока нет

- Hi-Acryl 1901 Acrylic Top Coat Is A One-Pack, Fast-Drying AcrylicДокумент4 страницыHi-Acryl 1901 Acrylic Top Coat Is A One-Pack, Fast-Drying AcrylicEvonne LeeОценок пока нет

- TDS - Supra Epoxy HB Mio CoatingДокумент2 страницыTDS - Supra Epoxy HB Mio CoatingSachin SinghalОценок пока нет

- Luxafloor ECO: Water Borne Epoxy Floor CoatingДокумент2 страницыLuxafloor ECO: Water Borne Epoxy Floor CoatinglivefreakОценок пока нет

- E Program Files An ConnectManager SSIS TDS PDF Interplus 256 Eng HK A4 20091005Документ4 страницыE Program Files An ConnectManager SSIS TDS PDF Interplus 256 Eng HK A4 20091005ram_babu_59Оценок пока нет

- 19.abcolux18hs Content 237Документ3 страницы19.abcolux18hs Content 237MbimbikОценок пока нет

- 38 Makeguard 614Документ3 страницы38 Makeguard 614taztika putriОценок пока нет

- Antifouling 2Документ2 страницыAntifouling 2gulsumОценок пока нет

- EPIGUARD 4 - PaintДокумент2 страницыEPIGUARD 4 - PaintDamodar UEОценок пока нет

- Ken Kyd 200 SPДокумент2 страницыKen Kyd 200 SPDany Muhammad FОценок пока нет

- Hempadur Zinc 17360Документ2 страницыHempadur Zinc 17360Bang OchimОценок пока нет

- Sikacor Eg PhosphatplusДокумент4 страницыSikacor Eg PhosphatplusCatalina ChescuОценок пока нет

- Pds CPD Sikafloor217a UsДокумент4 страницыPds CPD Sikafloor217a UsTony GaryОценок пока нет

- Berger: Product SpecificationsДокумент2 страницыBerger: Product SpecificationsAabhas UpadhyayaОценок пока нет

- NSF 61 PaintДокумент2 страницыNSF 61 Paintraviraj londheОценок пока нет

- Hi-Pon 200Ht Cui: Product DescriptionДокумент4 страницыHi-Pon 200Ht Cui: Product DescriptionGatra Bagus PrakosoОценок пока нет

- 105 - BODYFILL 307 - TdsДокумент2 страницы105 - BODYFILL 307 - TdsAlen Lišić100% (1)

- E-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Interprime - 198 - Eng - A4 - 20150204Документ4 страницыE-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Interprime - 198 - Eng - A4 - 20150204Zainal ArifinОценок пока нет

- 860 Moldable Polymer GasketingДокумент2 страницы860 Moldable Polymer GasketingprajanegaraОценок пока нет

- Epilux 155Документ2 страницыEpilux 155Tejinder KumarОценок пока нет

- ARMUS-Hull Pro - TDS - 07122023Документ3 страницыARMUS-Hull Pro - TDS - 07122023aleo.latam.ingenieriaОценок пока нет

- Inorganic Zinc Rich Primer RO123 GDH977 0517Документ3 страницыInorganic Zinc Rich Primer RO123 GDH977 0517Dante GimenezОценок пока нет

- PDS Hempaprime Multi 500 Summer en-GBДокумент2 страницыPDS Hempaprime Multi 500 Summer en-GBFreddyОценок пока нет

- Math CadДокумент20 страницMath CadSuterm SeccionОценок пока нет

- Pds - Epigard TL 543 Hs Finish (f15)Документ2 страницыPds - Epigard TL 543 Hs Finish (f15)Sachin SinghalОценок пока нет

- Epilux 8: Product DescriptionДокумент2 страницыEpilux 8: Product DescriptionMoin AltafОценок пока нет

- Carboguard 690 GF PDSДокумент4 страницыCarboguard 690 GF PDSgilbertjerryОценок пока нет

- Epilux 155Документ2 страницыEpilux 155Allana100% (1)

- Mono Ferro Pur Mono Zinc Me Iii Ax Grip: Product DescriptionДокумент3 страницыMono Ferro Pur Mono Zinc Me Iii Ax Grip: Product DescriptioncesarОценок пока нет

- Hempel'S Vinyl Ester GF 35910: Description: Recommended UseДокумент2 страницыHempel'S Vinyl Ester GF 35910: Description: Recommended UseEngTamerОценок пока нет

- Koerapur 689 GB 2017 01Документ2 страницыKoerapur 689 GB 2017 01dronlesnik88Оценок пока нет

- Hempadur Fast Dry 17410 En-GbДокумент2 страницыHempadur Fast Dry 17410 En-GbTrịnh Minh KhoaОценок пока нет

- Hempel'S Vinyl Ester GF 35910: Description: Recommended UseДокумент2 страницыHempel'S Vinyl Ester GF 35910: Description: Recommended UseSurendra KumarОценок пока нет

- Hempaline Prepare 130Документ2 страницыHempaline Prepare 130CRISTIAN SILVIU IANUCОценок пока нет

- EPILUX 850 SF VOC Jan-2017Документ2 страницыEPILUX 850 SF VOC Jan-2017PraveenОценок пока нет

- Pds Zincanode 690 VocДокумент2 страницыPds Zincanode 690 VocmuthukumarОценок пока нет

- Tds Aluminium Liquid SheetДокумент2 страницыTds Aluminium Liquid SheetRonnalyn TorresОценок пока нет

- CeRam-Kote 2000TL PDSДокумент2 страницыCeRam-Kote 2000TL PDSSaefuddin OrtegaОценок пока нет

- Berger: Product SpecificationsДокумент2 страницыBerger: Product SpecificationsAabhas UpadhyayaОценок пока нет

- Sikafloor®-161: Product Data SheetДокумент5 страницSikafloor®-161: Product Data SheetashayshaОценок пока нет

- 00.2.TDS - RS 500 PДокумент4 страницы00.2.TDS - RS 500 PMuhammad TantowiОценок пока нет

- Carboxane 2000 PDSДокумент4 страницыCarboxane 2000 PDSBERSE MAJU INDONESIAОценок пока нет

- Hempadur Quattro InglesДокумент3 страницыHempadur Quattro InglesElizabeth Maria Bazán MoralesОценок пока нет

- Steel Shield 1200Документ2 страницыSteel Shield 1200Moin AltafОценок пока нет

- Garlock GSK 3-86 Strainer Gasket 04.2017 en-NAДокумент2 страницыGarlock GSK 3-86 Strainer Gasket 04.2017 en-NAAbuhurairah MunshiОценок пока нет

- Zn03-Pv. Epoxy Zinc Primer Qd-EngДокумент2 страницыZn03-Pv. Epoxy Zinc Primer Qd-EngANIBALLOPEZVEGAОценок пока нет

- MS GF 35870 en-GBДокумент2 страницыMS GF 35870 en-GBLinnie McleodОценок пока нет

- Epilux 82: Product DescriptionДокумент2 страницыEpilux 82: Product DescriptionMoin AltafОценок пока нет

- ENG Siliconizer RC200 TDSДокумент2 страницыENG Siliconizer RC200 TDSPedro PaulinoОценок пока нет

- Interline 975+ds+eng PDFДокумент4 страницыInterline 975+ds+eng PDFMohamed NouzerОценок пока нет

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965От EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965Оценок пока нет

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsОт EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsРейтинг: 5 из 5 звезд5/5 (1)

- Handbook on Japanning: 2nd Edition For Ironware, Tinware, Wood, Etc. With Sections on Tinplating and GalvanizingОт EverandHandbook on Japanning: 2nd Edition For Ironware, Tinware, Wood, Etc. With Sections on Tinplating and GalvanizingОценок пока нет

- 28X50 MSDS Un1263Документ5 страниц28X50 MSDS Un1263ajaldacoОценок пока нет

- 20x50ts HD Bondtec Msds-AДокумент5 страниц20x50ts HD Bondtec Msds-AajaldacoОценок пока нет

- 20xx Poly Primer Sanding-ComДокумент1 страница20xx Poly Primer Sanding-ComajaldacoОценок пока нет

- 2000 Primers Msds Un1263Документ5 страниц2000 Primers Msds Un1263ajaldacoОценок пока нет

- 820 Resin MSDSДокумент5 страниц820 Resin MSDSajaldacoОценок пока нет

- 27xx Poly Hi-Gloss PigmentedДокумент1 страница27xx Poly Hi-Gloss PigmentedajaldacoОценок пока нет

- 27X Series MSDSДокумент5 страниц27X Series MSDSajaldacoОценок пока нет

- 820 Series TDSДокумент2 страницы820 Series TDSajaldaco100% (1)

- Prestec Comparison GuideДокумент1 страницаPrestec Comparison GuideajaldacoОценок пока нет

- Reflection in Sexually Transmitted DiseaseДокумент1 страницаReflection in Sexually Transmitted Diseasewenna janeОценок пока нет

- Chapter 20 AP QuestionsДокумент6 страницChapter 20 AP QuestionsflorenciashuraОценок пока нет

- 160kW SOFT STARTER - TAP HOLE 1Документ20 страниц160kW SOFT STARTER - TAP HOLE 1Ankit Uttam0% (1)

- What You Need To Know About Your Drive TestДокумент12 страницWhat You Need To Know About Your Drive TestMorley MuseОценок пока нет

- Gujarat Urja Vikas Nigam LTD., Vadodara: Request For ProposalДокумент18 страницGujarat Urja Vikas Nigam LTD., Vadodara: Request For ProposalABCDОценок пока нет

- LFF MGДокумент260 страницLFF MGRivo RoberalimananaОценок пока нет

- Marketing Micro and Macro EnvironmentДокумент8 страницMarketing Micro and Macro EnvironmentSumit Acharya100% (1)

- Java Complete Collection FrameworkДокумент28 страницJava Complete Collection FrameworkkhushivanshОценок пока нет

- On Animal Language in The Medieval Classification of Signs PDFДокумент24 страницыOn Animal Language in The Medieval Classification of Signs PDFDearNoodlesОценок пока нет

- LPS 1131-Issue 1.2-Requirements and Testing Methods For Pumps For Automatic Sprinkler Installation Pump Sets PDFДокумент19 страницLPS 1131-Issue 1.2-Requirements and Testing Methods For Pumps For Automatic Sprinkler Installation Pump Sets PDFHazem HabibОценок пока нет

- Flow of FoodДокумент2 страницыFlow of FoodGenevaОценок пока нет

- Unbound DNS Server Tutorial at CalomelДокумент25 страницUnbound DNS Server Tutorial at CalomelPradyumna Singh RathoreОценок пока нет

- IMDSI22Документ82 страницыIMDSI22Dang JinlongОценок пока нет

- John Wren-Lewis - NDEДокумент7 страницJohn Wren-Lewis - NDEpointandspaceОценок пока нет

- Cambridge IGCSE: CHEMISTRY 0620/42Документ12 страницCambridge IGCSE: CHEMISTRY 0620/42Khairun nissaОценок пока нет

- PNP Ki in July-2017 AdminДокумент21 страницаPNP Ki in July-2017 AdminSina NeouОценок пока нет

- William Hallett - BiographyДокумент2 страницыWilliam Hallett - Biographyapi-215611511Оценок пока нет

- Roles and Responsibilities of An InstructorДокумент4 страницыRoles and Responsibilities of An InstructorMohanlal SainiОценок пока нет

- DCN Dte-Dce and ModemsДокумент5 страницDCN Dte-Dce and ModemsSathish BabuОценок пока нет

- Procter and Gamble - MarketingДокумент10 страницProcter and Gamble - MarketingIvana Panovska100% (5)

- Honda IzyДокумент16 страницHonda IzyTerry FordОценок пока нет

- Existentialism in LiteratureДокумент2 страницыExistentialism in LiteratureGirlhappy Romy100% (1)

- Lenovo NotebooksДокумент6 страницLenovo NotebooksKamlendran BaradidathanОценок пока нет

- LEMBAR JAWABAN CH.10 (Capital Budgeting Techniques)Документ4 страницыLEMBAR JAWABAN CH.10 (Capital Budgeting Techniques)Cindy PОценок пока нет

- Bubble Test Direct Pressure InserviceДокумент3 страницыBubble Test Direct Pressure InserviceEdAlmОценок пока нет

- Parallel Port Programming With DelphiДокумент4 страницыParallel Port Programming With Delphiramadhan1933Оценок пока нет

- ইসলাম ও আধুনিকতা – মুফতি মুহম্মদ তকী উসমানীДокумент118 страницইসলাম ও আধুনিকতা – মুফতি মুহম্মদ তকী উসমানীMd SallauddinОценок пока нет

- Group 2 ITI Consensus Report: Prosthodontics and Implant DentistryДокумент9 страницGroup 2 ITI Consensus Report: Prosthodontics and Implant DentistryEsme ValenciaОценок пока нет